Stereoscopic meshed knitted fabric with unidirectional moisture guide function and production method thereof

A unidirectional moisture-guiding and three-dimensional mesh technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of single types of unidirectional moisture-guiding fabrics and few studies on unidirectional moisture-guiding weaving structures, and achieve effective control of human body heat and humidity Balanced, excellent water absorption and quick drying performance, long-lasting effect of wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Fabric name

[0031] 150D / 48F DTY (cross-section polyester yarn)+75D / 36F PP one-way moisture-wicking double-sided fabric

[0032] The fabric has a three-layer structure, the inner layer is a hydrophobic layer, which is a plain weave structure of 75D / 36F PP polypropylene yarn; the outer layer is a water-absorbing layer, which is a three-dimensional needle mesh structure of 150D / 48F DTY cross-section polyester yarn; the inner and outer layers Between is the moisture-wicking connection layer, which is 75D / 36F PP polypropylene yarn.

[0033] 2. The name of the yarn used

[0034] 150D / 48F DTY cross section polyester yarn; 75D / 36F PP polypropylene yarn

[0035] 3. Weaving process

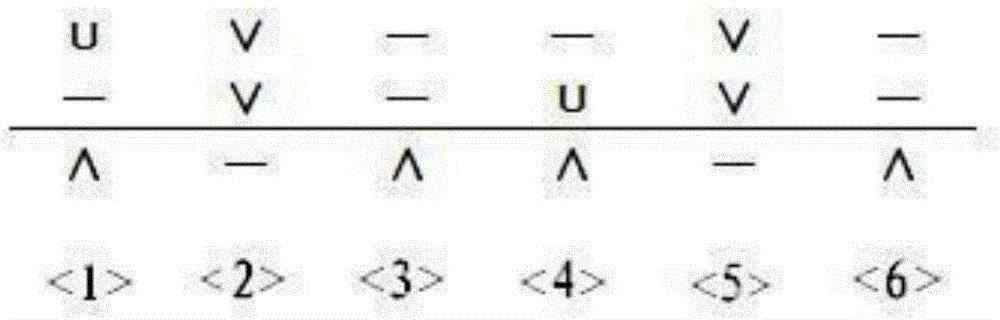

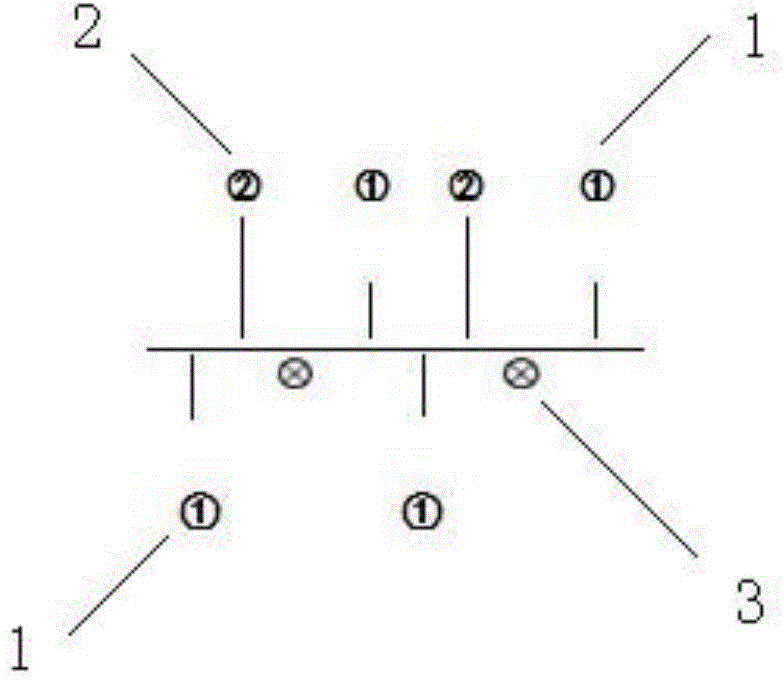

[0036] Choose the double-sided machine of Delo up472 model, the gauge is 24G needle cylinder, the diameter of the cylinder is 34", the ribbed needle configuration, the lower needle cylinder is 1 every 1 needle. The triangular arrangement method is as follows figure 1 As shown, knitting needl...

Embodiment 2

[0052] 1. Fabric name

[0053] 100D / 48F DTY (cross-section polyester yarn)+50D / 36F PP one-way moisture-wicking double-sided fabric

[0054] The fabric has a three-layer structure, the inner layer is a hydrophobic layer, which is a plain weave structure of 50D / 36F PP polypropylene yarn; the outer layer is a water-absorbing layer, which is a three-dimensional needle-drawing mesh structure of 100D / 48F DTY cross-section polyester yarn; the inner and outer layers Between is the moisture-wicking connection layer, which is 50D / 36F PP polypropylene yarn.

[0055] 2. The name of the yarn used

[0056] 100D / 48F DTY cross section polyester yarn; 50D / 36F PP polypropylene yarn

[0057] 3. Weaving process

[0058] Choose the double-sided machine of Delo up472 model, the gauge is 24G needle cylinder, the diameter of the cylinder is 34", the ribbed needle configuration, the lower needle cylinder is 1 every 1 needle. The triangular arrangement method is as followsfigure 1 As shown, knitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com