Cantilever-type piezoelectric diaphragm pump

A diaphragm pump and cantilever technology, applied in the field of cantilever piezoelectric diaphragm pump, can solve the problems of small output amplitude, chemical damage, and high harmonic frequency, and achieve good output characteristics, excellent wear resistance, and low harmonic frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

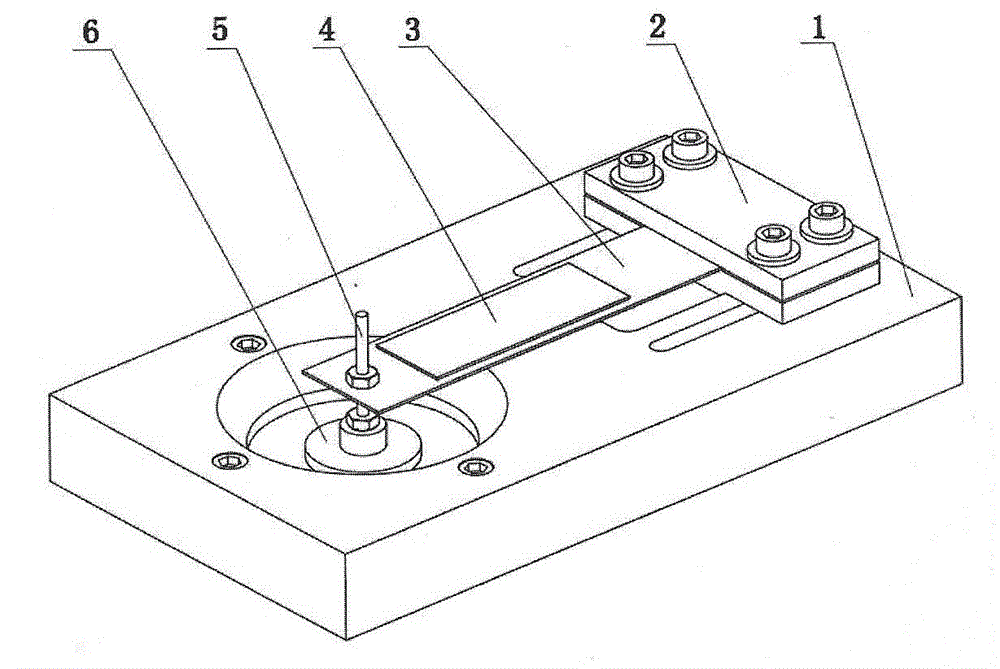

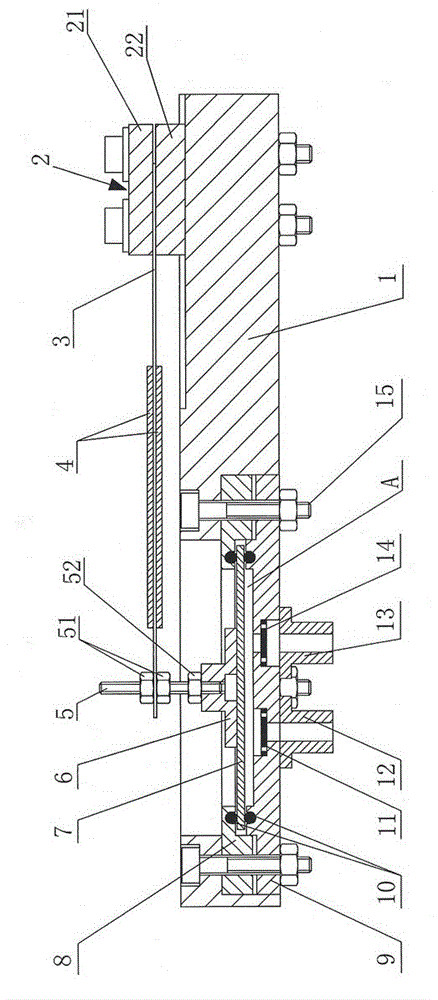

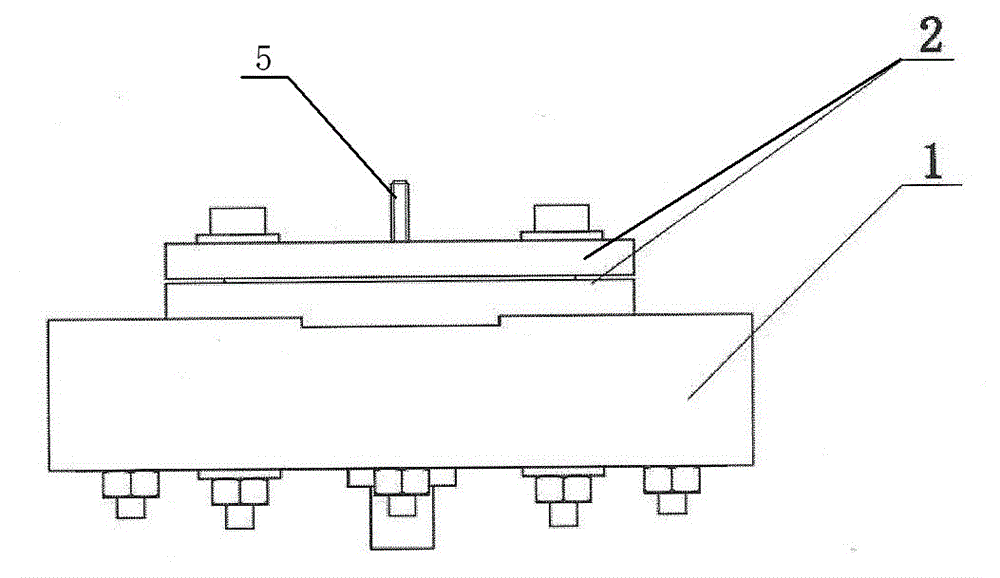

[0023] refer to Figure 1 to Figure 5 As shown, this embodiment is composed of an excitation unit, a pump cavity and a flow channel structure.

[0024] The vibration excitation unit is composed of a pump body 1, an adjustable compression mechanism 2, a piezoelectric vibrator, a vibration-transmitting piston 6 and a PET diaphragm 7. The pump body 1 is provided with a rectangular groove and a long hole for adjustable pressure. The tightening mechanism 2 is composed of an upper pressing block 21 and a lower pressing block 22. The boss at the bottom of the lower pressing block 22 is embedded in the rectangular groove on the pump body 1, and the adjustable pressing mechanism 2 can be moved left and right in the rectangular groove. Sliding, and can be fixed to a certain position of the pump body 1 through four bolts that pass through the long holes on the pump body 1; the piezoelectric vibrator is composed of a copper substrate 3 and a piezoelectric ceramic sheet 4, and the piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com