Ethylene-vinyl alcohol resin composition, multilayer structure, multilayer sheet, container, and packaging material

一种树脂组合物、乙烯醇的技术,应用在运输和包装、合成树脂层状产品、包装等方向,能够解决树脂组合物耐蒸煮性外观不良、无法实现降低效果等问题,达到连续制造运转时间延长、耐蒸煮性优异、外观性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

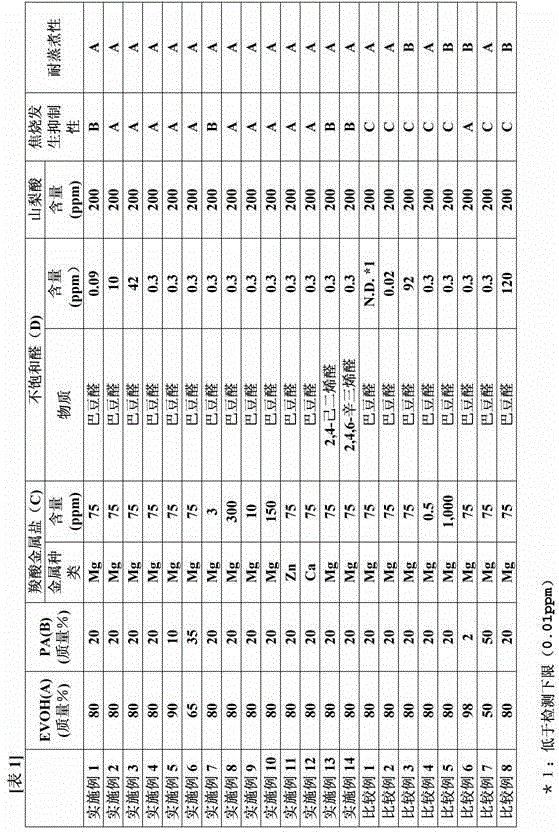

[0159] The following examples illustrate the present invention in detail, but the present invention is not limited by these examples. It should be noted that each quantification in this example was carried out by the following method.

[0160] [Ethylene content and degree of saponification of EVOH(A)]

[0161] Using a nuclear magnetic resonance apparatus ("JNM-GX-500 type", manufactured by JEOL Ltd.), DMSO-d 6 As a measurement solvent, by 1 Calculated by H-NMR.

[0162] [Quantification of unsaturated aldehyde (D)]

[0163] Add 50 mL of 1,1,1,3,3,3-hexafluoroisopropanol (HFIP), 11.5 mL of acetic acid and 8 mL of ion-exchange water to prepare a DNPH solution. 1 g of the measurement particles was added to 20 mL of the DNPH solution, and stirred at 35° C. for 1 hour to dissolve. Acetonitrile was added to the solution to separate out and precipitate the resin components, and then filtered, and the resulting solution was concentrated to obtain an extraction sample. The unsatu...

Synthetic example 1

[0169] Using a 250 L pressurized reaction tank, polymerization was carried out under the following conditions to synthesize an ethylene-vinyl acetate copolymer. the

[0170] (addition amount)

[0171] Vinyl acetate: 83.0kg

[0172] Methanol: 17.4kg

[0173] 2,2'-azobisisobutyronitrile: 66.4g

[0174] (aggregation condition)

[0175] Polymerization temperature: 60 ℃

[0176] Polymerization tank ethylene pressure: 3.9MPa

[0177] Polymerization time: 3.5 hours.

[0178] The polymerization rate of vinyl acetate in the above polymerization was 36%. Sorbic acid is added to the resulting copolymerization reaction solution, and then supplied to a displacement column (purchase column), and methanol vapor is introduced from the lower part of the column to remove unreacted vinyl acetate from the top of the column to obtain ethylene-vinyl acetate copolymerization 41 mass % methanol solution of the compound. The ethylene content of this ethylene-vinyl acetate copolymer was 32 mol...

Synthetic example 2

[0181] During the above-mentioned polymerization, crotonaldehyde was supplied so as to contain 0.5 ppm with respect to EVOH (A), and polymerization, saponification, granulation, and washing were carried out in the same manner as in Synthesis Example 1 to obtain granules. The saponification degree of the obtained EVOH (A) was 99.95 mol%.

[0182]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com