Biaxially stretched, multi-layereded polyamide film and production method thereof

A technology of biaxial stretching and polyamide film, which can be applied to other household appliances, etc., can solve the problems of not being able to improve barrier properties, and achieve excellent transparency, small shrinkage, and excellent pinhole resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

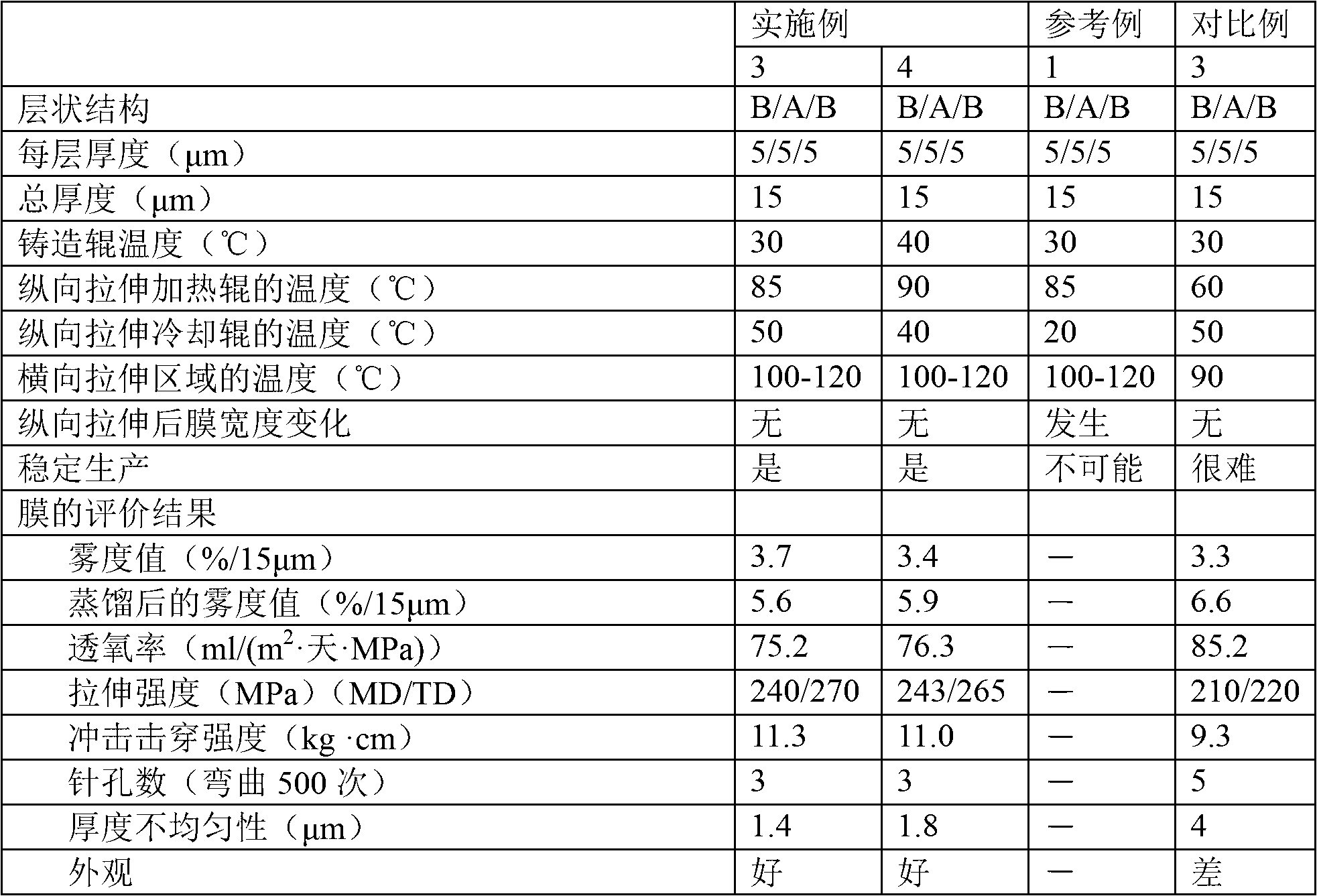

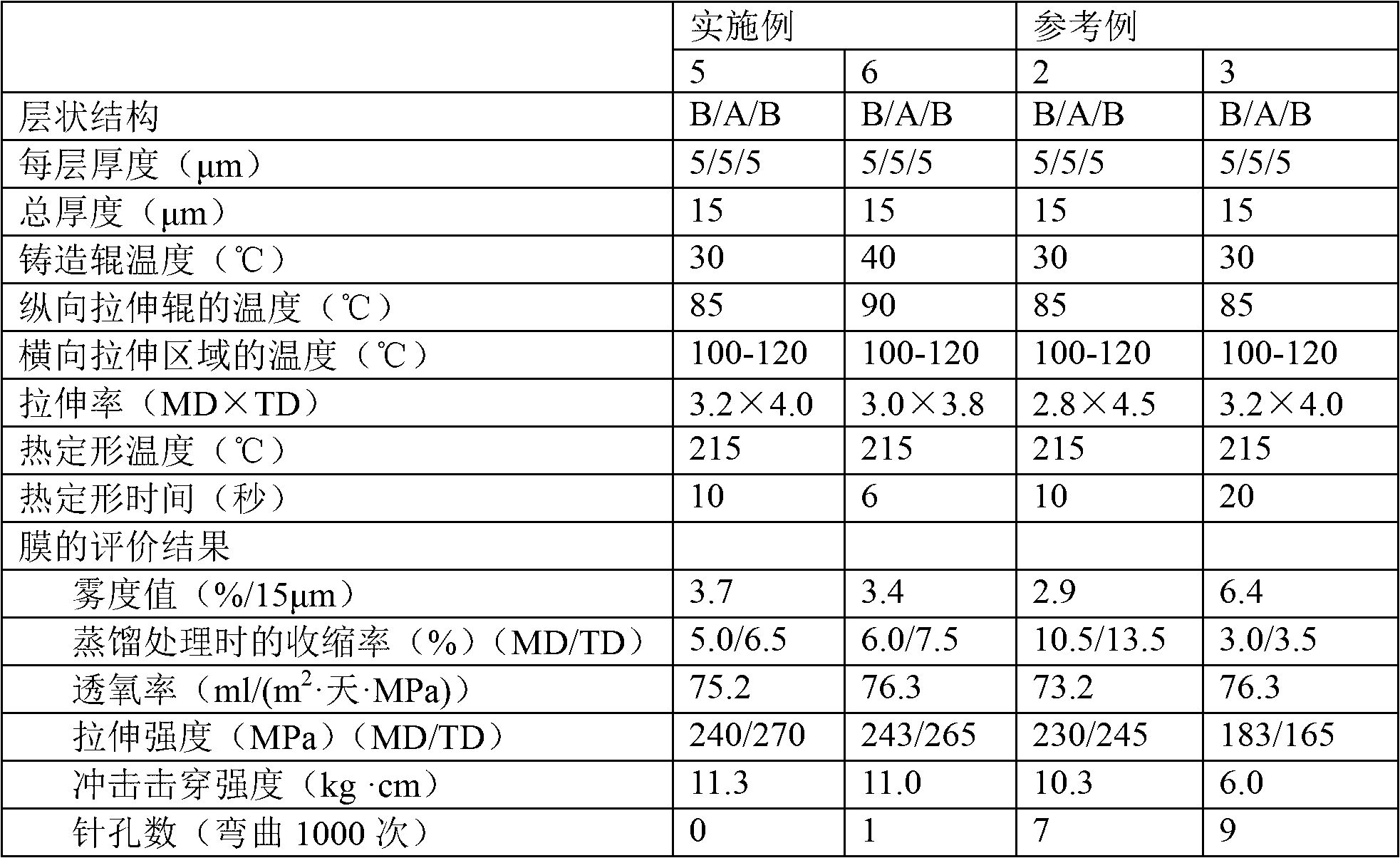

[0078] Through the above-mentioned preparation method, when measured using the Gelbo test (bending number: 1000) to be described below, the number of pinholes formed is preferably controlled at 2 / 624cm 2 or lower range. In order to effectively prepare such a biaxially stretched multilayer polyamide film resistant to pinhole formation, the following preparation conditions are preferred:

[0079] Casting roll temperature: 20-60°C,

[0080] Heating roller temperature for longitudinal stretching: 80-100°C,

[0081] Longitudinal stretch rate: 3.0-3.3 times,

[0082] Transverse stretching temperature: 80-120°C,

[0083] Transverse stretch rate: 3.6-4.2 times,

[0084] Heat treatment temperature: 210-220°C, and

[0085] Heat treatment time: 4-10 seconds.

[0086] Through the above-mentioned preparation method, when the distillation treatment is carried out at 121° C. for 30 minutes, the shrinkage in both the longitudinal and transverse directions is preferably controlled at 3-8...

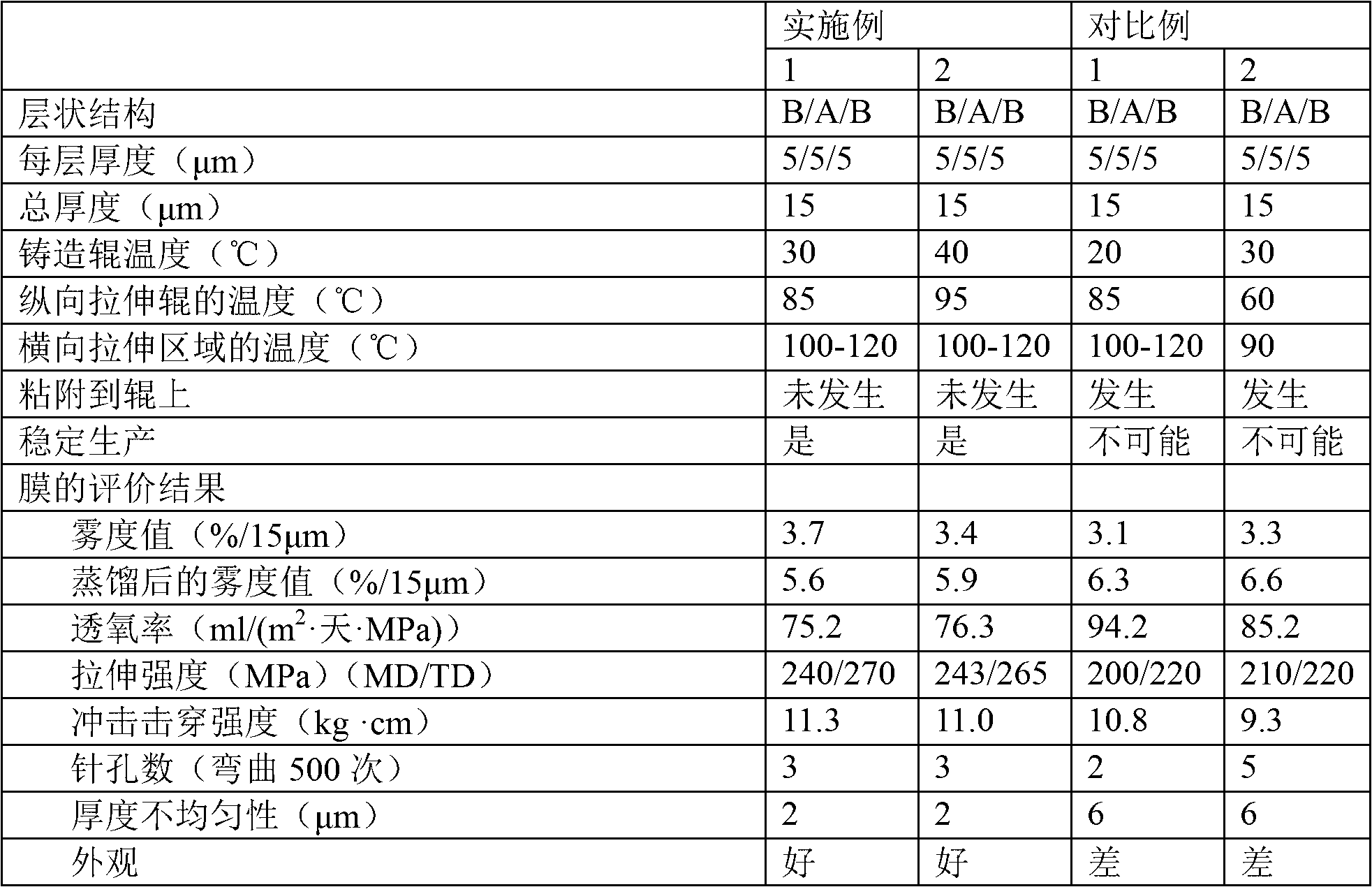

Embodiment 1

[0113] In three 65 mmΦ extruders, nylon MXD6 (polyamide resin X, "MX Nylon 6011" (trademark) manufactured by Mitsubishi Gas Chemical Company, Inc., diamine structural unit = m-xylylenediamine unit , dicarboxylic acid structural unit = adipic acid unit) and poly(ε-caprolactam) (aliphatic polyamide resin Y, "Ube Nylon1022FDX04" manufactured by Ube Industries, Ltd.), laminated in a T-die, and then extruded into a three-layer laminated film (Y / X / Y(B / A / B)). The laminated film was brought into close contact with a casting roll at 30°C for quenching using a pinning device to obtain a multilayer original film of Y / X / Y=50 / 50 / 50 μm (non-stretched laminated film ). The non-stretched laminated film was longitudinally stretched 3 times by a roll at 85° C. using a roll stretcher. After holding the edges of the film with tenter clips, the film was stretched 3.3 times in the transverse direction in a tenter oven at 100-120°C. Thereafter, the film was heat-set at 215° C. for 10 seconds to o...

Embodiment 2

[0115] A biaxially stretched multilayer polyamide film was obtained in the same manner as in Example 1, except that the temperature of the casting roll was changed to 40°C, and the temperature of the longitudinal stretching roll was changed to 95°C. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com