Etchant

An etchant and weight technology, applied in the direction of surface etching composition, removal of conductive materials by chemical/electrolytic methods, chemical instruments and methods, etc. The effect of preventing the reduction of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

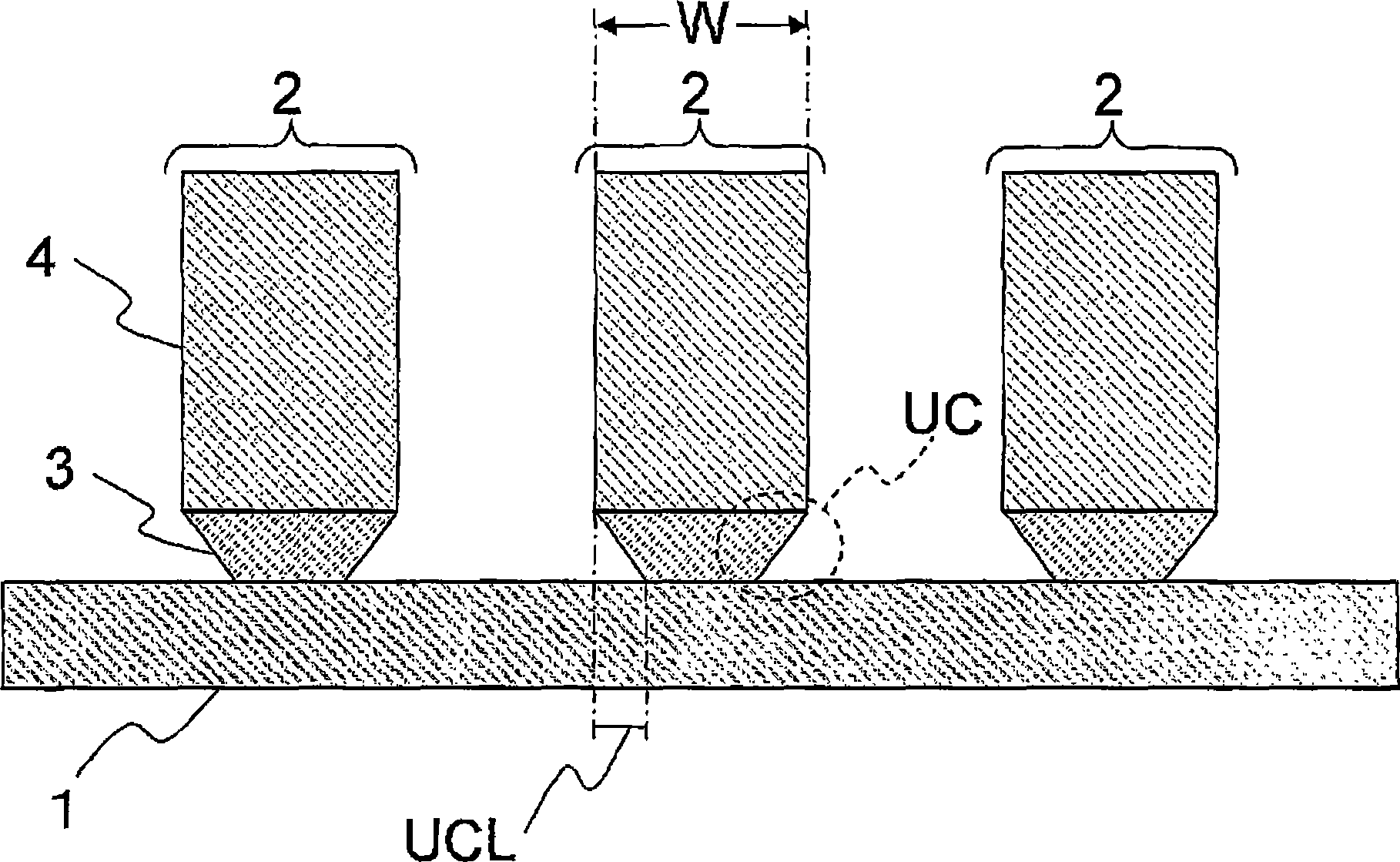

Image

Examples

Embodiment

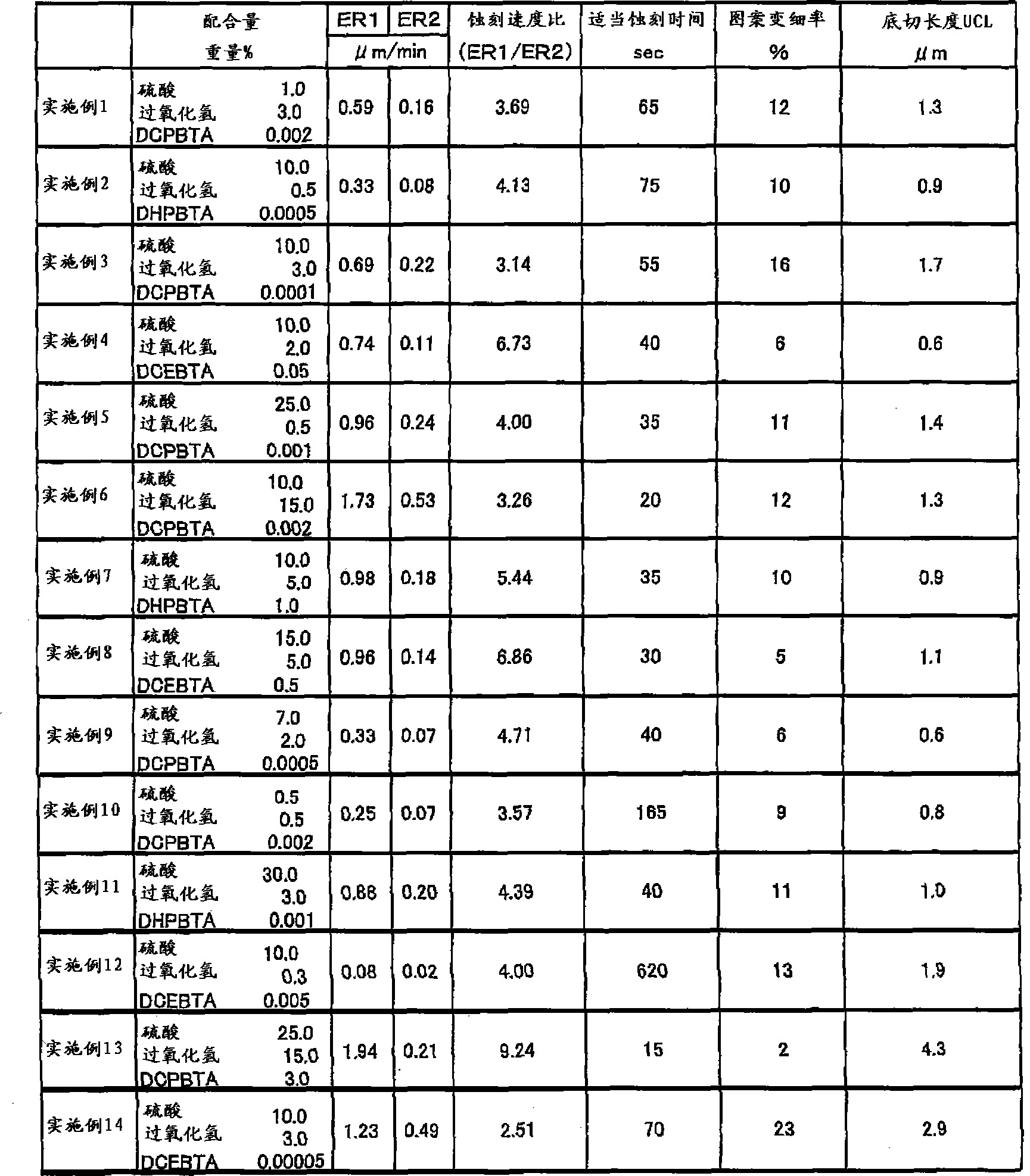

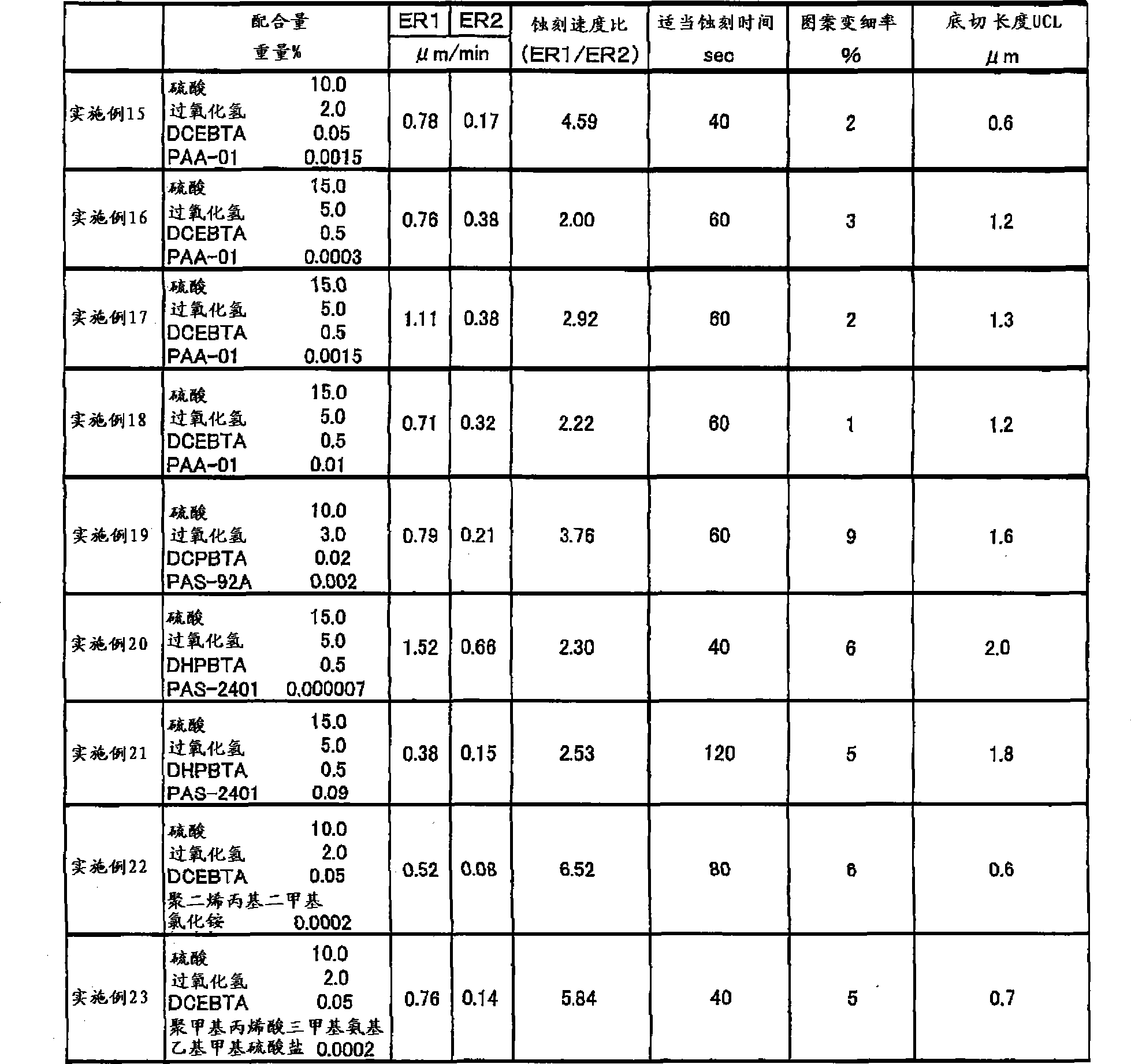

[0048] Furthermore, examples of the etchant according to the present invention will be described together with comparative examples. In addition, this invention is not limited to the following Example and interpreted.

[0049] Each item was evaluated by the measuring method shown below using the etchant of the composition shown in Tables 1-4. Examples 1 to 23 shown in Table 1 and Table 2 are examples of the above-mentioned first etchant of the present invention, and Examples 24 to 33 shown in Table 3 are examples of the above-mentioned second etchant of the present invention. In addition, Table 4 shows comparative examples. Each etchant was prepared by first dissolving metallic copper at a ratio of 25 g / L in a solution obtained by dissolving sulfuric acid and hydrogen peroxide in ion-exchanged water, and then adding the remaining components. In addition, the compounding quantity of each component shown in Tables 1-4 shows the weight ratio of each component with respect to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com