Polysilicon package

A polysilicon and packaging technology, applied in packaging, food packaging, transportation and packaging, etc., can solve the problems of reduced sealing performance, packaging performance, sealing performance, and sealing performance, etc., to avoid the reduction of puncture strength, The effect of avoiding the deterioration of sealing performance and excellent pinhole resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

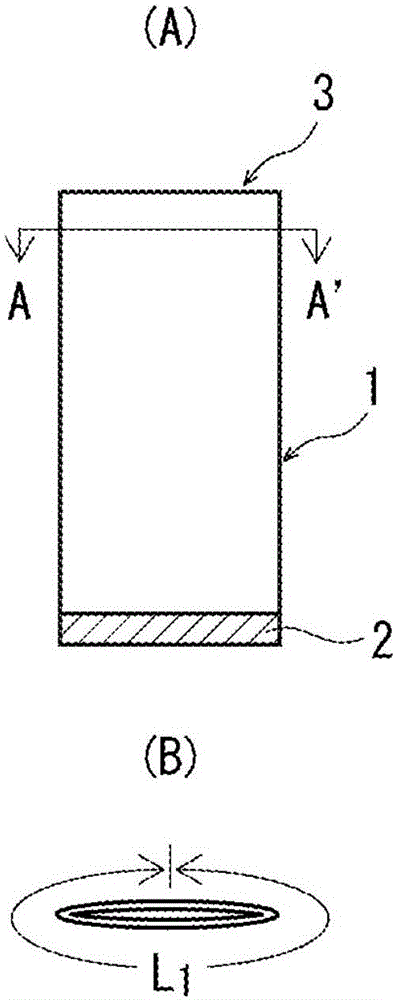

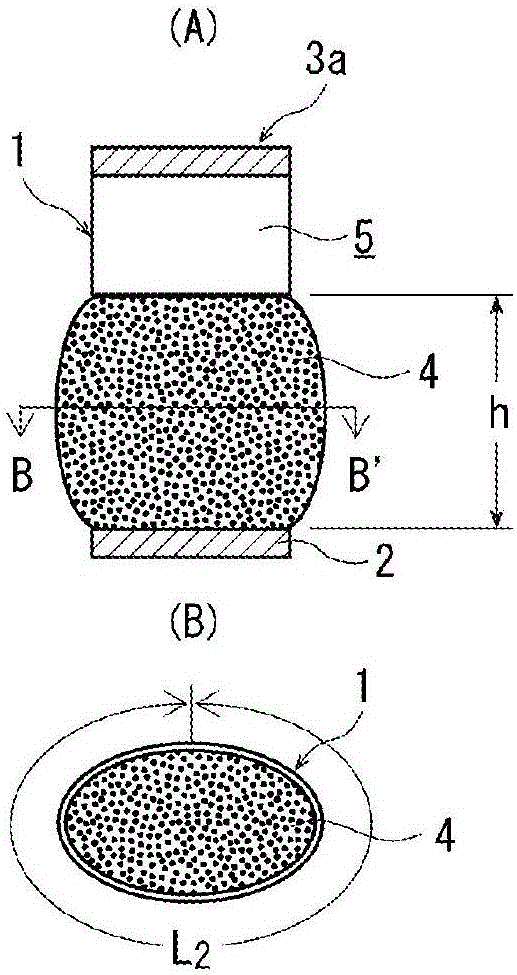

[0090] Prepare a film of metallocene LLDPE having the piercing strength (JIS-Z1707) and average thickness shown in Table 1, and use this film to make the inner perimeter L shown in Table 1 1 and length (height) of the bag (flat or gusseted). In addition, the MFR (190 degreeC) of the metallocene LLDPE used for film production was 2 g / 10 minutes.

[0091] It should be noted that the outer perimeter of the bag is substantially the same as the inner perimeter L in flat bags and gusseted bags 1 same.

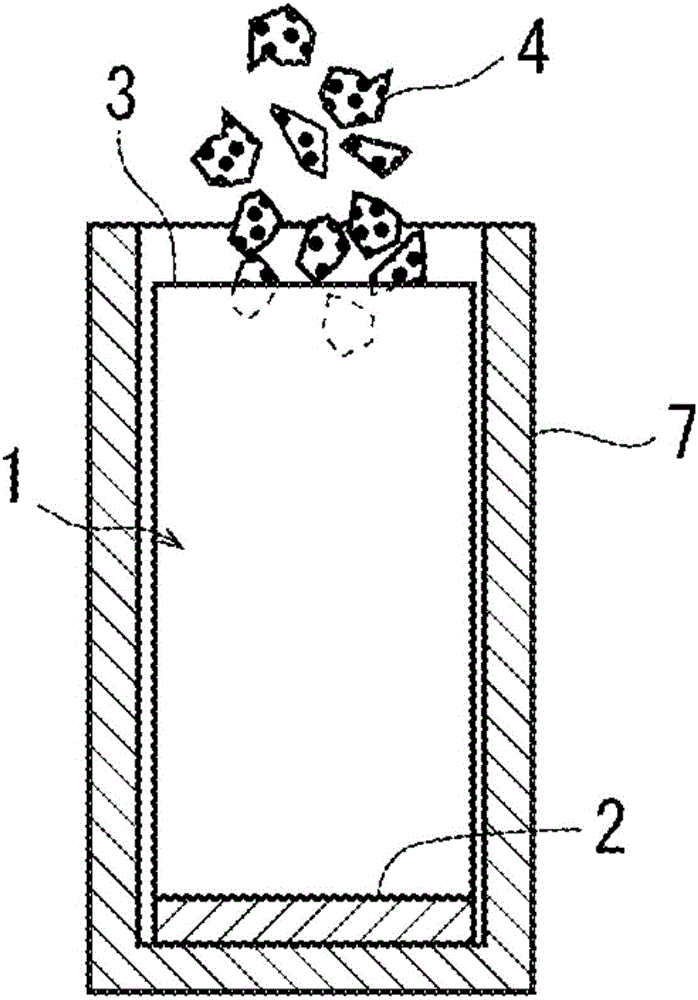

[0092] Prepare a frame made of a polyethylene plate-shaped body with a thickness of about 5 mm (the inner surface circumference is 956 mm), prepare the above-mentioned bag in the frame, and manually crush the Si pulverized product having the average maximum piece length shown in Table 1. After filling 10 kg into the bag, the filling opening of the bag was heat-sealed.

[0093] The average damage rate was measured about the obtained package, and the result is shown.

[0094] In ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com