Porous membrane for secondary battery, and secondary battery

A secondary battery and porous membrane technology, applied in the field of porous membranes, can solve problems such as explosion, and achieve the effect of improving output characteristics and long-term cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

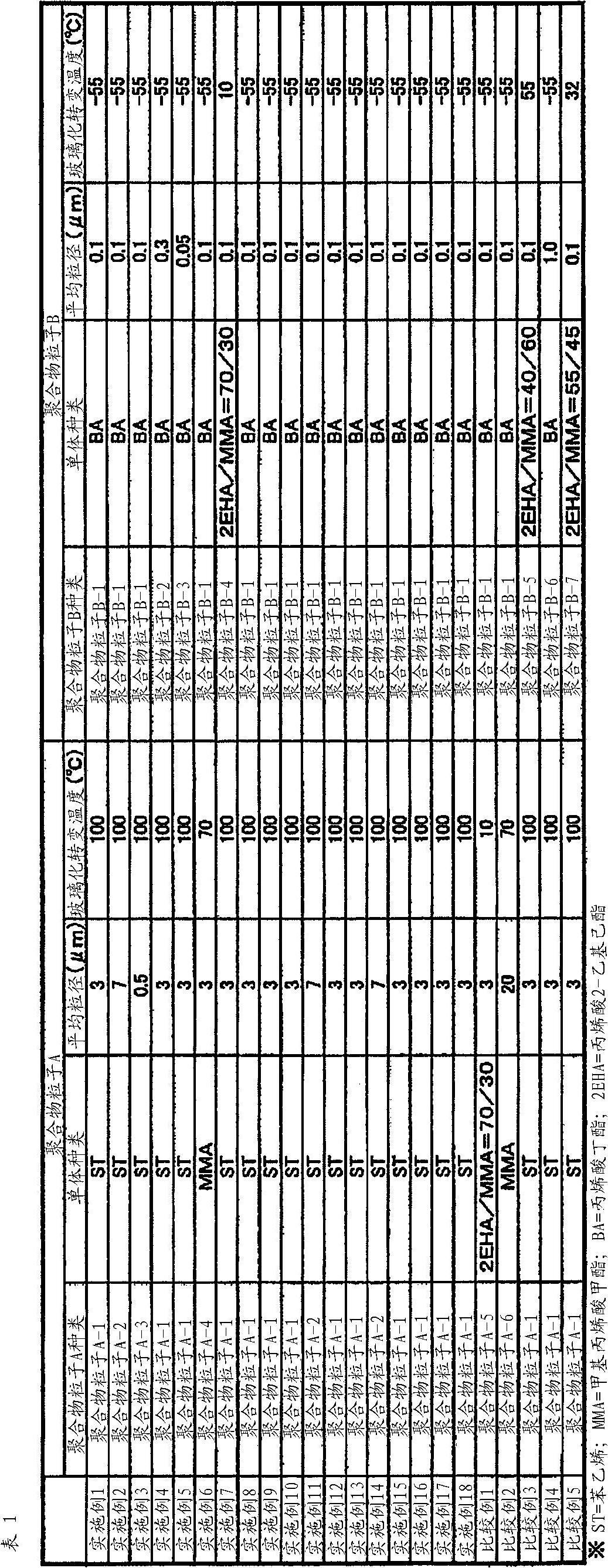

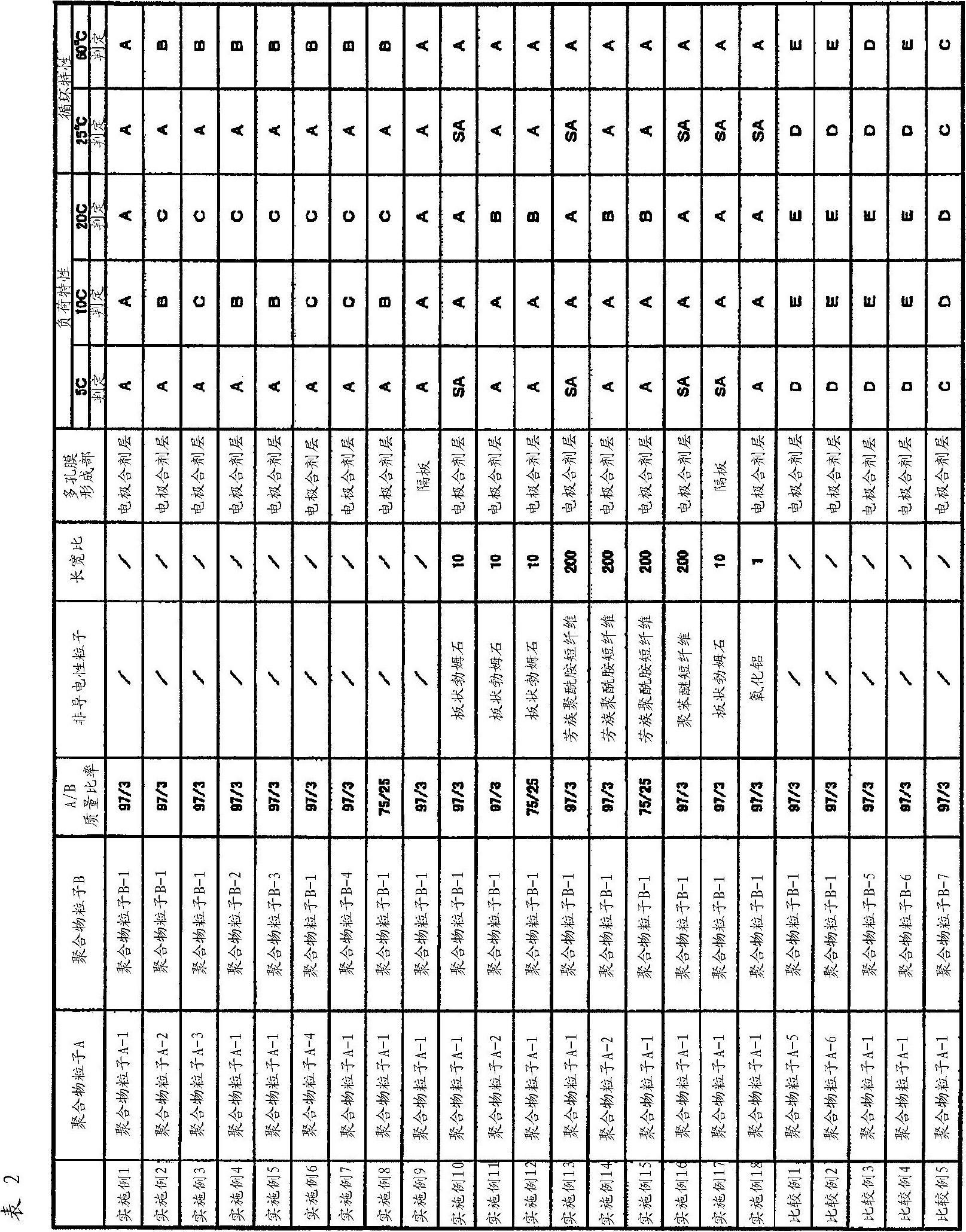

[0206] As the polymer particles A-1, polystyrene particles (PP-30-10 manufactured by Spherotech Corporation) having a number average particle diameter of 3 μm and a glass transition temperature of 100° C. were used.

[0207]

[0208] Add 12 parts of n-butyl acrylate, 0.12 parts of sodium lauryl sulfate, and 79 parts of ion-exchanged water into polymerization kettle A, add 0.2 parts of ammonium persulfate as a polymerization initiator, and 10 parts of ion-exchanged water, heat to 60°C and stir After 90 minutes, add 88 parts of n-butyl acrylate, 0.9 parts of sodium lauryl sulfate, and 46 parts of ion-exchanged water to other polymerization kettle B and stir, and add the prepared emulsion from polymerization kettle B to In the polymerization tank A, thereafter, stirring was performed for about 120 minutes, and when the monomer consumption reached 95%, the reaction was completed by cooling to obtain an aqueous dispersion of polymer particles B-1. The glass transition temperature...

Embodiment 2

[0220] As the polymer particles A, polystyrene particles (manufactured by Spherotech, PP-60-10, hereinafter sometimes referred to as "polymer particles A-2") with a glass transition temperature of 100° C. and a number average particle diameter of 7 μm were used. ), except that, in the same manner as in Example 1, the slurry for the porous membrane, the electrode with the porous membrane, and the coin-shaped lithium ion secondary battery were obtained, and the output characteristics and cycle characteristics were measured. The results are shown in Table 1.

Embodiment 3

[0222] As the polymer particles A, polystyrene particles with a glass transition temperature of 100° C. and a number average particle diameter of 0.5 μm (manufactured by Spherotech, PP-05-10, hereinafter sometimes referred to as “polymer particles A-3 "), except that, in the same manner as in Example 1, the slurry for the porous membrane, the electrode with the porous membrane, and the coin-type lithium ion secondary battery were obtained, and the output characteristics and cycle characteristics were measured. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com