Vacuum bag manufacturing method and product of the same

A production method and technology of vacuum bags, applied in the field of vacuum bags, can solve the problems of inconvenient opening of vacuum bags, insufficient sealing, unfavorable long-term use, etc., and achieve the advantages of long-term storage of items, good water resistance, and enhanced sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Example: see Figure 1 to Figure 4 , a kind of vacuum bag manufacturing method that the present embodiment provides, it is characterized in that: it comprises the following steps:

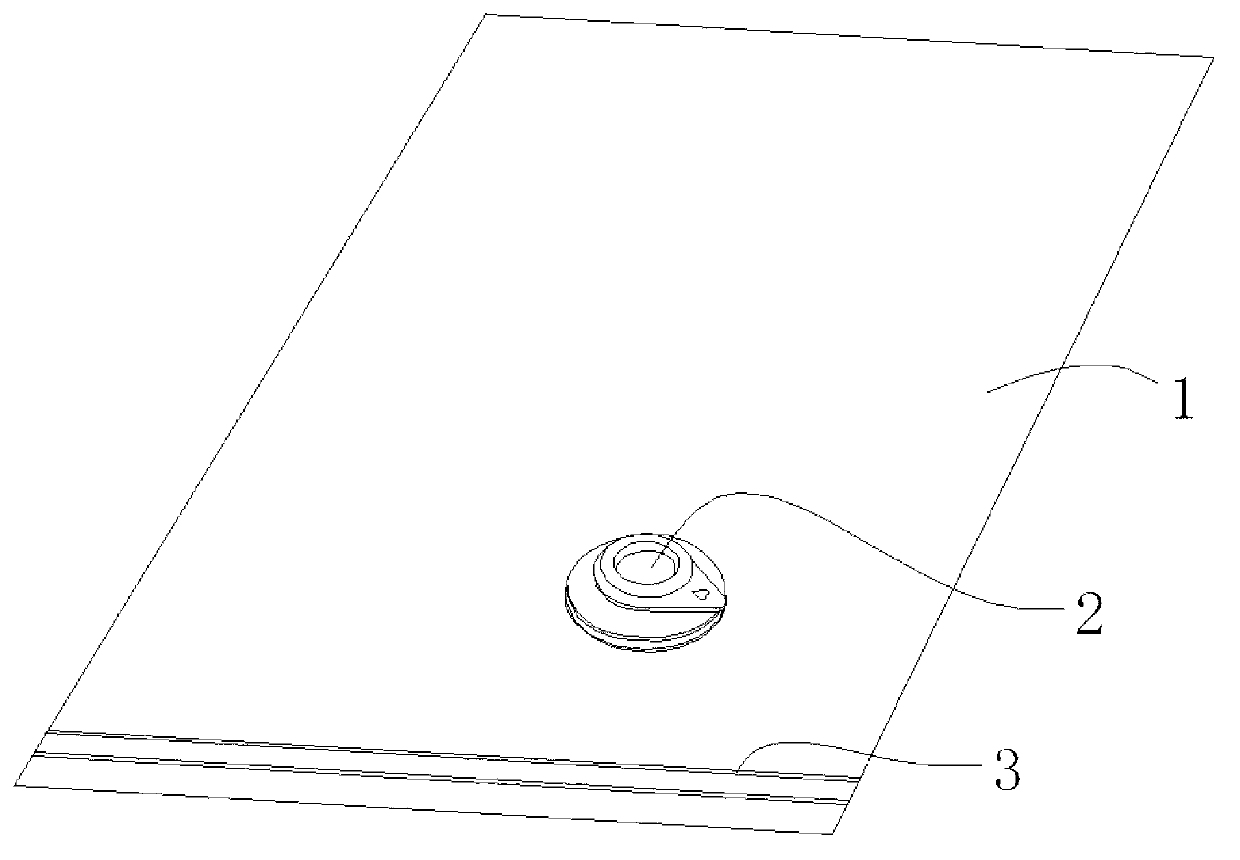

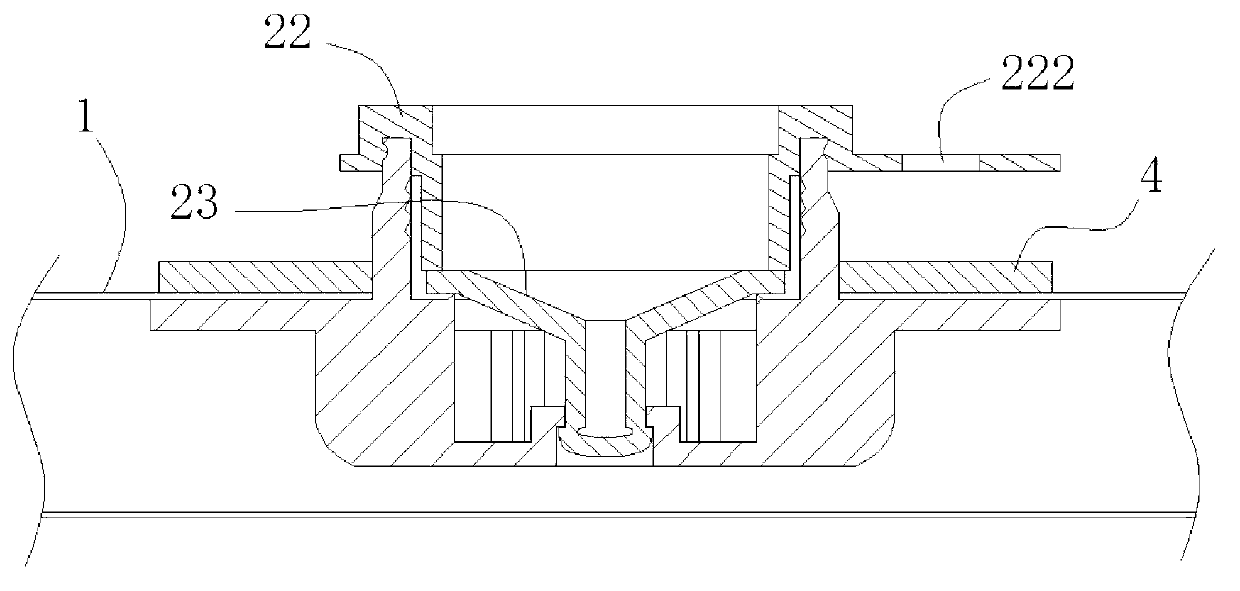

[0040] (1) Prepare sheet-shaped BOPET, and cut it into two pieces of BOPET films with the same shape; heat-melt the two BOPET films along their periphery to perform welding, edge sealing and sealing processing, so that a sandwich structure is formed between the two BOPET films, and the production A bag body 1 with a sealed air cavity is obtained, and a bag opening is provided on one side of the bag body 1;

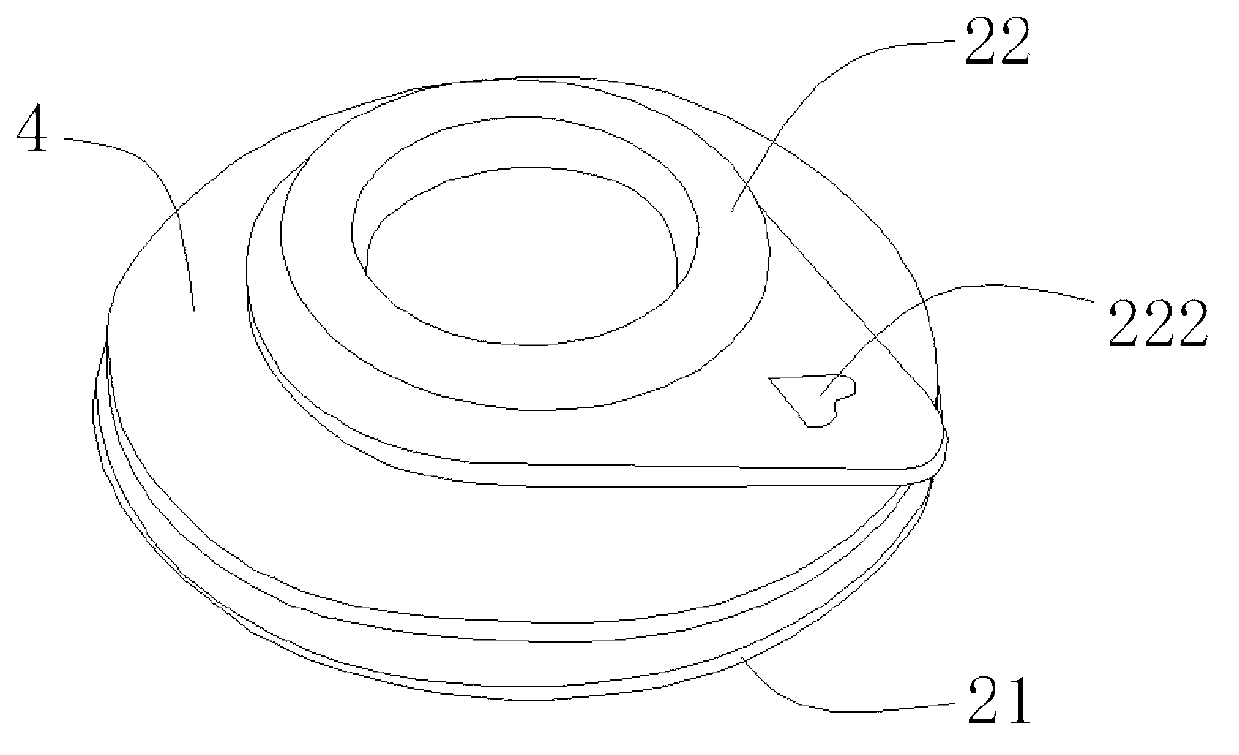

[0041] (2) Preparatory exhaust valve 2, the exhaust valve 2 includes a valve seat 21, a valve cover 22 and a conical cork 23, in the valve seat 21 there is a The adapted accommodating cavity 211 is provided with a number of ventilation grooves at the bottom of the valve seat 21 to communicate the accommodating cavity 211 with the inner cavity of the bag body 1, and a card is provided at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com