IF isotropic steel with stamping forming improved and manufacturing method thereof

A technology of stamping forming and manufacturing method, applied in the field of metal material manufacturing, can solve the problems of plasticity, deep drawing performance and anti-aging performance, pulling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

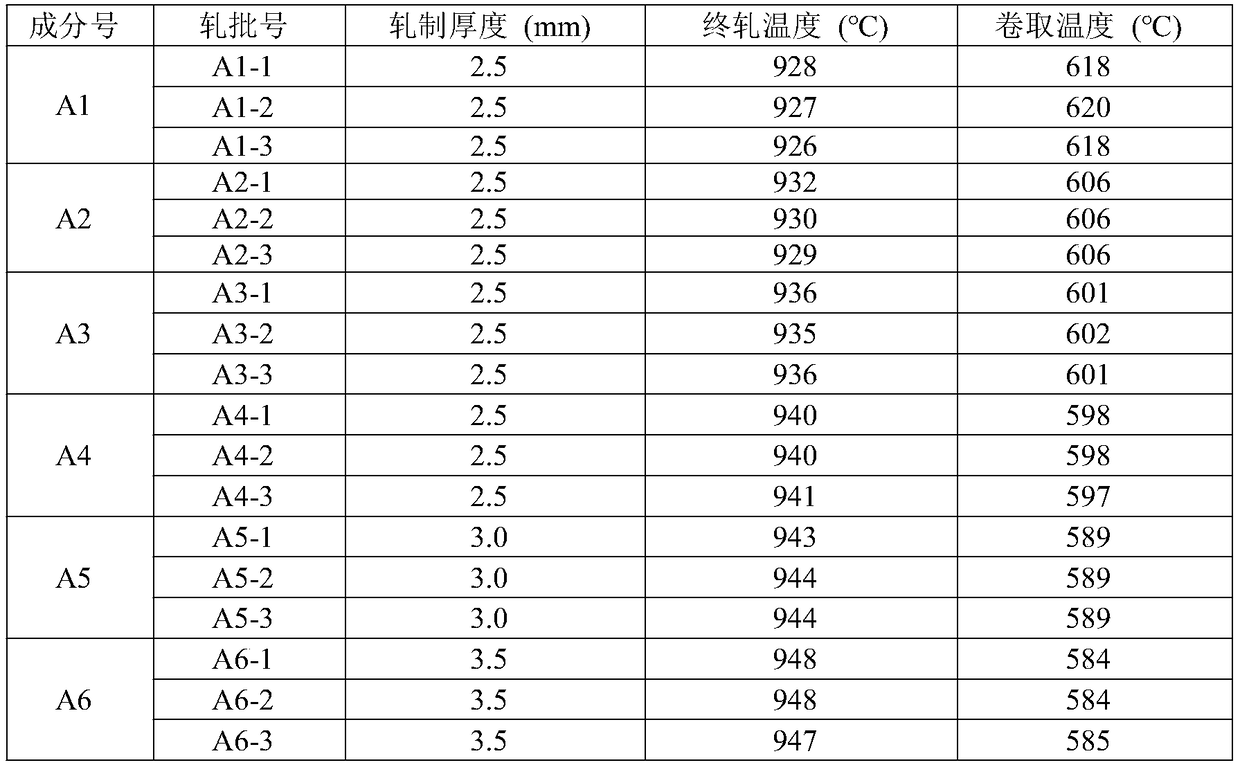

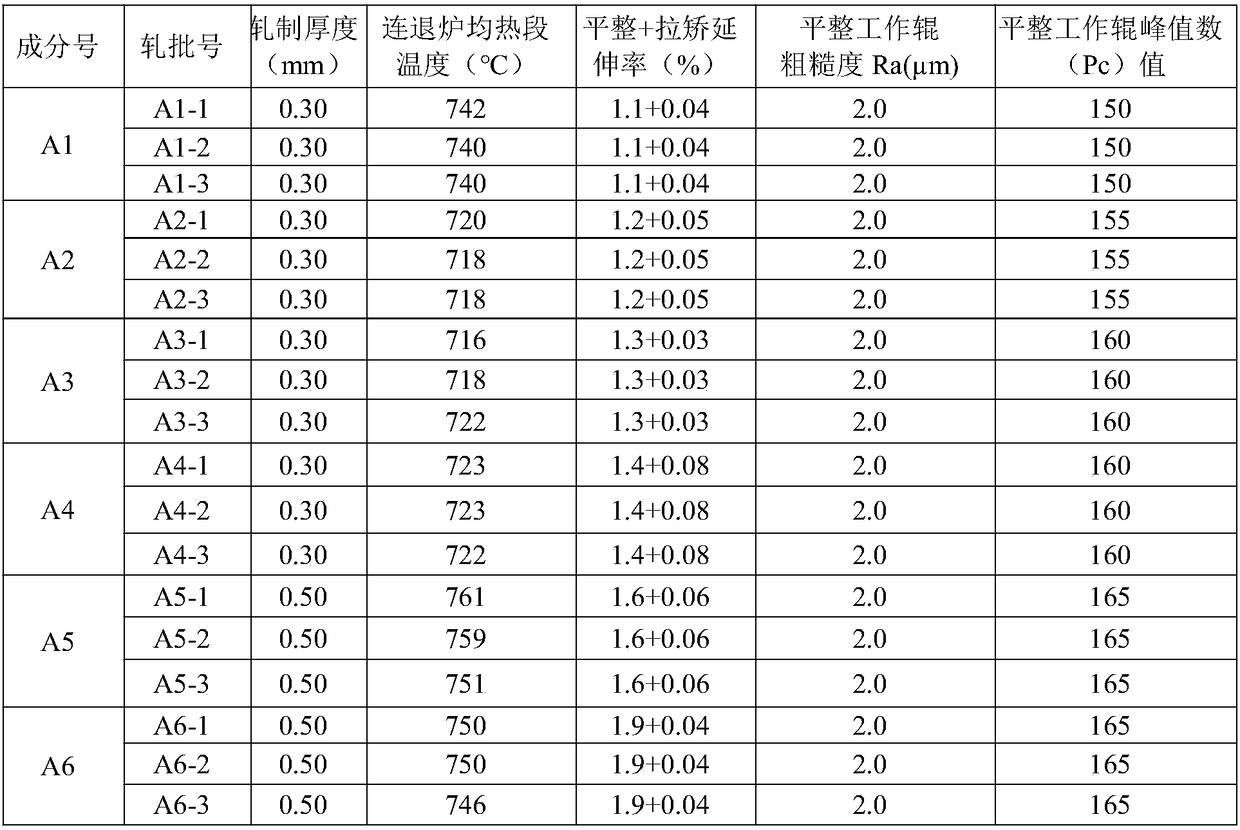

[0070] Embodiment 1: A kind of IF isotropic steel that improves stamping forming, described IF isotropic steel:

[0071] 1) After smelting in a converter, refining in an RH furnace, and continuous casting into a slab with the component number A1:

[0072] 2) Hot rolling: heat the slab with the component number A1, the target hot rolling thickness is 2.5 mm, the billet is rough rolled and finished rolled to obtain a hot rolled plate, the final rolling temperature is 926 ~ 928 ° C, and then the hot rolled The rolled plate is cooled by laminar flow, and then coiled into a hot-rolled coil at a coiling temperature of 618-620°C;

[0073] 3) Cold rolling: the target cold rolling thickness is 0.30 mm, and the hot rolled coil is rolled after pickling, and the reduction ratio is 87.4%;

[0074] 4) Annealing treatment: the temperature of the soaking section of the continuous annealing furnace is 740-742°C;

[0075] 5) Leveling and tension bridge: leveling elongation 1.1% + tension leve...

Embodiment 2

[0077] Embodiment 2: A kind of IF isotropic steel that improves stamping forming, described IF isotropic steel:

[0078] 1) After smelting in a converter, refining in an RH furnace, and continuous casting into a slab with the component number A2:

[0079] 2) Hot rolling: heat the slab with the component number A2, the target hot rolling thickness is 2.5mm, the billet is rough rolled and finished rolled to obtain a hot rolled plate, the final rolling temperature is 929 ~ 932 ° C, and then the hot rolled The rolled plate is cooled by laminar flow, and then coiled into hot-rolled coils at a coiling temperature of 606°C;

[0080] 3) Cold rolling: the target cold rolling thickness is 0.30 mm, and the hot rolled coil is rolled after pickling, and the reduction rate is 89.1%;

[0081] 4) Annealing treatment: the temperature of the soaking section of the continuous annealing furnace is 718-720°C;

[0082] 5) Leveling and tension bridge: leveling elongation 1.2% + tension leveling el...

Embodiment 3

[0084] Embodiment 3: A kind of IF isotropic steel that improves stamping forming, described IF isotropic steel:

[0085] 1) After smelting in a converter, refining in an RH furnace, and continuous casting into a slab with the component number A3:

[0086] 2) Hot rolling: heat the slab with the component number A3, the target hot rolling thickness is 2.5mm, the billet is rough rolled and finished rolled to obtain a hot rolled plate, the final rolling temperature is 935 ~ 936 ° C, and then the hot rolled The rolled plate is cooled by laminar flow, and coiled into hot rolled coil after cooling, the coiling temperature is 601-602°C;

[0087] 3) Cold rolling: the target cold rolling thickness is 0.30 mm, the hot rolled coil is rolled after pickling, and the reduction rate is 90.3%;

[0088] 4) Annealing treatment: the temperature of the soaking section of the continuous annealing furnace is 716-722°C;

[0089] 5) Leveling and tension bridge: leveling elongation 1.3% + tension lev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com