Flexographic printing original plate and method for manufacturing flexographic printing plate

A technology of flexographic printing and original plate, applied in printing plate, printing, printing plate preparation, etc., can solve the problems of inflexibility of film, shallow relief depth, inability to form tiny dots, etc., and achieve excellent pinhole resistance and washability. High, excellent printing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

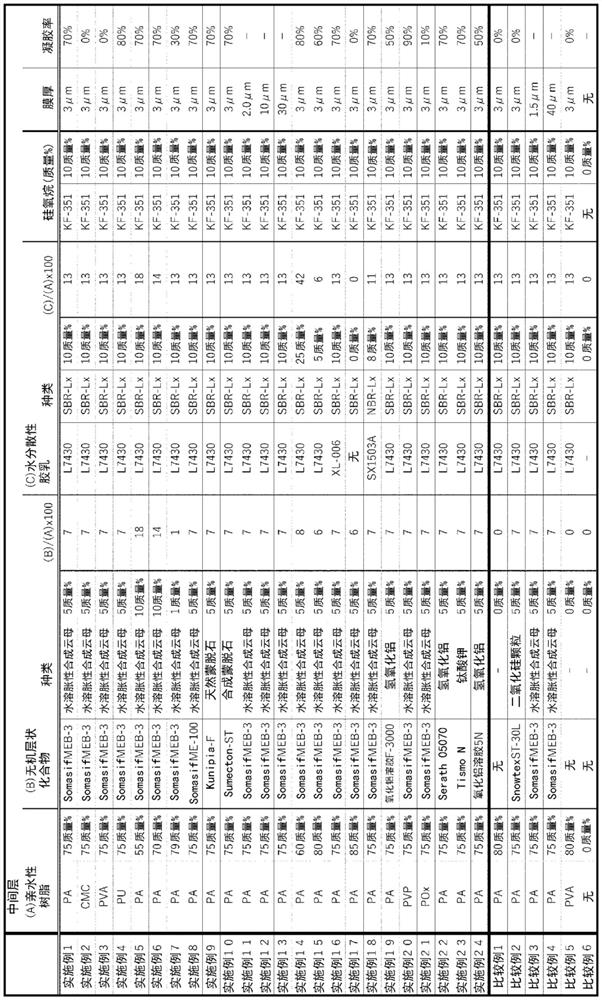

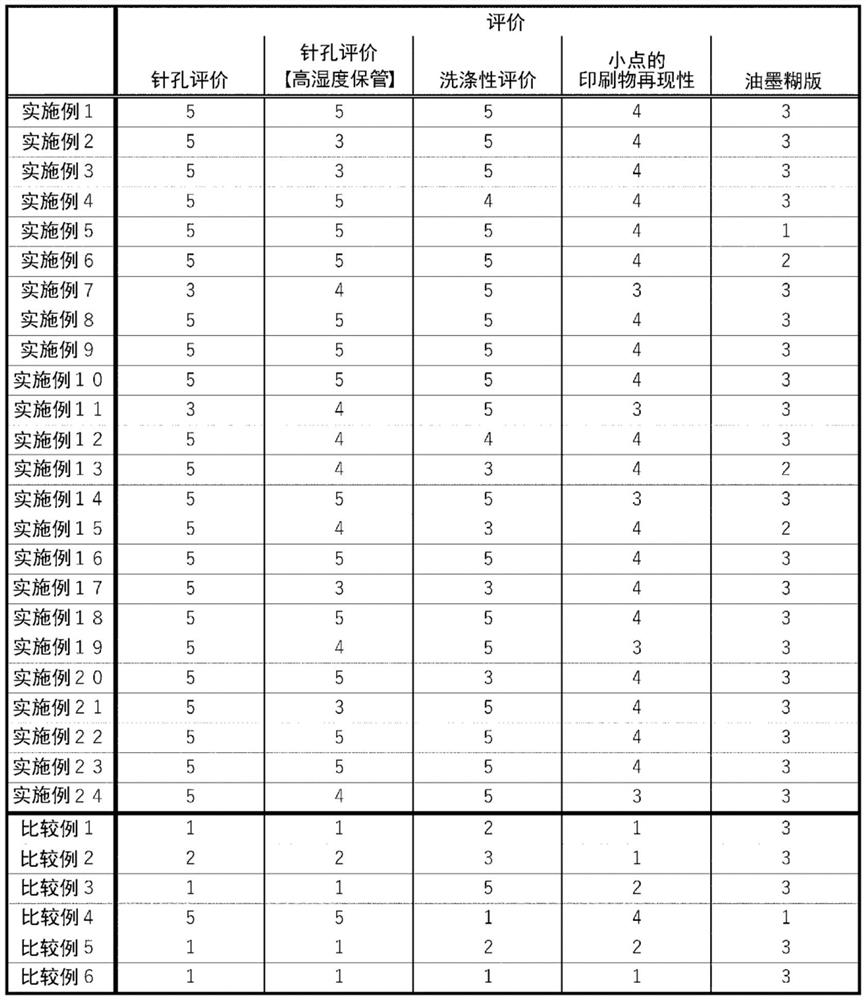

Examples

manufacture example 1

[0302] (Synthesis of Hydrophilic Copolymer)

[0303] In a pressure-resistant reaction vessel equipped with a stirring device and a jacket for temperature adjustment, 125 parts by mass of water and (α-sulfo(1-nonylphenoxy)methyl-2- (2-Propyleneoxy)ethoxy-poly(oxy-1,2-ethanediyl) ammonium salt "ADEKAREASOAP" (manufactured by Asahi Denka Industries) 2 parts by mass, the inner temperature was raised to 80°C, respectively A monomer mixture containing 10 parts by mass of styrene, 60 parts by mass of butadiene, 23 parts by mass of butyl acrylate, 5 parts by mass of methacrylic acid, and 2 parts by mass of acrylic acid was added at a constant flow rate for 5 hours and 6 hours. An oily mixed solution of 2 parts by mass of dialkylmercaptan, and 28 parts by mass of water, 1.2 parts by mass of sodium persulfate, 0.2 parts by mass of sodium hydroxide, and (α-sulfo(1-nonylphenoxy) An aqueous solution of 2 parts by mass of an ammonium salt of methyl-2-(2-propenyloxy)ethoxy-poly(oxy-1,2-etha...

manufacture example 2

[0308] (Preparation of base film (support body))

[0309] As a solution for the adhesive layer coated on the support (base film), Tufprene 912 (manufactured by Asahi Kasei Co., Ltd., trade name) which is a block copolymer of styrene and 1,3-butadiene was used at 55 The ratio of parts by mass, the ratio of 38 parts by mass of paraffin oil (average carbon number 33, average molecular weight 470, density at 15° C. of 0.868), the ratio of 2.5 parts by mass of 1,9-nonanediol diacrylate, 2 , 2-dimethoxy-phenylacetophenone at a ratio of 1.5 parts by mass, EPOXY ESTER3000M (manufactured by Kyoeisha Chemical Co., Ltd., trade name) at a ratio of 3 parts by mass, and Balifast YELLOW 3150 (ORIENT CHEMICAL INDUSTRIES CO. ., LTD., trade name) was dissolved in toluene at a ratio of 1.5 parts by mass to obtain a solution with a solid content of 25%.

[0310] Then, it was coated on one side of a polyester film with a thickness of 100 μm using a knife coater so that the UV transmittance was 10...

manufacture example 3

[0313] (Fabrication of thin film with infrared ablation layer)

[0314] 65% by mass of Asaflex 810 (manufactured by Asahi Kasei Co., Ltd., trade name) which is a block copolymer of styrene and 1,3-butadiene, and 35% by mass of carbon black which is an infrared sensitive substance were kneaded by a kneader, After being cut into pellets, the ratio of 90 parts by mass of the pellets and 10 parts by mass of 1,6-hexanediol adipate was dissolved in ethyl acetate / butyl acetate / propylene glycol monomethyl ether by ultrasonic waves. Acetate = 50 / 30 / 20 mass ratio of the mixed solvent produced to produce a solid content of 12 mass % of the homogeneous solution.

[0315] Then apply the solution at a dry coating amount of 4 to 5 g / m 2 The method was coated on a polyester film with a thickness of 100 μm as a cover sheet using a knife coater, and dried at 80° C. for 1 minute to obtain a film with an ultraviolet shielding layer (infrared ablation layer) that can be cut by infrared rays.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com