Patents

Literature

130results about How to "Long-lasting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

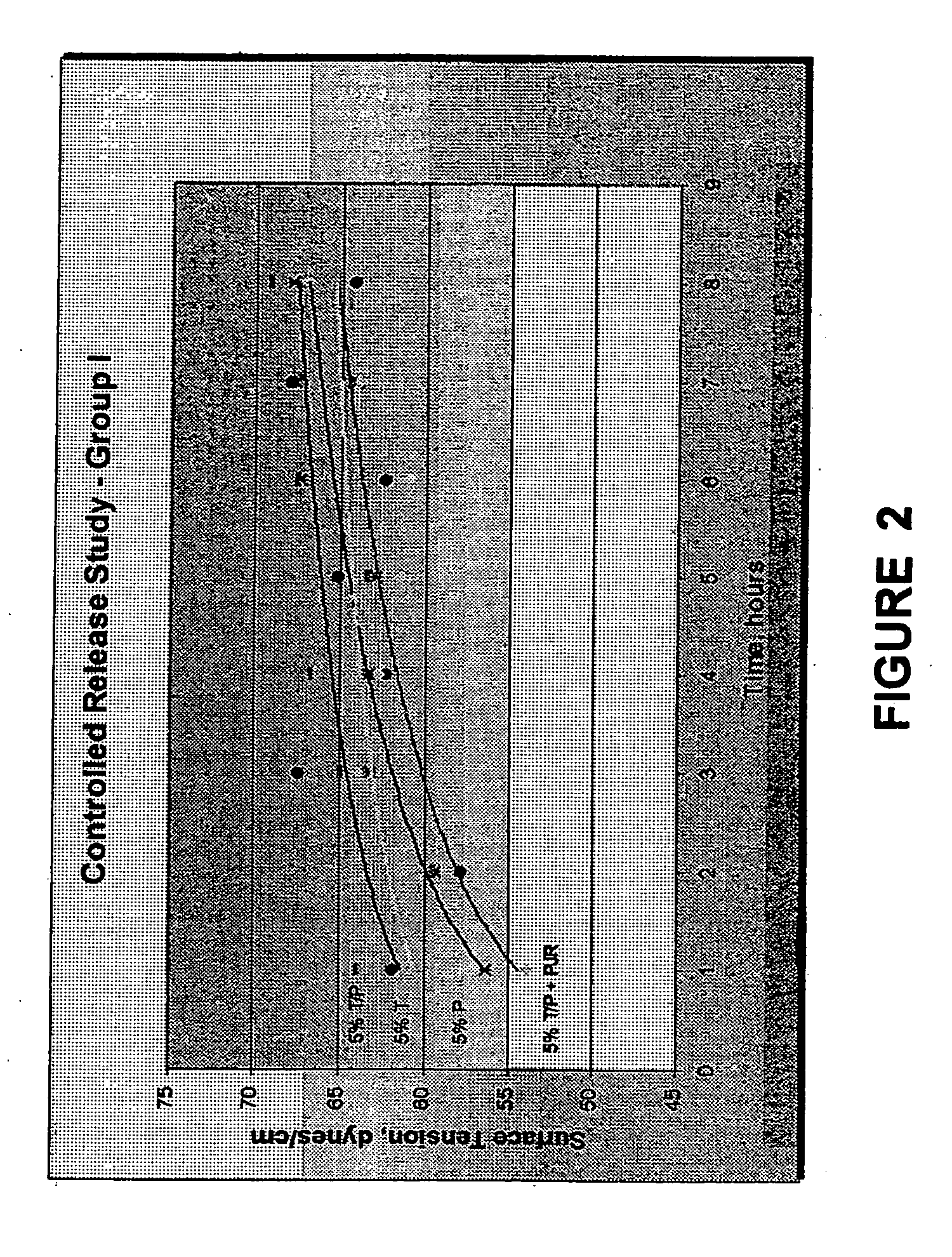

Method and composition for contact lenses

InactiveUS20060073185A1Reduce drynessLonger wetting performancePharmaceutical delivery mechanismProsthesisCationic polyelectrolytesChemistry

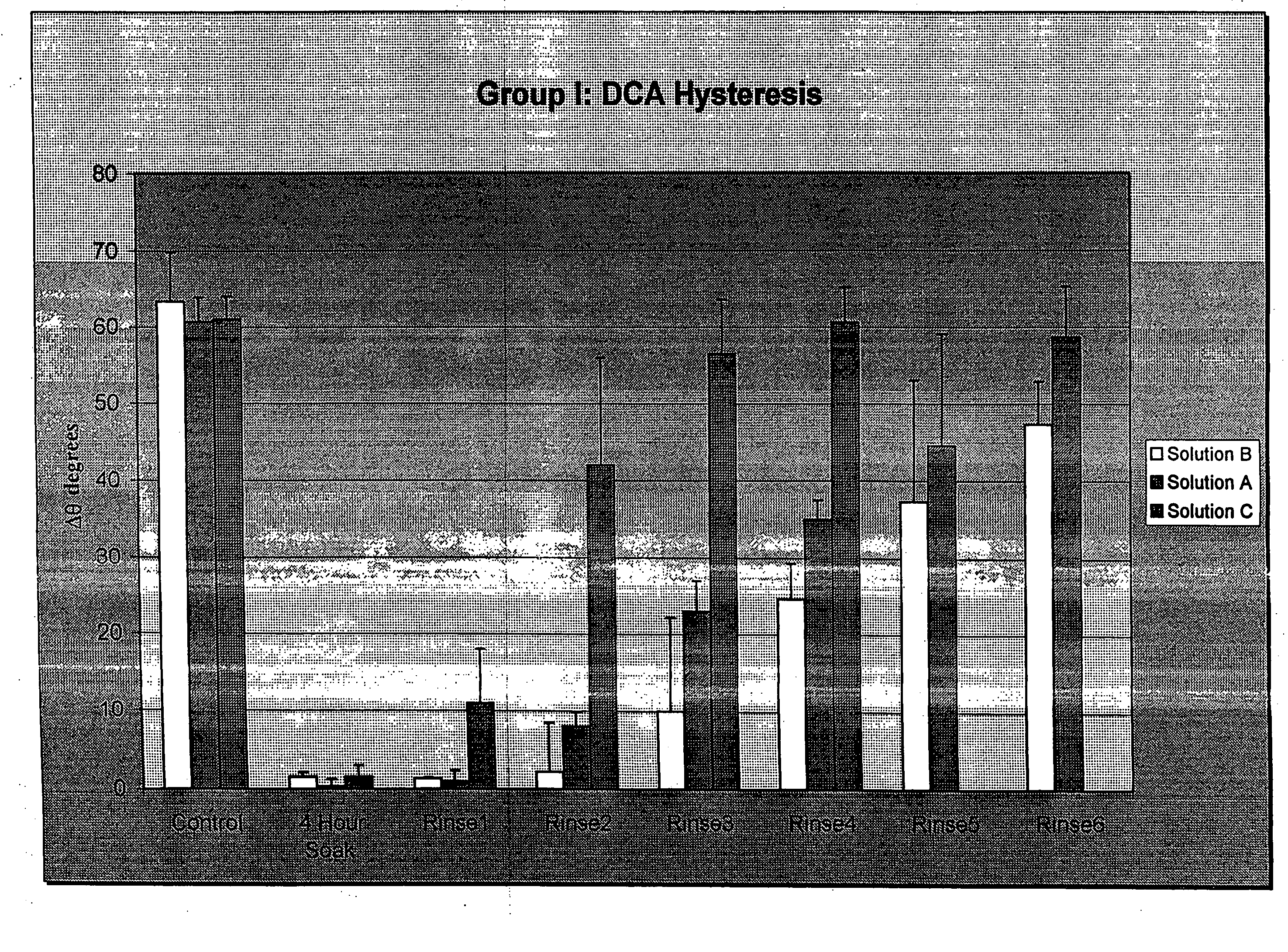

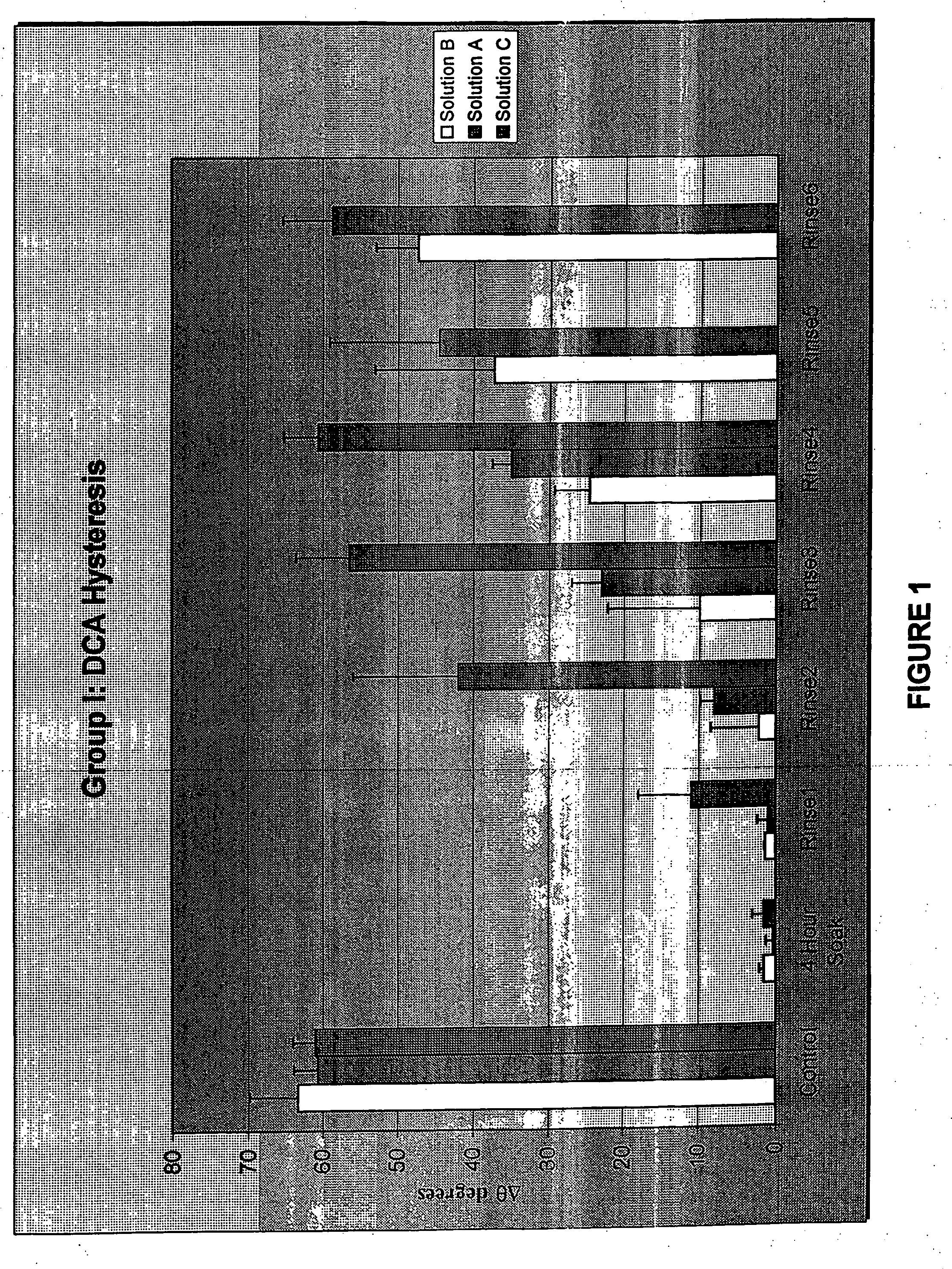

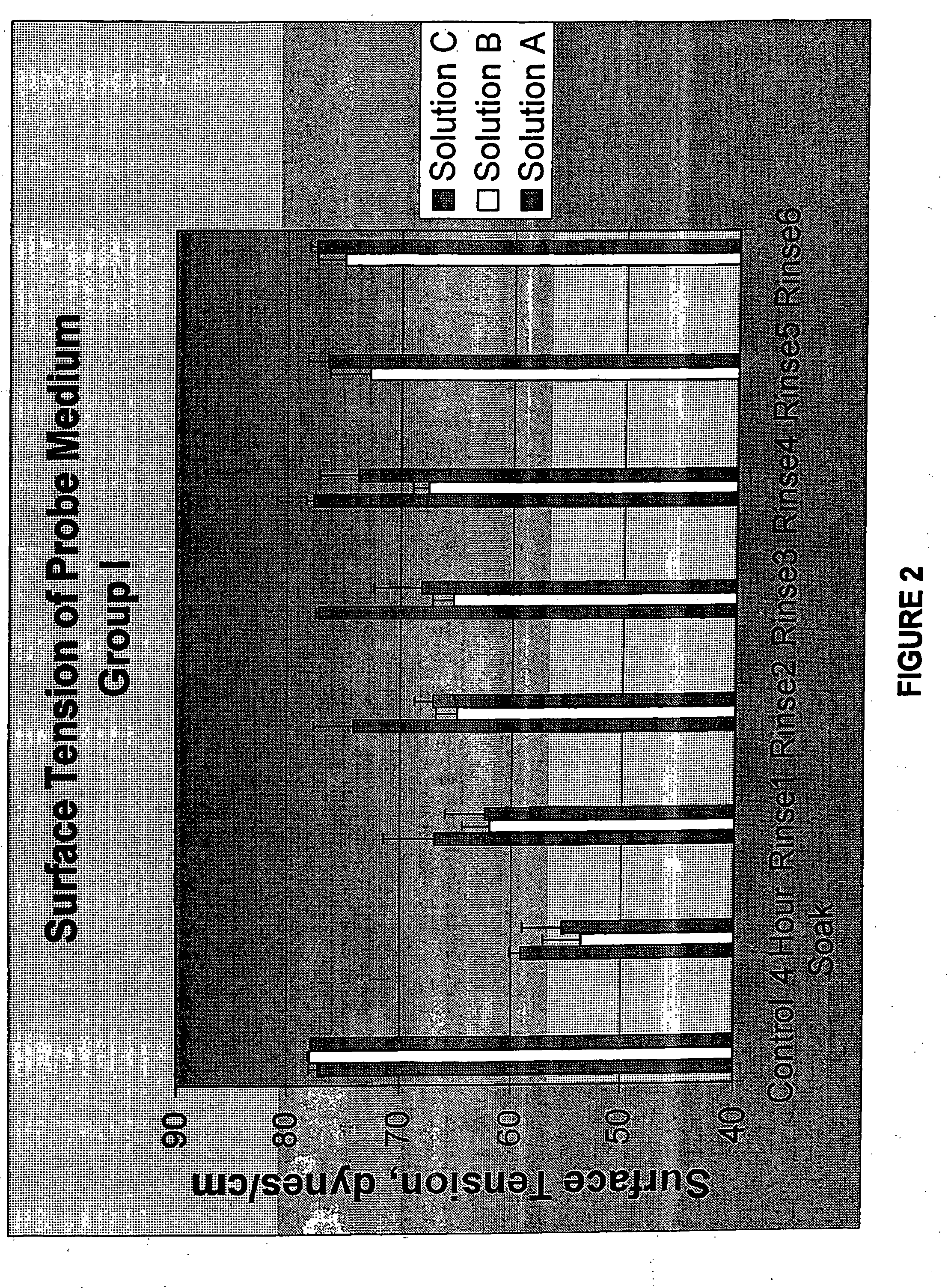

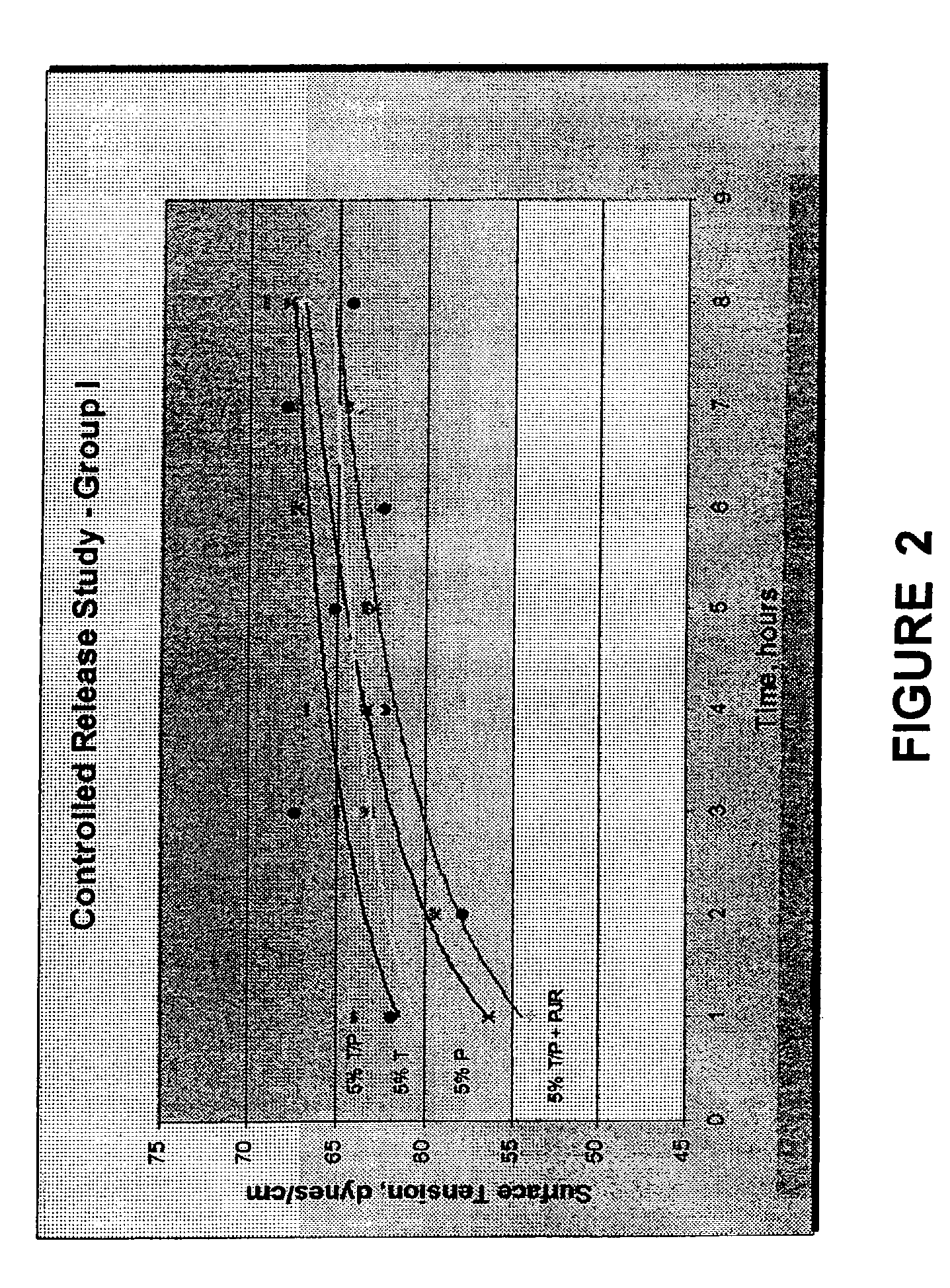

A solution for soft, hydrogel contact lenses includes a polyether that is controllably released into an eye's tear film when the lens is worn. Polyether components of the subject solution are released from the soft contact lens material matrix over long time periods to produce longer lasting wetting performance, improved lubricity, improved comfort, and / or reduced feeling of dryness from wearing contact lenses. The solution further includes a cationic polyelectrolyte.

Owner:BAUSCH & LOMB INC

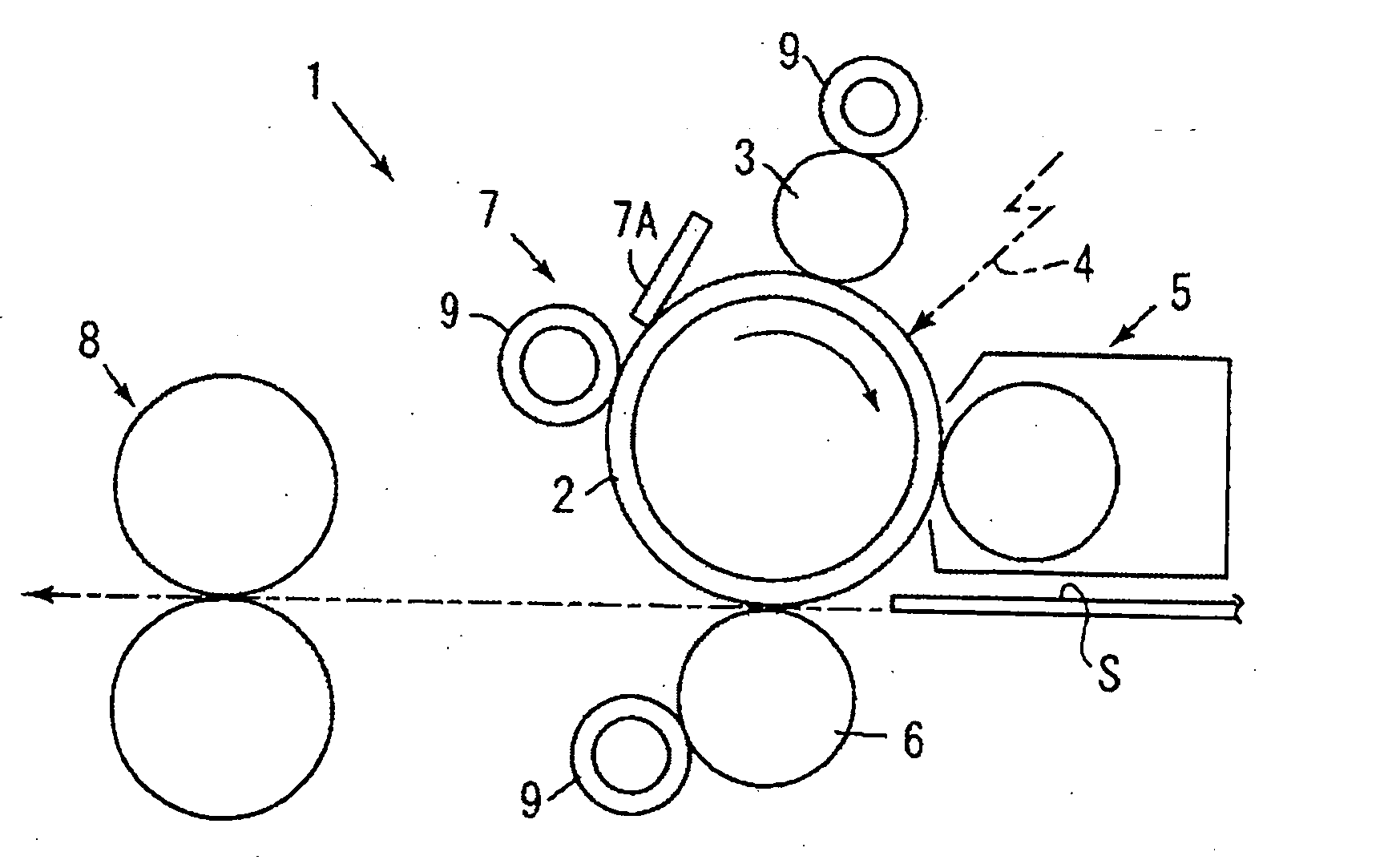

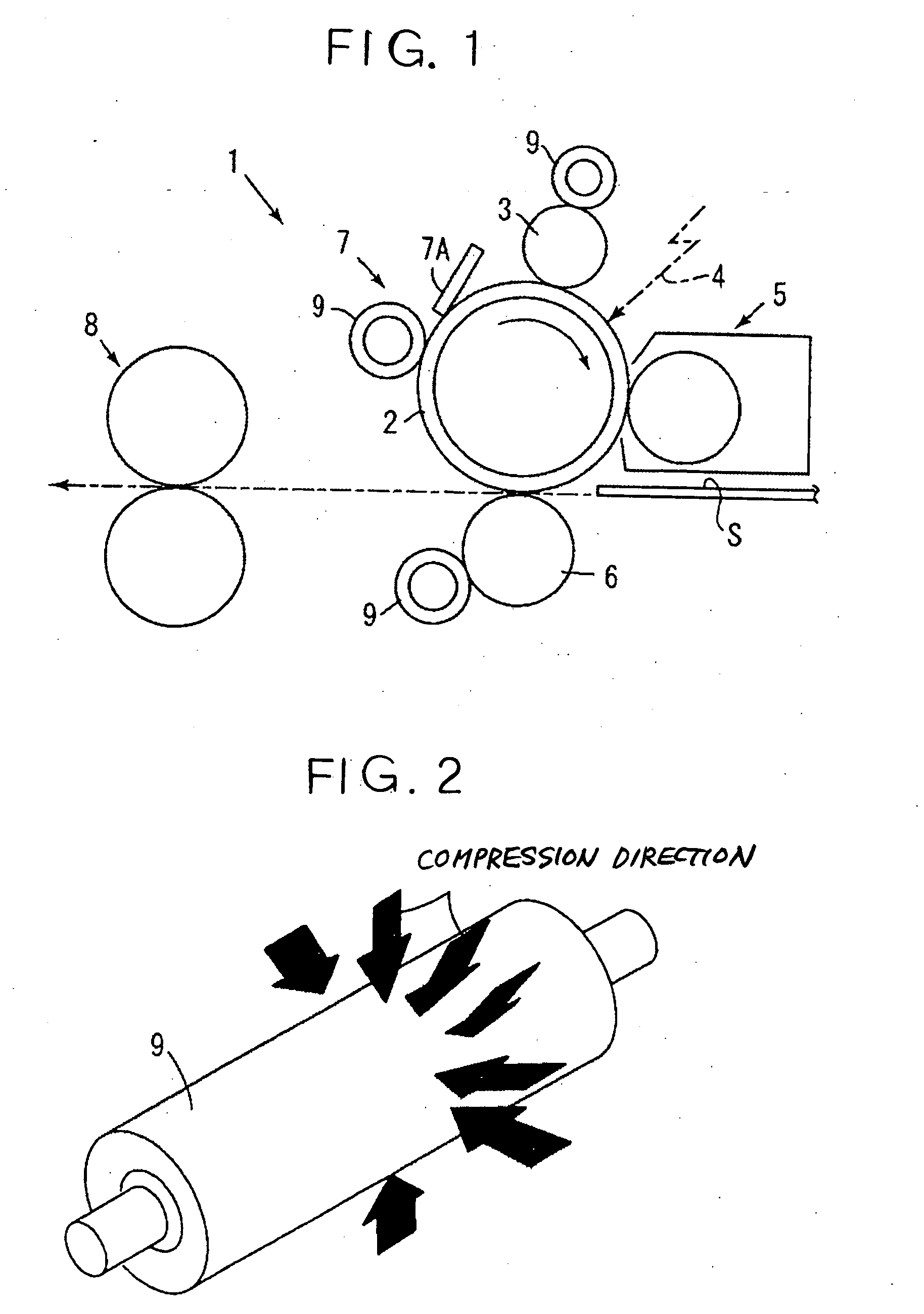

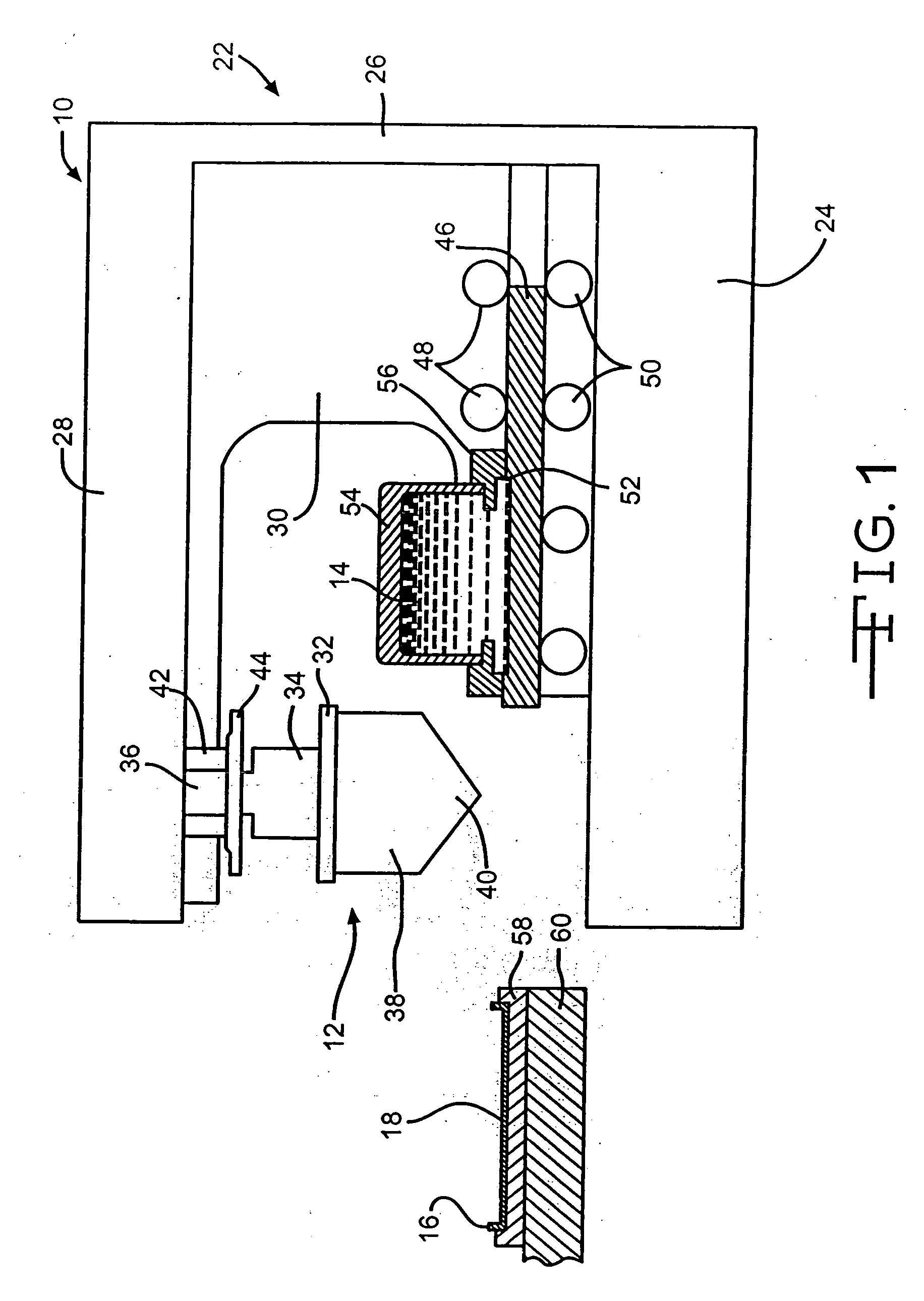

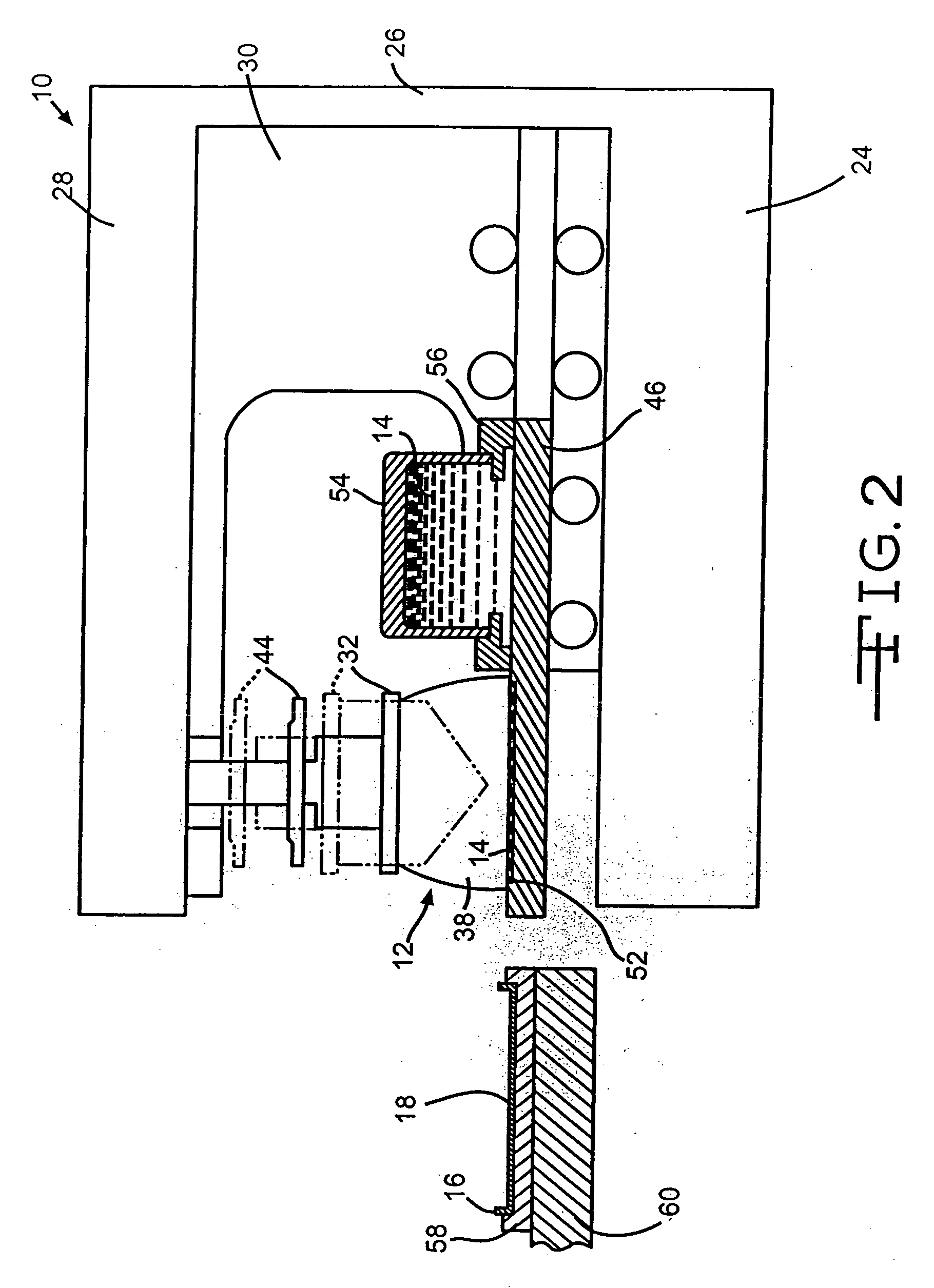

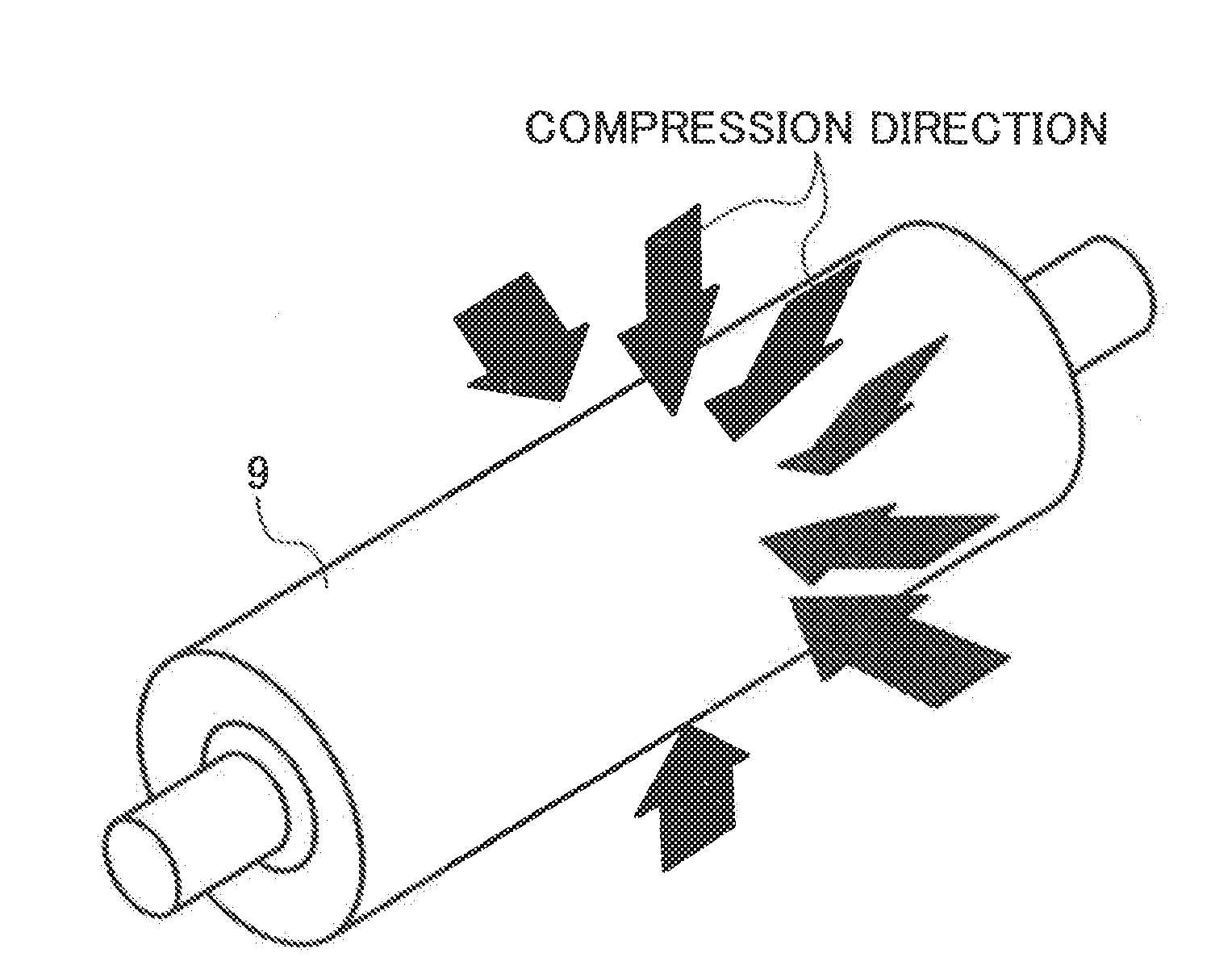

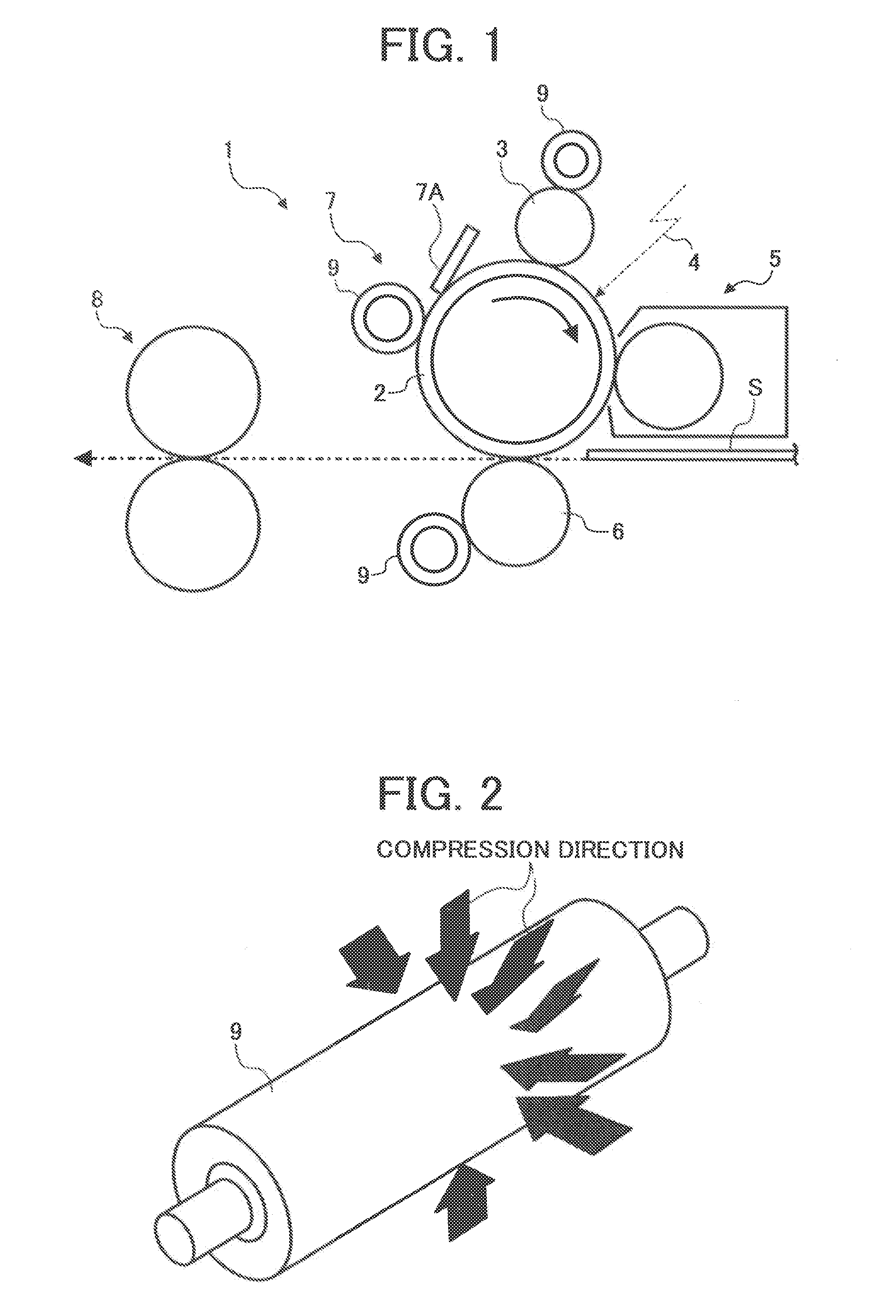

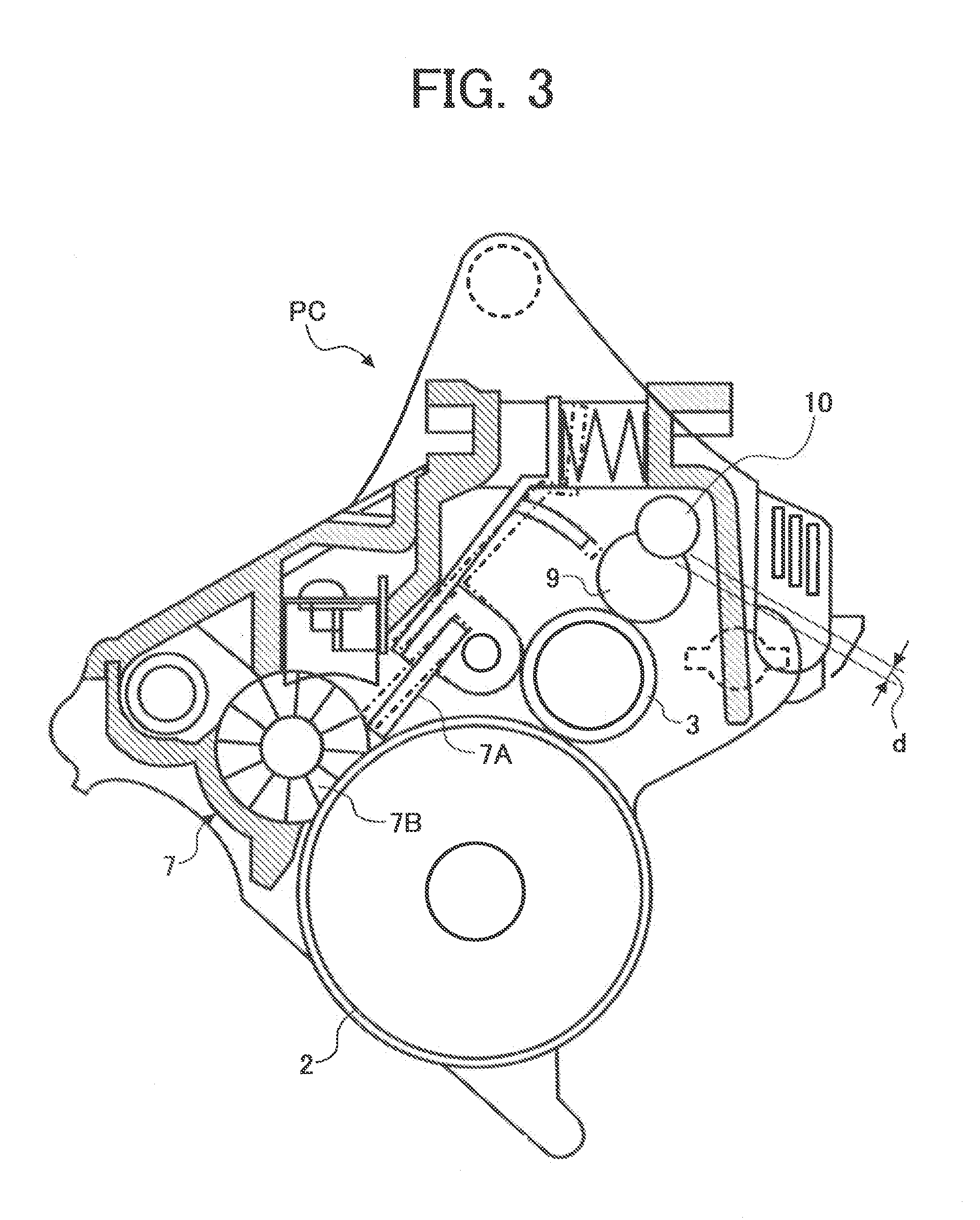

Charged device, cleaning device, process cartridge, toner, and image-forming device that uses these

ActiveUS20050191081A1Increase costReduce image qualityElectrographic process apparatusCorona dischargeForeign matterImaging quality

There is provided a cleaning device for an image-forming device configured so as to be capable of preventing the image quality from deteriorating by being able to prevent the deterioration of the charging state caused by deposits of foreign matter without increasing costs. There is also provided a cleaning member that can make contact with the cleaning target-members. The cleaning member has a portion composed of melamine resin foam for making contact with at least the cleaning target members, and the melamine resin foam has an Asker F hardness of 5 to 25 points and a hardness variation of 5 points or less, and is used on the cleaning target members in a state obtained by heat compression from the original shape. The pressing member is furthermore disposed in contact with the cleaning member.

Owner:RICOH KK

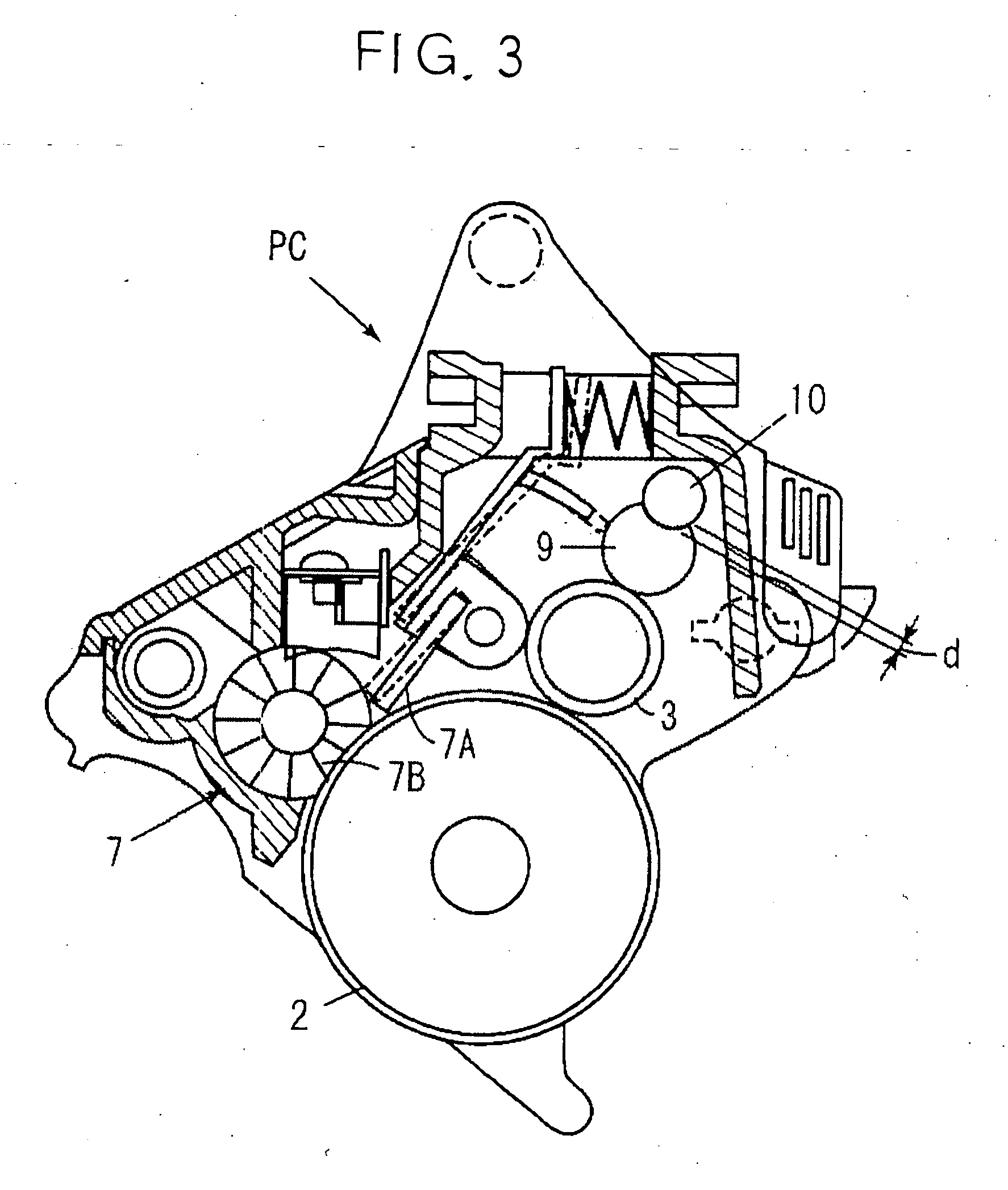

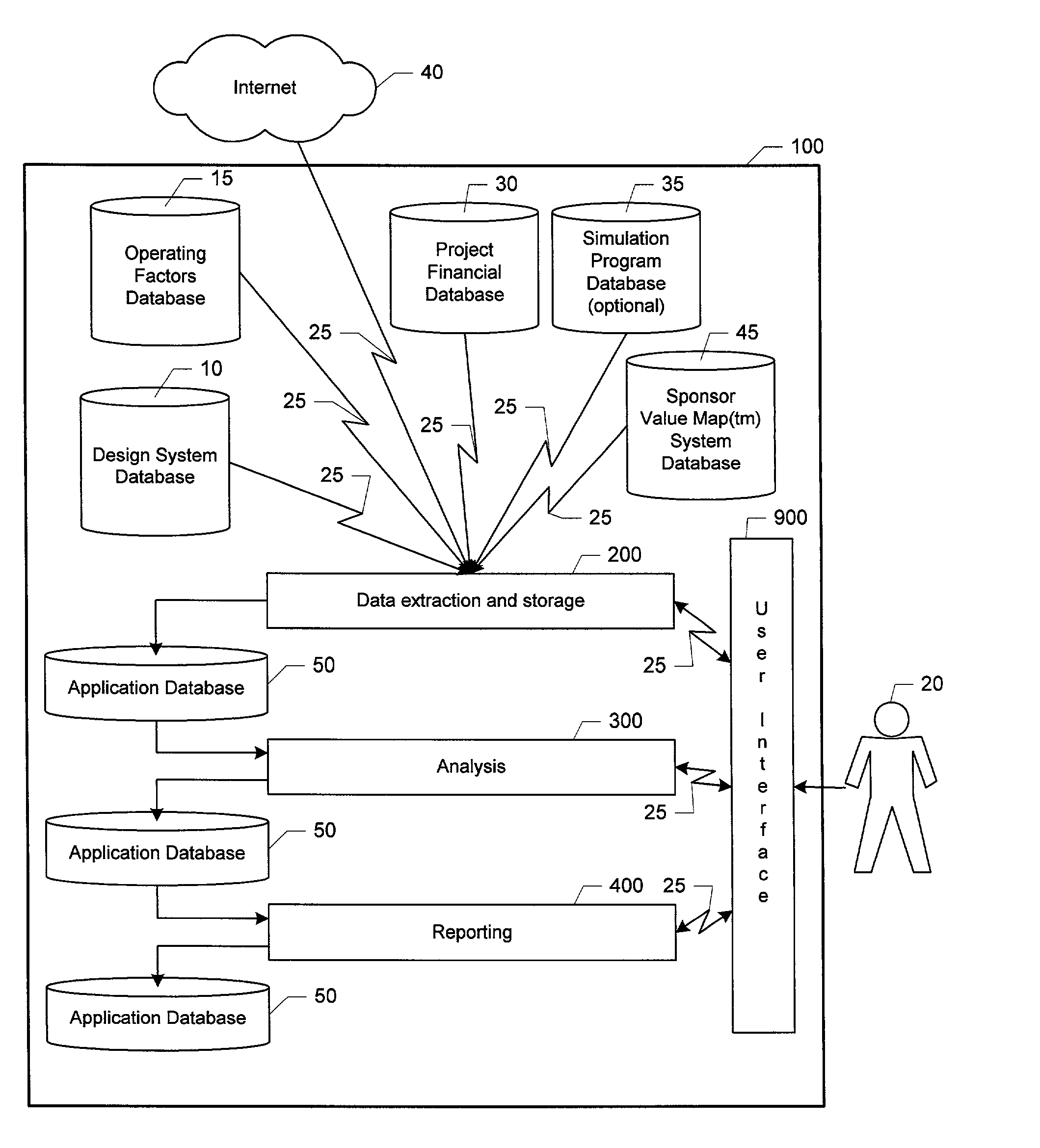

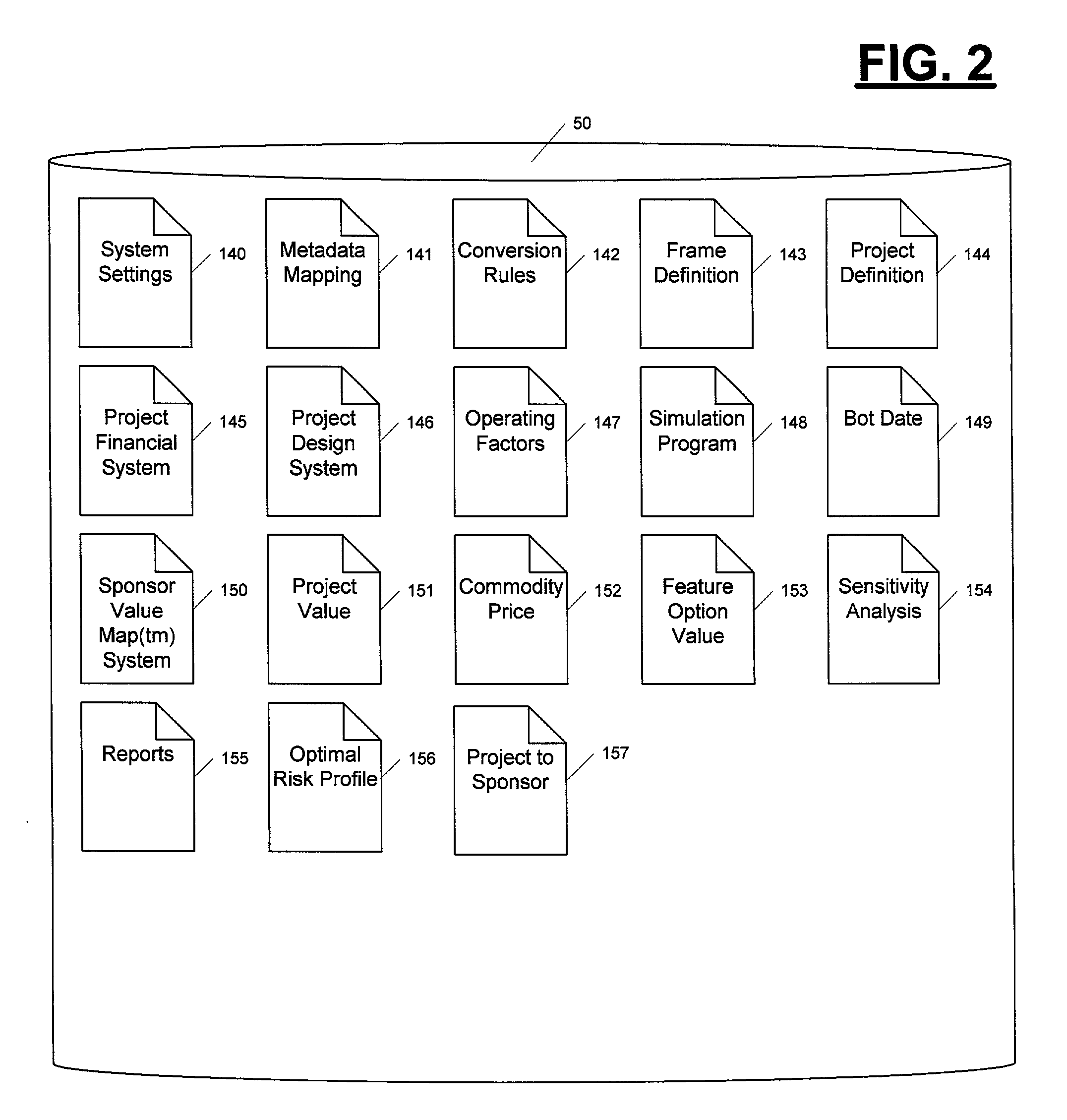

Project optimization system

An automated system (100) and method for optimizing project risk and return from the perspective of the sponsor. The project, project features and feature options are defined using project design system and project financial system data. The expected project outputs are then mapped to matrices of value and risk for the sponsor. The system calculates a value for the project then identifies the mix of features and feature options that maximize expected project value from the perspective of the sponsor. The system also identifies the mix of features and feature options that maximize expected project value while minimizing project risk from other frames.

Owner:SQUARE HALT SOLUTIONS LIMITED LIABILITY +1

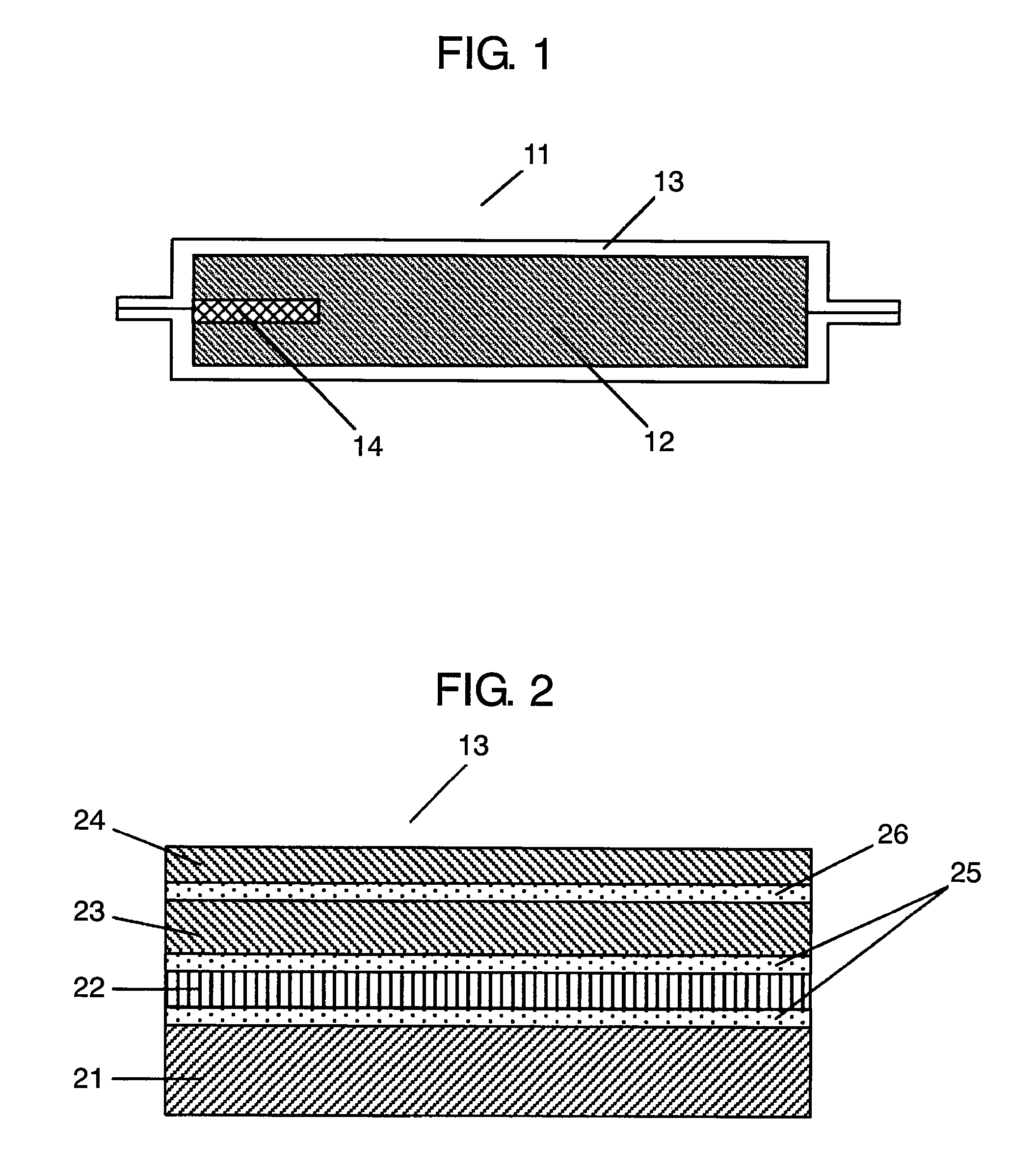

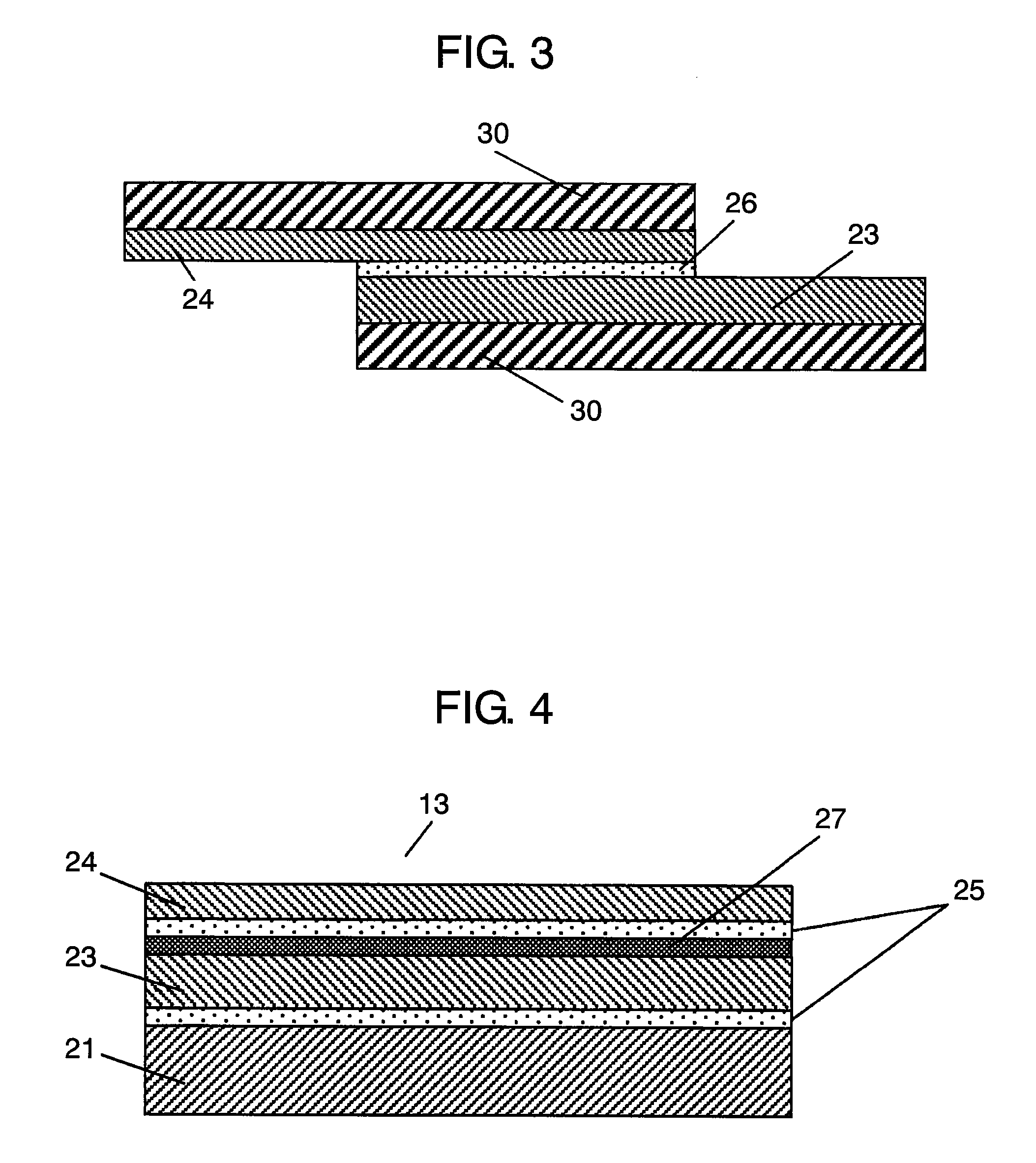

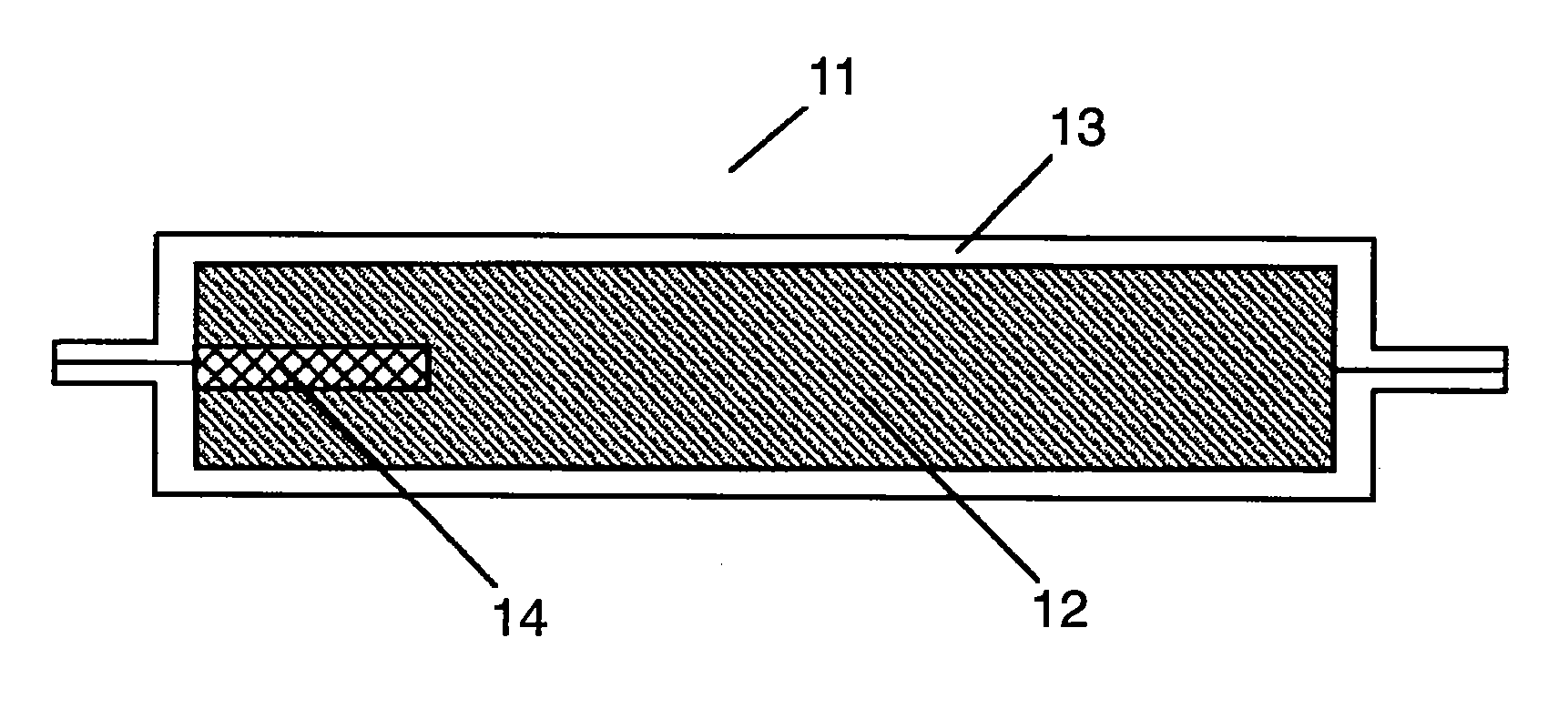

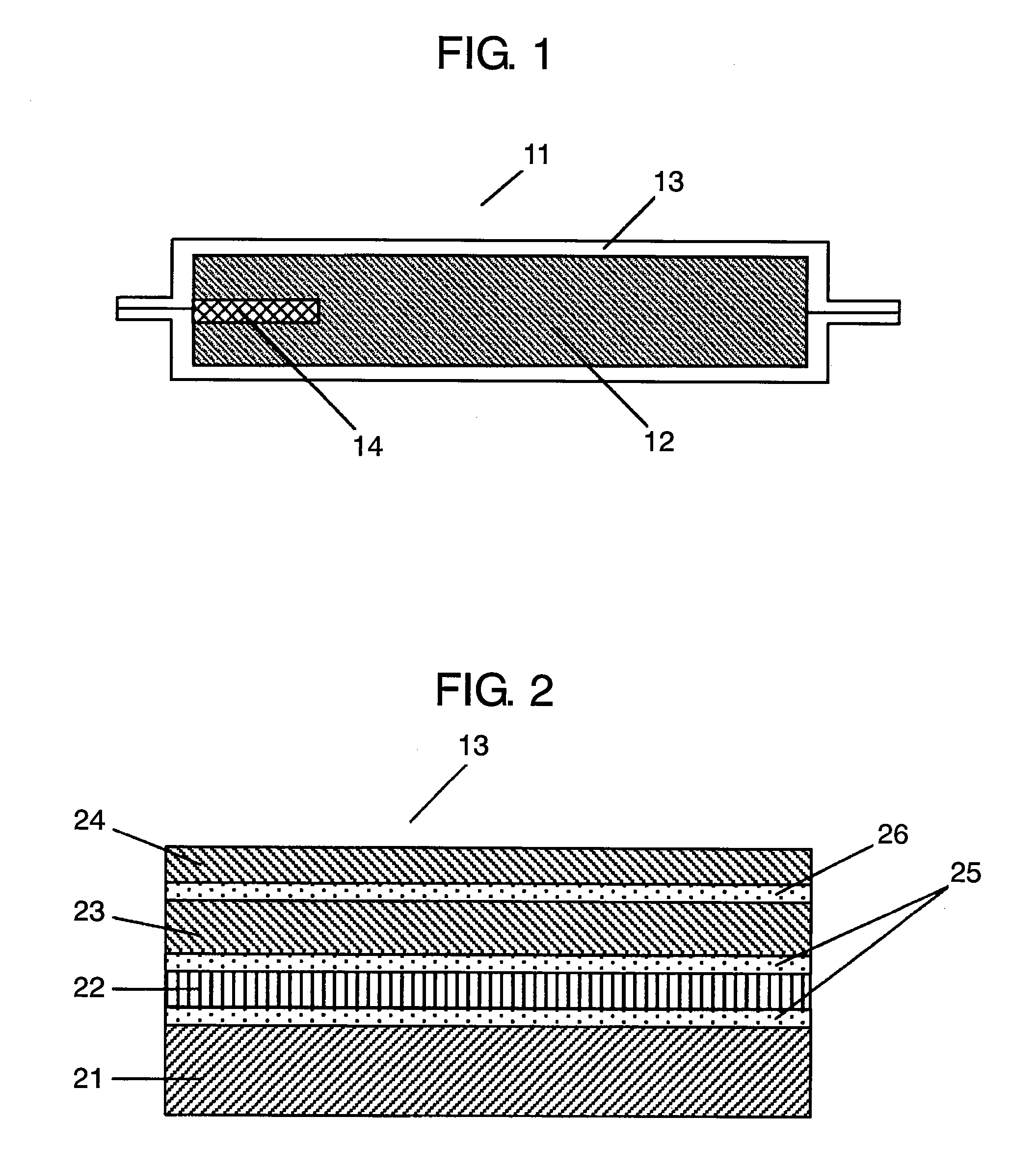

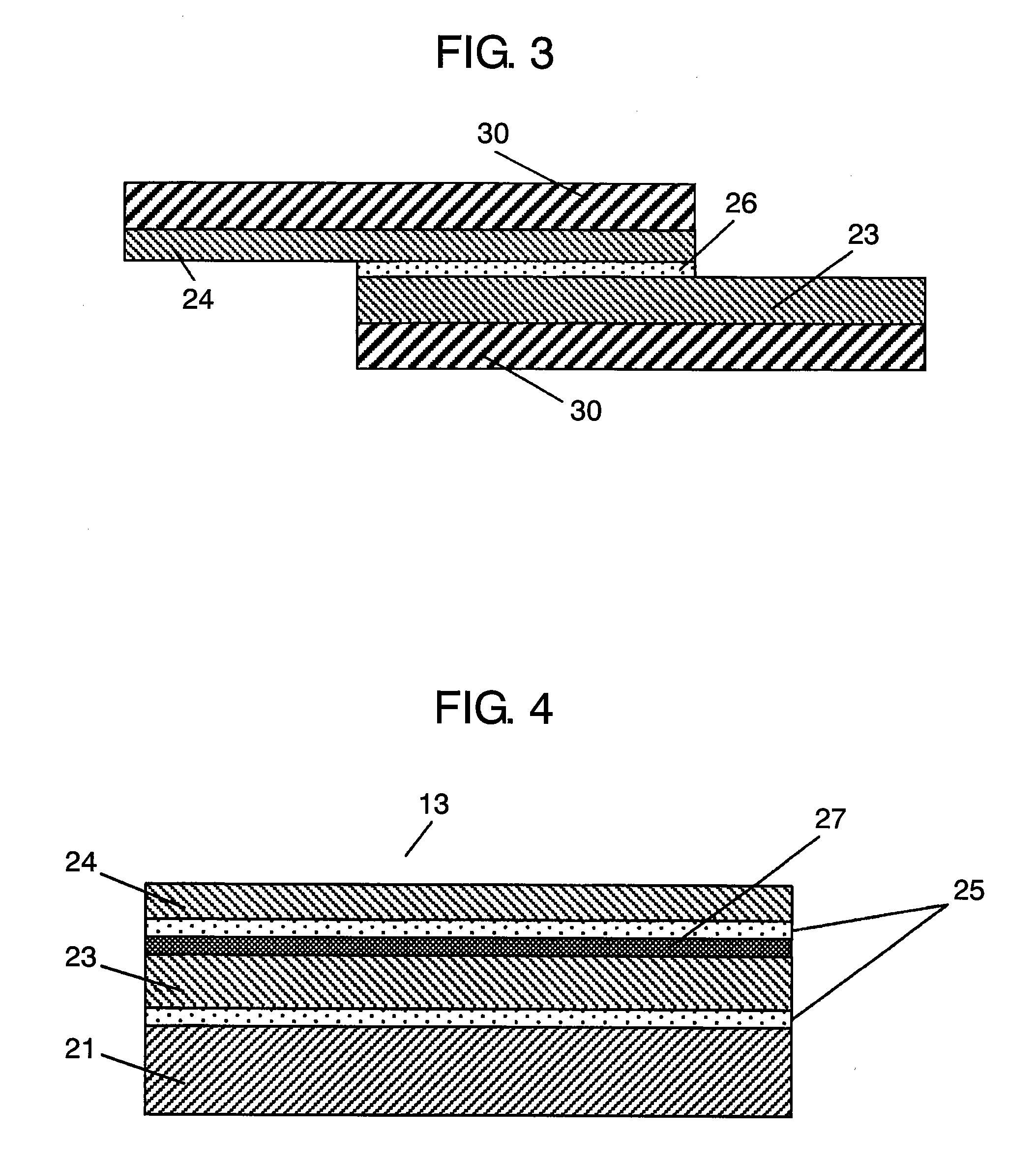

Vacuum heat insulation material and cold reserving apparatus with the same

ActiveUS7762634B2Long-lasting performanceExcellent pinhole resistanceThermal insulationSynthetic resin layered productsForeign matterMetal foil

A vacuum heat insulation material has a covering material which is a lamination body including a sealant layer, a metal foil layer, a first plastic film layer, and a second plastic film layer which are laminated in this order from inside to outside via adhesive layers. When a foreign body is pierced into the vacuum heat insulation material, the propagation of breakage caused by the piercing is blocked somewhere inside the lamination body, thereby preventing the formation of through-pinholes. This results in the provision of a high-quality vacuum heat insulation material with excellent long-term insulation performance by using a covering material excellent in gas barrier properties and pinhole resistance to the piercing of minute foreign bodies.

Owner:PANASONIC CORP

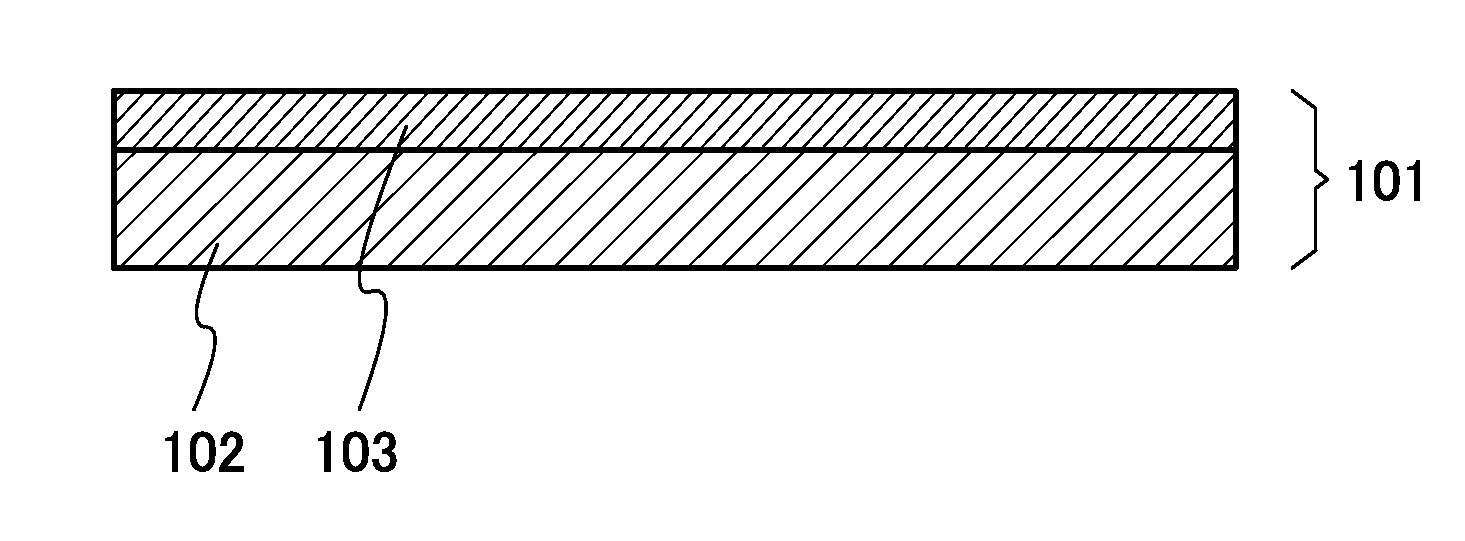

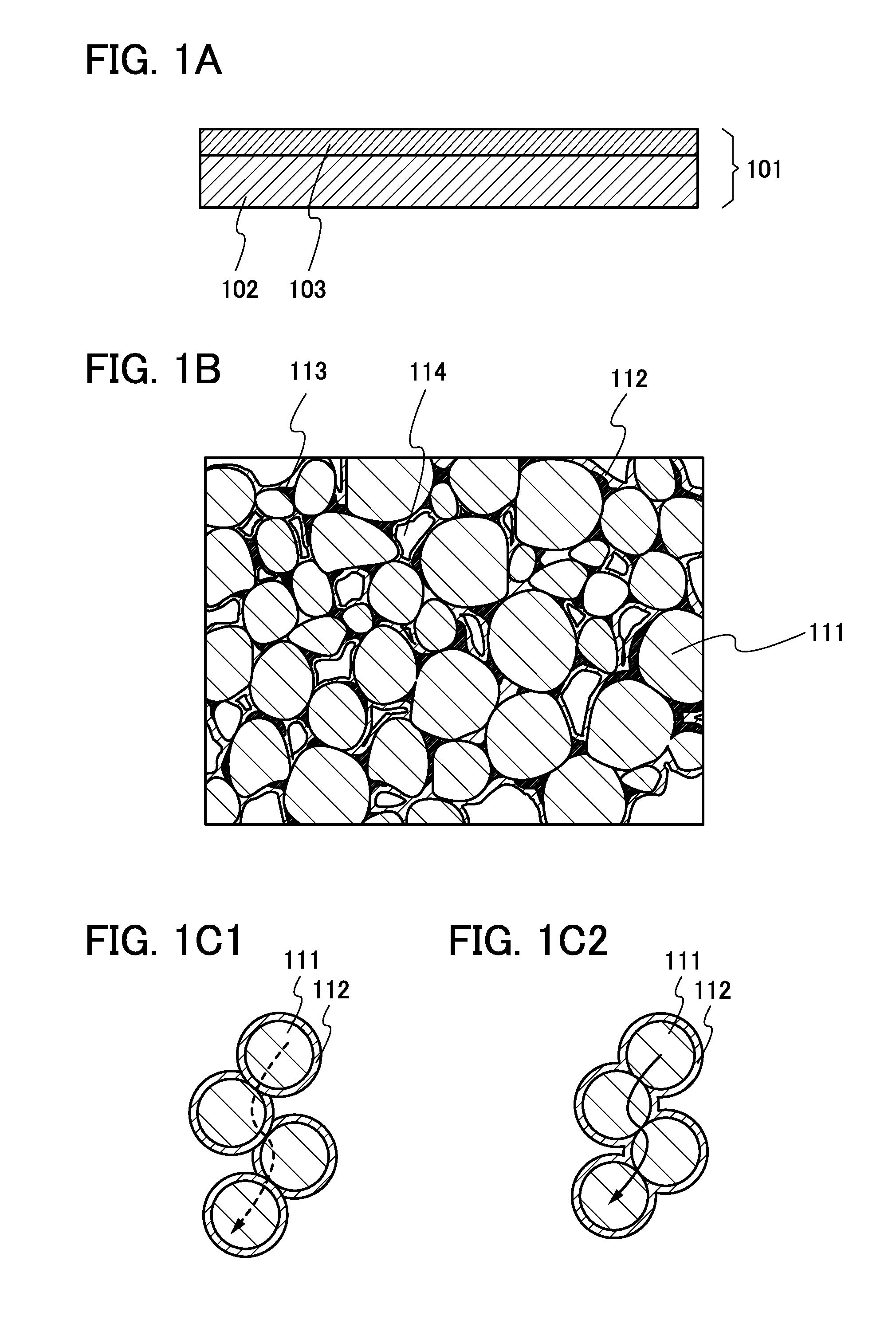

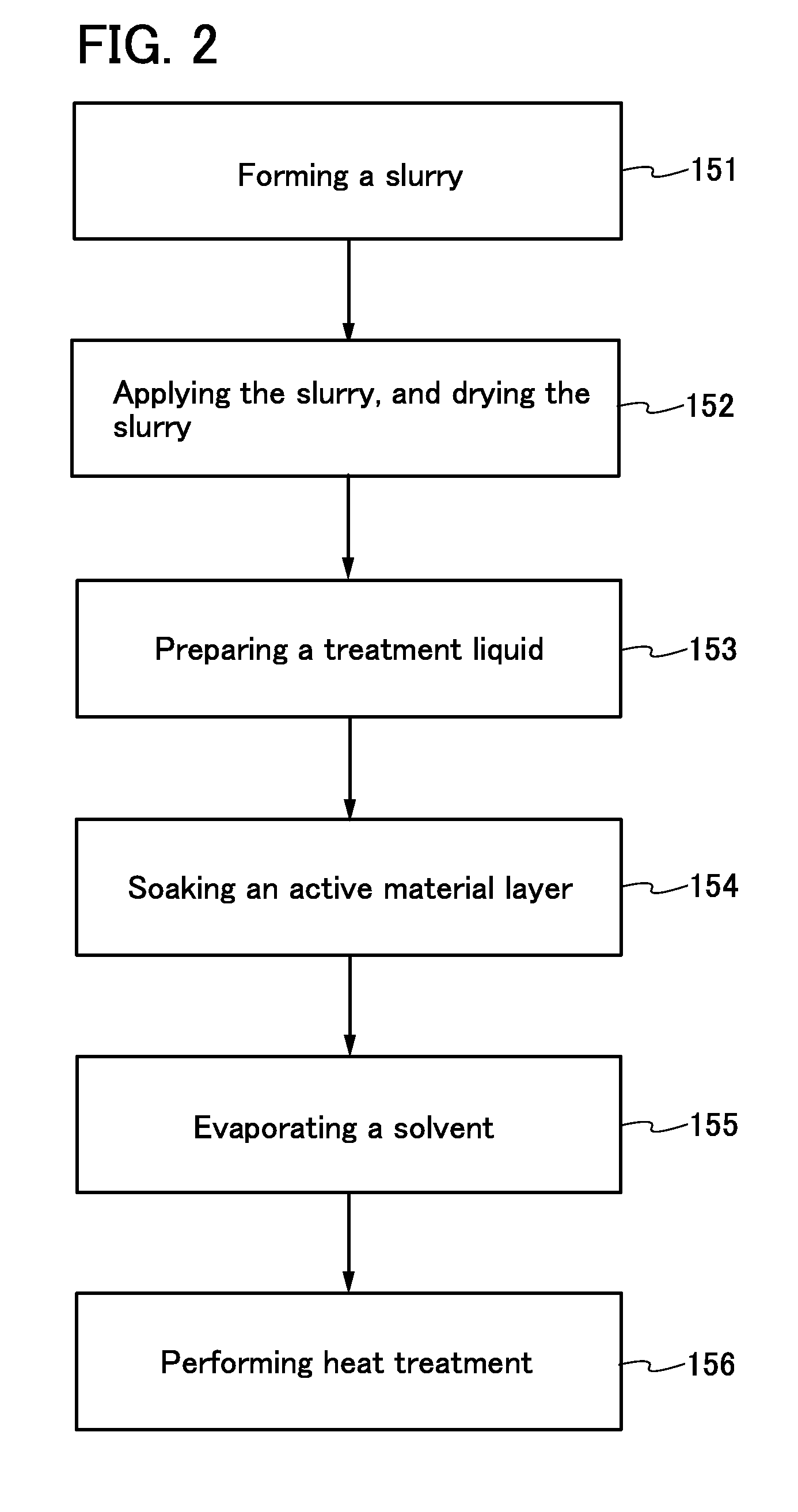

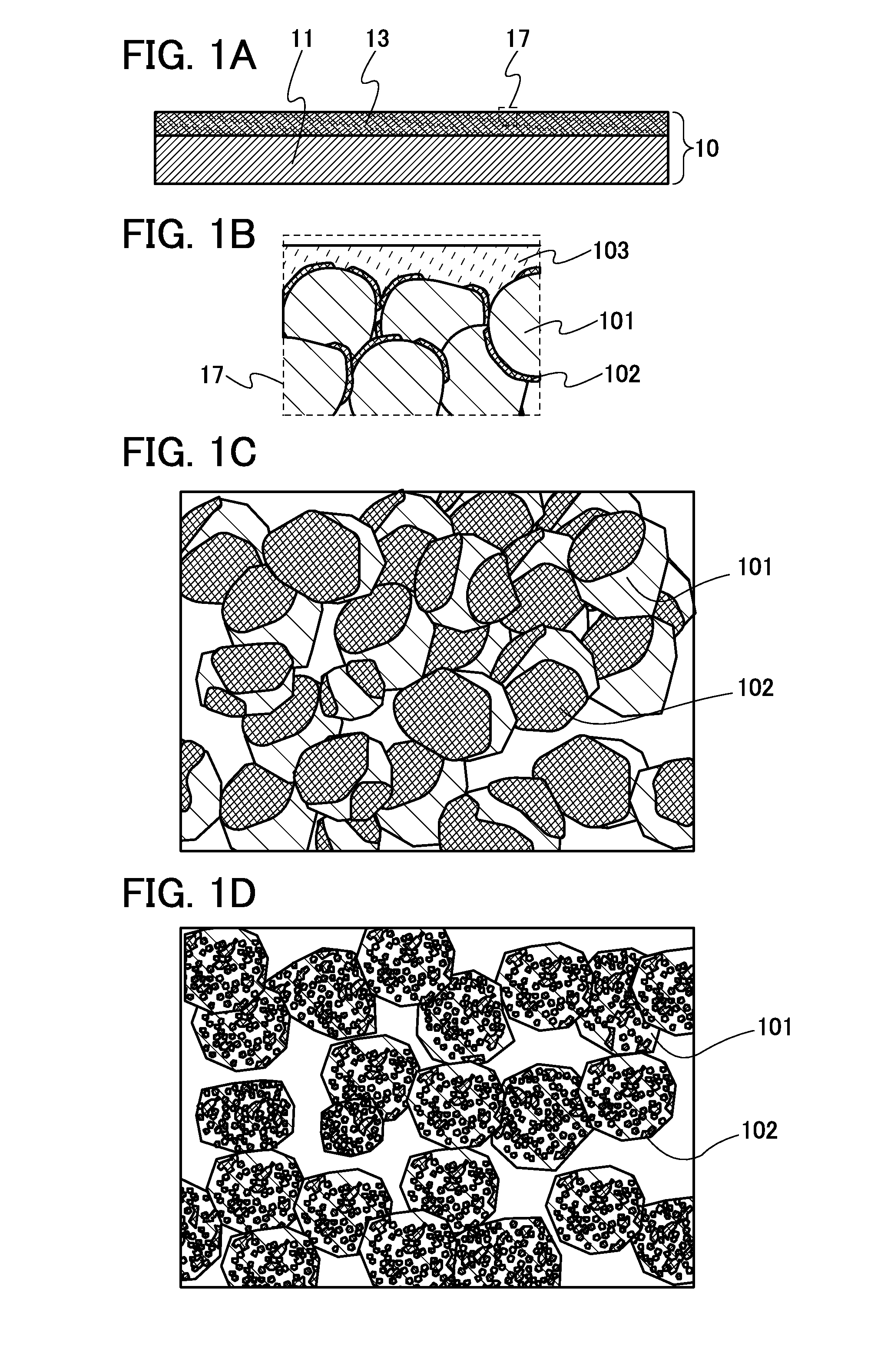

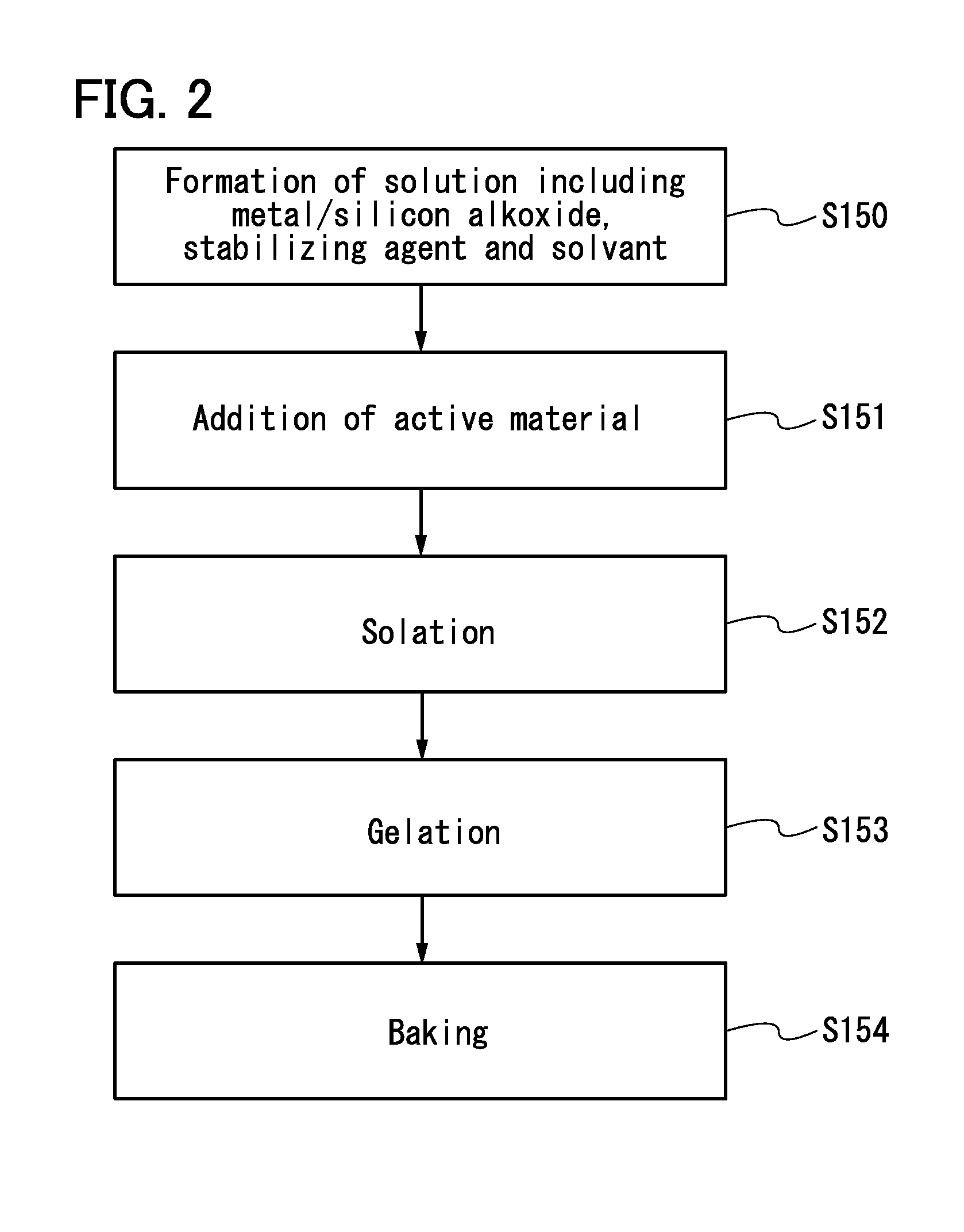

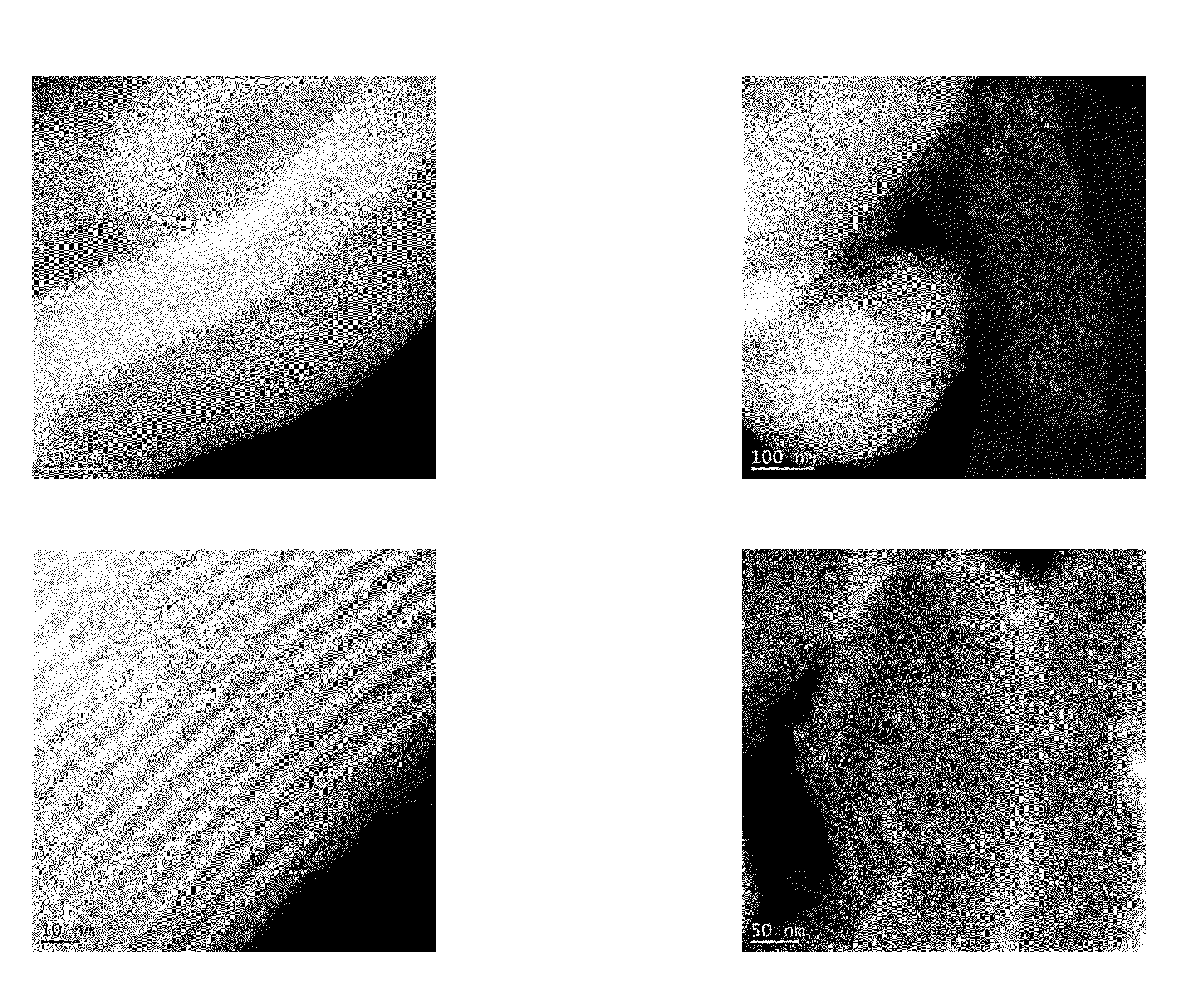

Electrode for power storage device, power storage device, and manufacturing method of electrode for power storage device

ActiveUS20140127567A1Minimize electrochemical decompositionMinimizing reactionHybrid capacitor electrodesActive material electrodesDecompositionSilicon oxide

To improve the long-term cycle performance of a lithium-ion battery or a lithium-ion capacitor by minimizing the decomposition reaction of an electrolytic solution and the like as a side reaction of charge and discharge in the repeated charge and discharge cycles of the lithium-ion battery or the lithium-ion capacitor. A current collector and an active material layer over the current collector are included in an electrode for a power storage device. The active material layer includes a plurality of active material particles and silicon oxide. The surface of one of the active material particles has a region that is in contact with one of the other active material particles. The surface of the active material particle except the region is partly or entirely covered with the silicon oxide.

Owner:SEMICON ENERGY LAB CO LTD

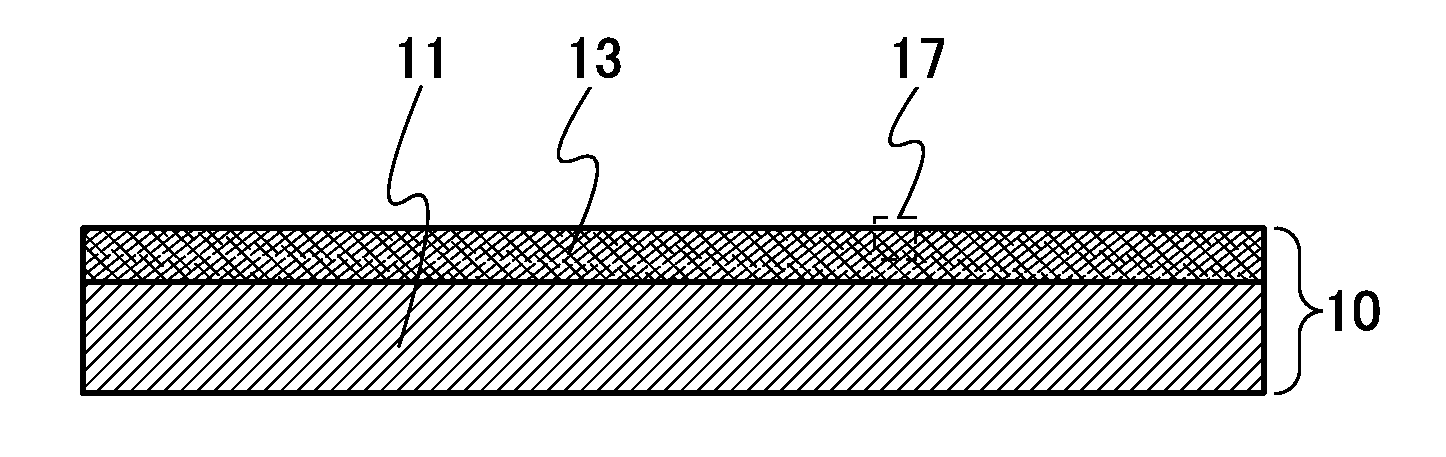

Negative electrode for power storage device and power storage device

ActiveUS20130323585A1AdhesionImprove adhesionHybrid capacitor electrolytesHybrid capacitor electrodesDecompositionLithium-ion capacitor

A decomposition reaction of an electrolyte solution and the like caused as a side reaction of charge and discharge is minimized in repeated charge and discharge of a lithium ion battery or a lithium ion capacitor, and thus the lithium ion battery or the lithium ion capacitor can have long-term cycle performance. A negative electrode for a power storage device includes a negative electrode current collector and a negative electrode active material layer which includes a plurality of particles of a negative electrode active material. Each of the particles of the negative electrode active material has an inorganic compound film containing a first inorganic compound on part of its surface. The negative electrode active material layer has a film in contact with an exposed part of the negative electrode active material and part of the inorganic compound film. The film contains an organic compound and a second inorganic compound.

Owner:SEMICON ENERGY LAB CO LTD

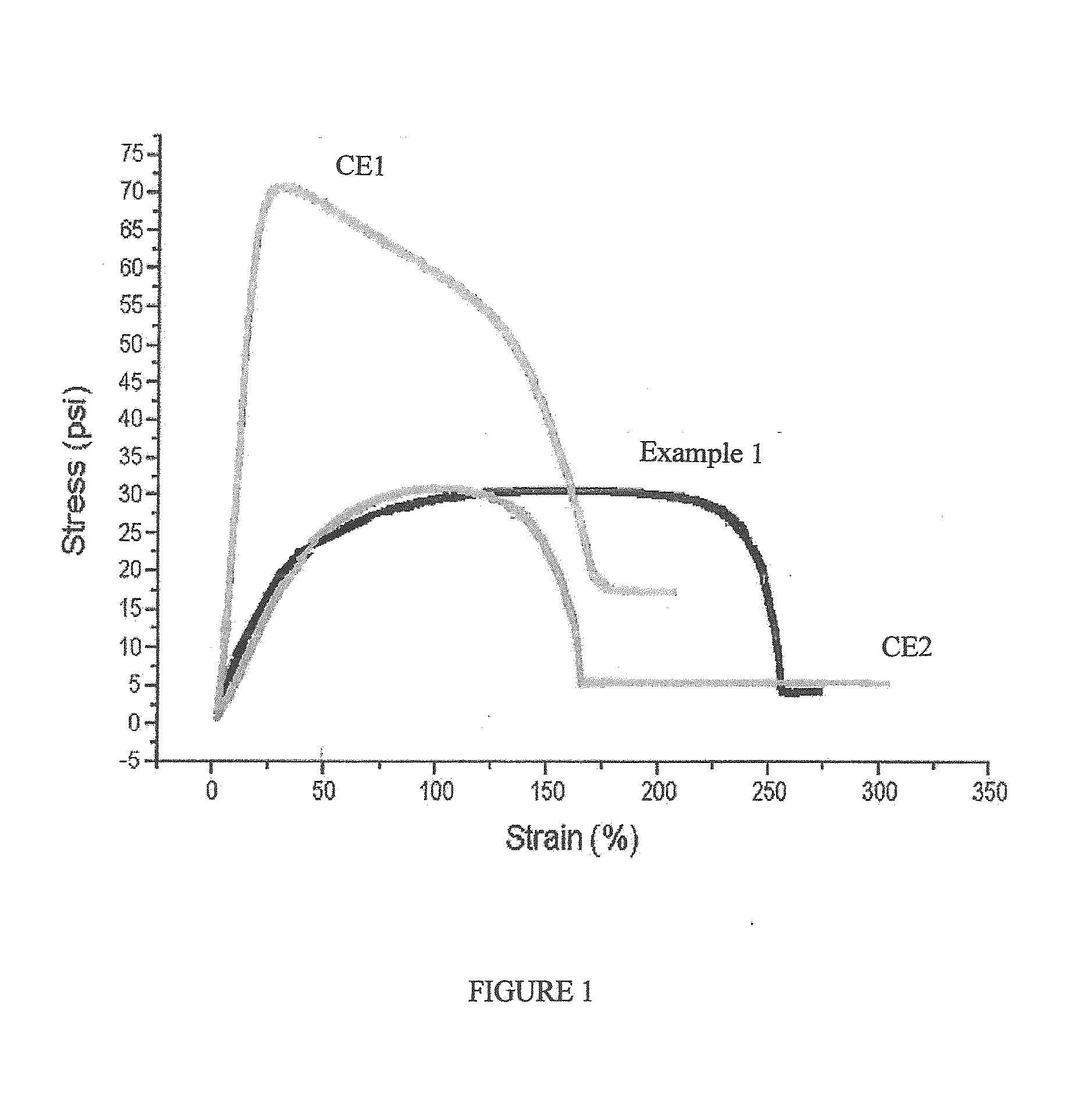

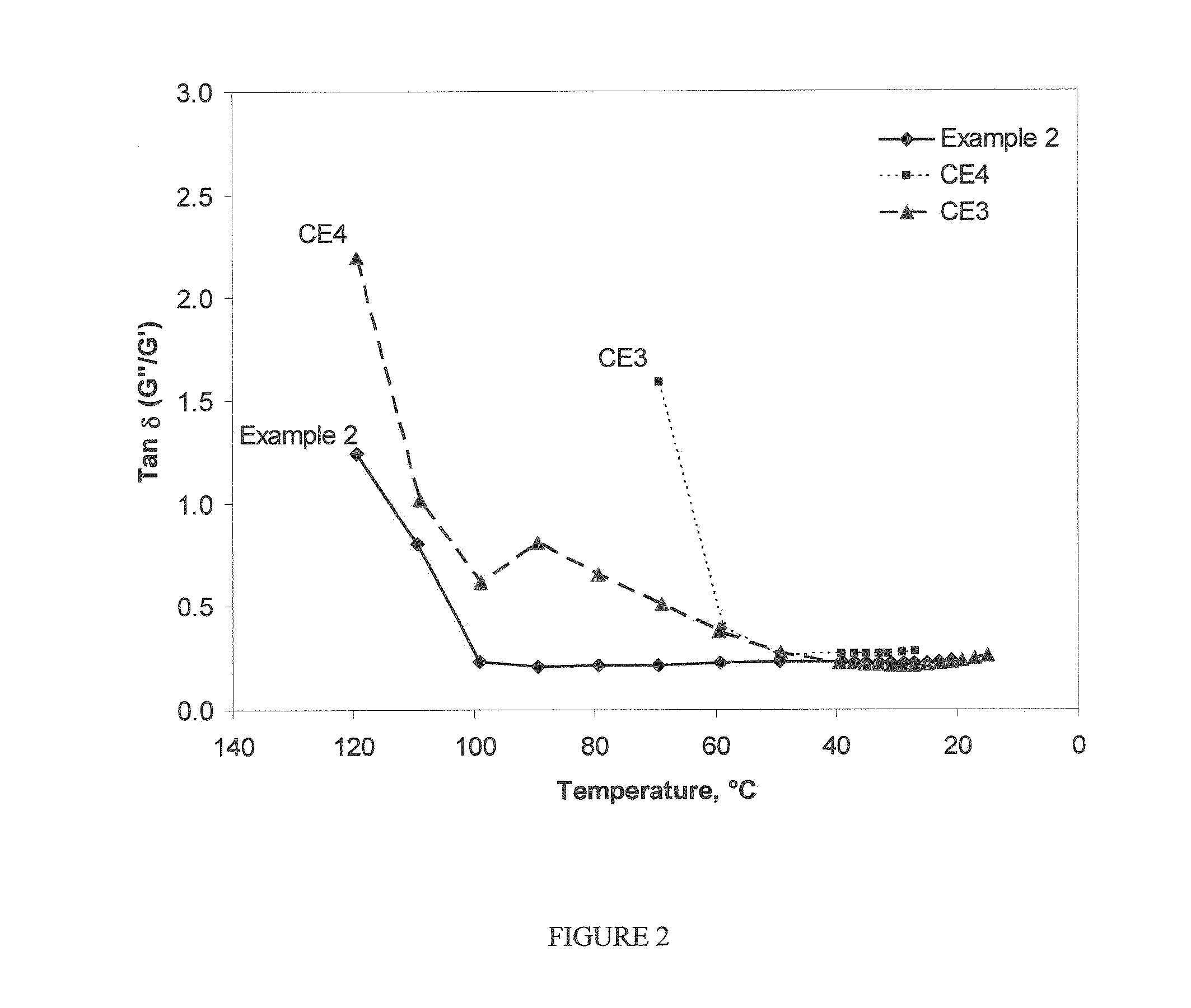

Polyolefin-Based Hot Melt Adhesives With Improved Properties

ActiveUS20150299526A1Fast set rateImproved balance of mechanical propertyAluminium compoundsNon-macromolecular adhesive additivesPolypropylenePolyolefin

Owner:BOSTIK INC

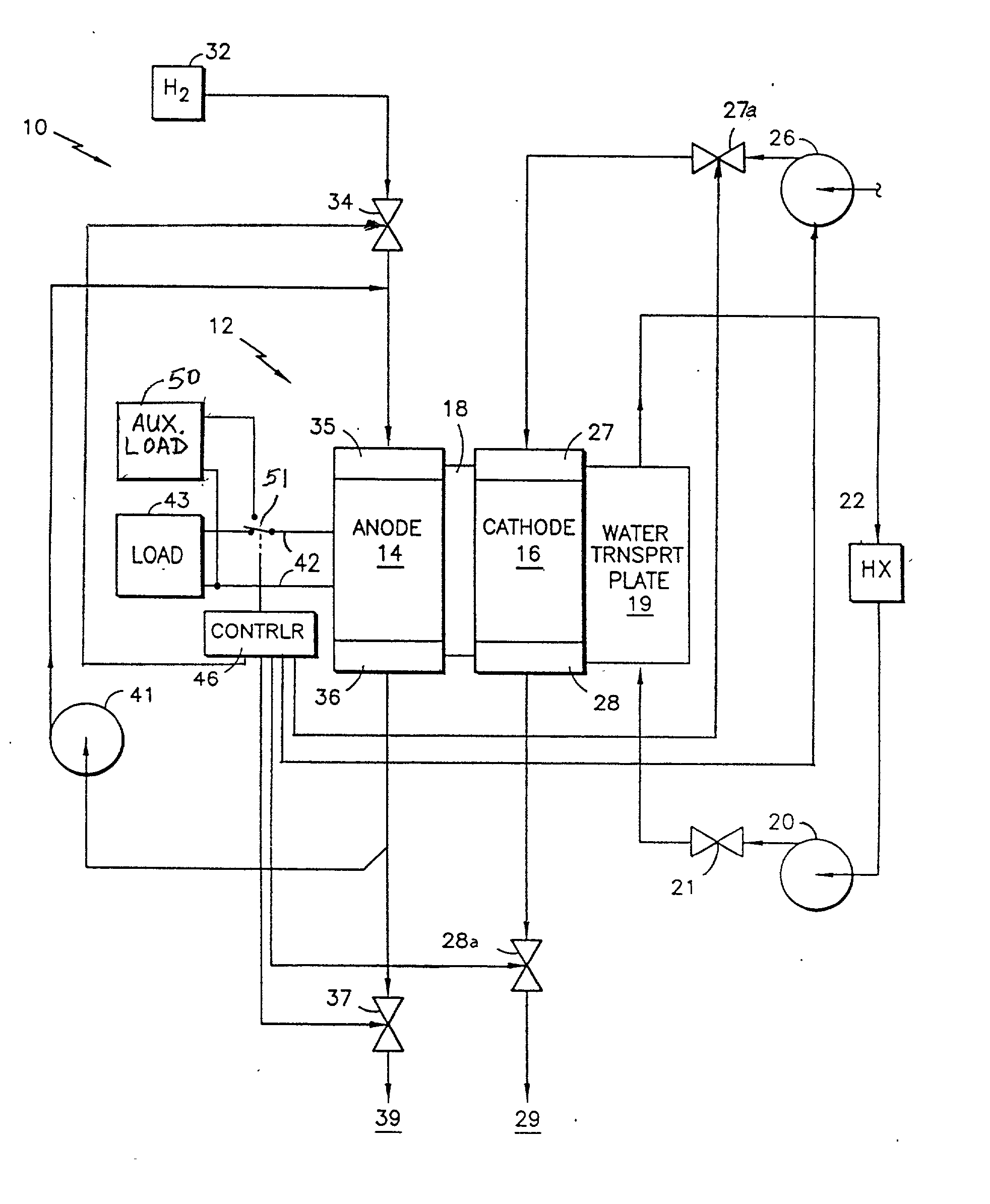

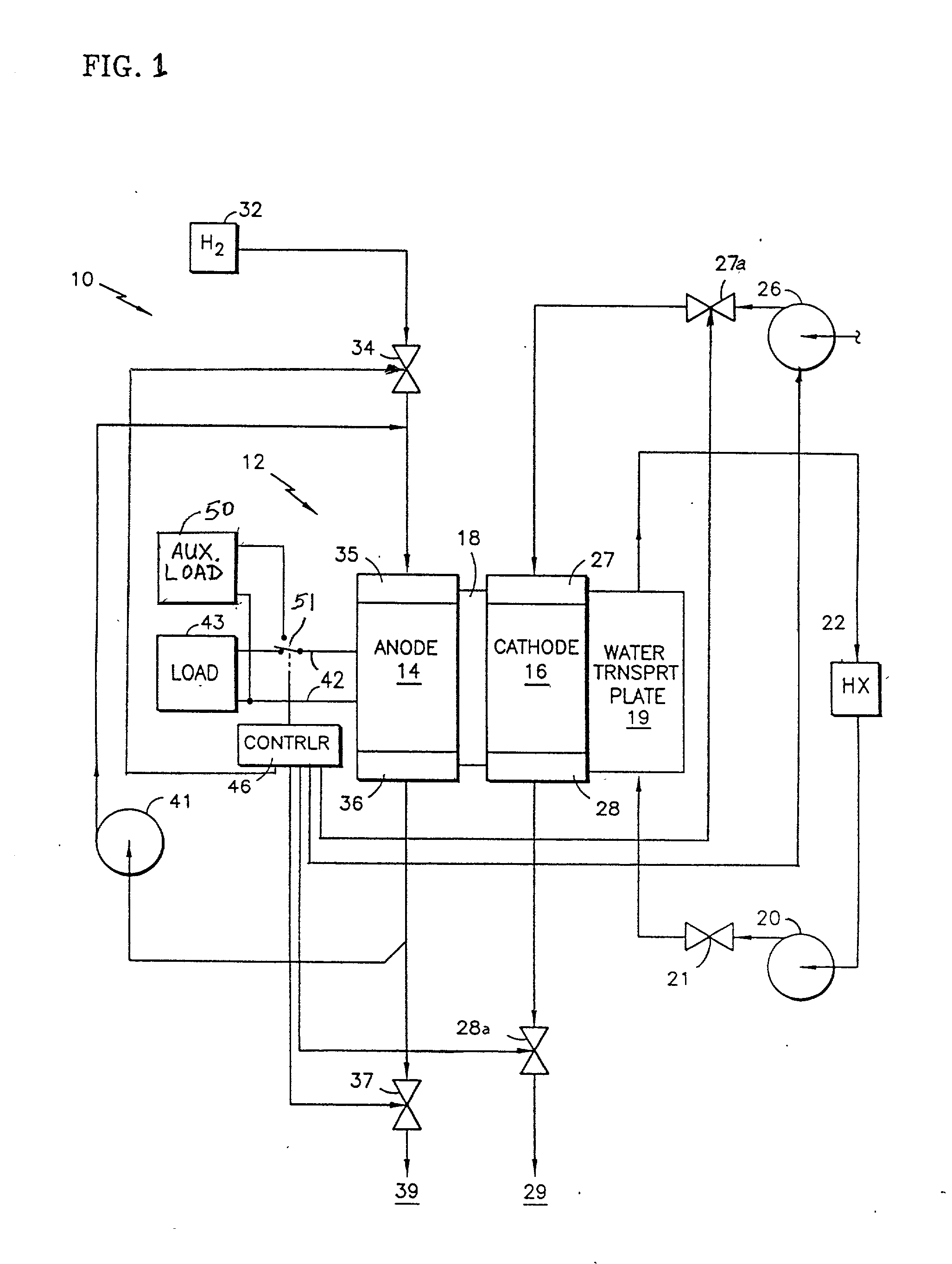

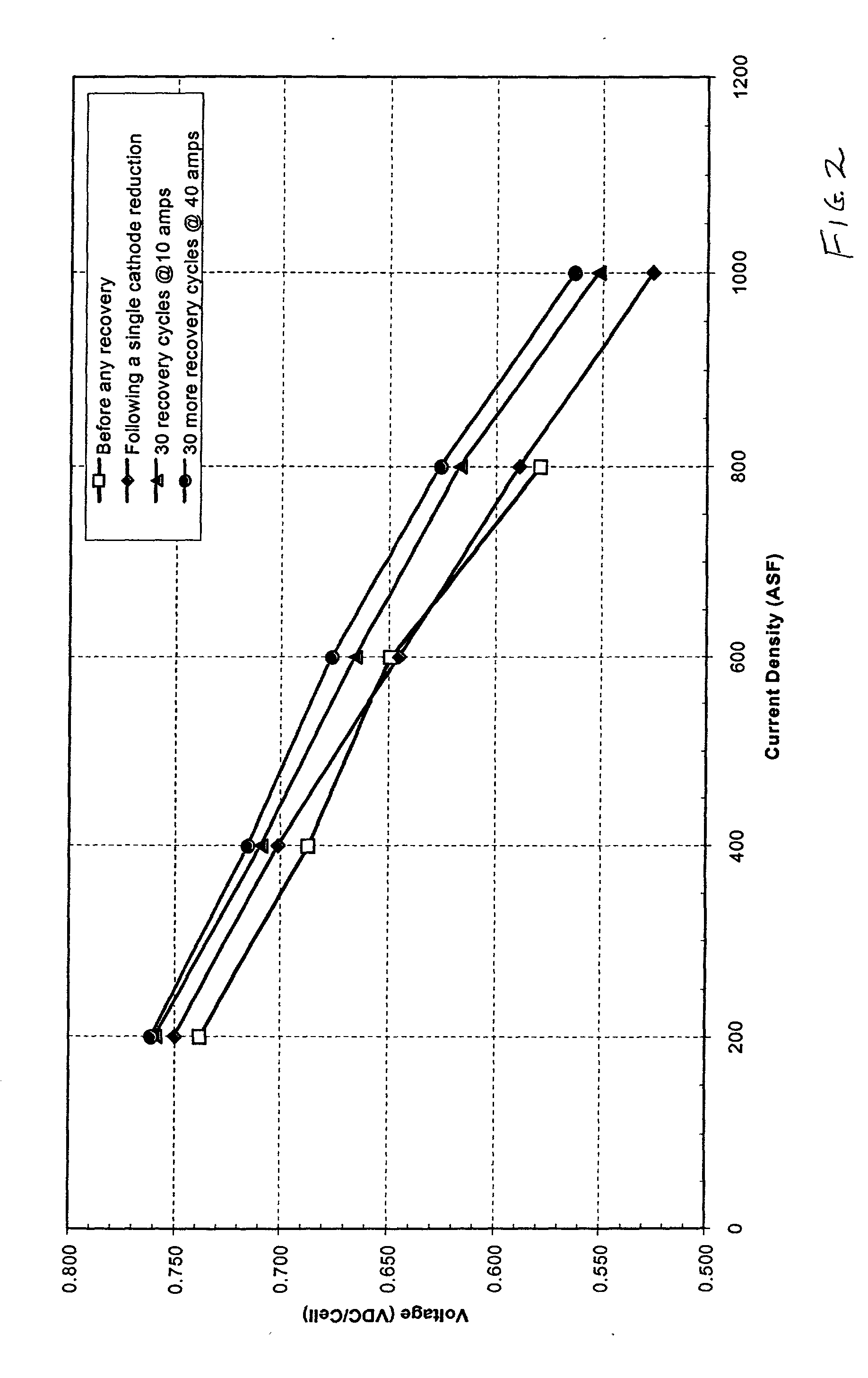

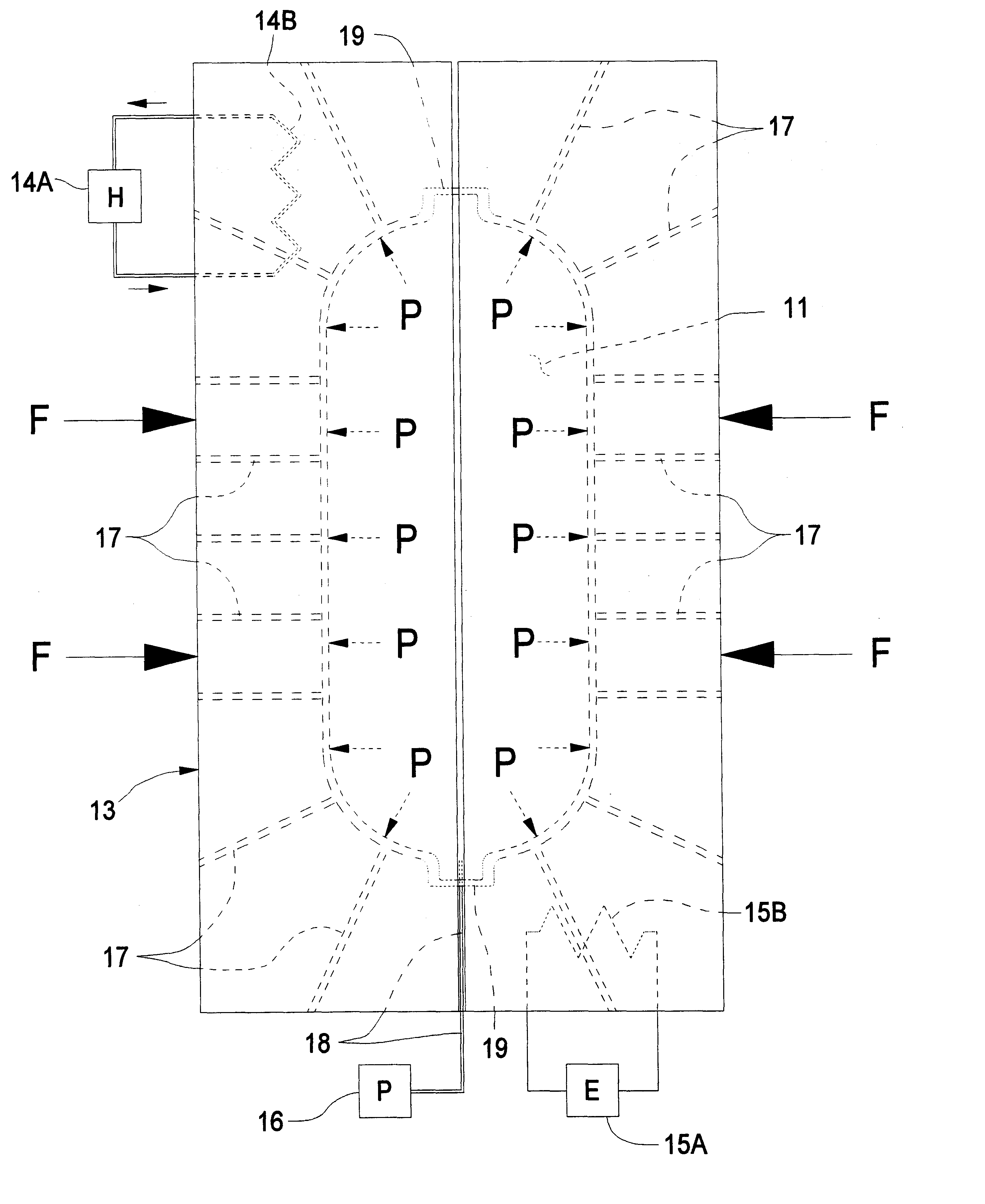

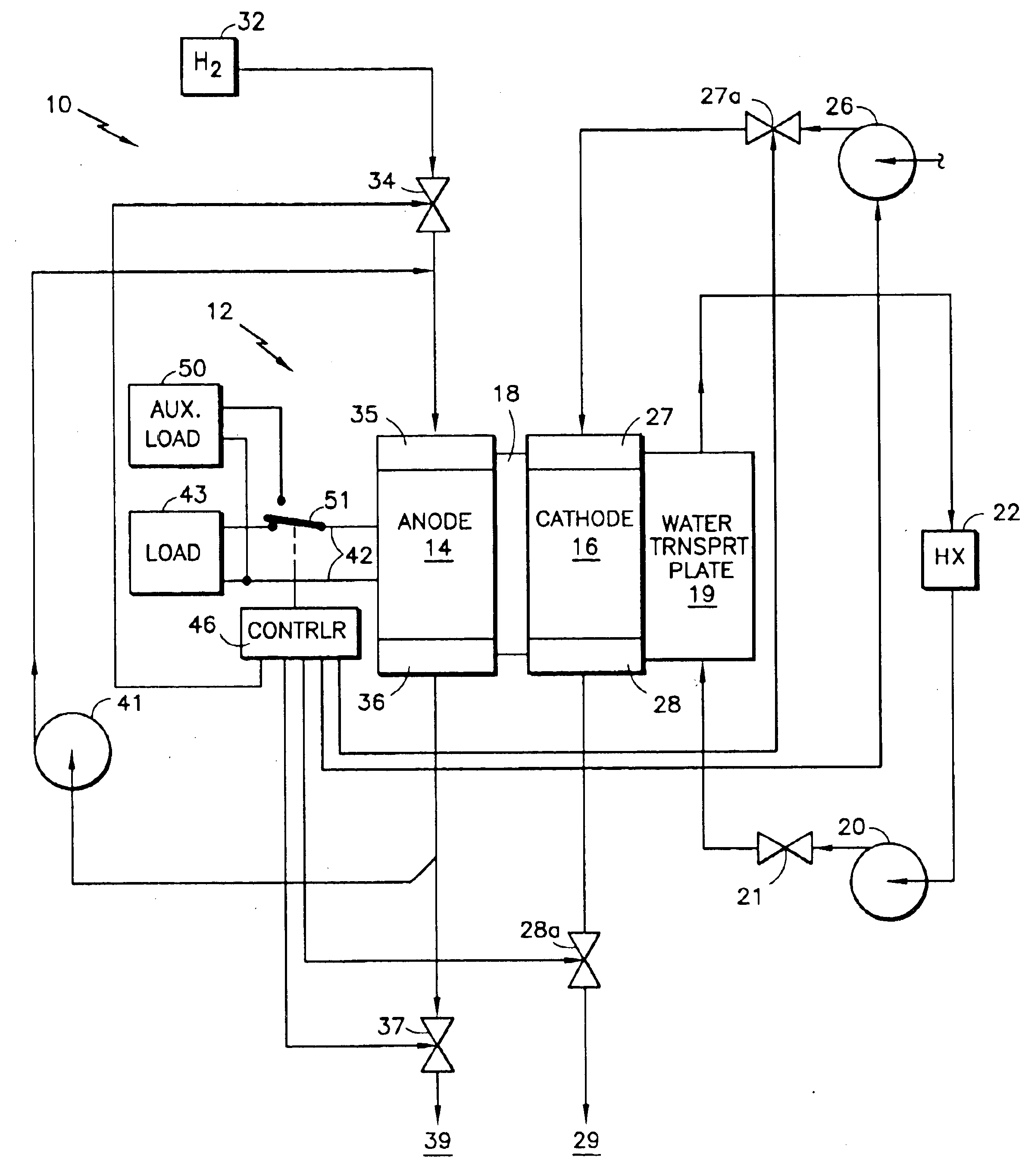

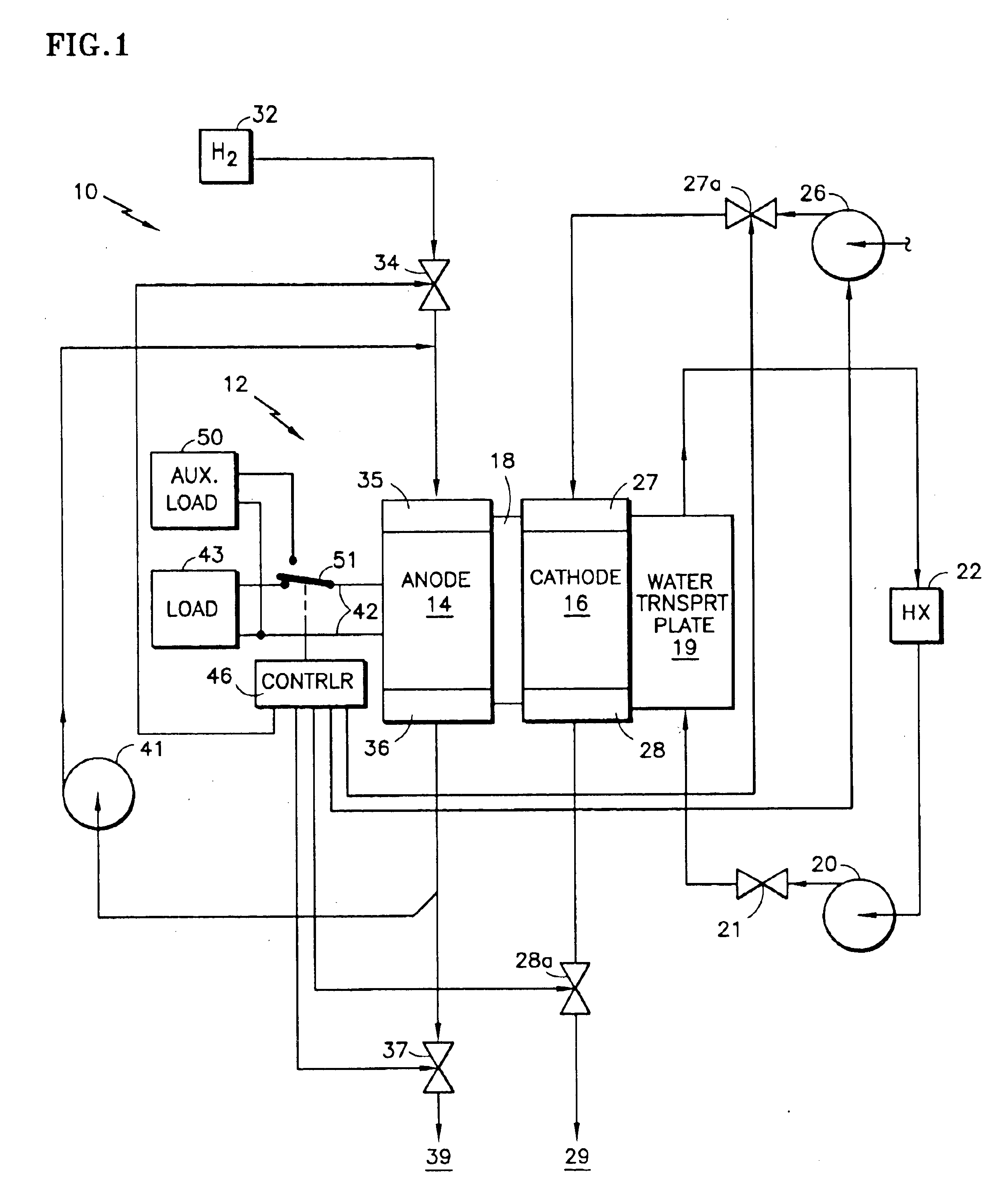

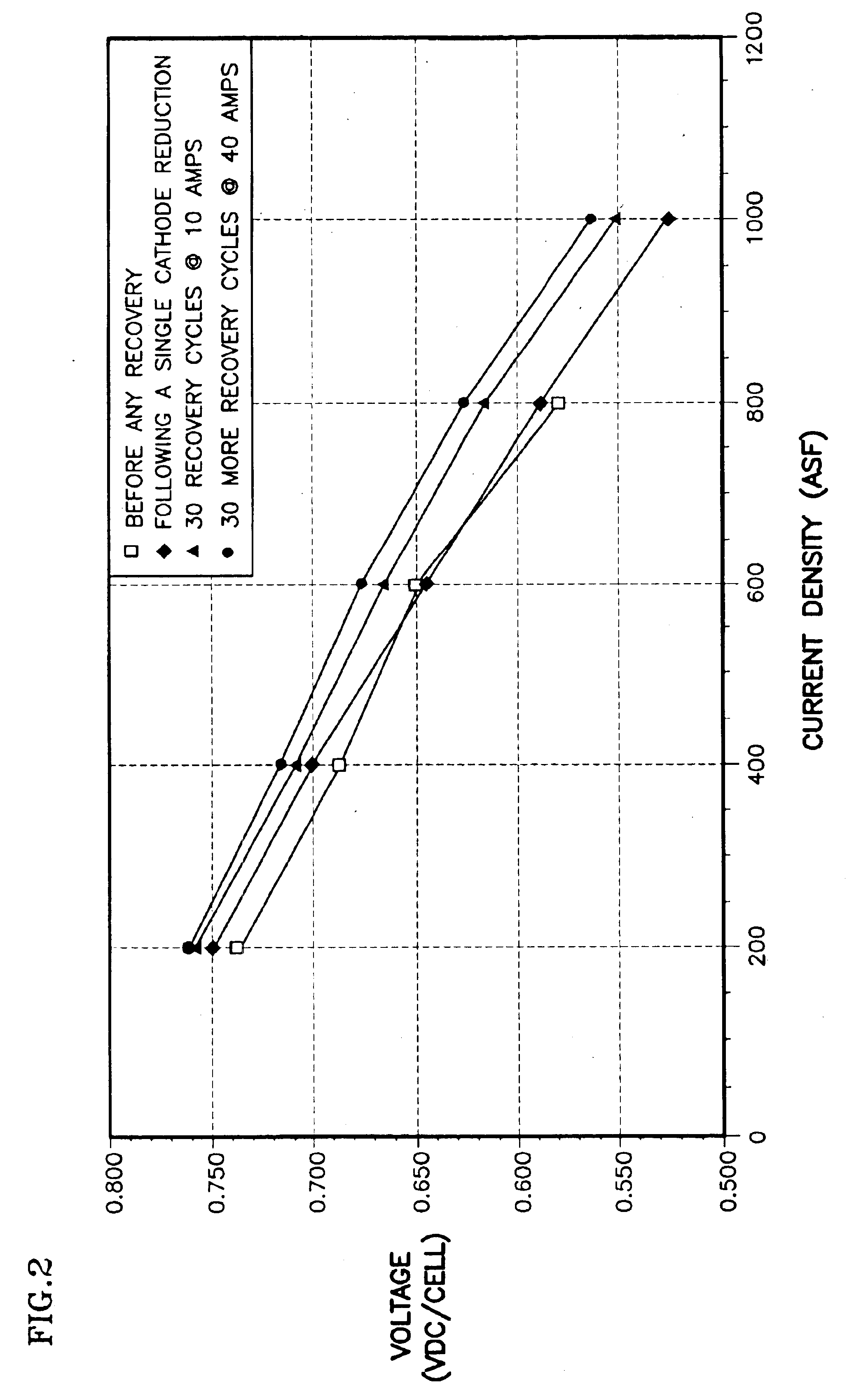

Fuel cell performance recovery by cyclic oxidant starvation

InactiveUS20030224228A1Improve regenerative abilityShorten the timeFuel cells groupingFuel cell auxillariesHydrogenFuel cells

Performance of a fuel cell stack (12) is recovered following long term decay by connecting (51) an auxiliary load (50) to the fuel cell while shutting off one or more of oxidant inlet valve (27a), oxidant pressure regulating valve (28a) or oxidant pump (26), which all may be achieved with a controller (46), to cyclically starve the cathode of oxidant so that it achieves hydrogen potential, e.g., less than 0.1 volts, for on the order of tens of seconds, repetitively, such as at every 10 or 20 seconds, while the auxiliary load remains connected, initially drawing 10 to 100 mASC, for example. Complete rejuvenation is obtained following 1800 or more cycles over a period of five or more hours.

Owner:AUDI AG

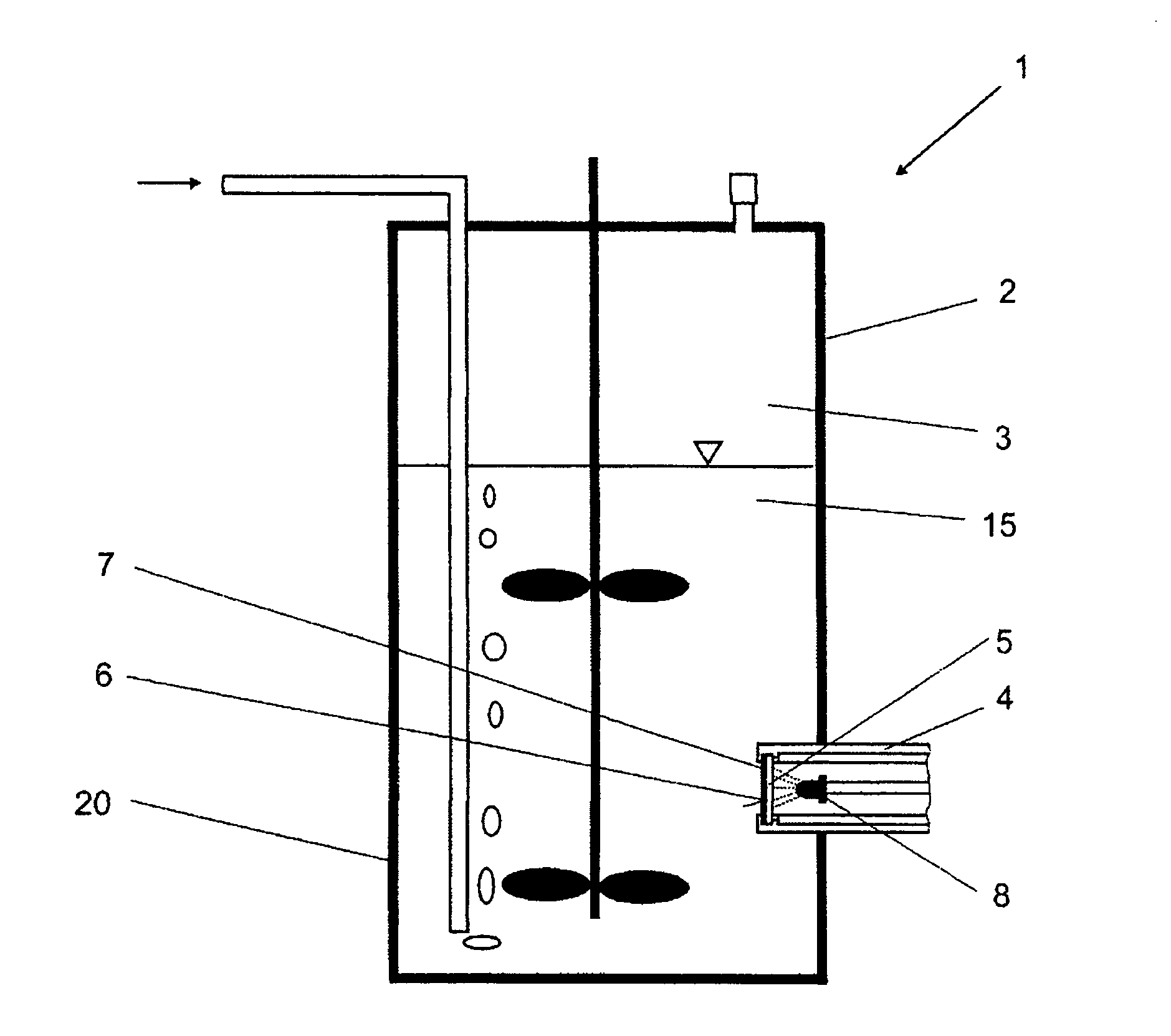

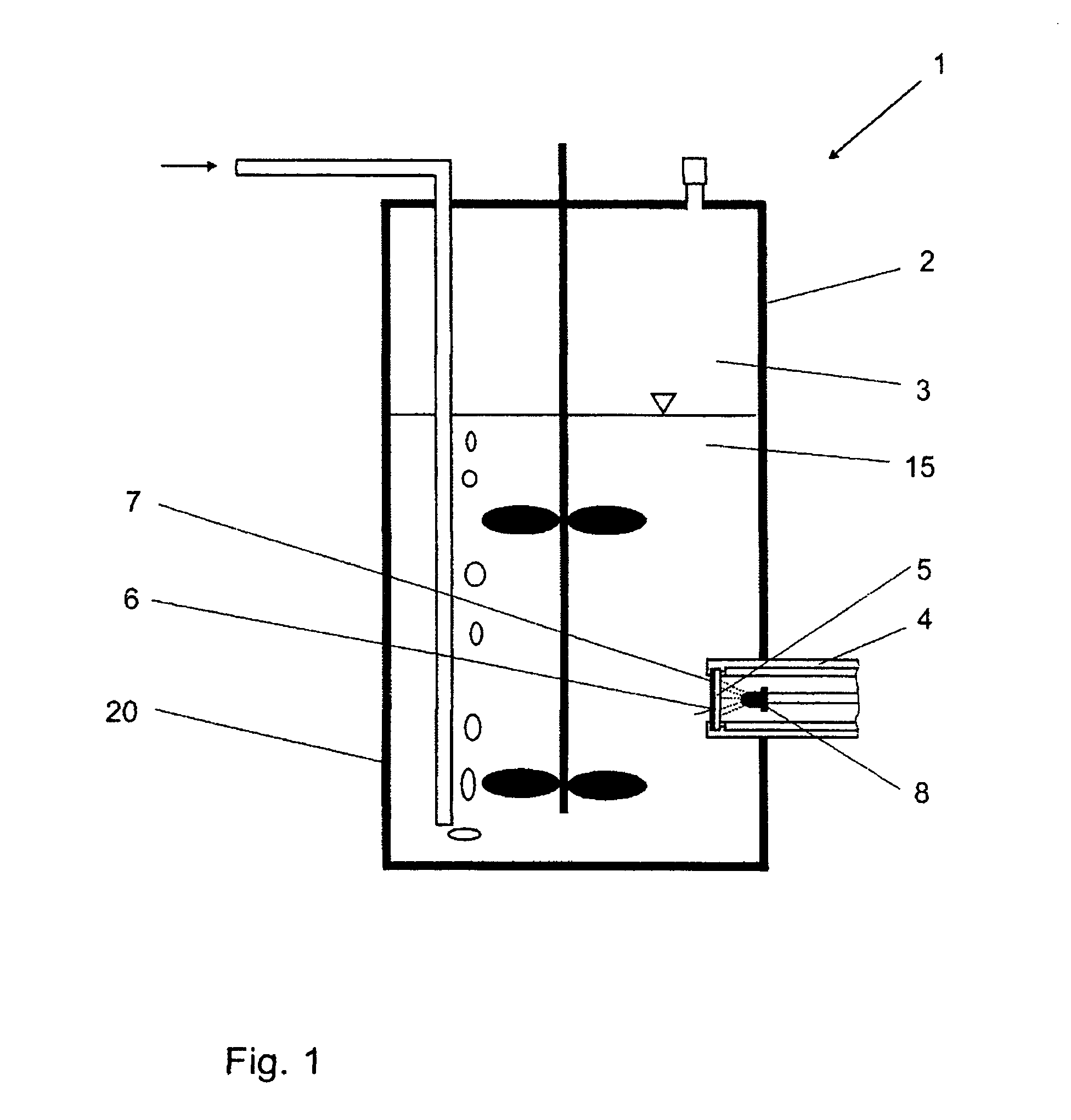

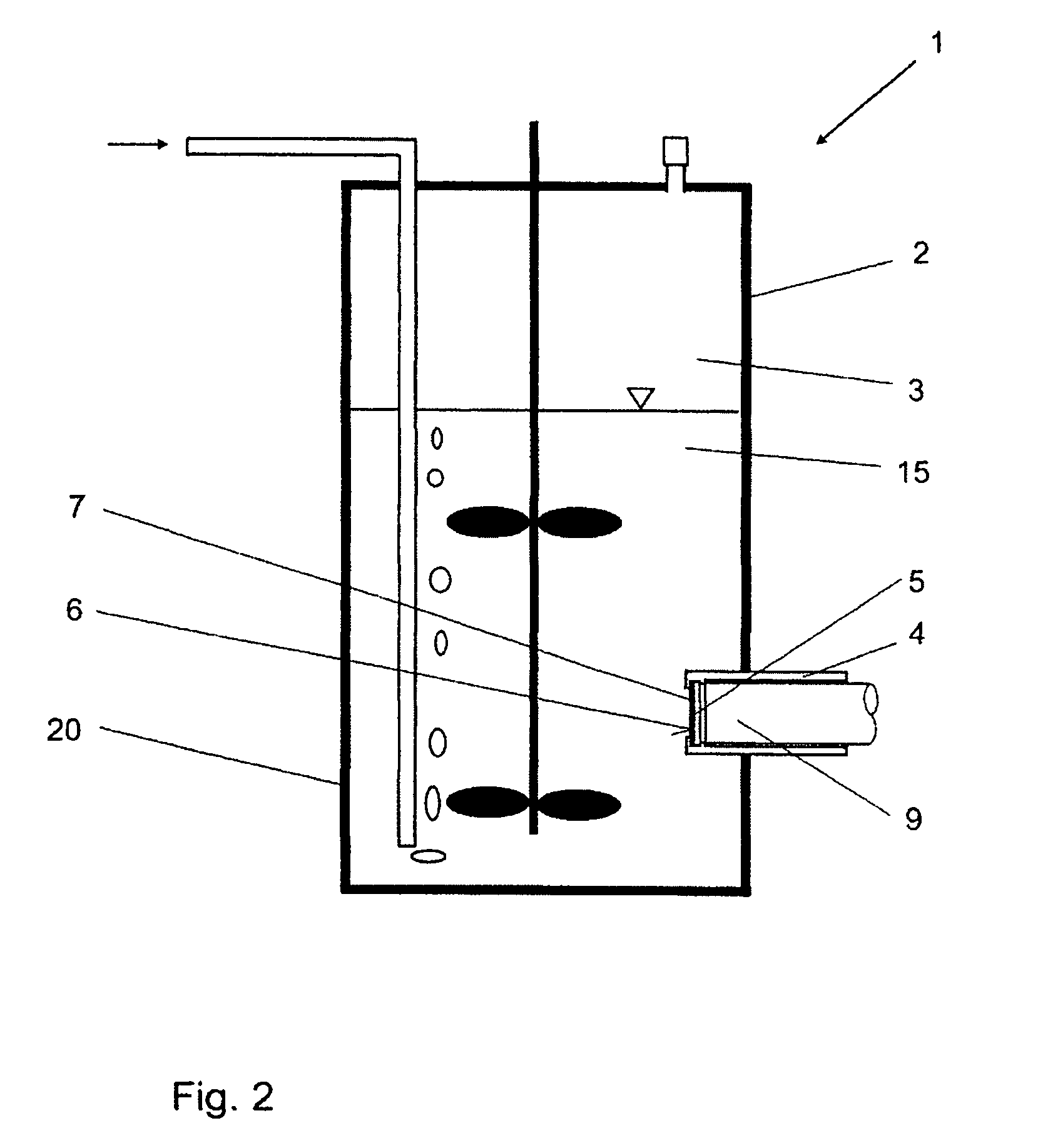

Bioreactor with window

InactiveUS20100035337A1Convenient lightingSave spaceBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBioreactor

Bioreactor having at least one transparent window (5, 12, 13), the inner side (6) of which can be touched by a medium that can be arranged in a reactor interior (3), wherein the window (5, 12, 13) has a photocatalytic coating (7) on its inner side (6) facing the reactor interior (3), which coating can be activated by at least one light source from the outer side remote from the inner side (6).

Owner:SARTORIUS STEDIM BIOTECH GMBH

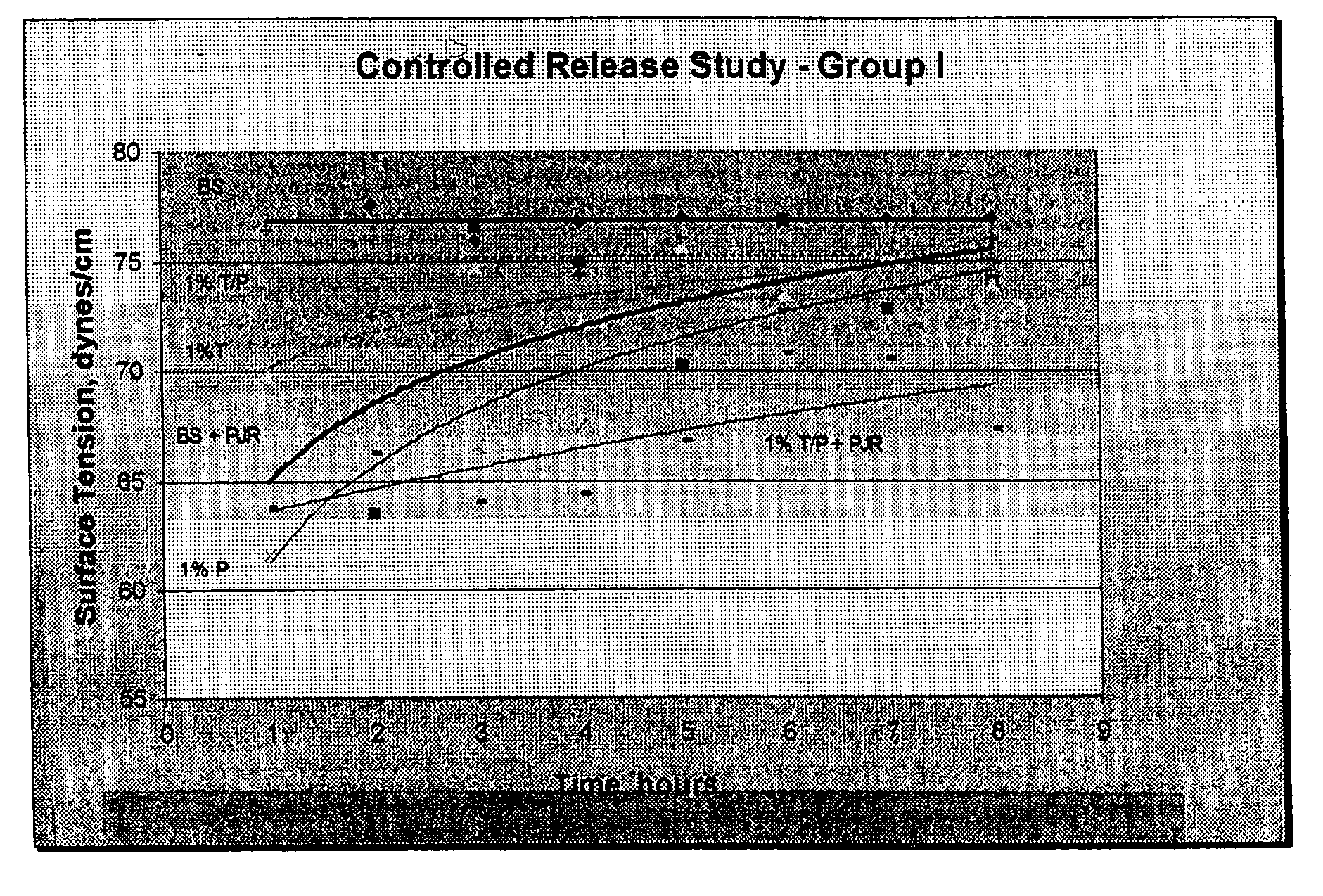

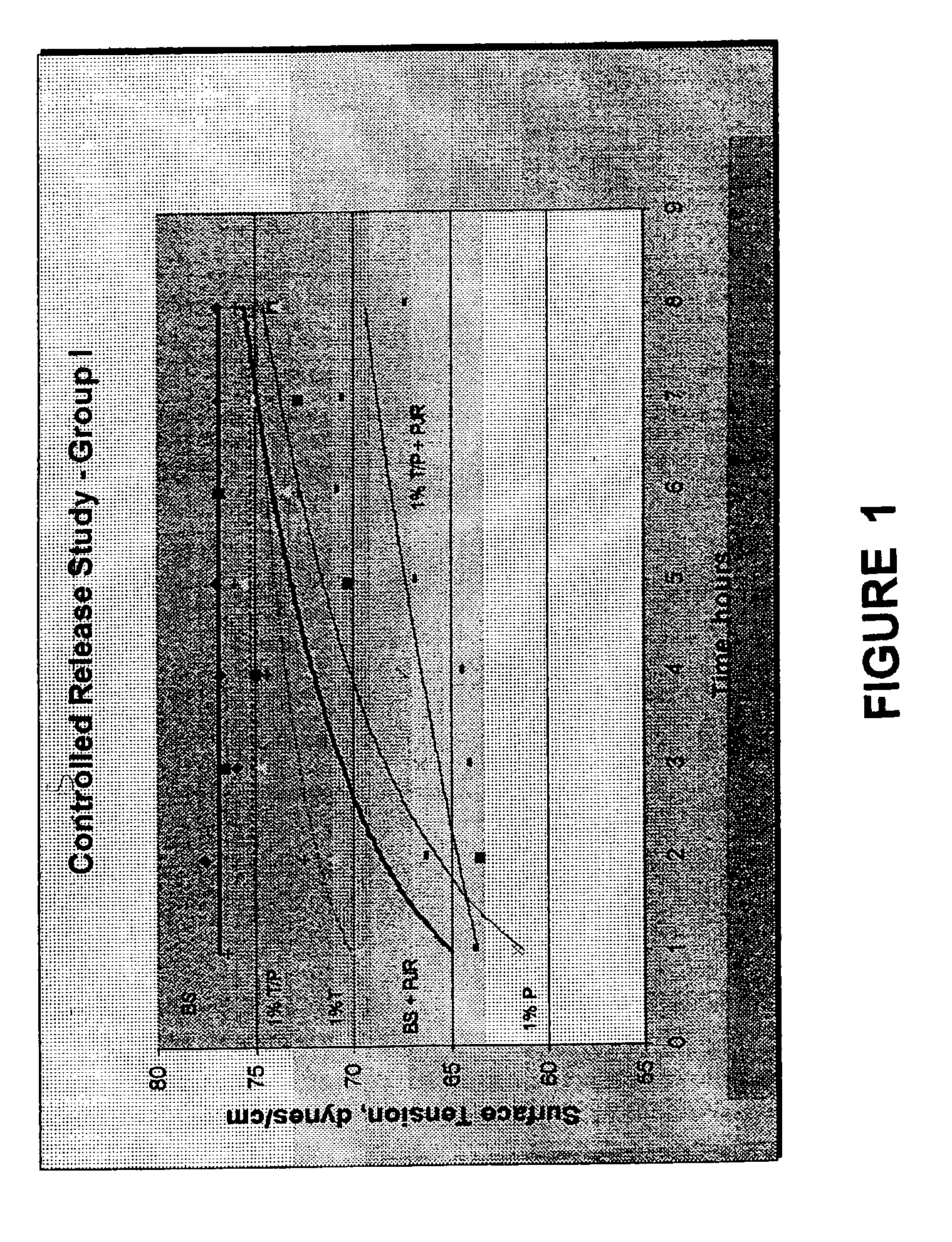

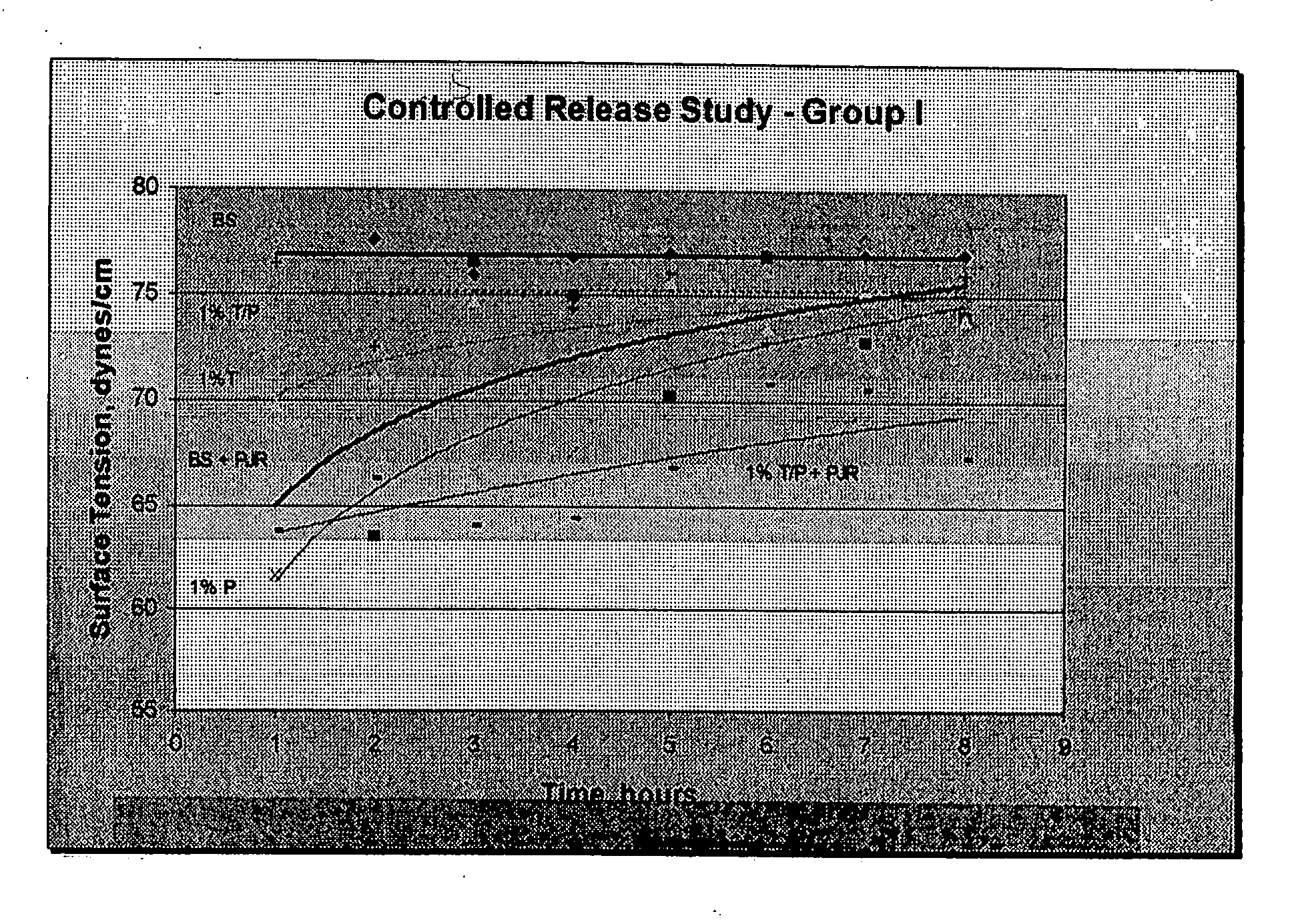

Method and composition for reducing contact lens swelling

InactiveUS7037469B2Preserve visual acuityLonger lasting wetting performanceSenses disorderCationic surface-active compoundsHigh concentrationControlled release

The present invention is directed to an ophthalmic solution for soft contact lenses for controlled release of polyethers into an eye's tear film. Polyether components of the subject solution are released from the soft contact lens material matrix over long time periods to produce longer lasting wetting performance, improved lubricity, improved end-of-the-day comfort and reduced feeling of dryness from wearing contact lenses. The present invention also includes the use of cationic polyelectrolytes for controlling the swelling of hydrogel contact lenses typically caused by the absorption of high concentrations of polyethers.

Owner:BAUSCH & LOMB INC

Nonaqueous electrolyte solution and lithium secondary battery using same

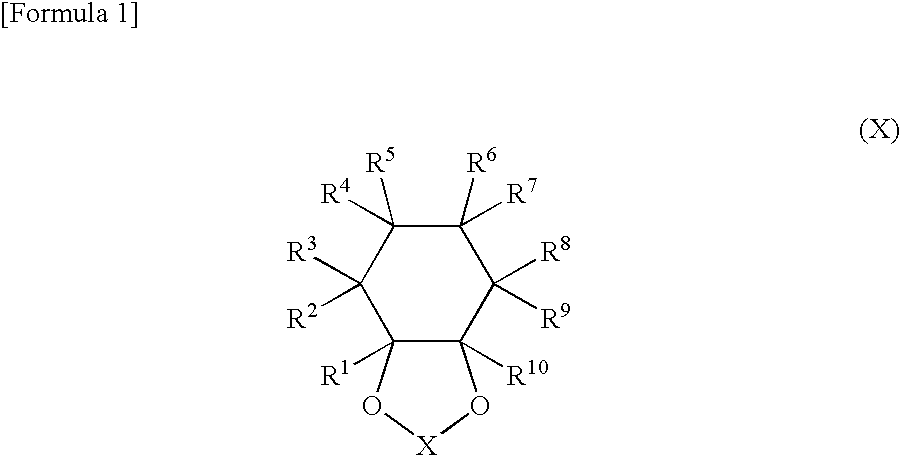

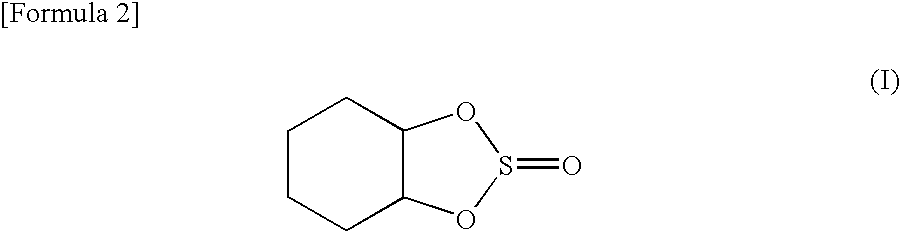

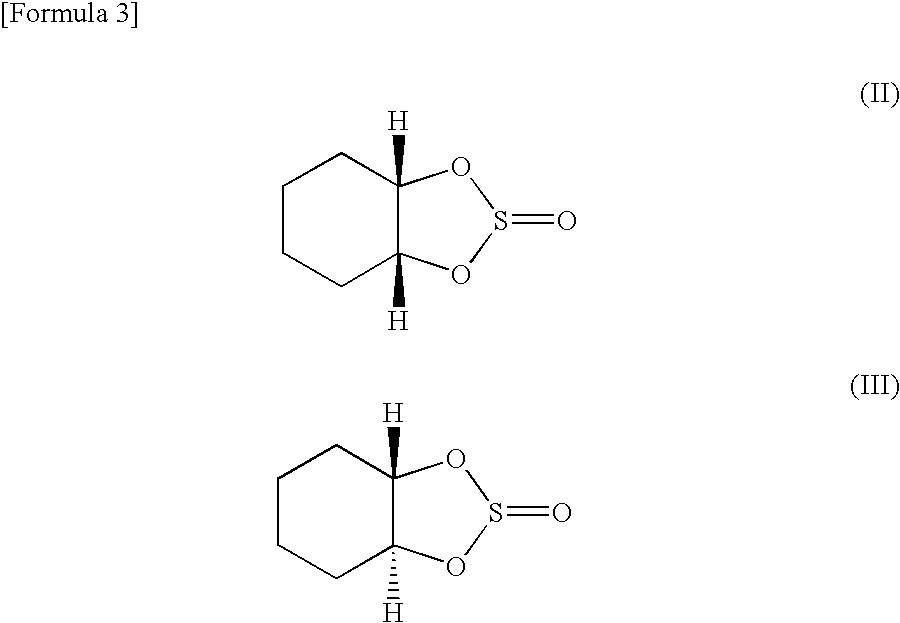

InactiveUS20090170006A1Improve featuresBattery performanceElectrolytic capacitorsFinal product manufactureLithiumPhysical chemistry

The present invention provides a nonaqueous electrolytic solution in which an electrolyte salt is dissolved in a nonaqueous solvent, containing 0.01% to 30% by weight of a 1,2-cyclohexanediol derivative having a specific structure; and a lithium secondary battery using the nonaqueous electrolytic solution. The lithium secondary battery exhibits excellent battery characteristics such as electrical capacity, cycle property, and storage property and can maintain excellent long-term battery performance.

Owner:UBE IND LTD

Vacuum heat insulation material and cold reserving apparatus with the same

ActiveUS20070196665A1Insulation performanceExcellent pinhole resistanceThermal insulationSynthetic resin layered productsForeign matterMetal foil

A vacuum heat insulation material has a covering material which is a lamination body including a sealant layer, a metal foil layer, a first plastic film layer, and a second plastic film layer which are laminated in this order from inside to outside via adhesive layers. When a foreign body is pierced into the vacuum heat insulation material, the propagation of breakage caused by the piercing is blocked somewhere inside the lamination body, thereby preventing the formation of through-pinholes. This results in the provision of a high-quality vacuum heat insulation material with excellent long-term insulation performance by using a covering material excellent in gas barrier properties and pinhole resistance to the piercing of minute foreign bodies.

Owner:PANASONIC CORP

Hydrothermal performance of catalyst supports

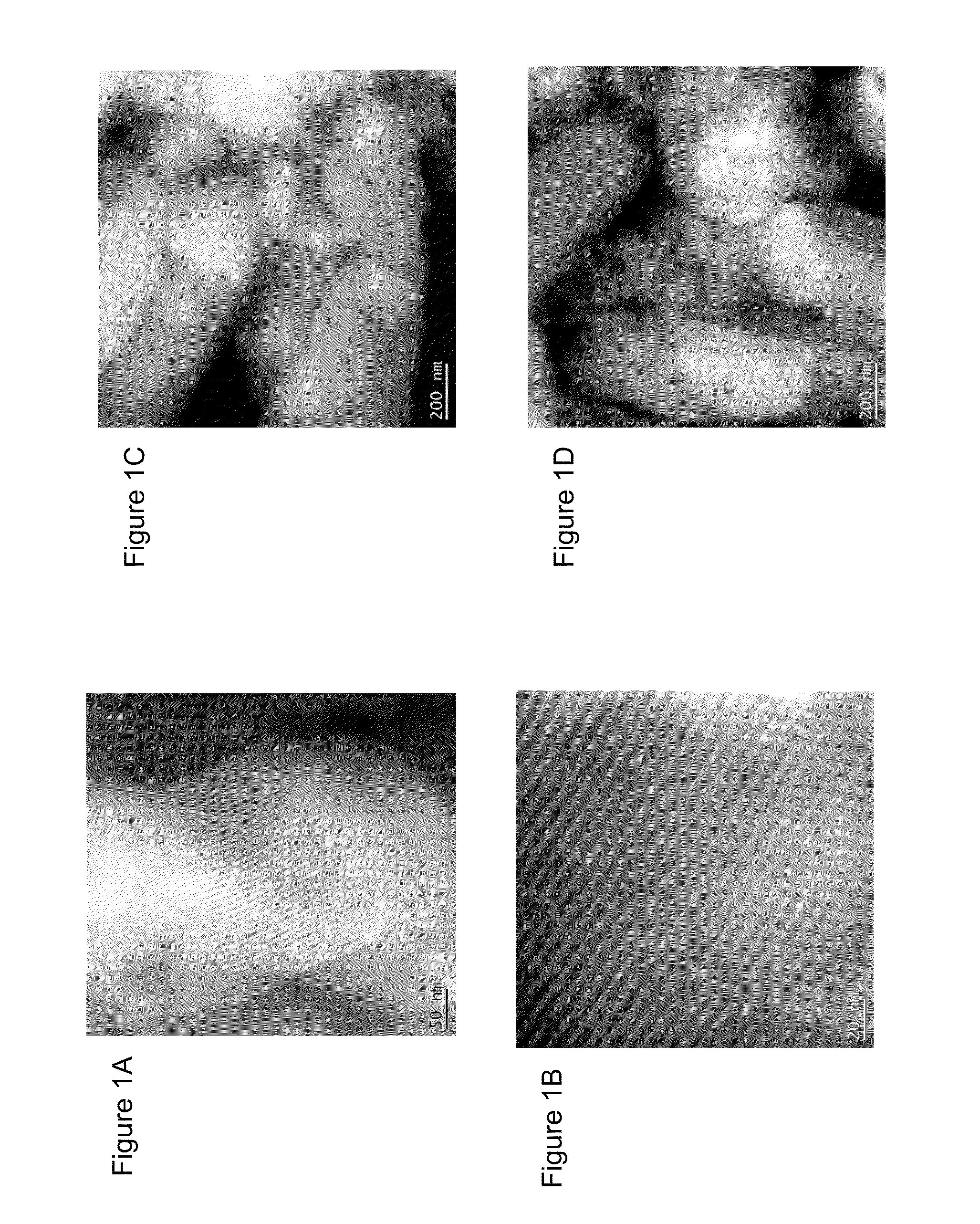

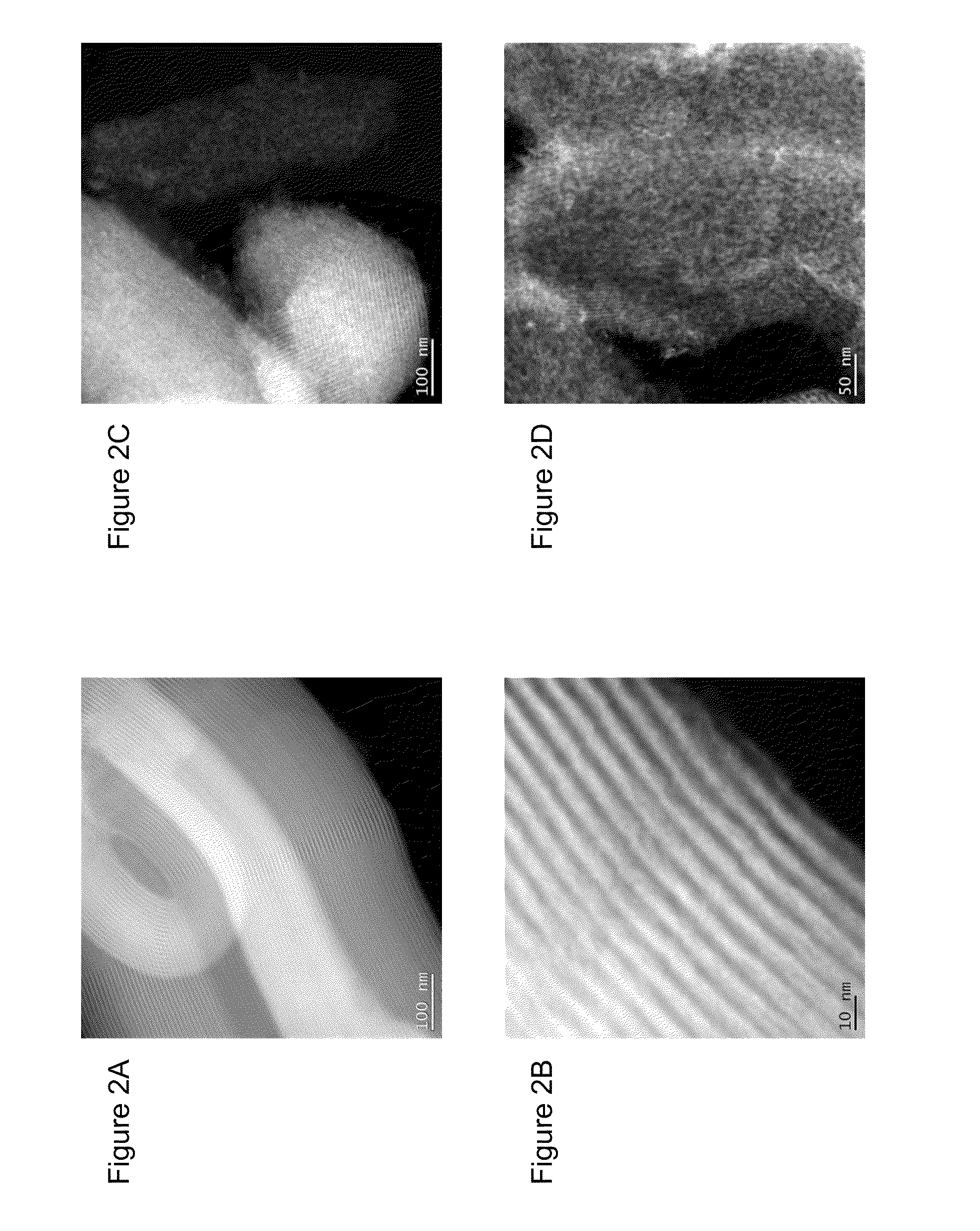

ActiveUS20120021898A1Improved long-term catalytic performanceImprove structural performanceMolecular sieve catalystsCatalyst activation/preparationPtru catalystMesoporous silica

A high surface area catalyst with a mesoporous support structure and a thin conformal coating over the surface of the support structure. The high surface area catalyst support is adapted for carrying out a reaction in a reaction environment where the thin conformal coating protects the support structure within the reaction environment. In various embodiments, the support structure is a mesoporous silica catalytic support and the thin conformal coating comprises a layer of metal oxide resistant to the reaction environment which may be a hydrothermal environment.

Owner:UCHICAGO ARGONNE LLC +1

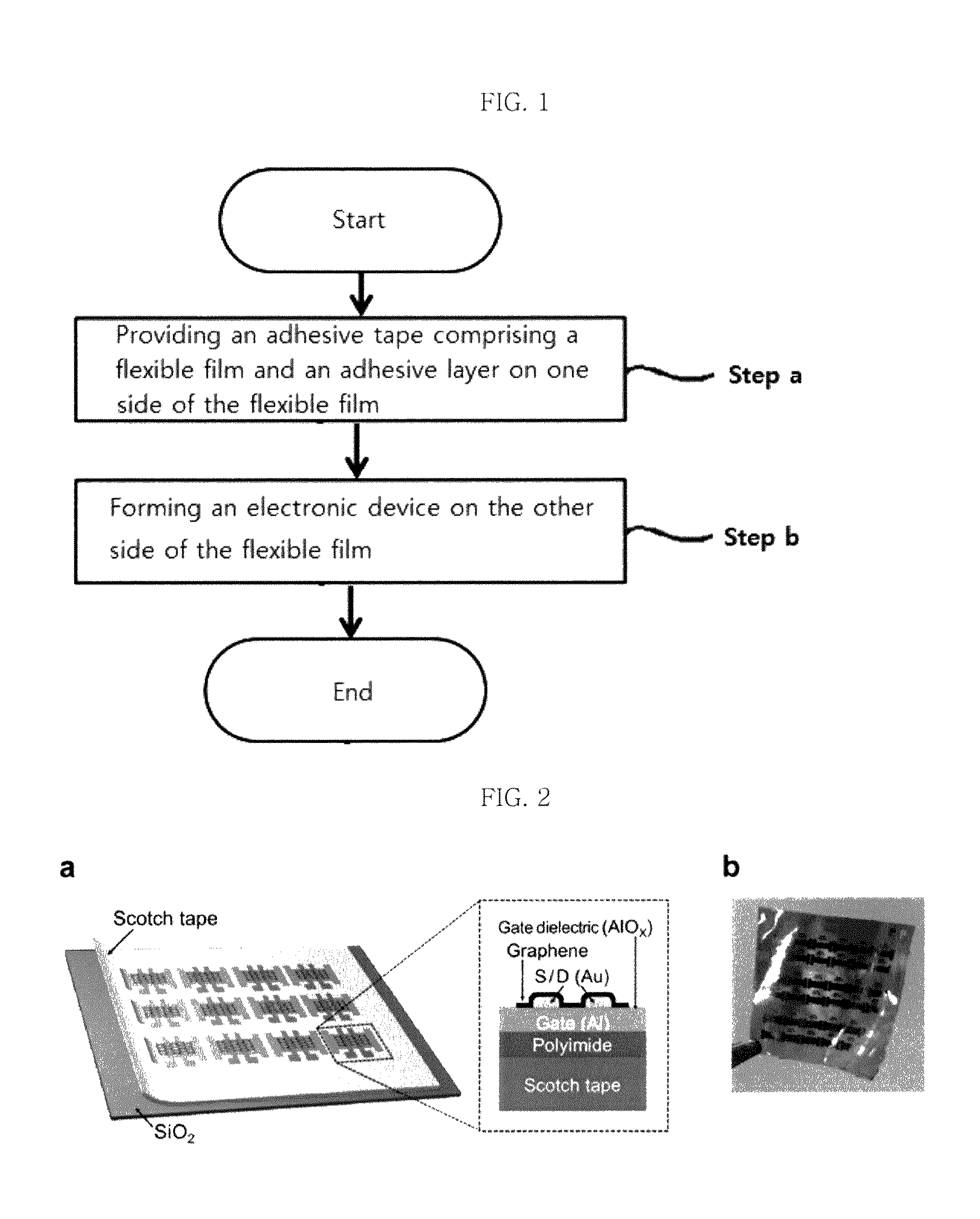

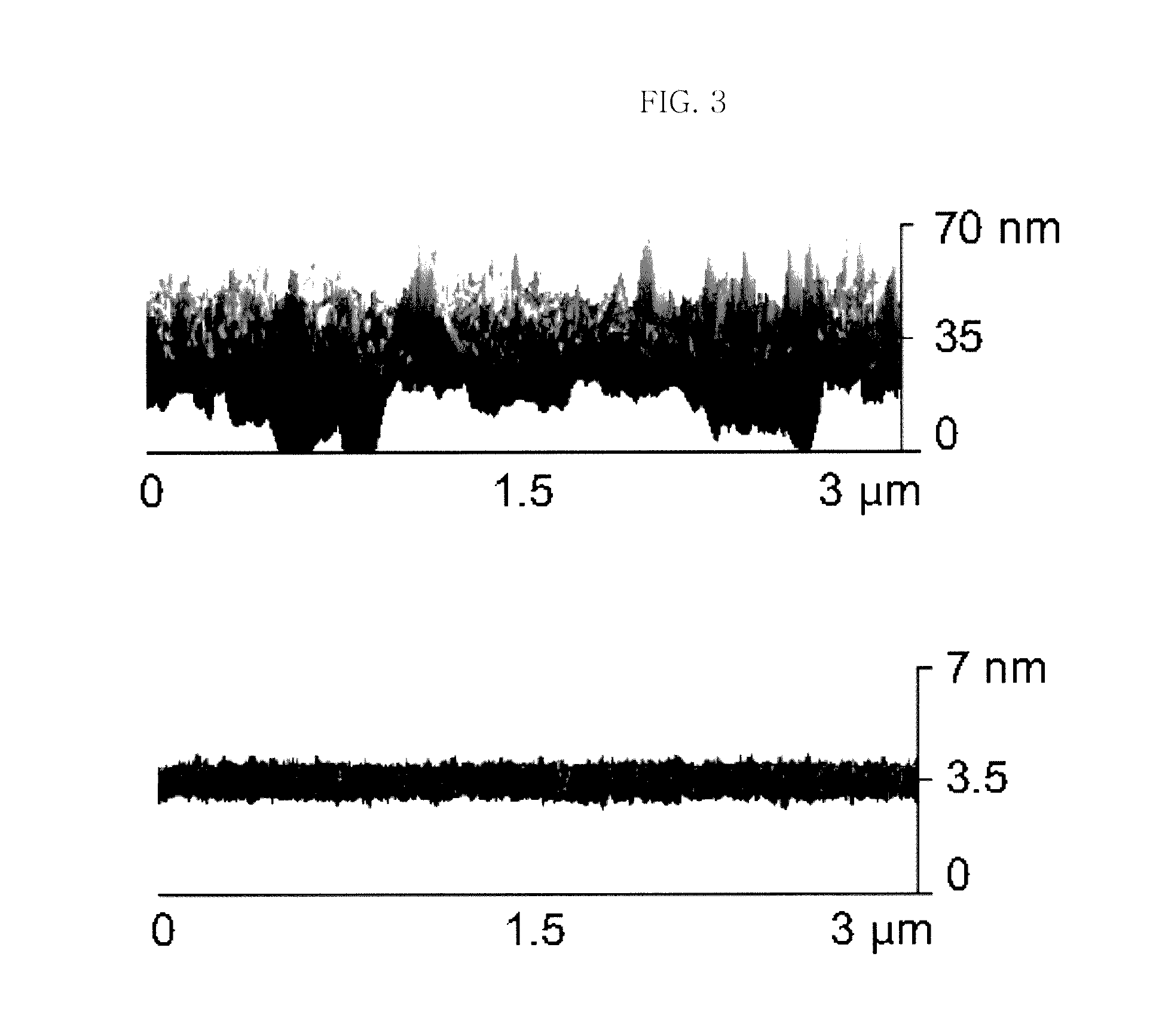

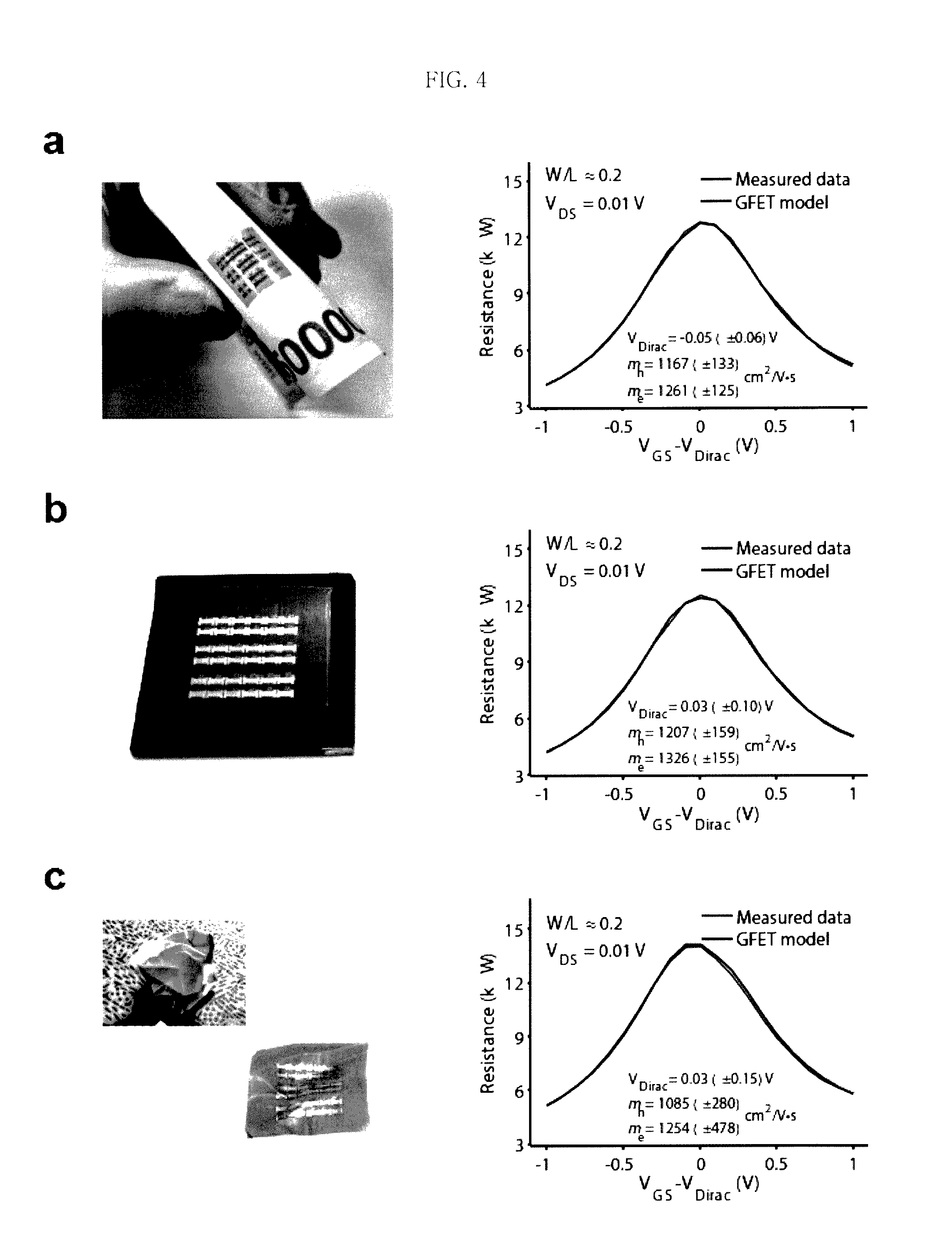

Flexible electronic device having adhesive function and method for manufacturing same

ActiveUS20170025547A1Maintain performanceMinimize breakageTransistorFinal product manufactureDevice formEngineering

Disclosed is a flexible electronic device having an adhesive function, including an adhesive tape that includes a flexible film and an adhesive layer formed on one side of the flexible film, and an electronic device formed on a remaining side of the flexible film of the adhesive tape. Accordingly, the flexible electronic device of the present invention is transferred on a surface of various flexible materials or materials having a curved surface so as to freely adhere and minimize breakage of the electronic device and maintain performance over a long period of time, even if the substrate is modified or repeatedly bent.

Owner:CENT FOR ADVANCED SOFT ELECTRONICS +1

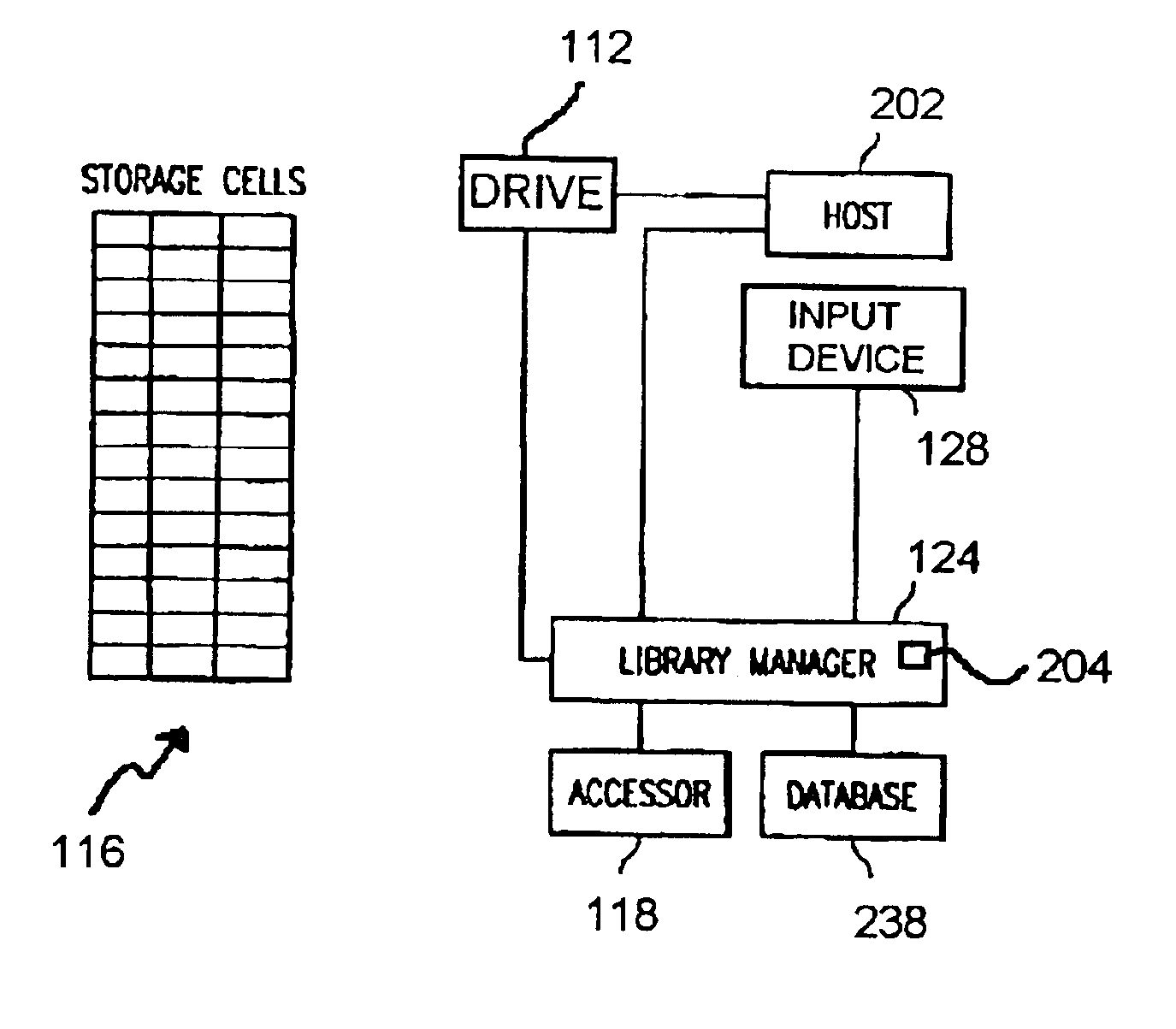

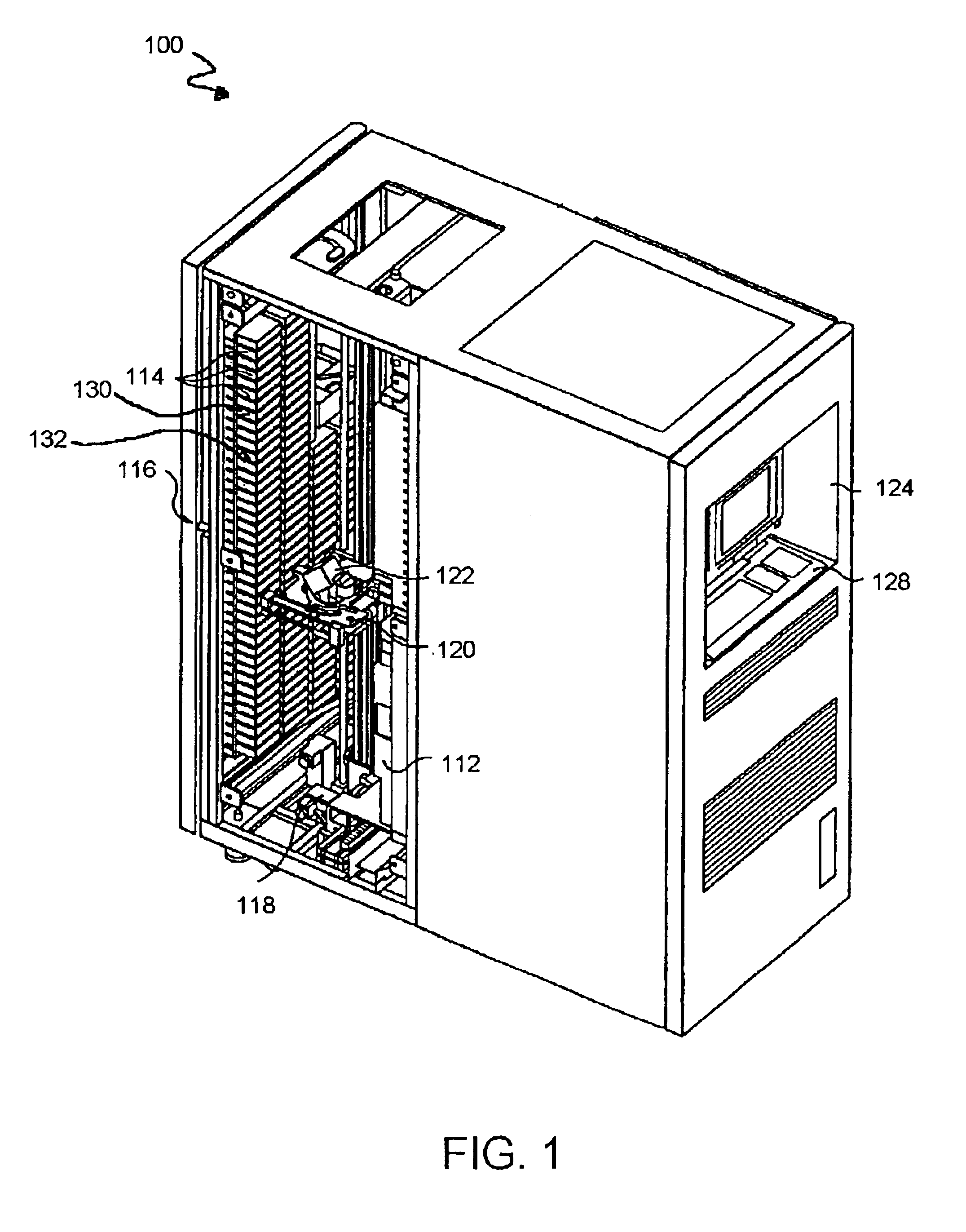

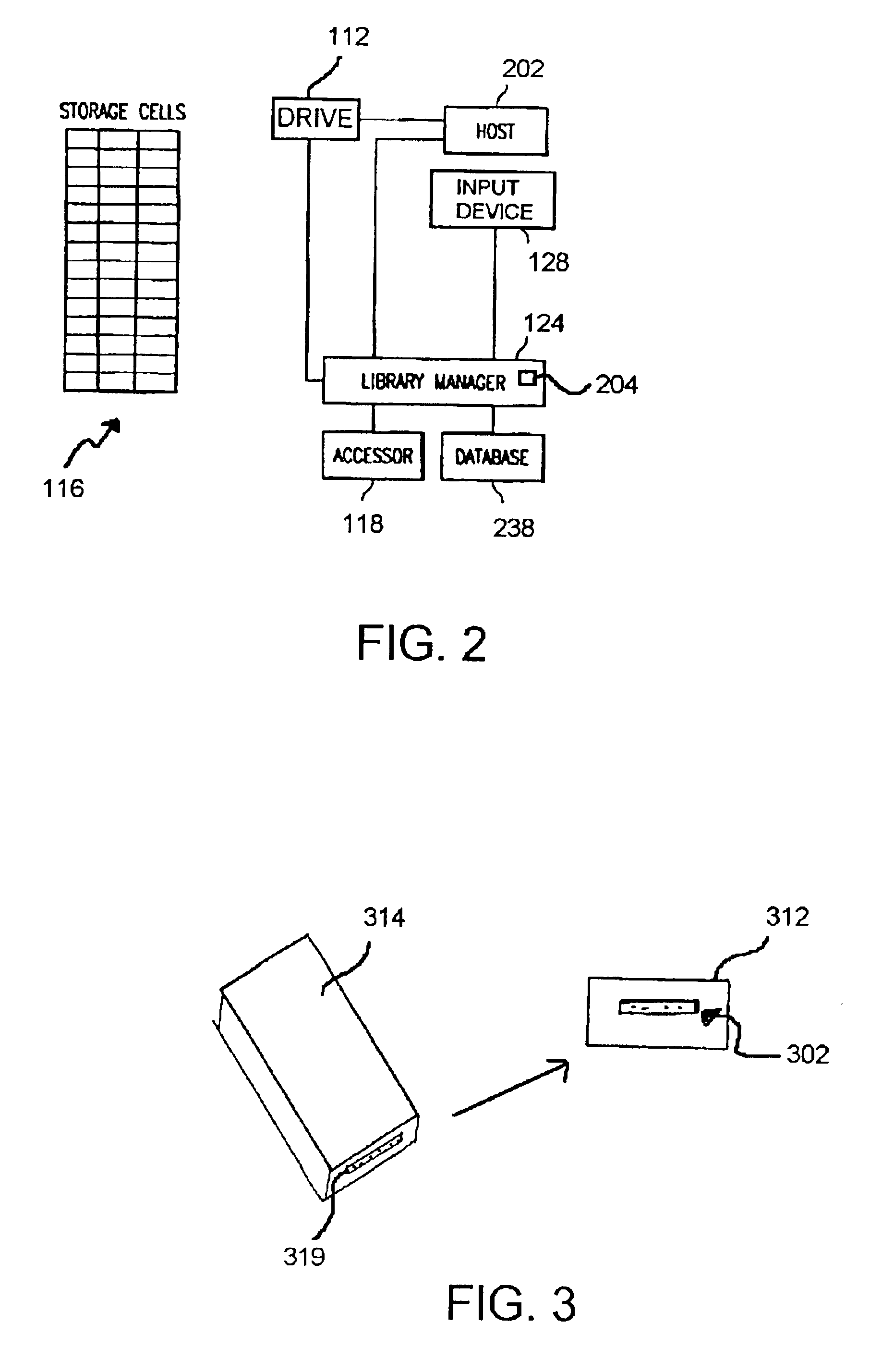

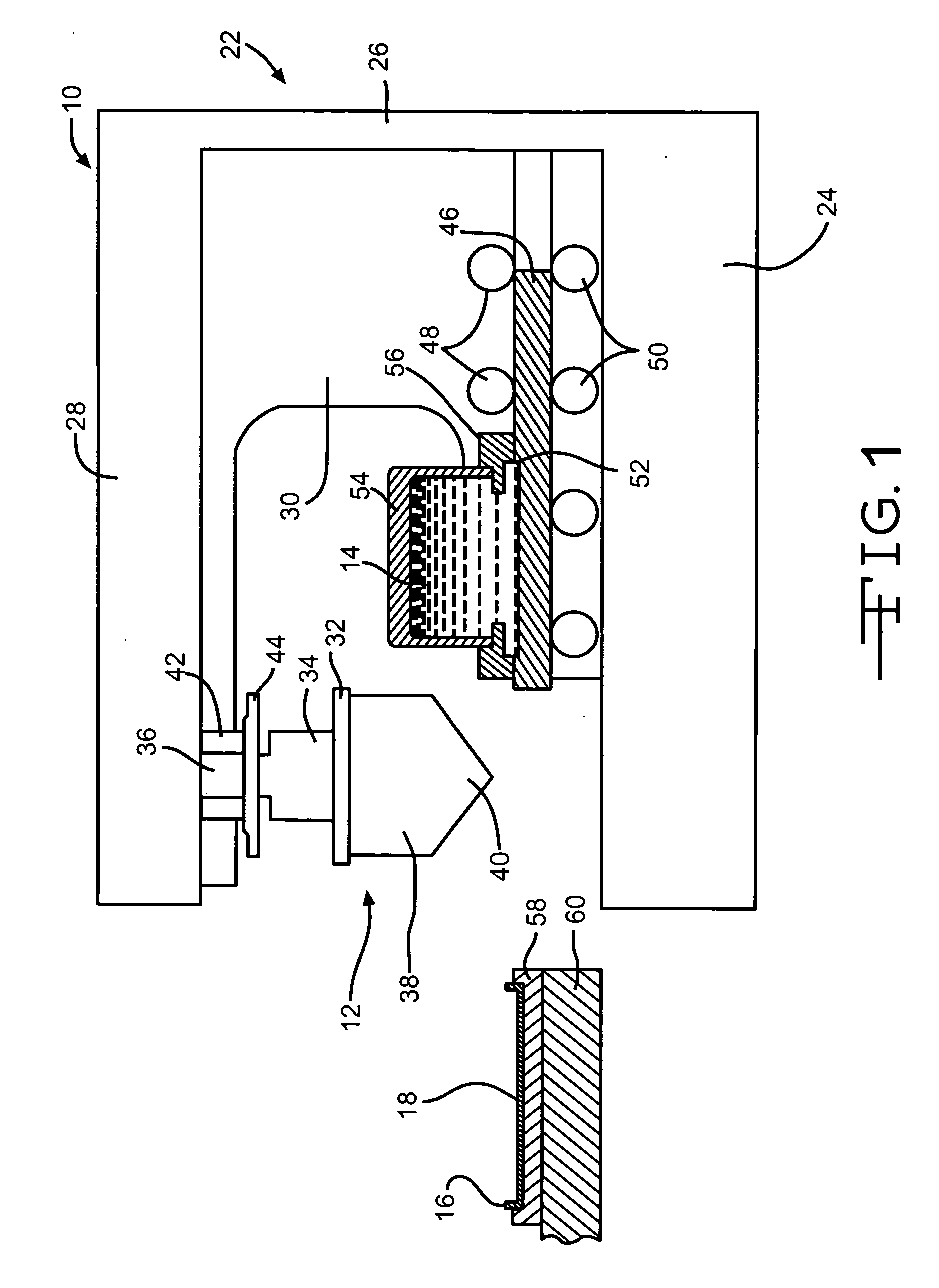

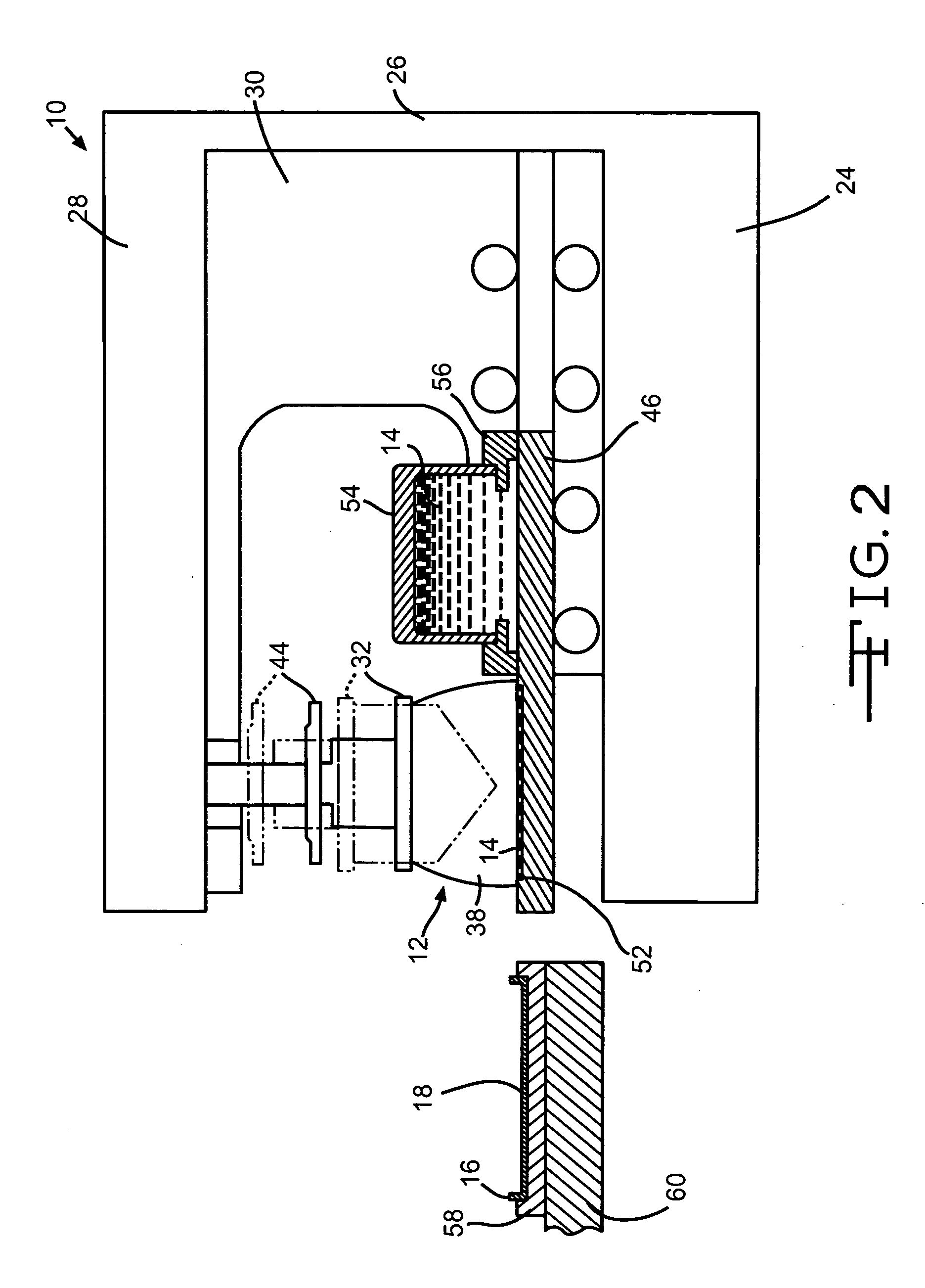

Stackable connector system for automated removal/addition in a storage media library

InactiveUS6850380B2Performance of driveLong-lasting performanceFlat record carrier combinationsDisc-shaped record carriersComputer hardwareAutomated data

An automated data storage library includes a plurality of storage slots, a drive having a stacked connector system, and a library control manager configured to monitor usage data for the stacked connector system representative of the number of times the stacked connector system is mounted by a media connector from any of a plurality of media elements, and wherein the library manager is further configured to coordinate refreshment of the stacked connector system when the usage data reaches a predetermined usage level threshold. The stacked connector system may be refreshed by replacement or addition of a separate connector. Various methods of improving the long term performance of a drive in a media library by replacing or adding a connector to a stacked connector system of a drive are also provided.

Owner:QUANTUM CORP

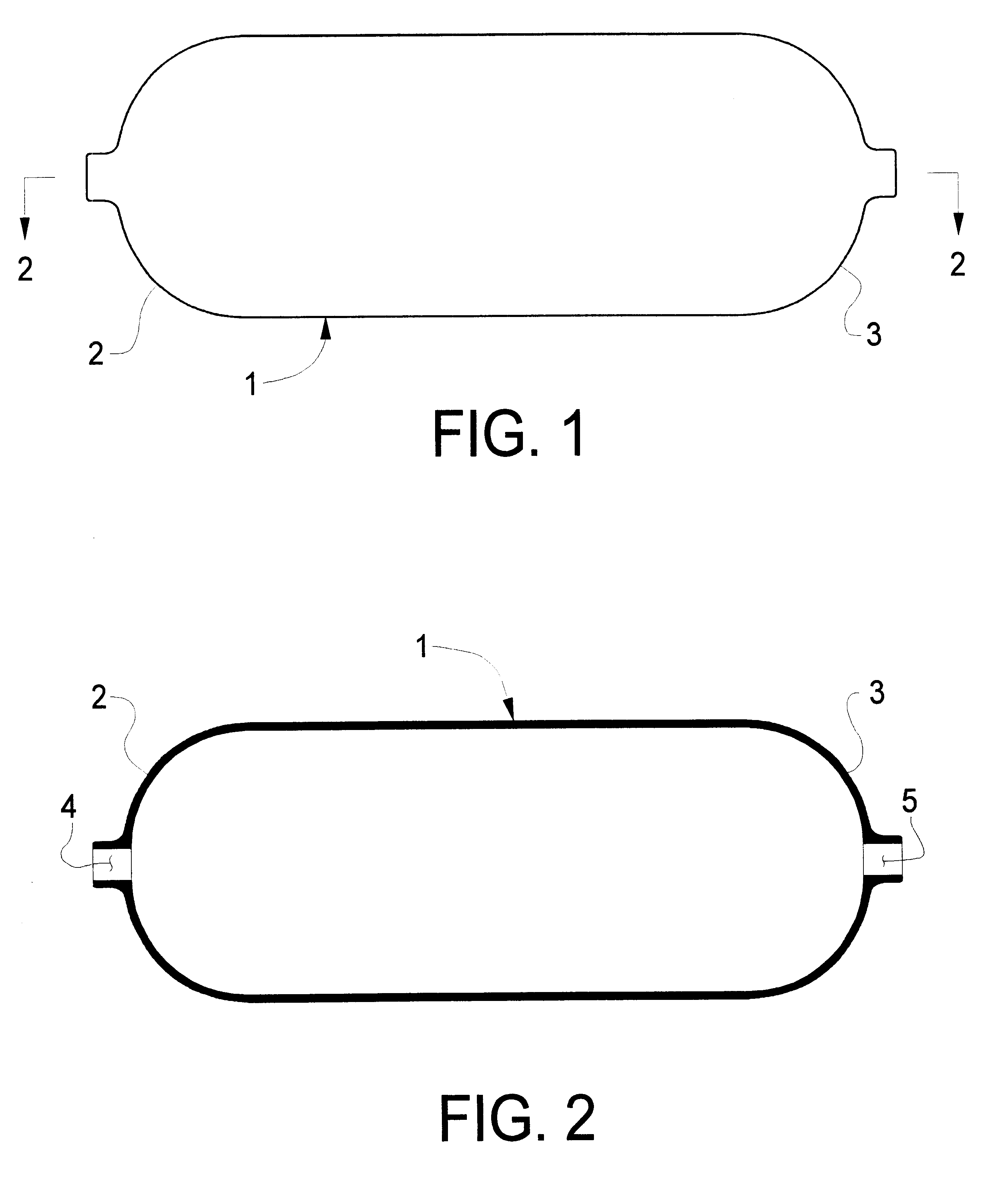

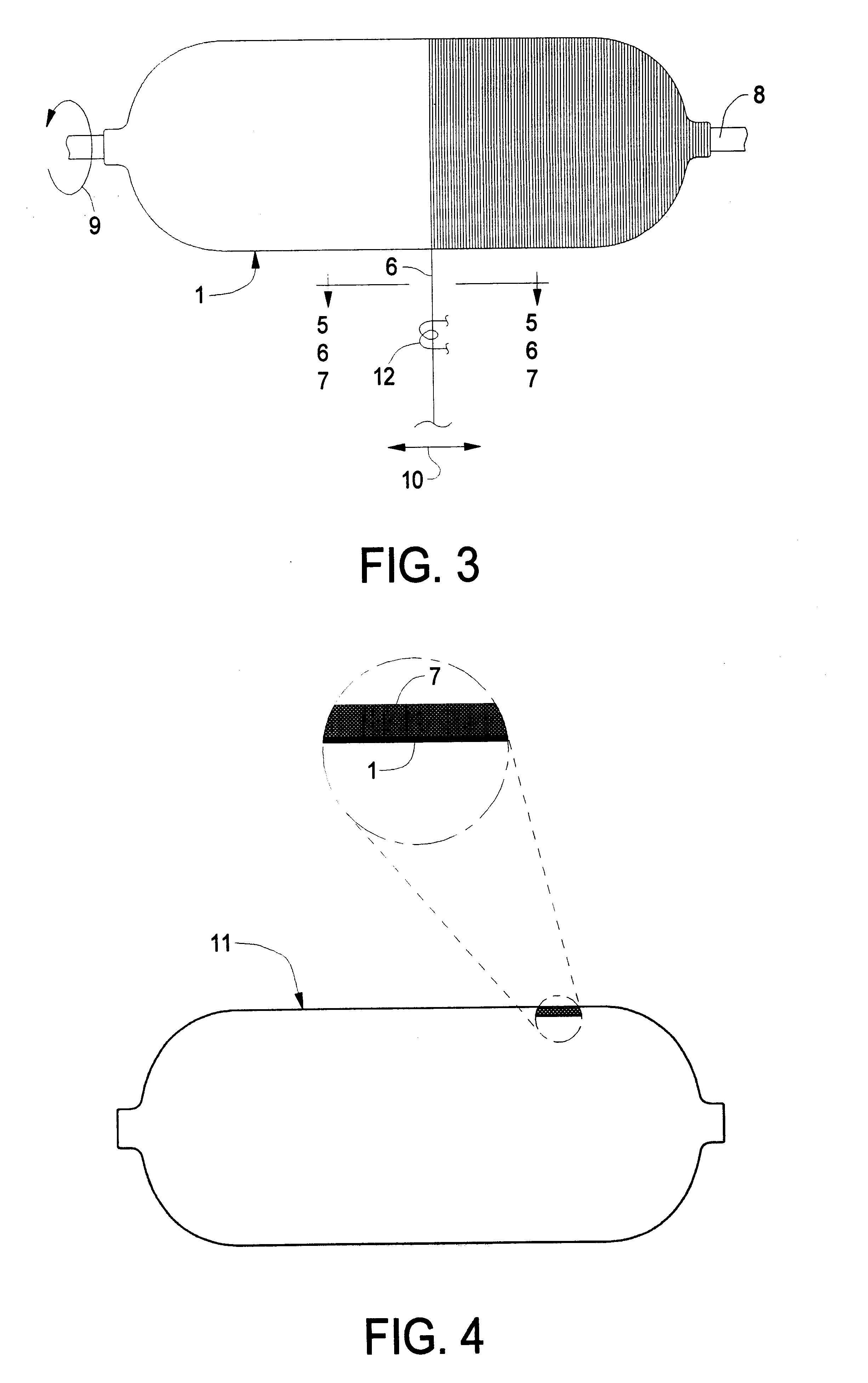

Method for fabricating composite pressure vessels

InactiveUS6565793B1Speed up the processRatio is limitedLabelling non-rigid containersLaminationFiberPolytetramethylene terephthalate

A process of fabricating a composite vessel includes the steps of: A) fabricating a thermoplastic liner for the vessel; B) overlaying a layer comprising fiber and a thermoplastic material (preferably by winding commingled filaments, rovings or yarns) onto the thermoplastic liner to obtain a composite intermediate structure (the fiber and thermoplastic material can be heated if desired during the overlaying, e.g. winding, step); C) heating the composite intermediate structure in a mold while applying at least one force thereto tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold; D) continuing step C) until the thermoplastic liner and the overlaid layer consolidate to form a composite vessel; E) cooling the mold and composite vessel until the composite vessel is solidified; and F) removing the formed composite vessel from the mold. The at least one force applied during step C) may be obtained by introducing gas pressure into the interior of the composite intermediate structure. Suitable materials for the thermoplastic material include: polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

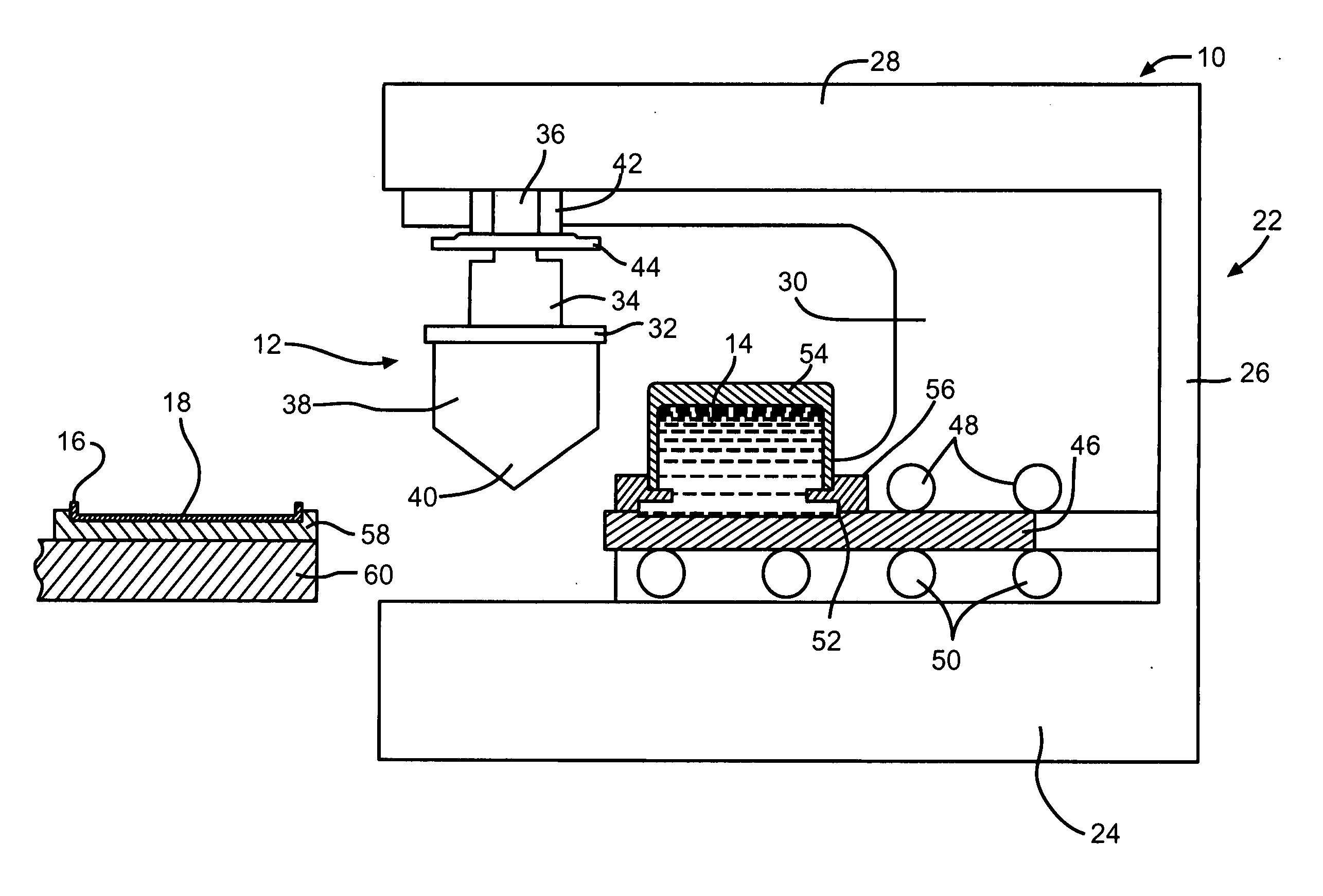

Use of pad printing in the manufacture of capacitors

ActiveUS20050041374A1Increase productionImprove adhesionRotary intaglio printing pressHybrid capacitor electrodesPad printingCarbide coating

Deposition of a metal-containing reagent solution or suspension onto a conductive substrate by various pad-printing techniques is described. This results in a pseudocapacitive oxide coating, nitride coating, carbon nitride coating, or carbide coating having an acceptable surface area for incorporation into an electrolytic capacitor, such a s one have a tantalum anode.

Owner:WILSON GREATBATCH LTD

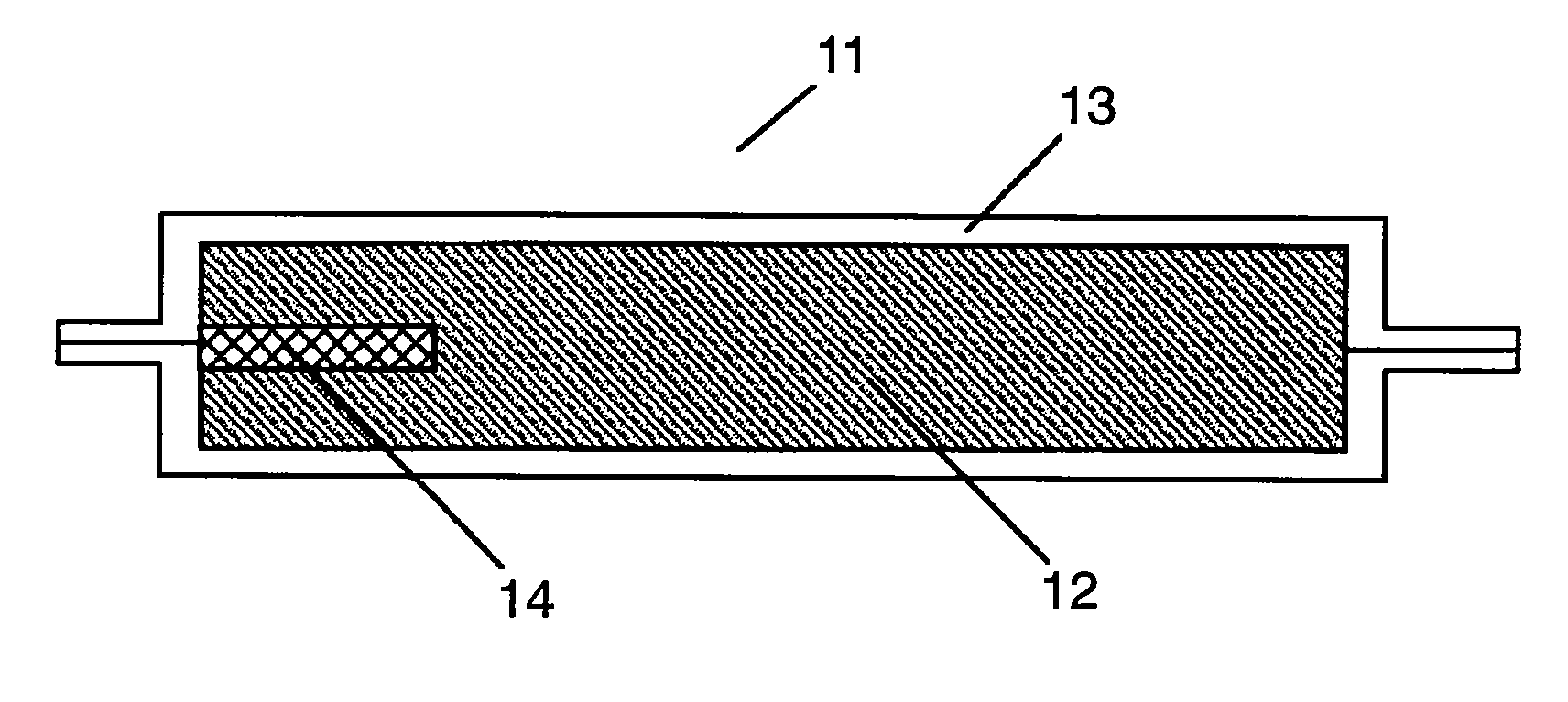

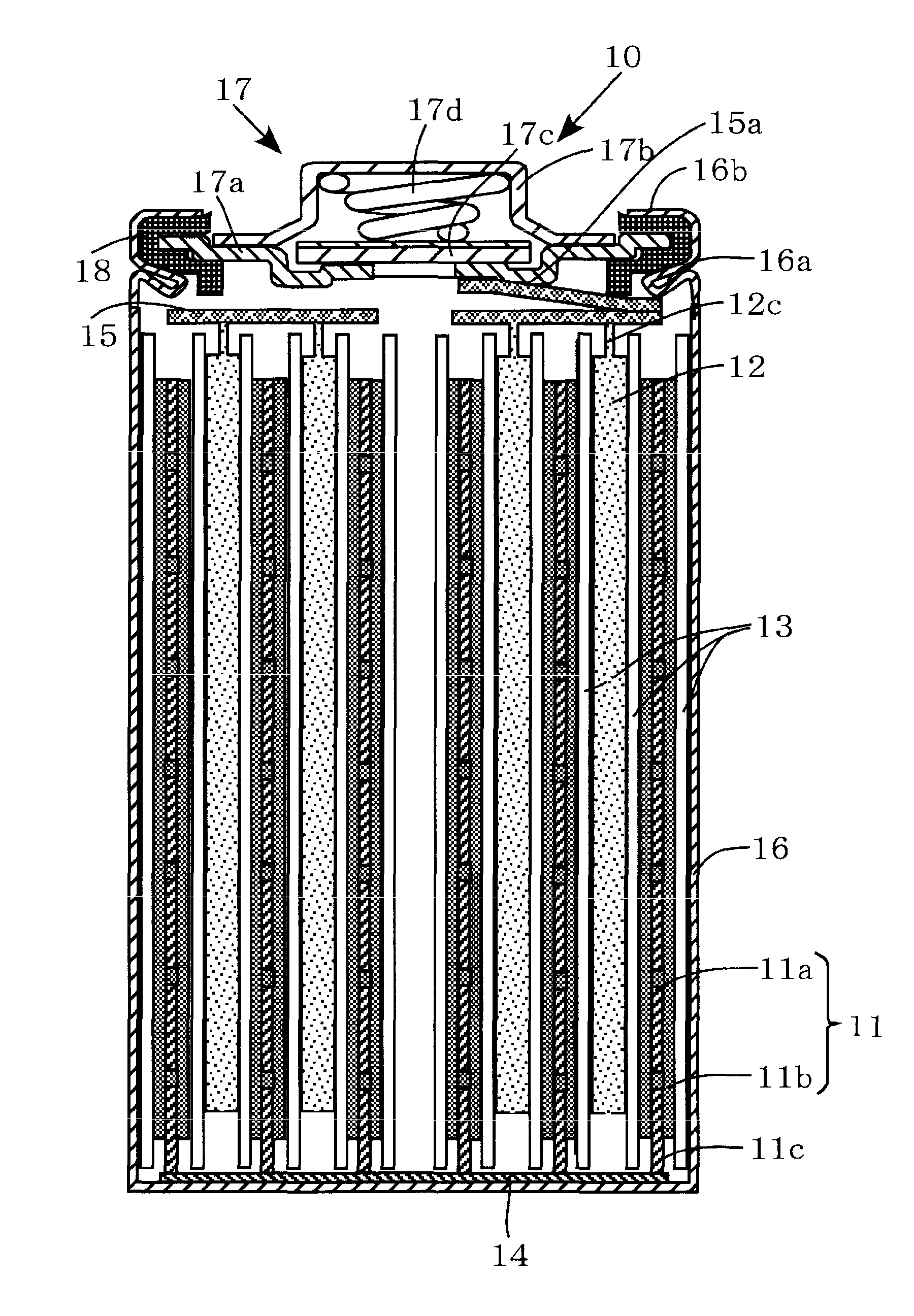

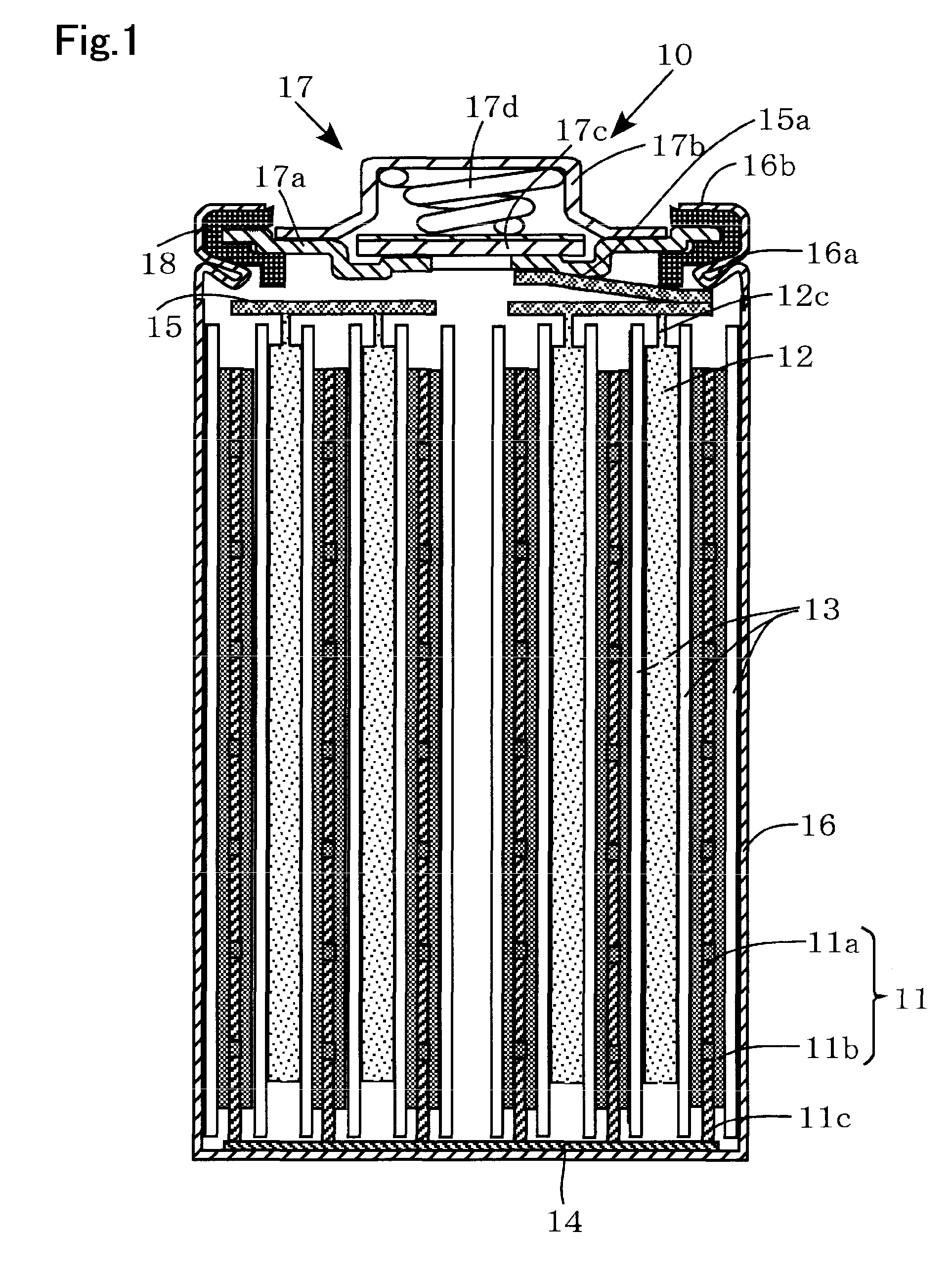

Alkaline storage battery

ActiveUS8409753B2Improve output characteristicsImprove featuresFinal product manufactureNegative electrodesMetallurgyLong term durability

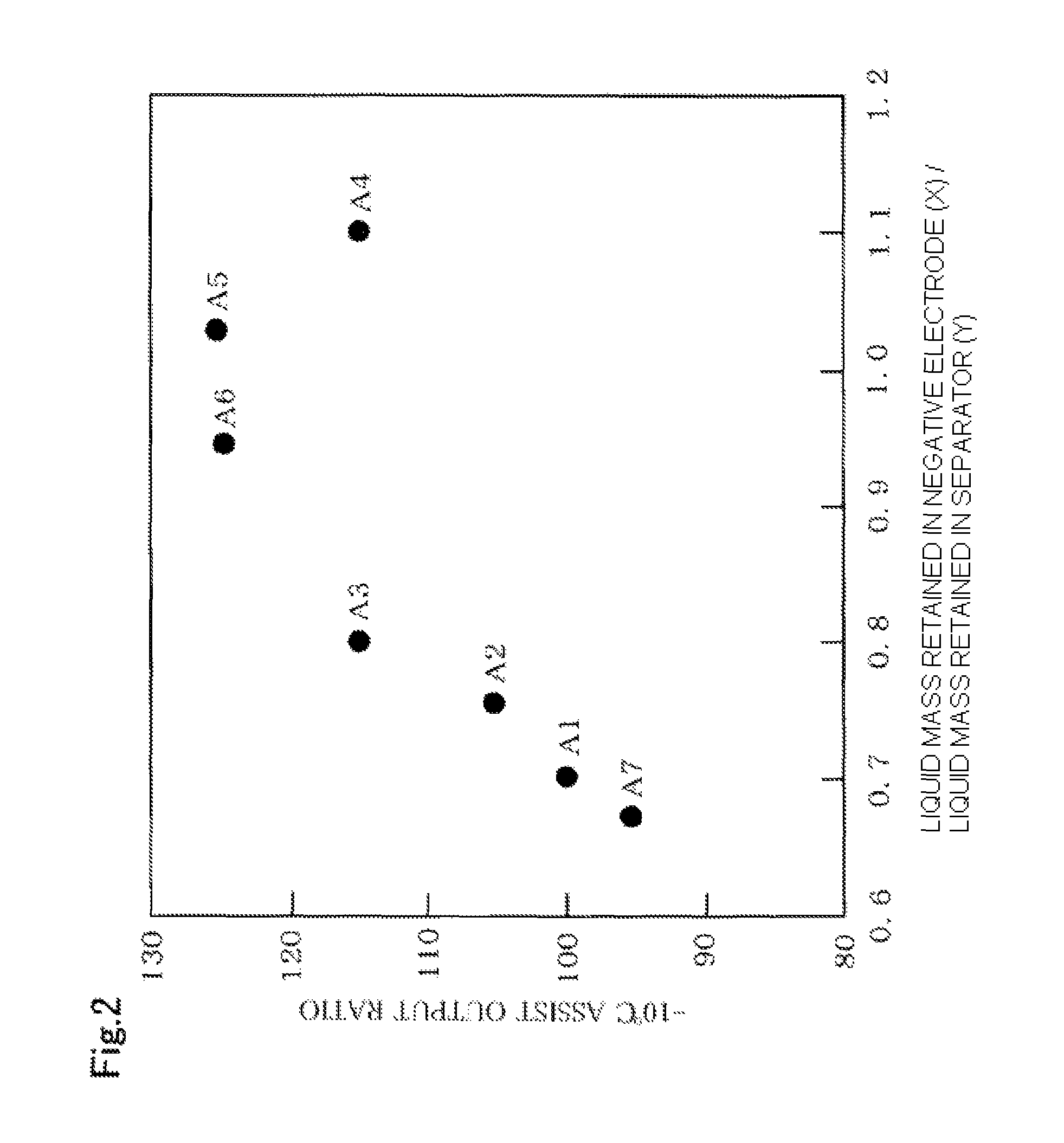

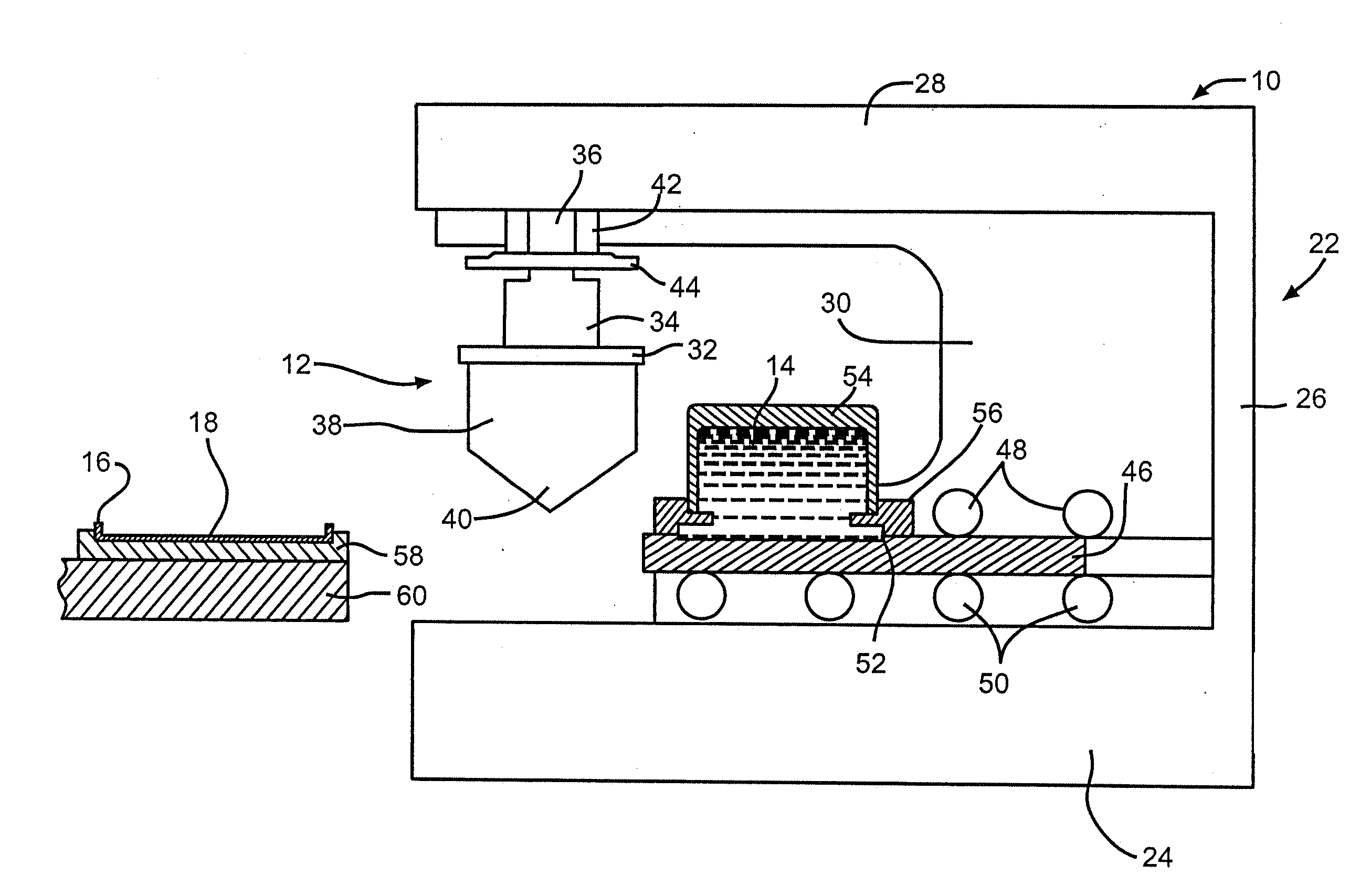

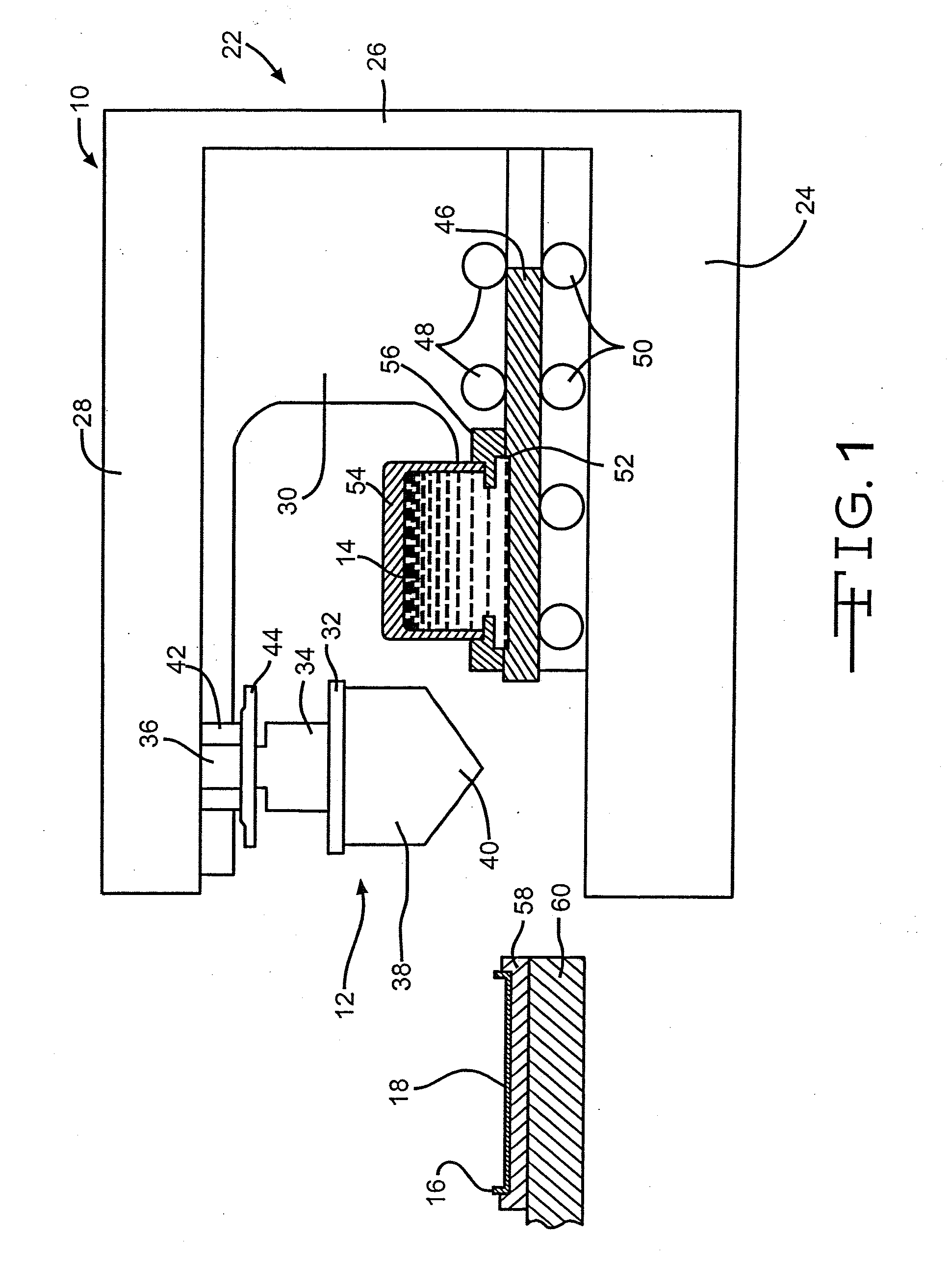

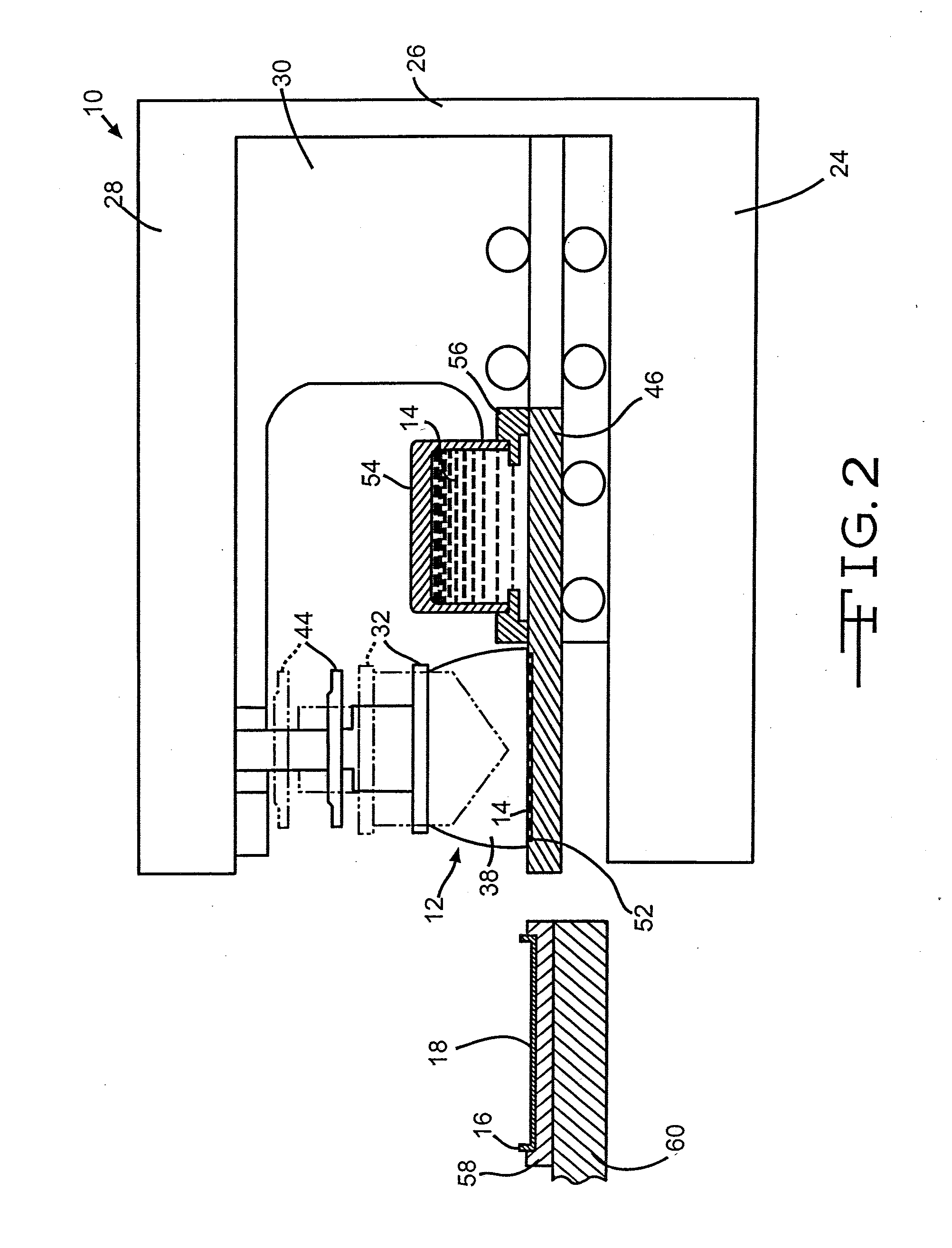

An alkaline storage battery in which an actual reaction area is not reduced after increasing a reaction area is provided. A hydrogen storage alloy negative electrode 11 of an alkaline storage battery 10 of the present invention is formed in a strip form including a long axis and a short axis, in which the ratio (A / B) of a length A (cm) of the long axis to a length B (cm) of the short axis is 20 or more and 30 or less (20≦A / B≦30), and the ratio (X / Y) of an electrolyte volume X (g) retained in the hydrogen storage alloy negative electrode 11 to an electrolyte volume Y (g) retained in a separator 13 is 0.8 or more and 1.1 or less (0.8≦X / Y≦1.1). With this arrangement, an alkaline storage battery with high output characteristics and long-term durability performance is obtained.

Owner:SANYO ELECTRIC CO LTD

Poly(Alkylene) Carbonates As Binders In The Manufacture Of Valve Metal Anodes For Electrolytic Capacitors

InactiveUS20080013257A1Increase productionImprove adhesionElectrode manufacturing processesElectrolytic capacitorsElectrolysisCarbonate

An anode for an electrolytic capacitor is described. The anode is of a valve metal in powdered form, for example tantalum powder, that has been pressed into a pellet and sintered under a vacuum at high temperatures. Preferably, a poly(alkylene)carbonate binder is used to promote cohesion with the pressed powder body. The binder adds green strength to the pressed body and helps with powder flow before pressing. The poly(alkylene)carbonate binders are superior in that they leave virtually no residual carbon behind when burnt out during the sintering process. The pressed valve metal powder structure is then anodized to a desired voltage in a formation electrolyte to form a continuous dielectric oxide film on the sintered body as well as a terminal lead / anode lead weld extending therefrom.

Owner:WILSON GREATBATCH LTD

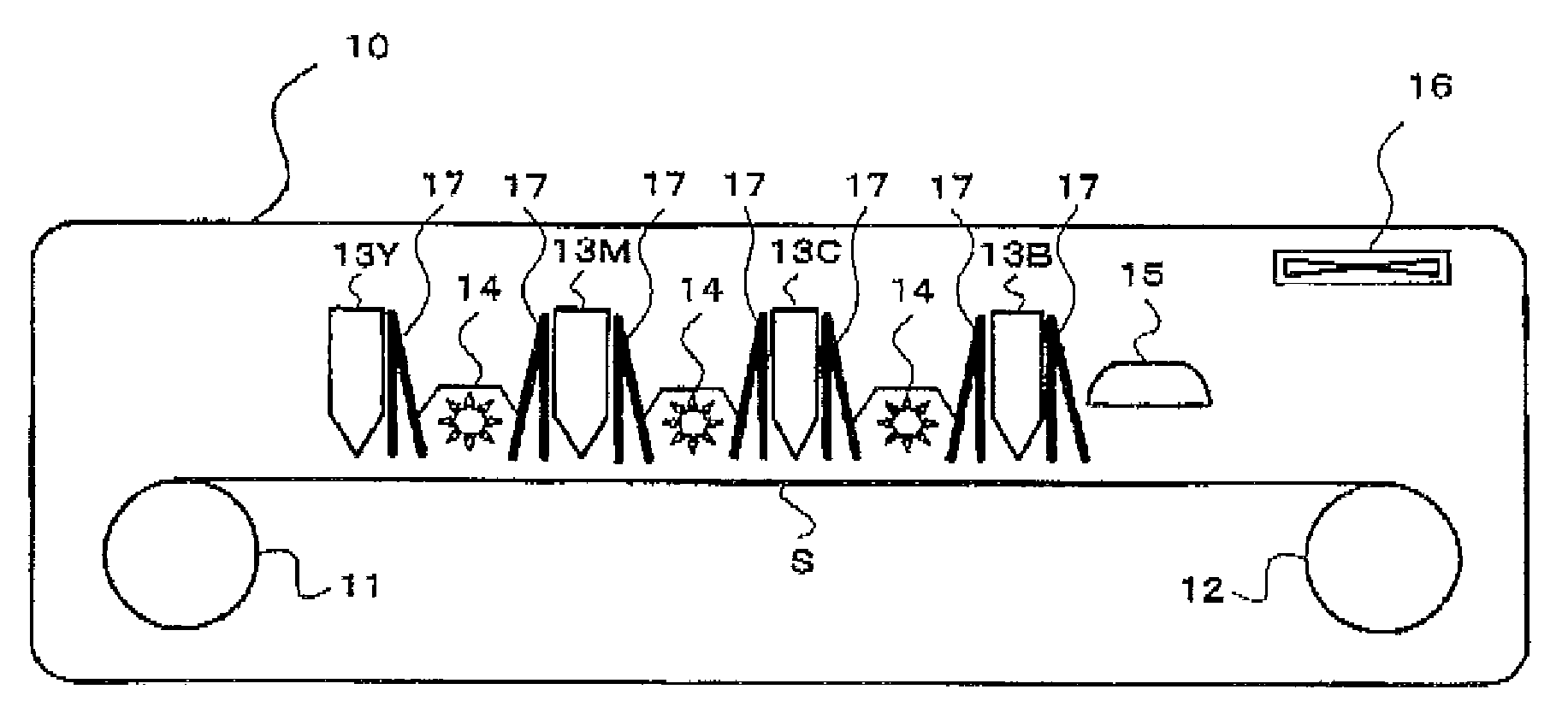

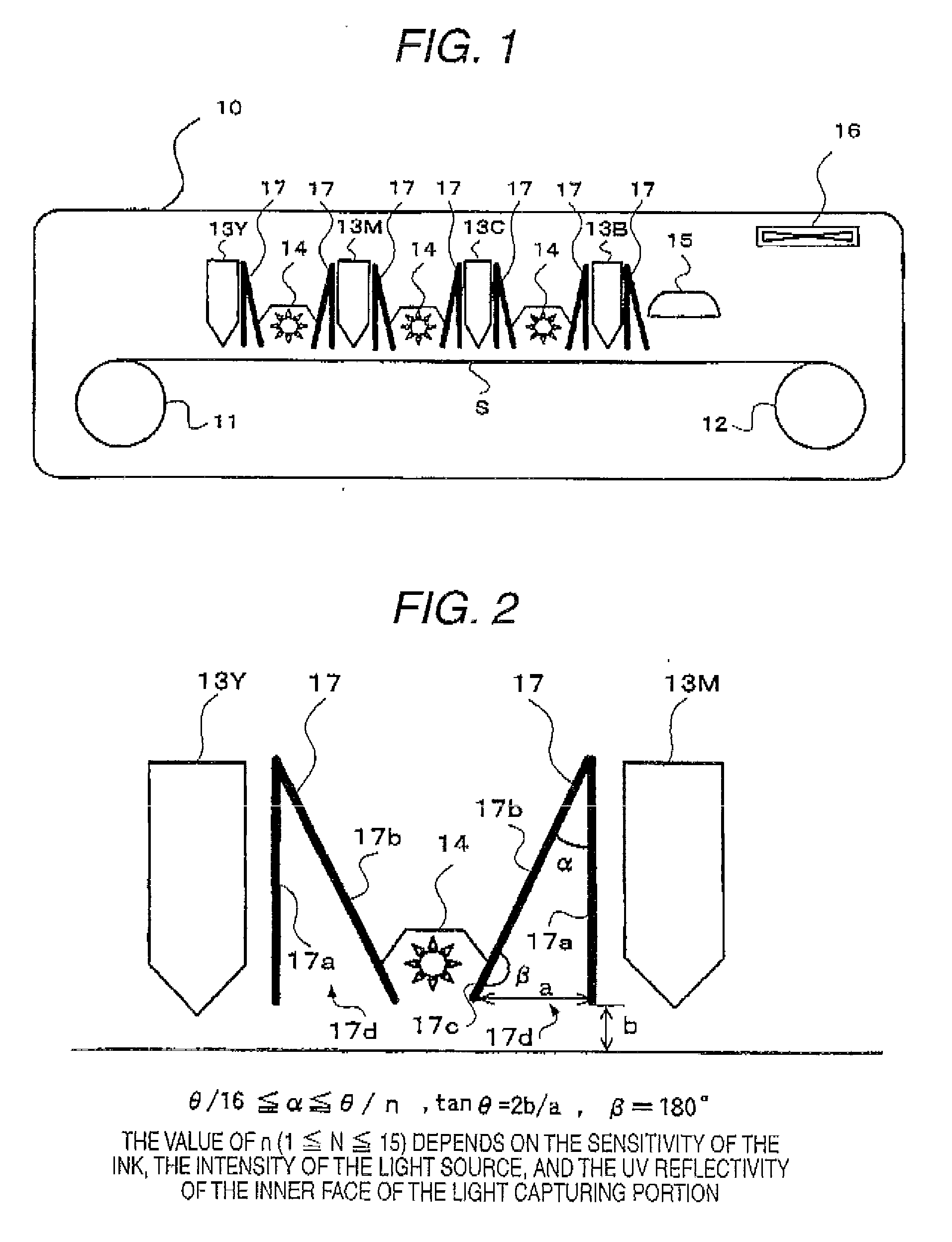

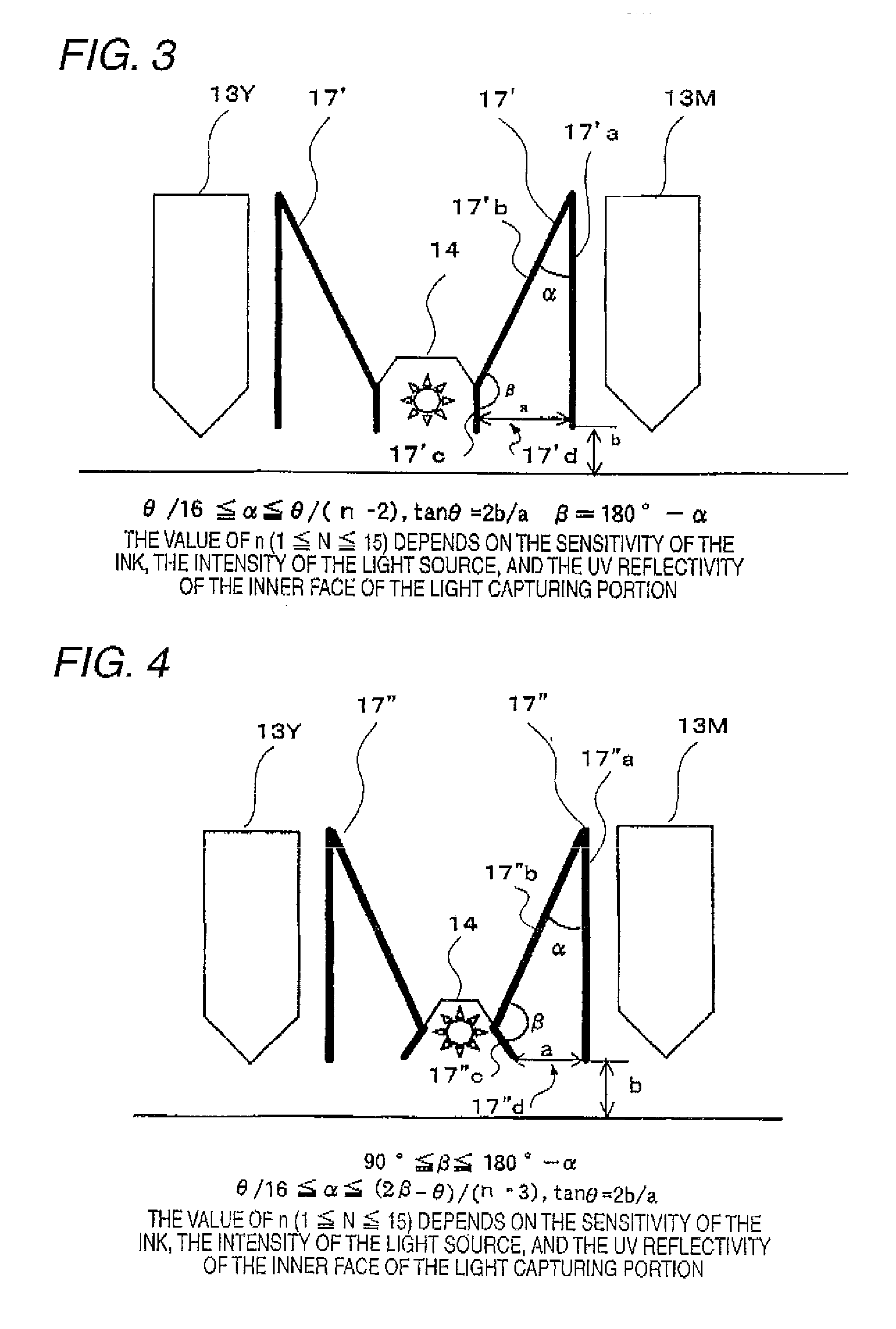

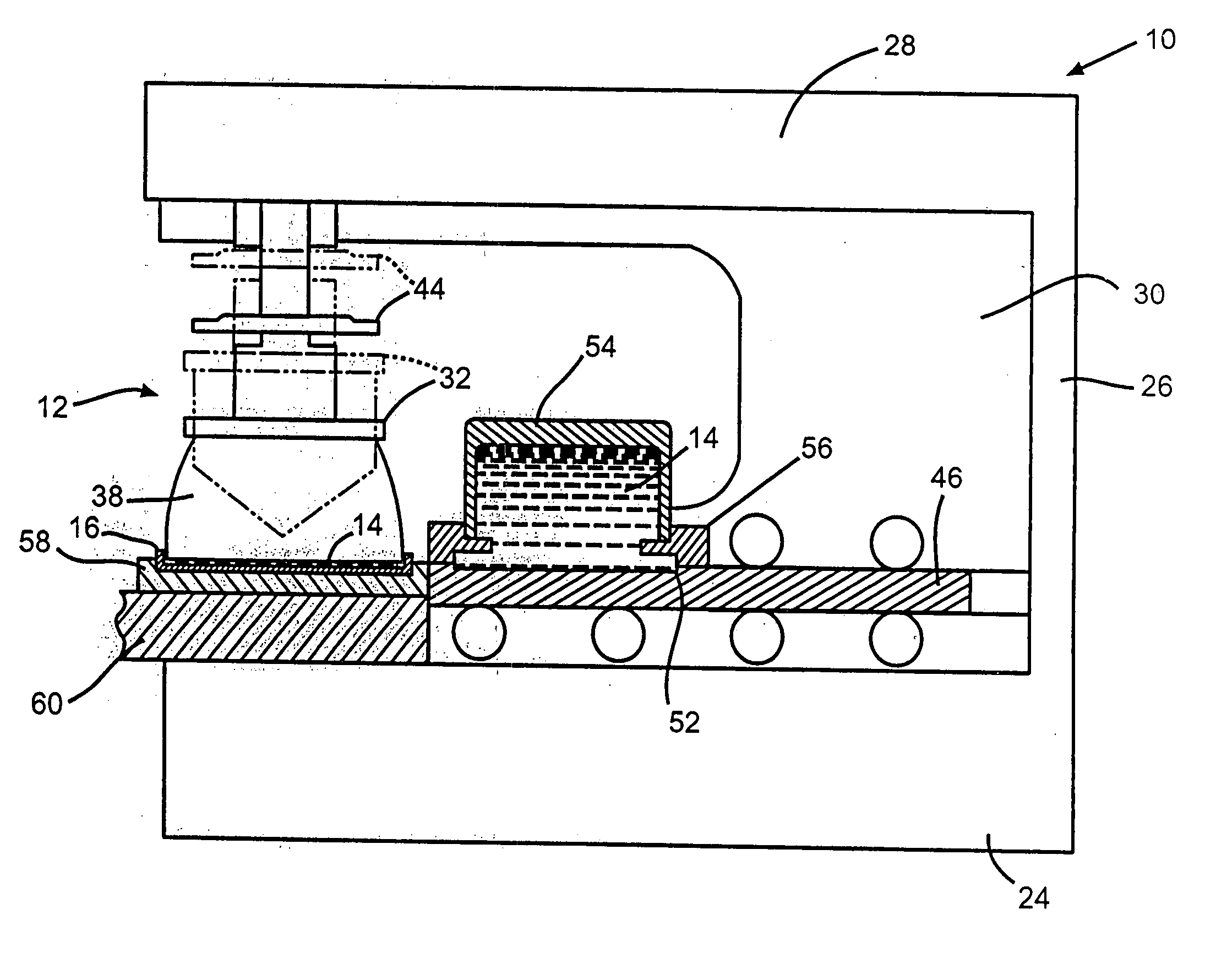

UV curable ink-jet recording apparatus

InactiveUS20080239044A1Improve productivityEasy to useOther printing apparatusOpen wedgeRecording media

A UV curable ink-jet recording apparatus includes: a recording medium transporting unit; an ink-jet head; and a UV irradiating unit, wherein the apparatus includes a light capturing portion between the UV irradiating unit and the ink-jet head, at least a part of the light capturing portion as seen in a longitudinal section taken vertically along a direction of transporting the recording medium has an opened wedge shape having no base side and comprising: a side vertical to the recording medium; and an oblique side which is in contact with a top of the vertical side, and which extends obliquely downward, the vertical side is located on the side of the ink-jet head, and the oblique side downward extends from the top toward the UV irradiating unit.

Owner:FUJIFILM CORP

Method of pad printing in the manufacture of capacitors

InactiveUS20060154416A1Increase productionImprove adhesionElectrode thermal treatmentHybrid capacitor electrodesPad printingCarbide coating

Deposition of a metal-containing reagent solution or suspension or a carbon nanotube-containing suspension onto a conductive substrate by various pad-printing techniques is described. In the case of a metal-containing solution or suspension, a pseudocapacitive oxide coating, nitride coating, carbon nitride coating, carbide coating, or carbon nanotube coating results. In any event, the active coating has acceptable surface area for incorporation into an electrolytic capacitor, such as one having a tantalum anode.

Owner:WILSON GREATBATCH LTD

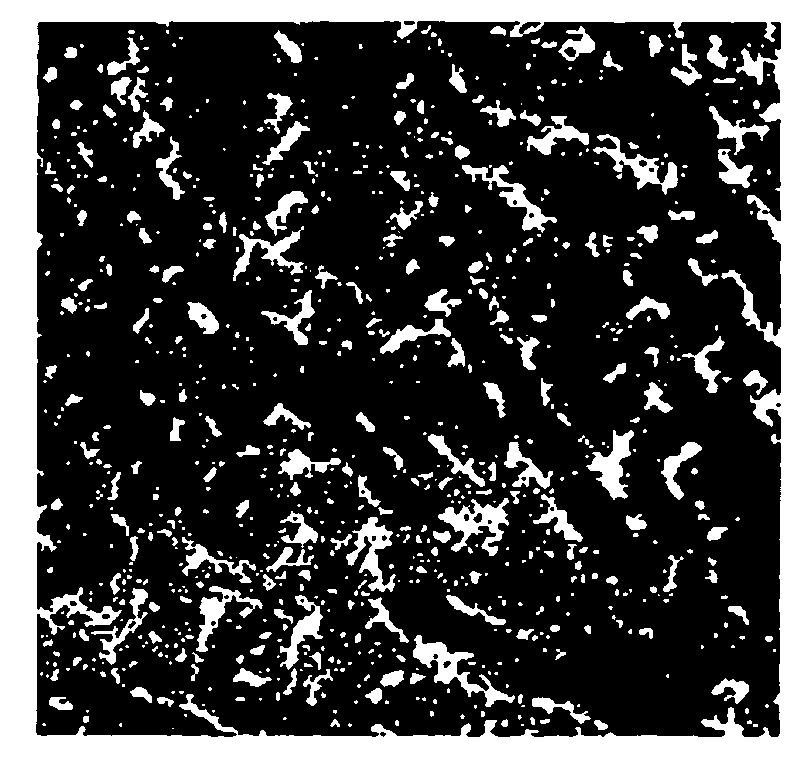

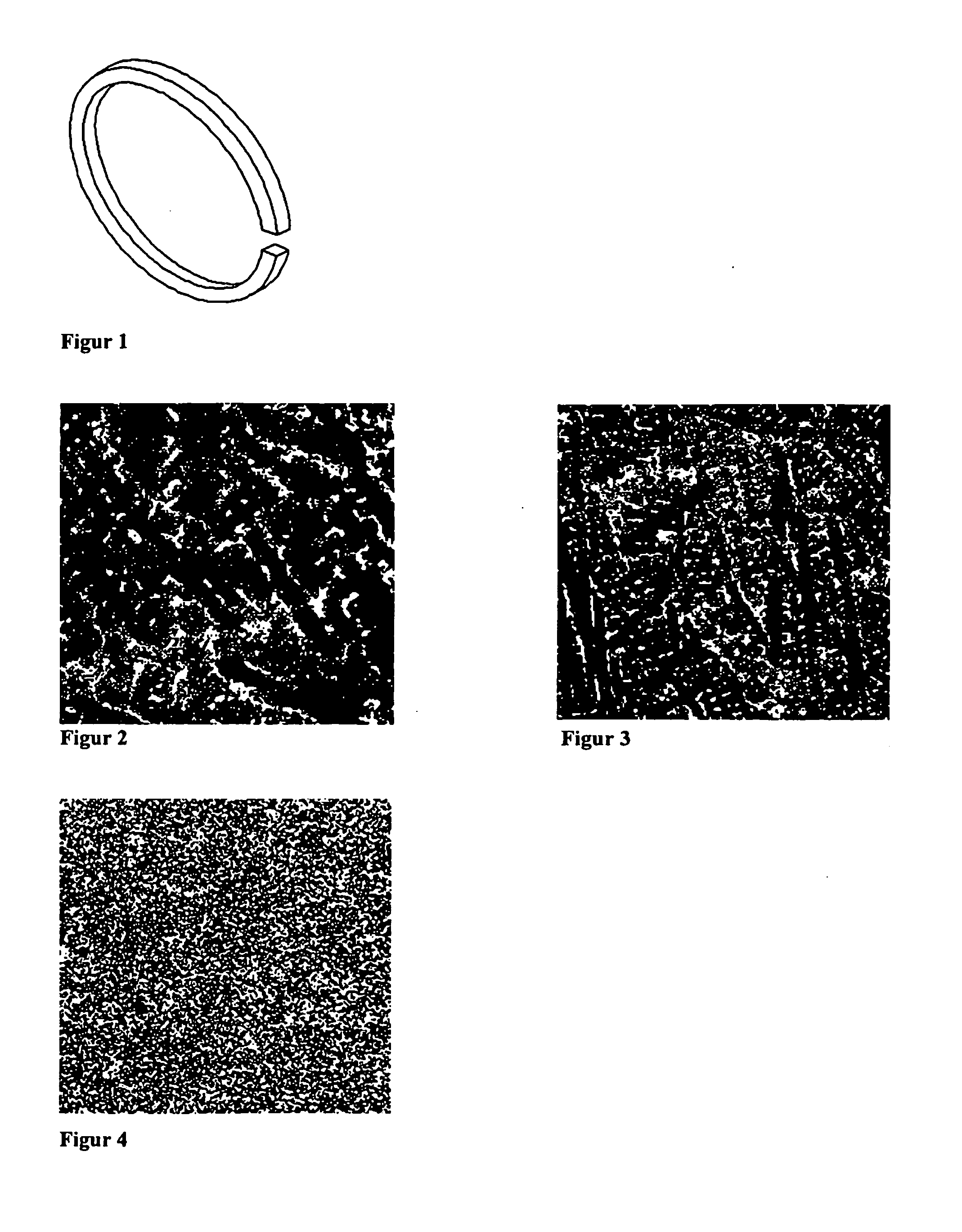

Nitratable steel piston rings and steel cylindrical sleeves, and casting method for the production thereof

InactiveUS20120090462A1Good nitridabilityEasy transitionPiston ringsBraking action transmissionCast ironSteel cylinder

A steel piston ring and a steel cylinder liner are described which comprise as the main body a steel composition which has good nitridability. The steel composition consists of the following elements: 0-0.5 weight % B, 0.5-1.2 weight % C, 4.0-20.0 weight % Cr, 0-2.0 weight % Cu, 45.30-91.25 weight % Fe, 0.1-3.0 weight % Mn, 0.1-3.0 weight % Mo, 0-0.05 weight % Nb, 2.0-12.0 weight % Ni, 0-0.1 weight % P, 0-0.05 weight % Pb, 0-0.05 weight % S, 2.0-10.0 weight % Si, 0-0.05 weight % Sn, 0.05-2.0 weight % V, 0-0.2 weight % Ti and 0-0.5 weight % W. The steel piston ring and the steel cylinder liner can be manufactured in a casting process using the machinery and technology employed for the manufacture of cast iron parts.

Owner:FEDERAL MOGUL BURSCHEID

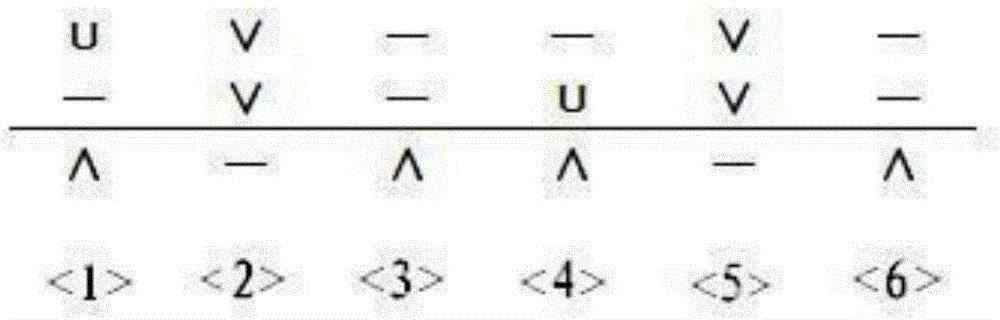

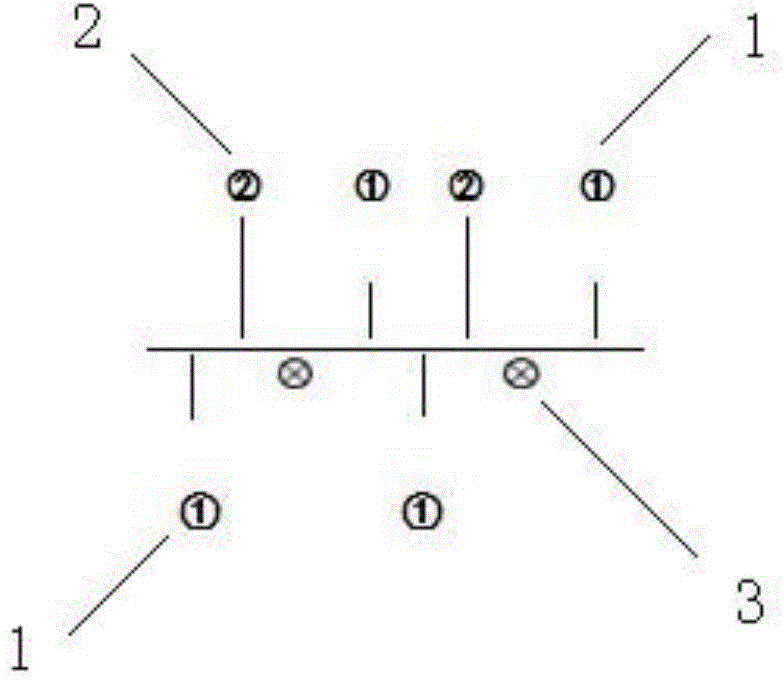

Stereoscopic meshed knitted fabric with unidirectional moisture guide function and production method thereof

InactiveCN104695121AControl the heat and humidity balanceImprove breathabilityWeft knittingPolyesterYarn

The invention discloses stereoscopic meshed knitted fabric with unidirectional moisture guide function and a production method thereof. An inner hydrophobic layer is in a polypropylene yarn plain structure. An outer absorbent layer is in a cross-sectional polypropylene stereoscopic drop-needle mesh structure. A middle moisture guide connecting layer is made of polypropylene yarns. The fabric is woven with a double knit machine; rib needle setting is adopted; needles are dropped from lower needle cylinders at intervals of single needles; every six paths form a repeat; the second and the fifth are polypropylene yarns, two needle rows form loops on a needle plate, a single needle row on the needle cylinders is used for weaving rise yarns, and the inner plain structure is woven; the first and the fourth are polypropylene yarns, one of every two needle rows on the needle plate perform tucking, the single needle row on the needle cylinder form loops, and the middle layer is woven; the third and the sixth are cross-sectional polyester yarns, two needle rows on the needle plate are used for weaving rise yarns, the single needle row on the need cylinders form loops, the needles are dropped from the lower need cylinders at intervals of single needles, and the outer stereoscopic drop-needle mesh structure is woven. The fabric is capable of guiding sweat from the inner layer of the fabric to the outer layer thereof fast, the sweat is spread and vaporized from the surface of the fabric, and when the outer layer of the fabric contacts water, the water can be avoided entering the inner layer of the fabric.

Owner:上海云鼎纺织品股份有限公司

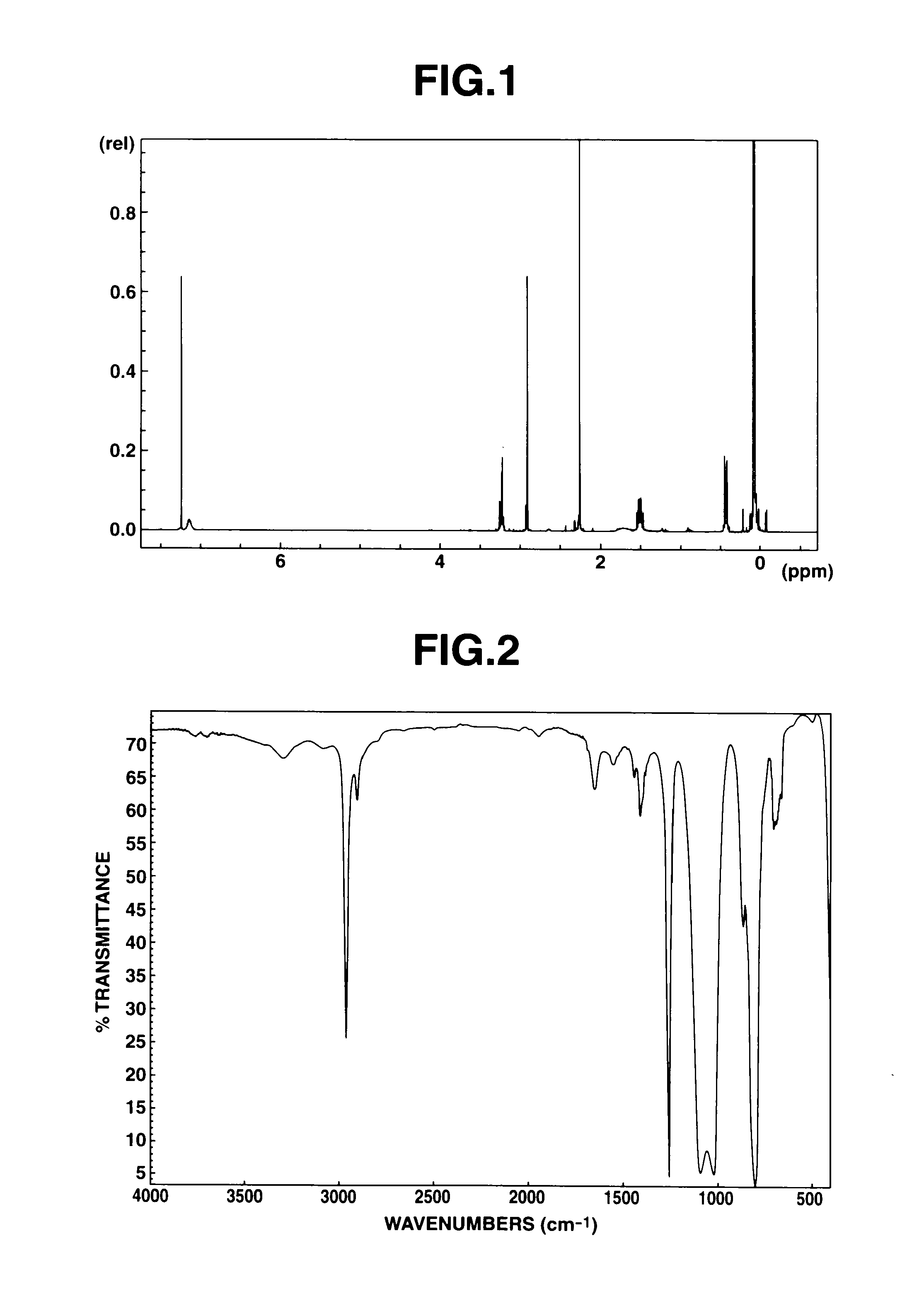

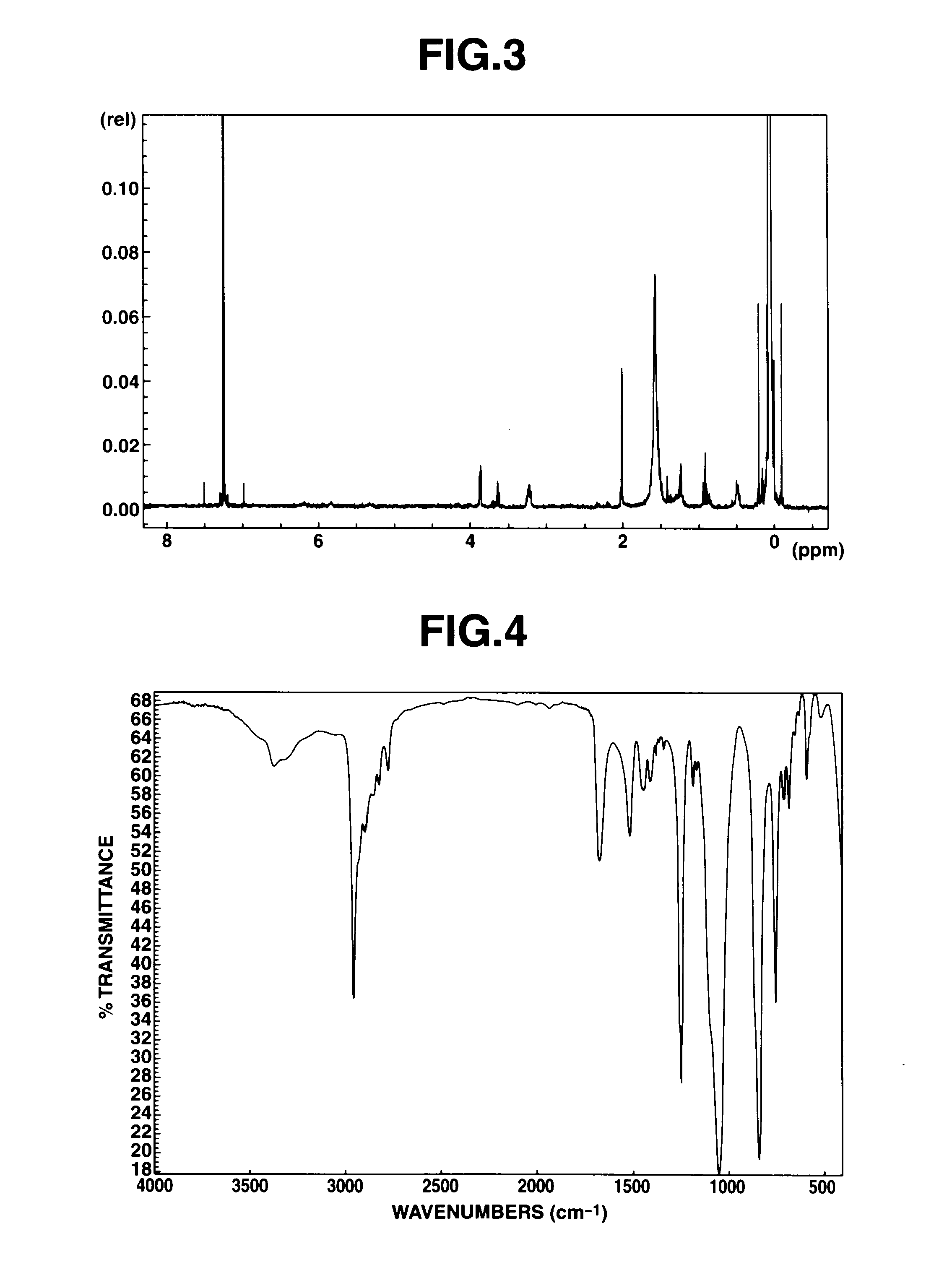

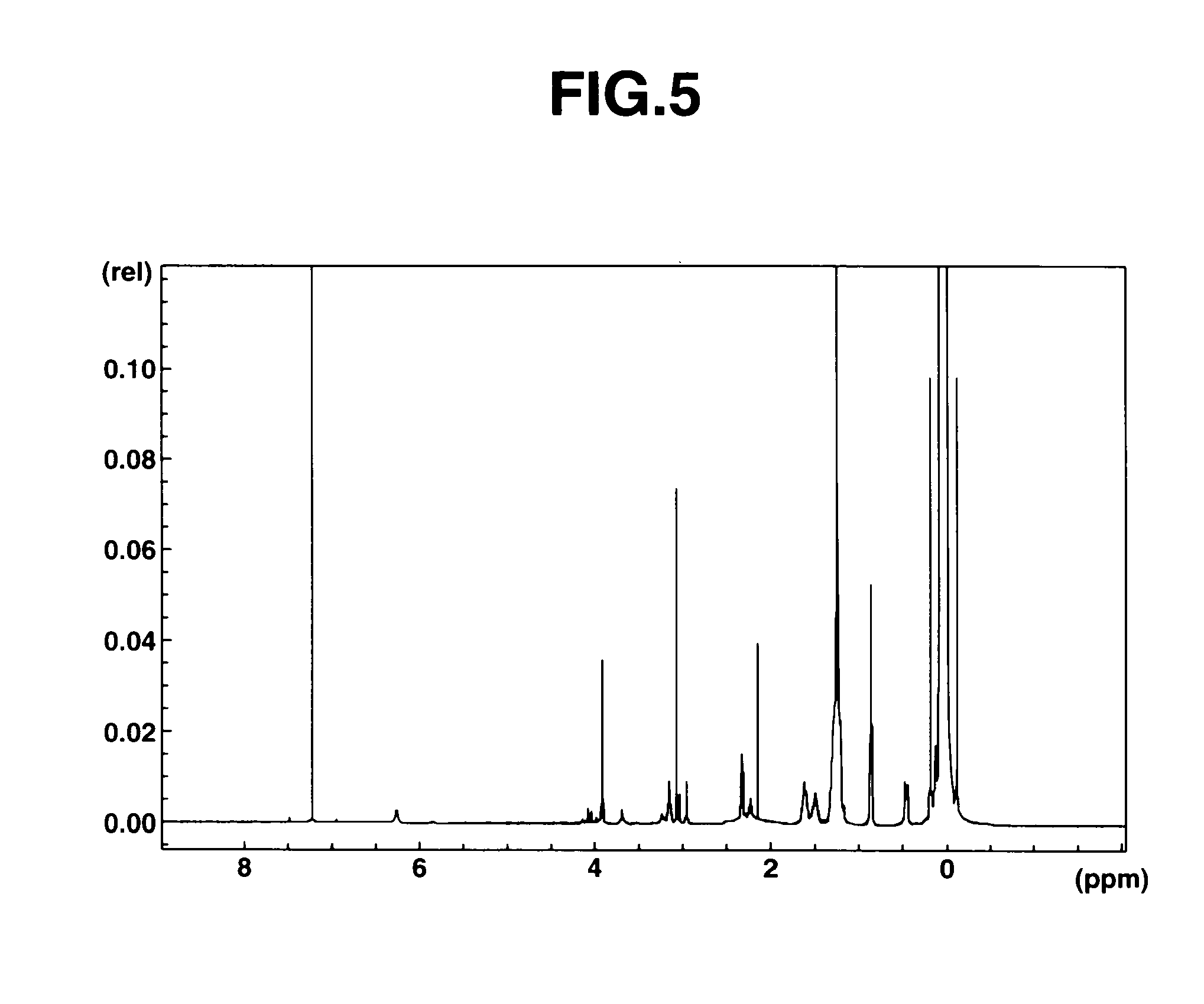

Amino acid-modified organopolysiloxane, making method, and cosmetics

ActiveUS20120093746A1Long-lasting performanceCosmetic preparationsBiocideFiberOrganometallic catalysis

An amino acid-modified organopolysiloxane can be prepared under mild reaction conditions by reacting an amino-modified organopolysiloxane with an amino acid or amino acid derivative ester in the presence of an organometallic catalyst. The amino acid-modified organopolysiloxane having a hydrophilic group is useful in cosmetics, powder surface treatment, fiber or fabric treatment, coating, and resin modification.

Owner:SHIN ETSU CHEM IND CO LTD

Charged device, cleaning device, process cartridge, toner, and image-forming device that uses these

ActiveUS7477862B2Increasing costQuality improvementElectrographic process apparatusCorona dischargeForeign matterImaging quality

Owner:RICOH KK

Poly (Alkylene) Carbonates As Binders In The Manufacture Of Valve Metal Anodes For Electrolytic Capacitors

InactiveUS20080007894A1Increase productionImprove adhesionLiquid electrolytic capacitorsActive material electrodesElectrolysisCarbonate

An anode for an electrolytic capacitor is described. The anode is of a valve metal in powdered form, for example tantalum powder, that has been pressed into a pellet and sintered under a vacuum at high temperatures. Preferably, a poly(alkylene) carbonate binder is used to promote cohesion with the pressed powder body. The binder adds green strength to the pressed body and helps with powder flow before pressing. The poly(alkylene) carbonate binders are superior in that they leave virtually no residual carbon behind when burnt out during the sintering process. The pressed valve metal powder structure is then anodized to a desired voltage in a formation electrolyte to form a continuous dielectric oxide film on the sintered body as well as a terminal lead / anode lead weld extending therefrom.

Owner:WILSON GREATBATCH LTD

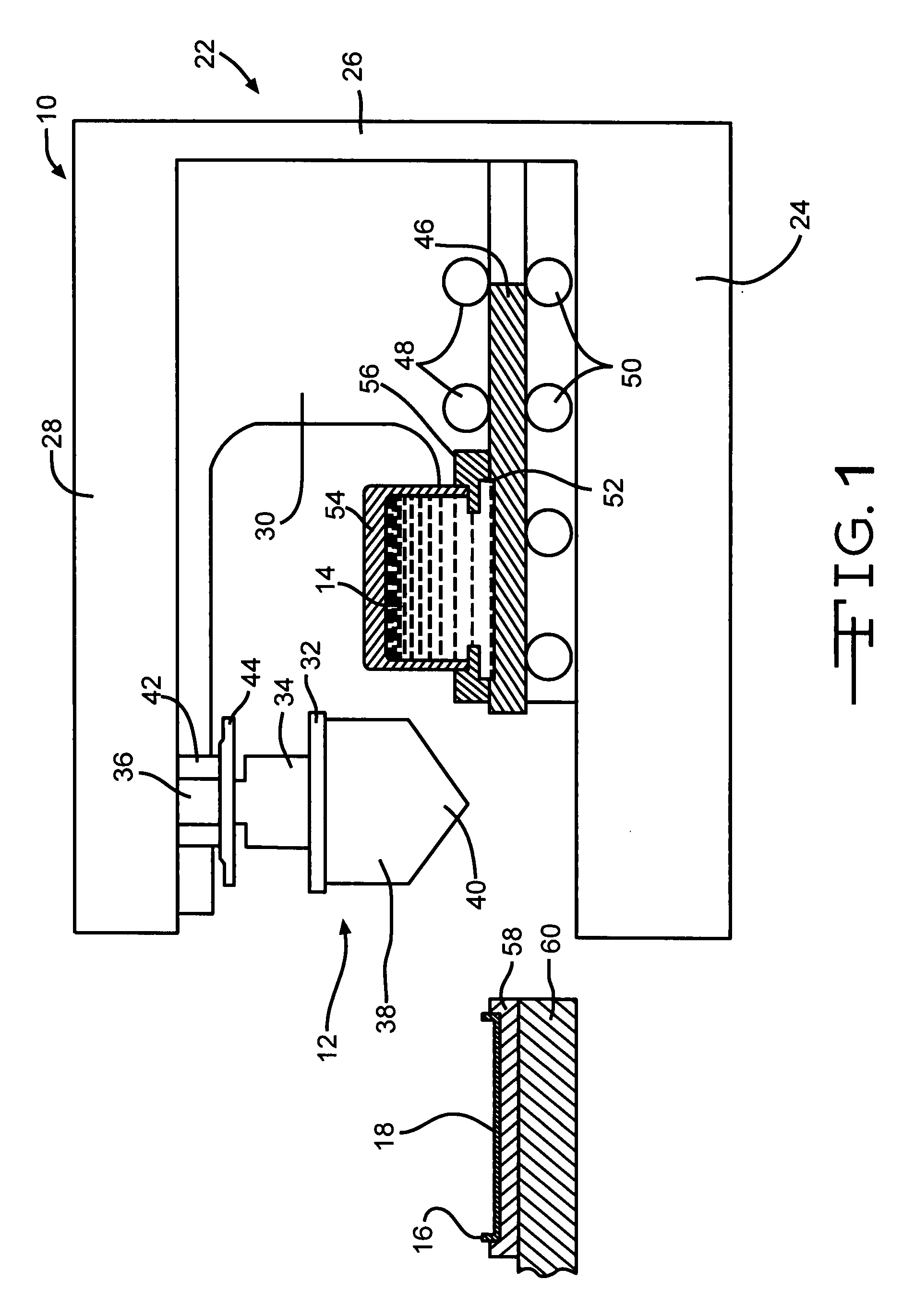

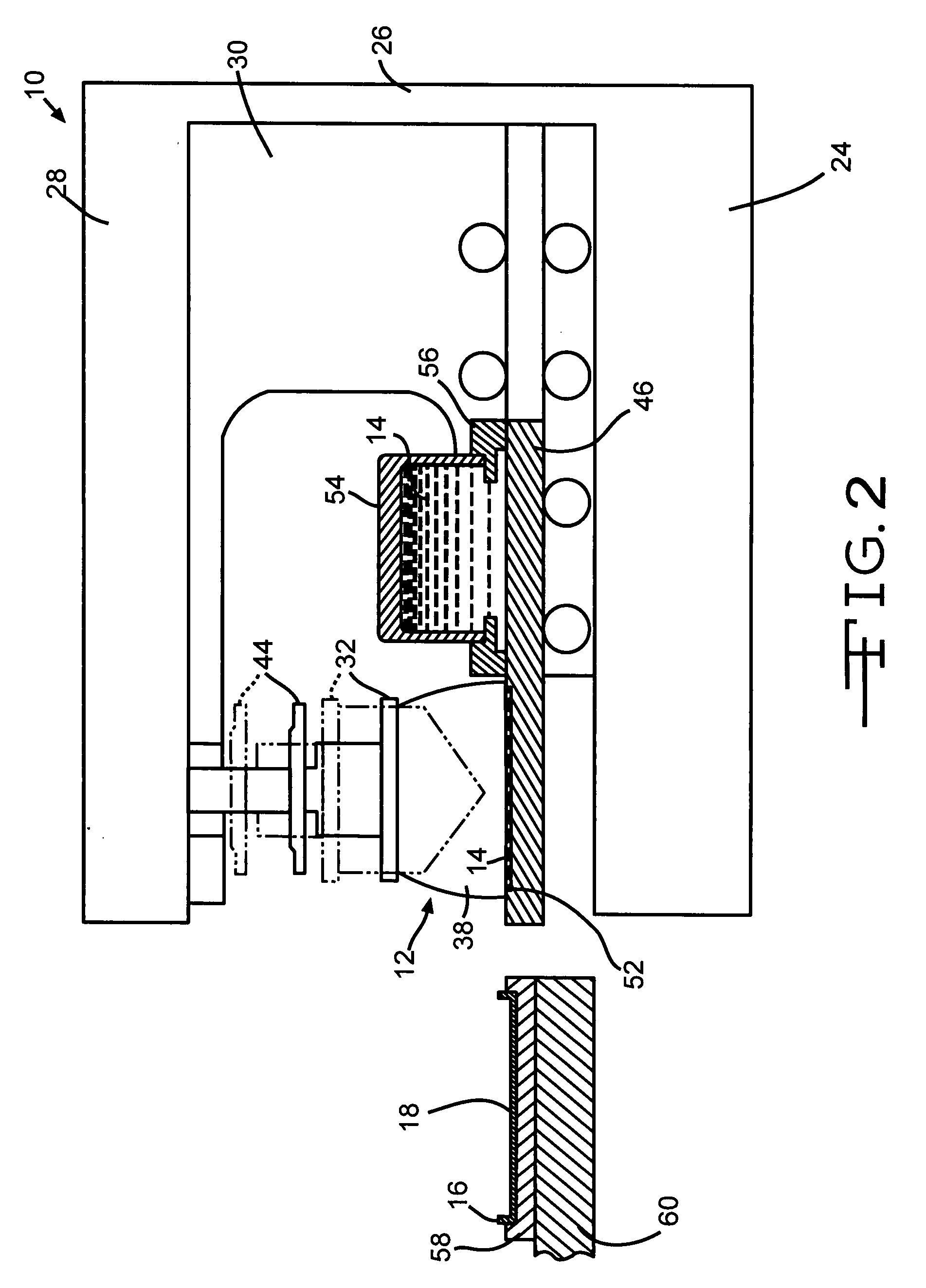

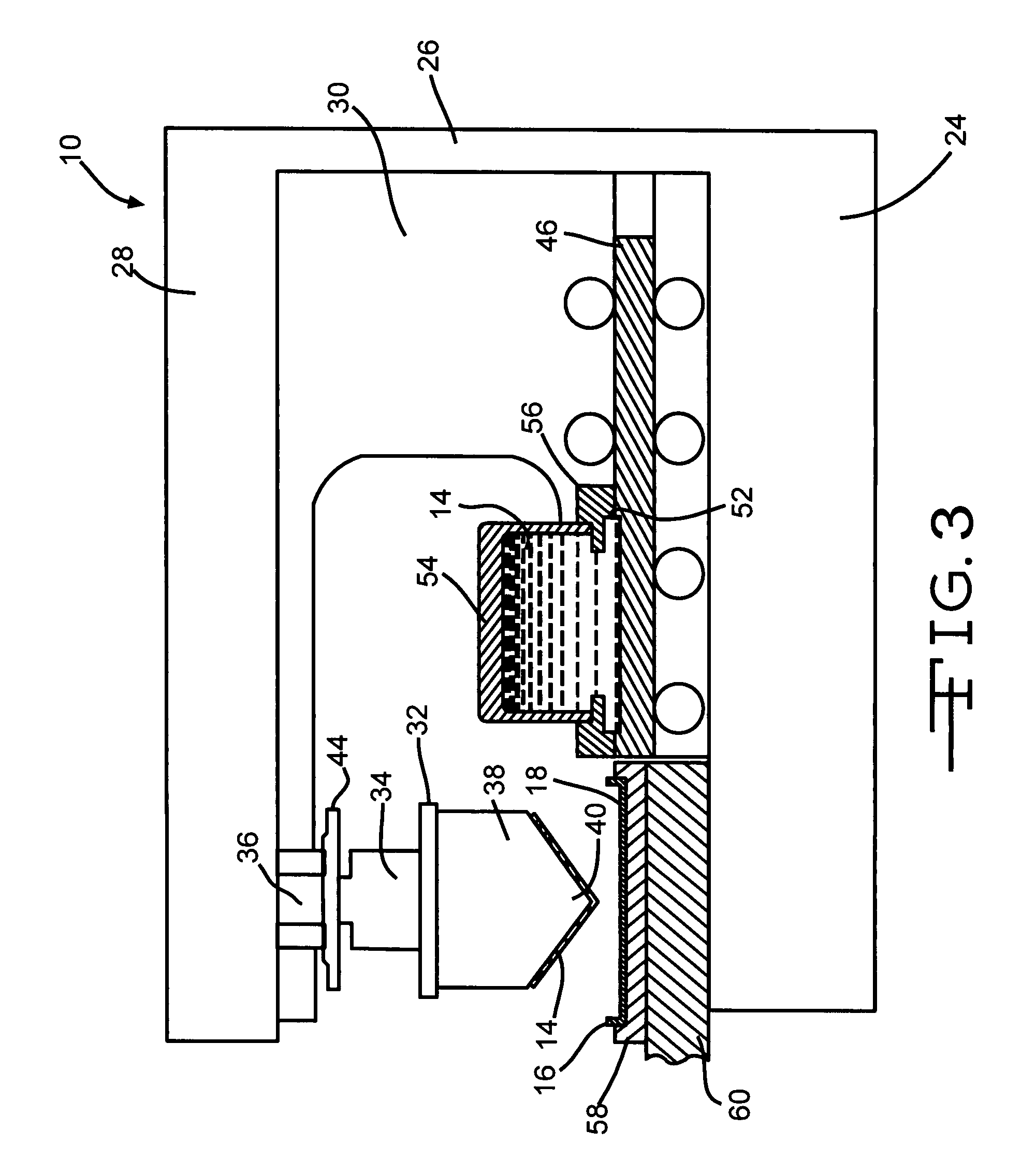

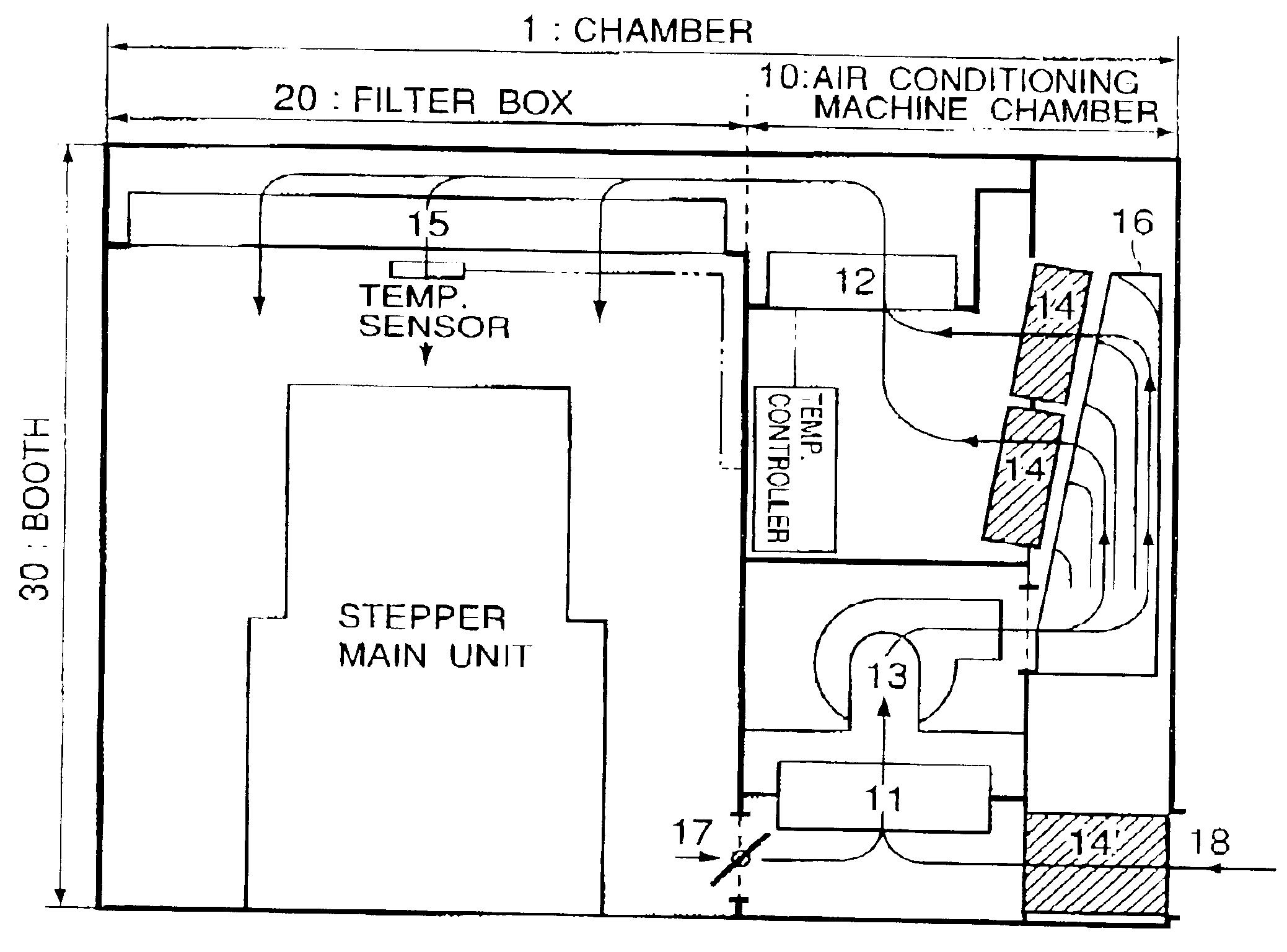

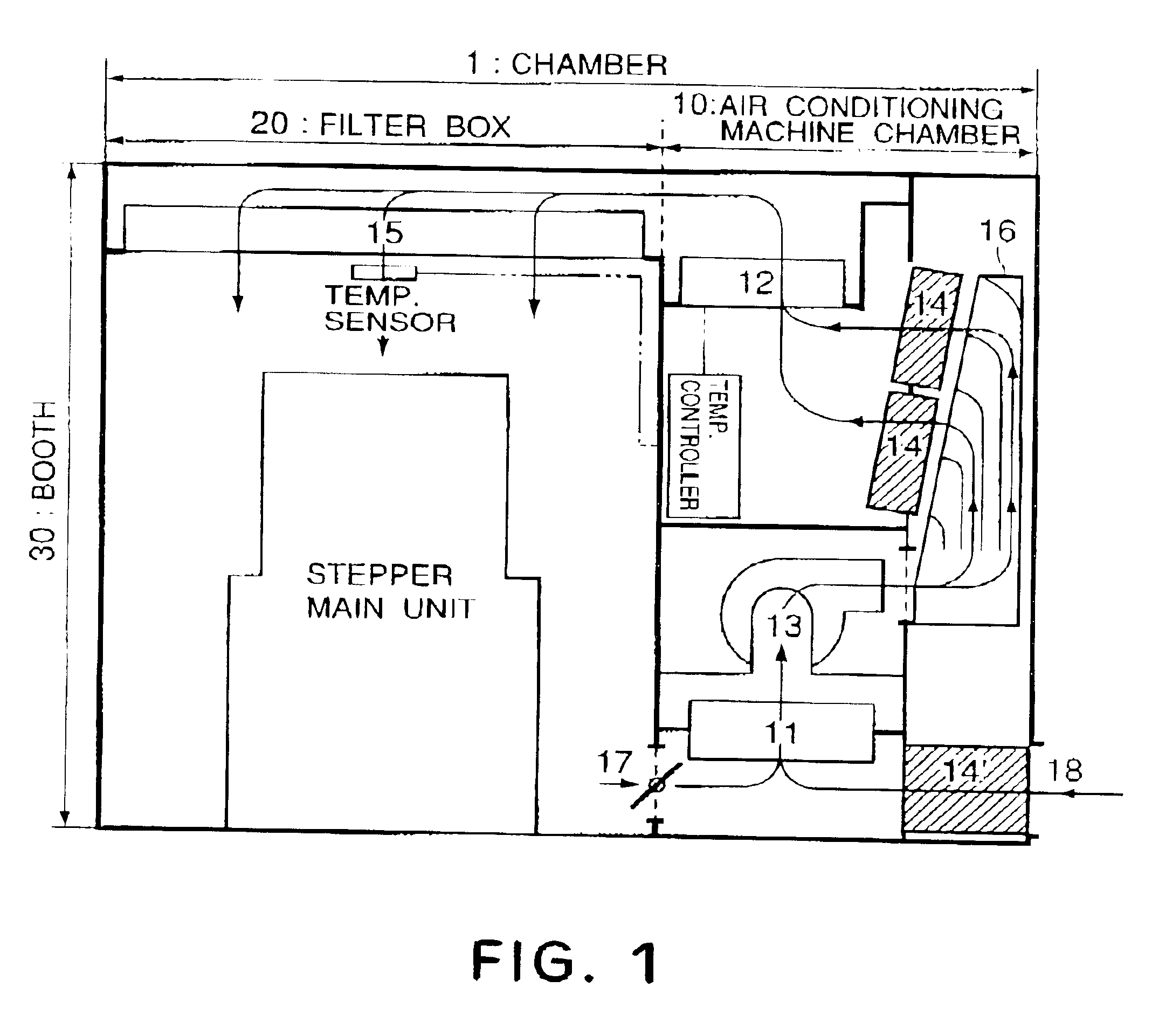

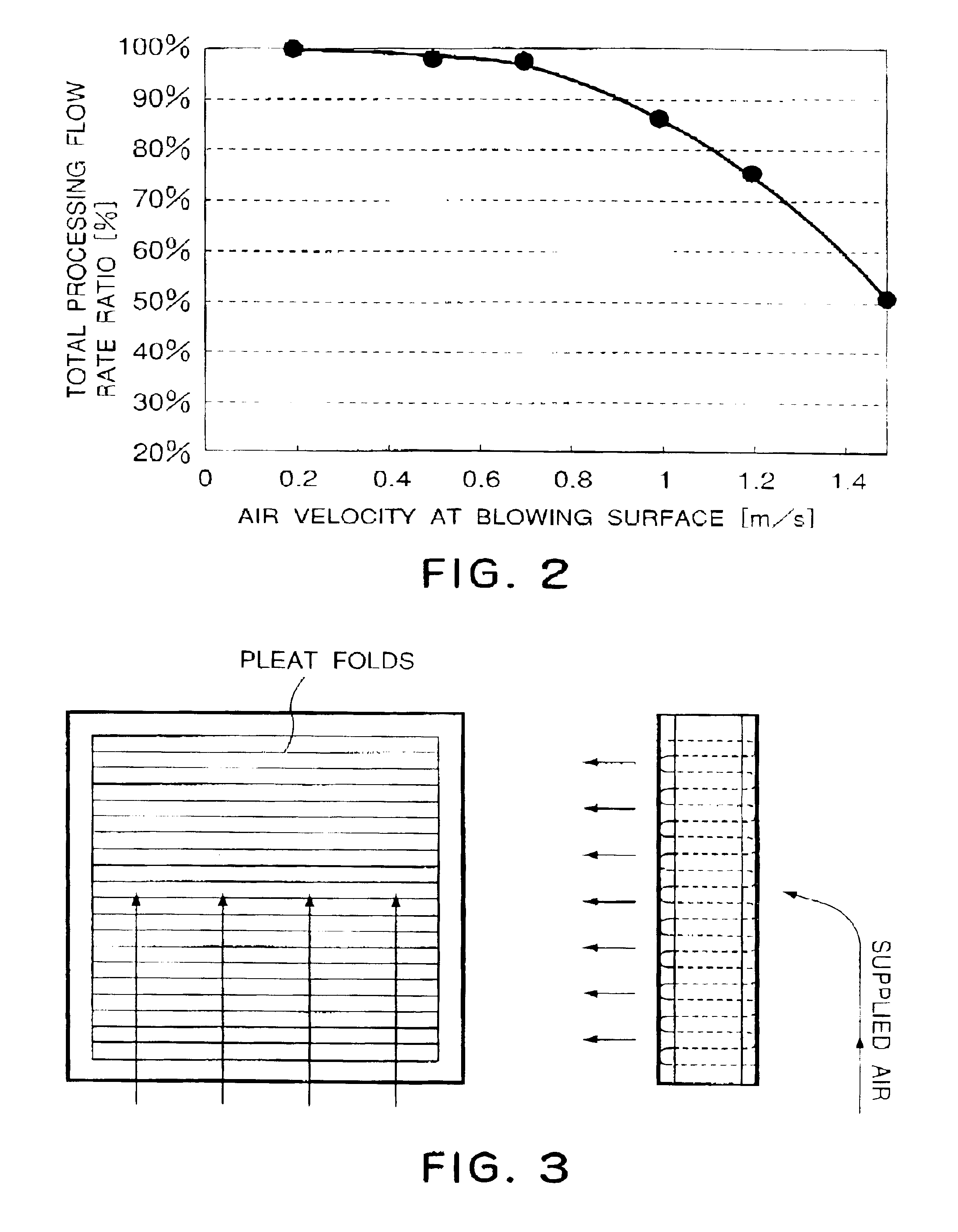

Chemical filter arrangement for a semiconductor manufacturing apparatus

InactiveUS6924877B2Efficient use ofReduced space requirementsMechanical apparatusGas treatmentManufactured apparatusDust particles

Disclosed is a semiconductor exposure apparatus which includes a chamber for accommodating therein a main unit of the exposure apparatus, a gas controlling unit for controlling a gas in the chamber, a chemical filter for attracting a chemical substance in a controlling gas, and a dust removing filter for catching a dust particle in a controlling gas, wherein a gas blowing area of the chemical filter is smaller than that of the dust removing filter, wherein said chemical filter and said dust removing filter are disposed separately from each other. The chemical filter is mounted obliquely with respect to a direction of flow of a supplied gas. A gas rectifying device is disposed at a gas inlet side of the chemical filter and the dust removing filter. The chemical filter can be a pleat filter, and it is mounted so that the pleat thereof is orthogonal to the direction of flow of the supplied air.

Owner:CANON KK

Method and composition for reducing contact lens swelling

InactiveUS20060135381A1Reduce drynessPreserve visual acuityCationic surface-active compoundsSenses disorderControlled releaseHigh concentration

The present invention is directed to an ophthalmic solution for soft contact lenses for controlled release of polyethers into an eye's tear film. Polyether components of the subject solution are released from the soft contact lens material matrix over long time periods to produce longer lasting wetting performance, improved lubricity, improved end-of-the-day comfort and reduced feeling of dryness from wearing contact lenses. The present invention also includes the use of cationic polyelectrolytes for controlling the swelling of hydrogel contact lenses typically caused by the absorption of high concentrations of polyethers.

Owner:BAUSCH & LOMB INC

Fuel cell performance recovery by cyclic oxidant starvation

InactiveUS6841278B2Improve regenerative abilityShorten the timeFuel cells groupingFuel cell auxillariesFuel cellsHydrogen

Performance of a fuel cell stack (12) is recovered following long term decay by connecting (51) an auxiliary load (50) to the fuel cell while shutting off one or more of oxidant inlet valve (27a), oxidant pressure regulating valve (28a) or oxidant pump (26), which all may be achieved with a controller (46), to cyclically starve the cathode of oxidant so that it achieves hydrogen potential, e.g., less than 0.1 volts, for on the order of tens of seconds, repetitively, such as at every 10 or 20 seconds, while the auxiliary load remains connected, initially drawing 10 to 100 mASC, for example. Complete rejuvenation is obtained following 1800 or more cycles over a period of five or more hours.

Owner:AUDI AG

Method for producing glass and plastic composite geogrid

InactiveCN102079136AHigh tensile strengthImprove deformation resistanceDomestic articlesGlass fiberYarn

The invention discloses a method for producing a glass and plastic composite geogrid, which is characterized by comprising the following steps of: a, mixing high-density polyethylene and an additive serving as raw materials; b, coating and mixing the raw materials through an extruder and glass fiber yarns by guide co-extrusion; c, forming a strip blank through a mold; d, stretching the strip blank; e, metering and coiling; f, fixing horizontal strips and vertical strips and performing stepping traction to form a geogrid network; and g, metering and winding. Compared with the prior art, the production method has the advantages of high strength, high toughness, high corrosion resistance and the like.

Owner:TAIAN ROAD ENG MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com