Barrier-property lapped polymer film packaging material

A polymer film and packaging material technology, which is applied in packaging, wrapping paper, flexible coverings, etc., can solve the problems that the performance of co-extrusion films cannot be continuously improved, the number of construction layers is high, and the number of layers of co-extrusion films is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

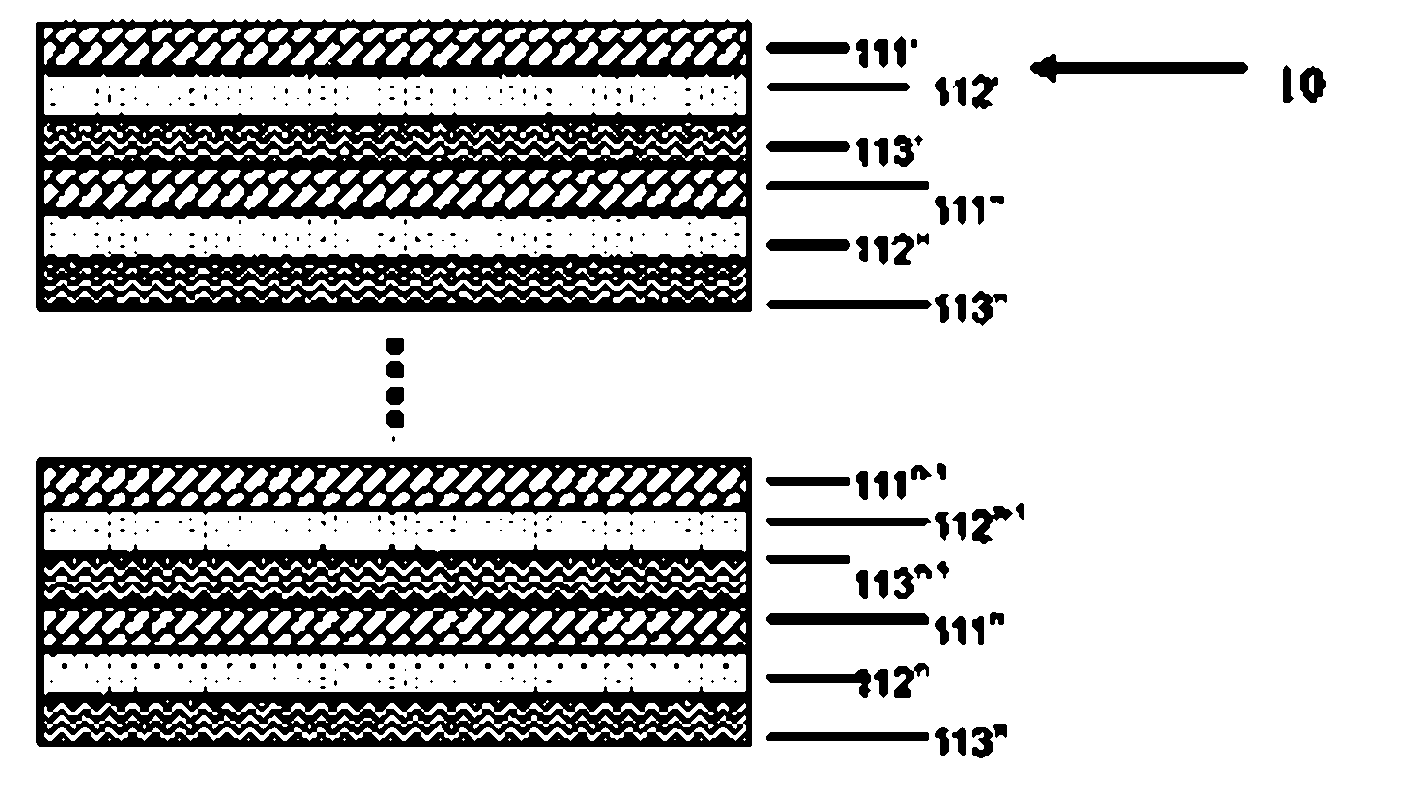

[0049] In this example, the packaging film comprises only one repeat unit of a layer multiplied extruded composite barrier layer comprising only three individual layers, of which only one barrier polymer is composed. In repeating units, one individual layer corresponds to a barrier polymer composition A of extrusion grade ethylene-vinyl alcohol copolymer (EVOH), and one individual layer corresponds to a non-barrier polymer composition B of 95 wt% low density polyethylene and 5wt% maleic anhydride-modified low-density polyethylene blend (LDPE+maLDPE), one individual layer corresponds to non-barrier polymer composition C is ethylene-acrylic acid copolymer (EAA), and the repeating unit structure is B / A / C.

[0050] Three single-screw extruders provide molten material flow to a three-channel feed head, and the initial layered material flow with a repeating unit structure passes through eight double-layer multipliers connected in series from end to end. The total number of layers o...

Embodiment 2

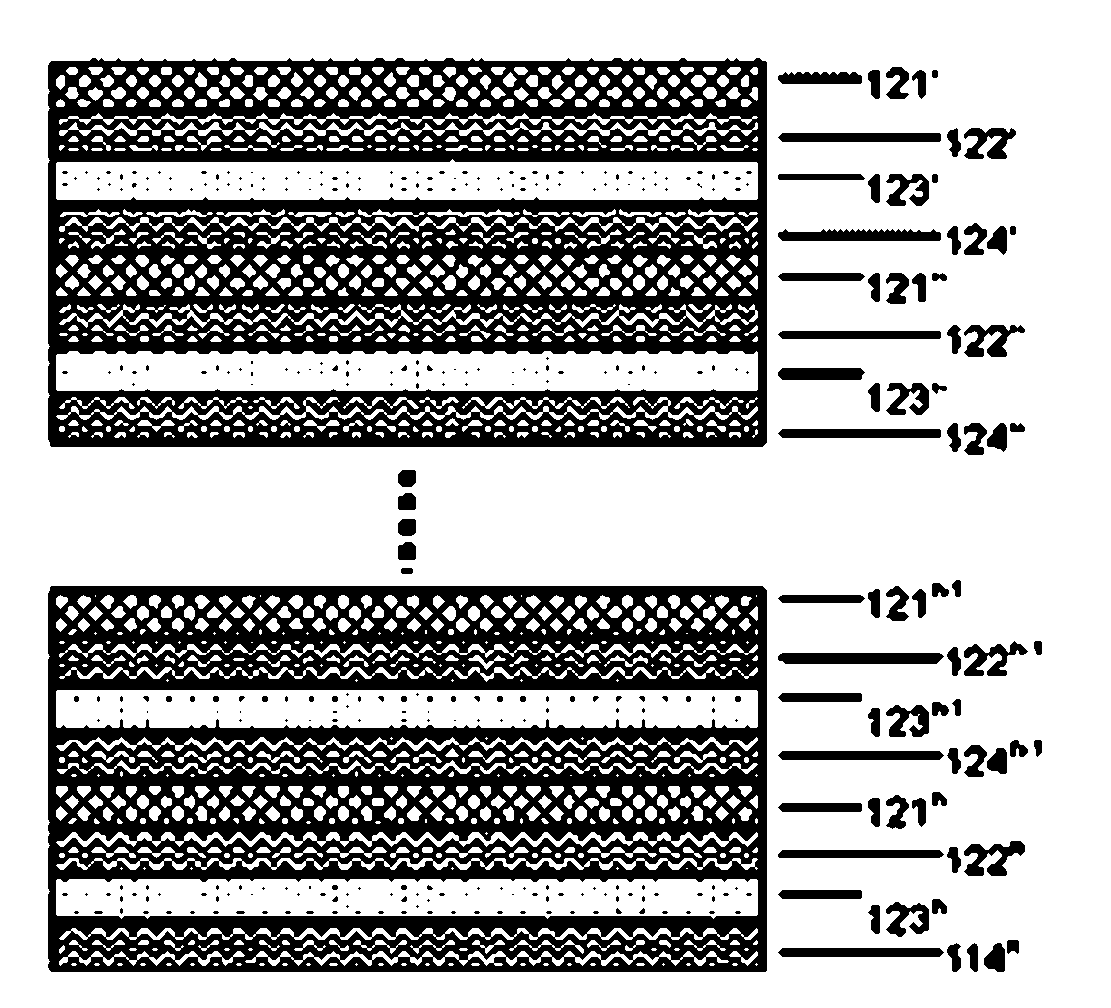

[0053] In this example, only one layer multiplied extruded barrier composite layer is included in the packaging film material, where the repeat unit has four individual layers, but only three polymer compositions with only one barrier composition. One barrier individual layer corresponds to polymer composition A of 5 wt% nanoclay-filled nylon 6, and the two non-barrier individual layers correspond to polymer composition B of 97 wt% polypropylene and 3 wt% maleic anhydride-modified polypropylene The mixture of a non-barrier individual layer corresponds to a polymer composition C of metallocene low-density polyethylene, and a repeating unit structure of C / B / A / B.

[0054]Three single-screw extruders and a two-way splitter provide molten material flow to a four-channel feed head, and the initial layered material flow with repeating unit structure passes through 7 double-layer multipliers in series. The total number of composite barrier layers The number of layers is 512; finally, ...

Embodiment 3

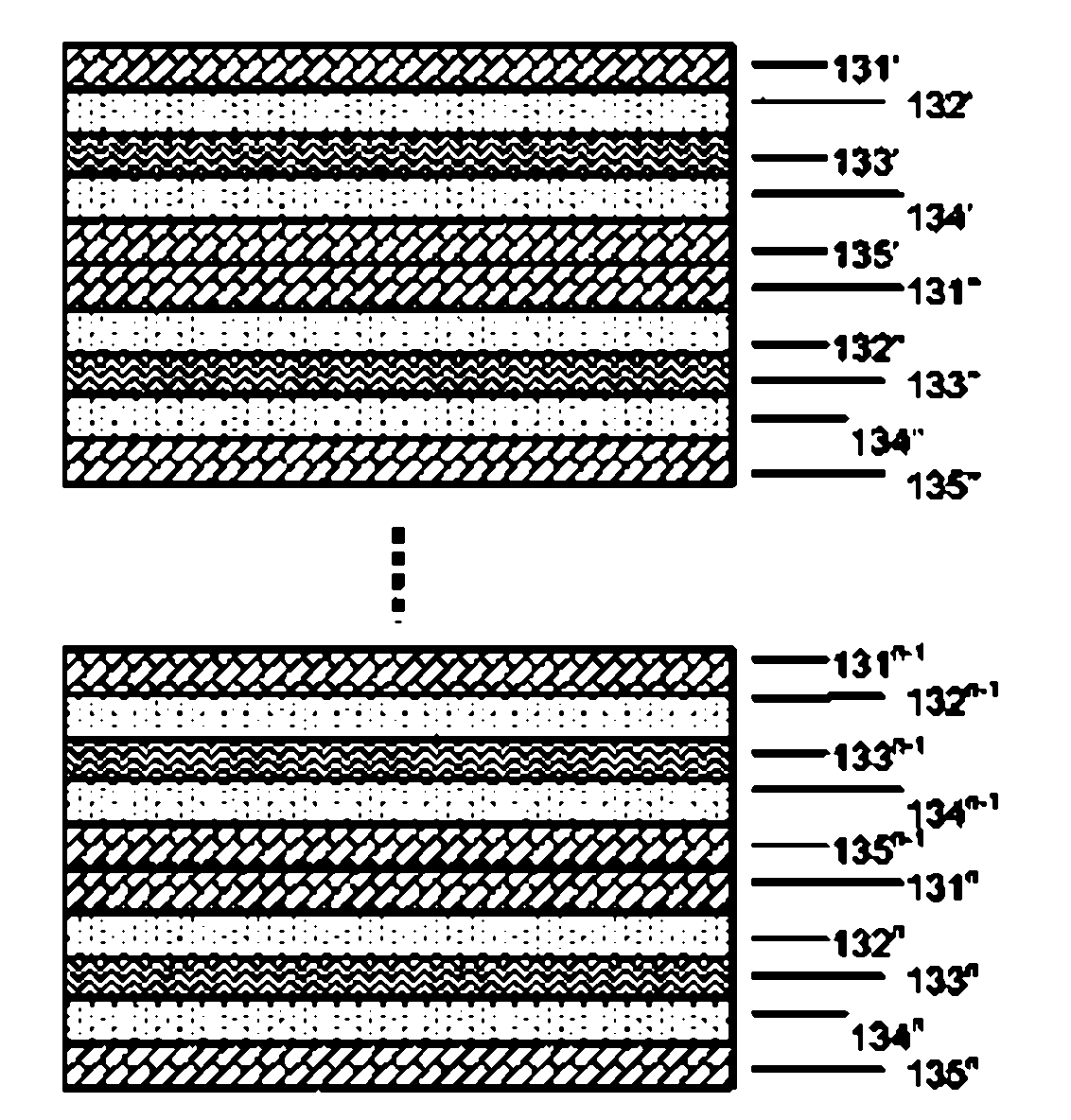

[0056] In this example, only one layer multiplied extruded barrier composite layer was included in the packaging film, where the repeat unit had five individual layers, but only three polymer compositions and only one barrier composition among them. Among the five individual layers, the barrier polymer composition A corresponding to one barrier individual layer is polyvinylidene chloride (PVDC), and the non-barrier polymer composition B corresponding to the two non-barrier individual layers is polyester polyurethane, The non-barrier polymer composition corresponding to the two non-barrier individual layers C is a biopolyester hydroxybutyrate-hydroxyvalerate copolymer (PHBV), which is laminated into repeating units in a C / B / A / B / C structure .

[0057] Three single-screw extruders and two bidirectional splitters provide molten streams to a five-channel feed head, and the initial stacked streams with repeating unit structures pass through 7 double-layer multipliers in series, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com