Alkaline storage battery

a storage battery and alkaline technology, applied in the direction of nickel accumulators, cell components, sustainable manufacturing/processing, etc., can solve the problems of reducing the operating voltage, unable to achieve high current discharge, and not recognizing the improvement of output characteristics, so as to accelerate the adsorption and desorption of hydrogen, and improve the high-output characteristics. , the effect of high output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

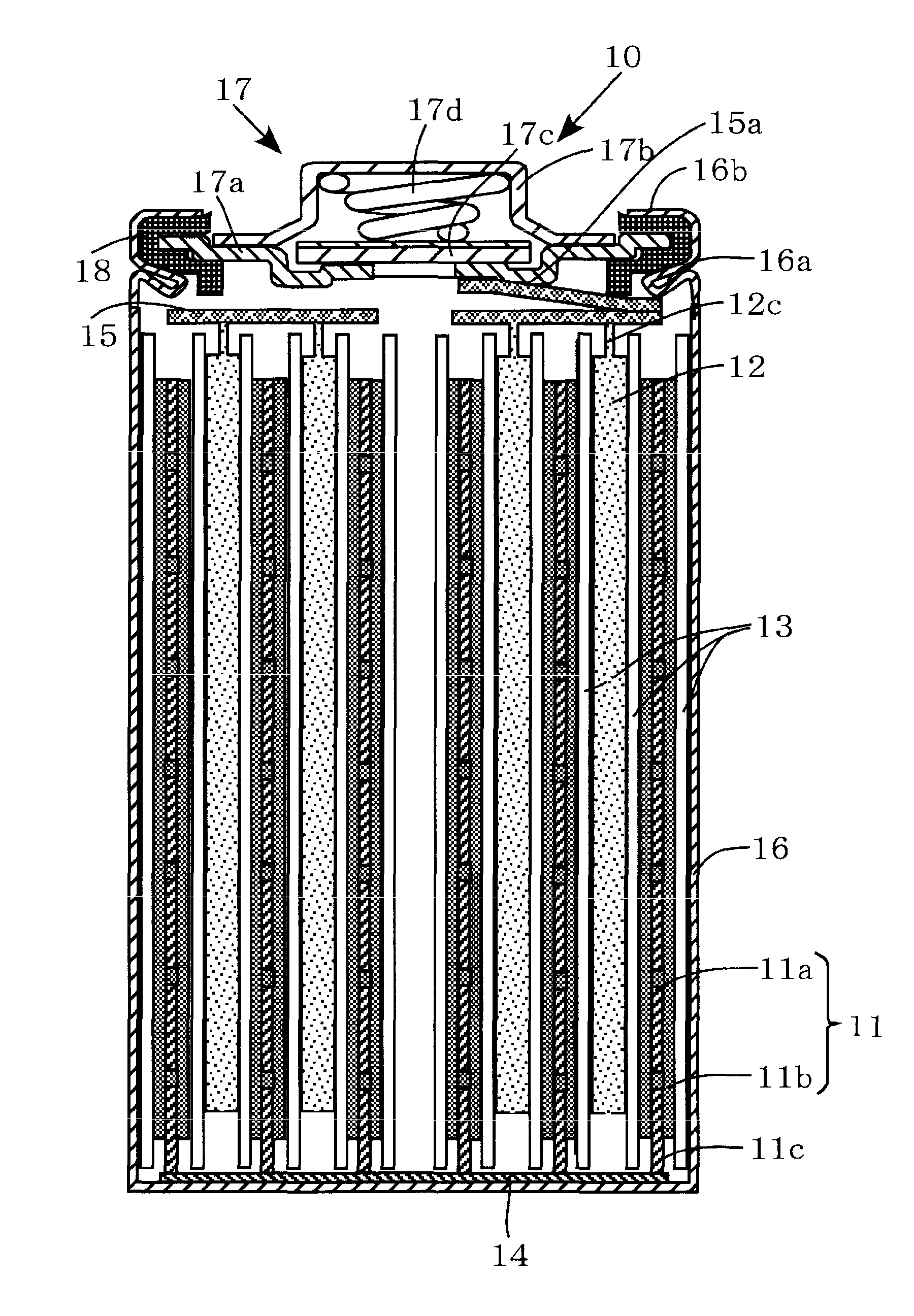

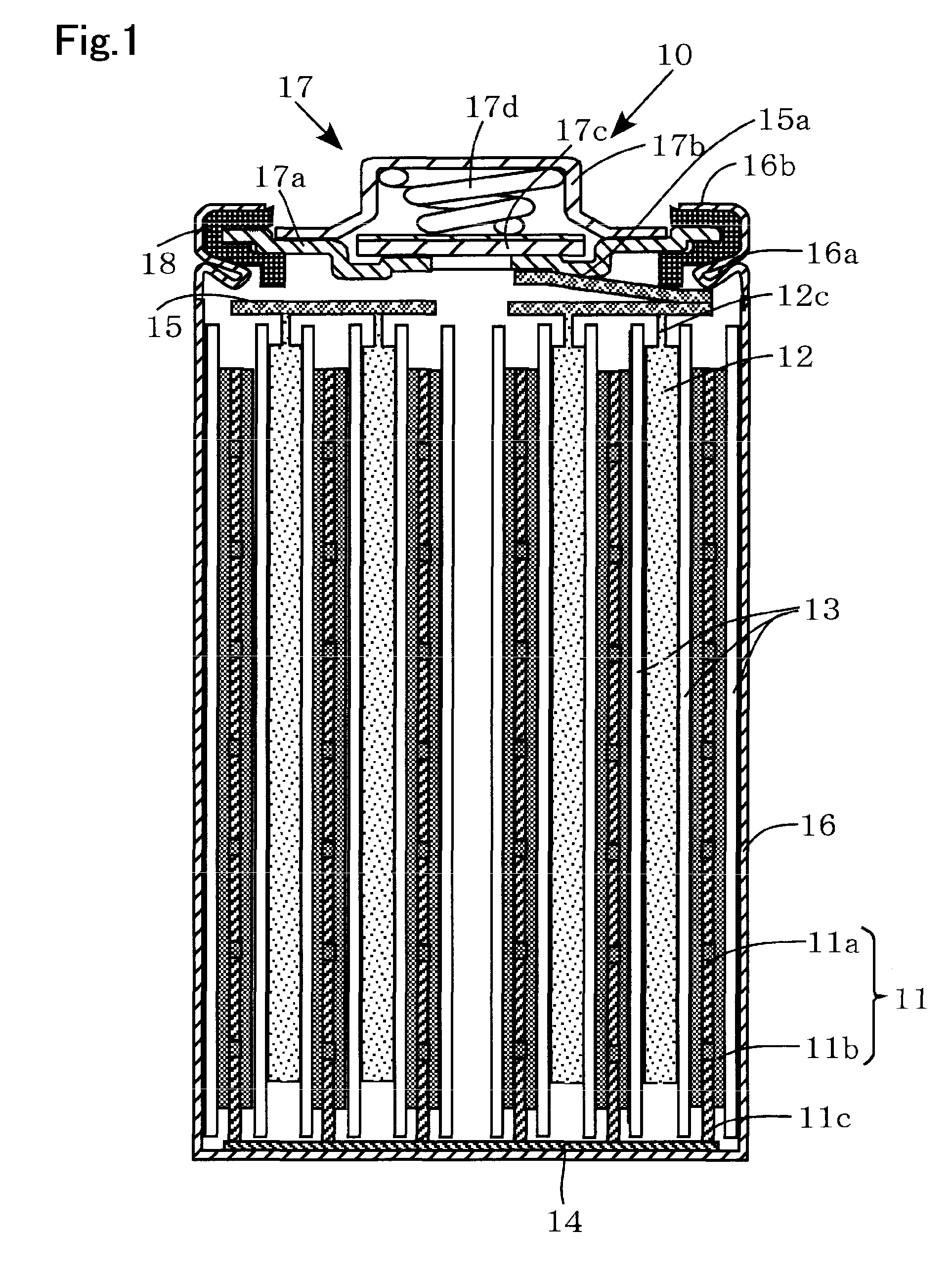

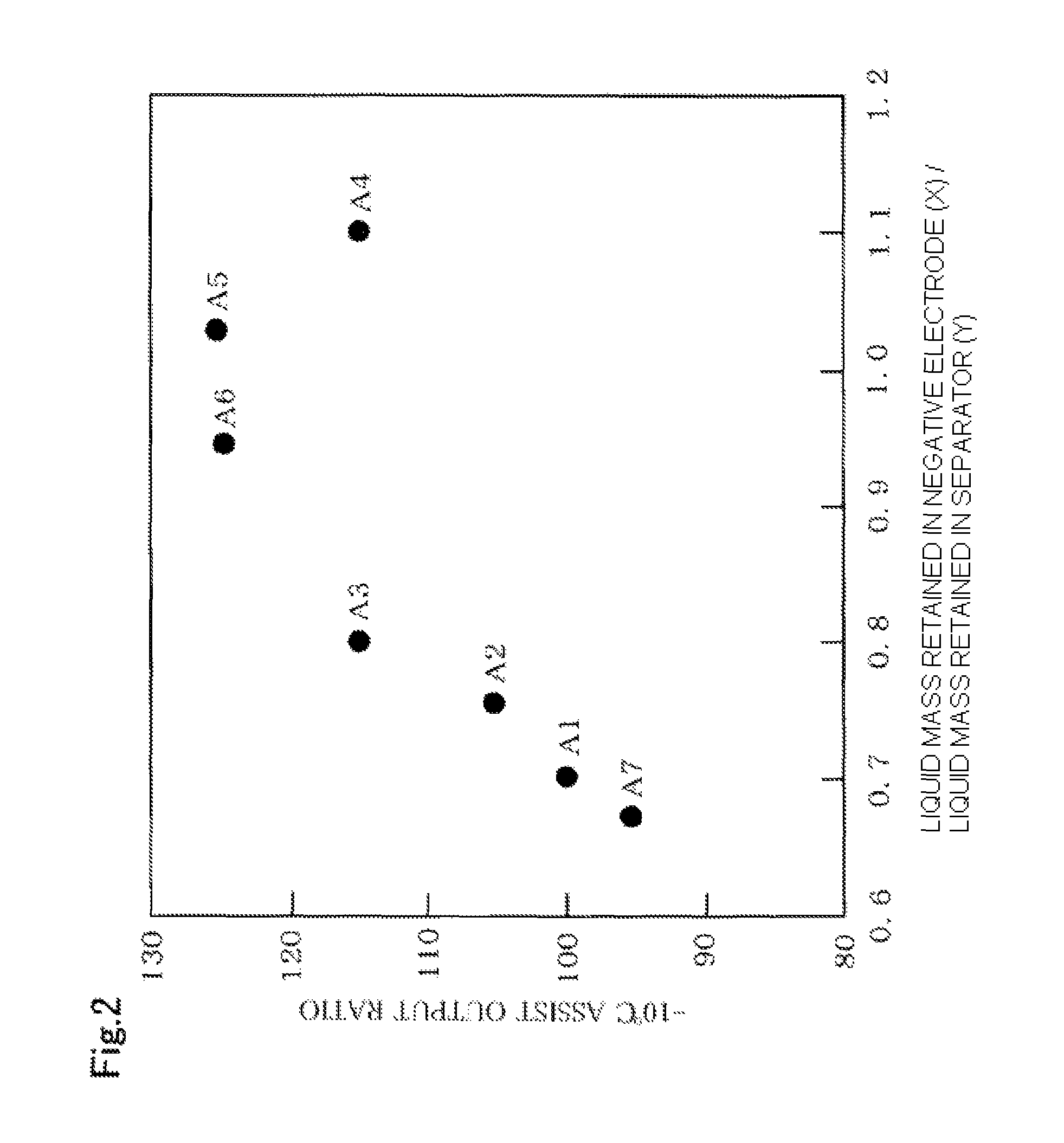

[0026]Next, the embodiments of the invention are described in detail as follows. However, the invention is not limited to these specific embodiments and, within the spirit and scope of the invention, various modifications and alterations may be made. FIG. 1 is a cross sectional view schematically showing an alkaline storage battery of the invention. FIG. 2 is a graph showing a relationship between a ratio (X / Y) of an electrolyte mass (X) retained to a negative electrode to an electrolyte mass (Y) retained to a separator and a −10° C. assist output ratio. FIG. 3 is a graph showing the relationship between a storage term and a residual capacity rate.

[0027]After mixing metal elements such as lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), magnesium (Mg), nickel (Ni), aluminum (Al), cobalt (Co), and manganese (Mn) to be a predetermined molar ratio specified in Table 1 below, these mixtures are put into a high-frequency induction furnace under an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| Tm | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com