Co-extrusion hot-pressing functional film for disposable sugarcane paper pulp container

A functional film, a one-off technology, used in the field of plastic film for packaging and co-extrusion hot-pressed functional film, it can solve the problems of water resistance and oil resistance, and achieve easy oil leakage, excellent adhesion, and excellent needle resistance. The effect of hole performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The co-extruded and hot-pressed functional film for disposable sugarcane pulp container described in Example 1 of the present invention includes a polyethylene resin layer with a three-layer structure.

[0024] The raw material of the polyethylene resin layer includes the following components in weight percentage: low density polyethylene resin (LDPE) 5-75%, vinyl acetate copolymer resin (EVA) 5-75%, linear low-density polymer containing 6 carbon atoms Vinyl resin (C6LLDPE) 10-25%, linear low-density polyethylene resin (C8LLDPE) containing 8 carbon atoms 10-25%.

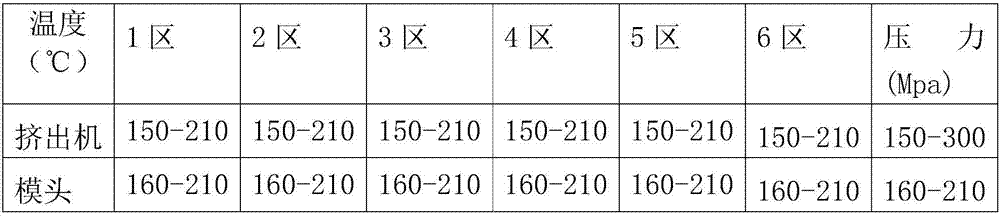

[0025] The method of preparing this co-extrusion hot-pressing functional film is: adding the raw materials into the extruder to melt and plasticize and then output, convey the material output from the extruder to the die, extrude the blown film, and then cool it by air cooling. The co-extrusion hot-pressed functional film can be obtained; the parameters of the extruder and the die are set as follows: the processing...

Embodiment 2

[0027] The co-extruded hot-pressed functional film for disposable sugarcane pulp container described in Example 2 of the present invention includes a polypropylene resin layer with a three-layer structure.

[0028] The raw material of the polypropylene resin layer includes the following components in weight percentage: 10-30% of homopolypropylene, 10-40% of copolymer polypropylene, and 30-80% of ternary polypropylene resin.

[0029] The method of preparing this co-extrusion hot-pressed functional film is: adding the raw materials to the extruder to melt and plasticize and then output, transport the materials output from the extruder of each layer to the die, extrude the blown film, and then pass the air cooling After cooling, a co-extrusion hot-pressed functional film can be obtained; the parameters of the extruder and die are set as follows: the processing temperature is 200℃, the processing pressure is 90Mpa, and the processing temperature of the die is 250℃.

Embodiment 3

[0031] The co-extruded hot-pressed functional film for disposable sugarcane pulp container described in Example 3 of the present invention includes a three-layer multi-layer co-extruded film; the multi-layer co-extruded film layer is a barrier layer, an adhesive layer and a thermal The sealing layer, the barrier layer is a three-membered cyclohexanoic acid ring-opening superposition PA resin, the adhesive layer is α, β-unsaturated acid or modified polyolefin resin, and the heat sealing layer is a polyethylene resin layer.

[0032] The raw material of the polyethylene resin layer includes the following components in weight percentage: low-density polyethylene resin (LDPE) 5-75%, vinyl acetate copolymer resin (EVA) 5-75%, linear low-density polymer containing 6 carbon atoms Vinyl resin (C6LLDPE) 10-25%, linear low-density polyethylene resin (C8LLDPE) containing 8 carbon atoms 10-25%.

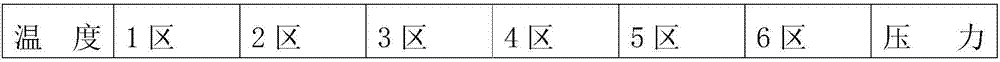

[0033] The method of preparing a multi-layer co-extruded film with special functions is: adding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com