Surface-treated copper foil and copper-clad laminate using same

A surface treatment, copper foil technology, applied in the field of copper clad laminates, can solve the problem of multiple pinholes, and achieve the effect of excellent pinhole resistance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

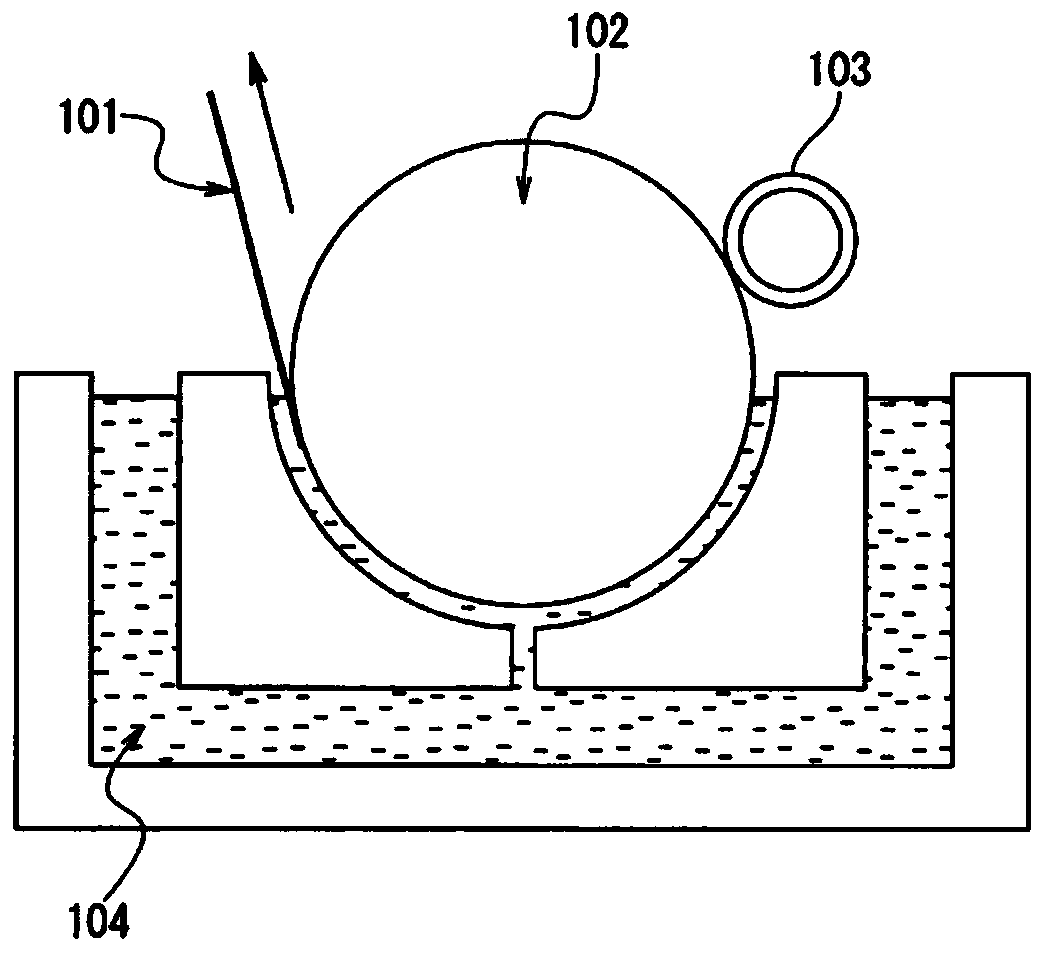

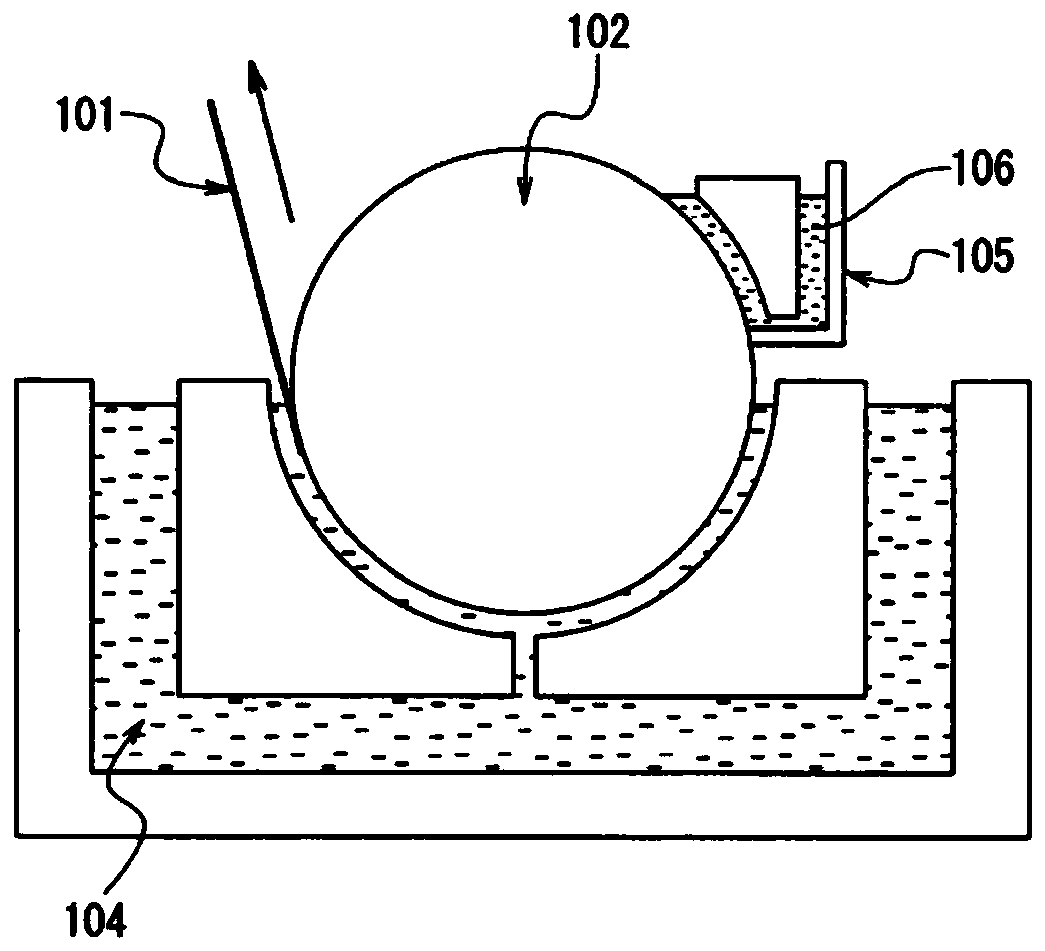

Image

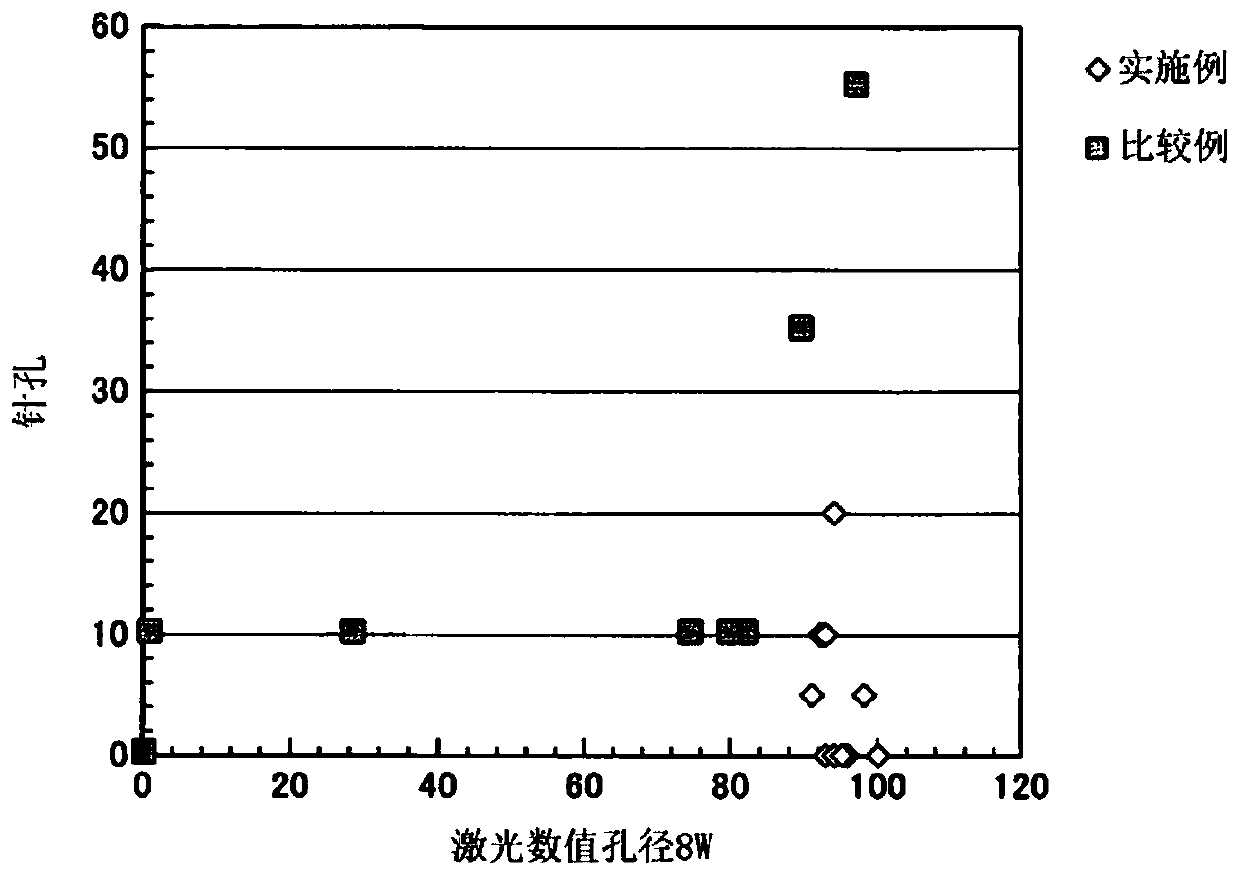

Examples

Embodiment

[0081] Hereinafter, the present invention will be described in detail through examples.

[0082] (1) Manufacture of copper foil and formation of laser absorbing layer

[0083] Electrodeposited copper foils of Examples 1 to 21 and Comparative Examples 1 to 9 were produced through the cathodic reduction step of the electrolytic solution, current density, and bath temperature shown in Table 1, and the electrolytic deposition step based on the electrolysis conditions shown in Table 2. For these electrolytic copper foils, laser absorption was formed by electrolytic plating treatment under the plating bath, treated surface, and electrolytic conditions (pulse voltage pulse width, current density, time, bath temperature) having the composition shown in Table 3, respectively. Floor. In addition, in Example 22, the laser absorption layer was formed by alternating current, and in Example 23, the laser absorption layer was formed by MecEtchBondCZ-8000 treatment. Furthermore, under the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com