Composite film

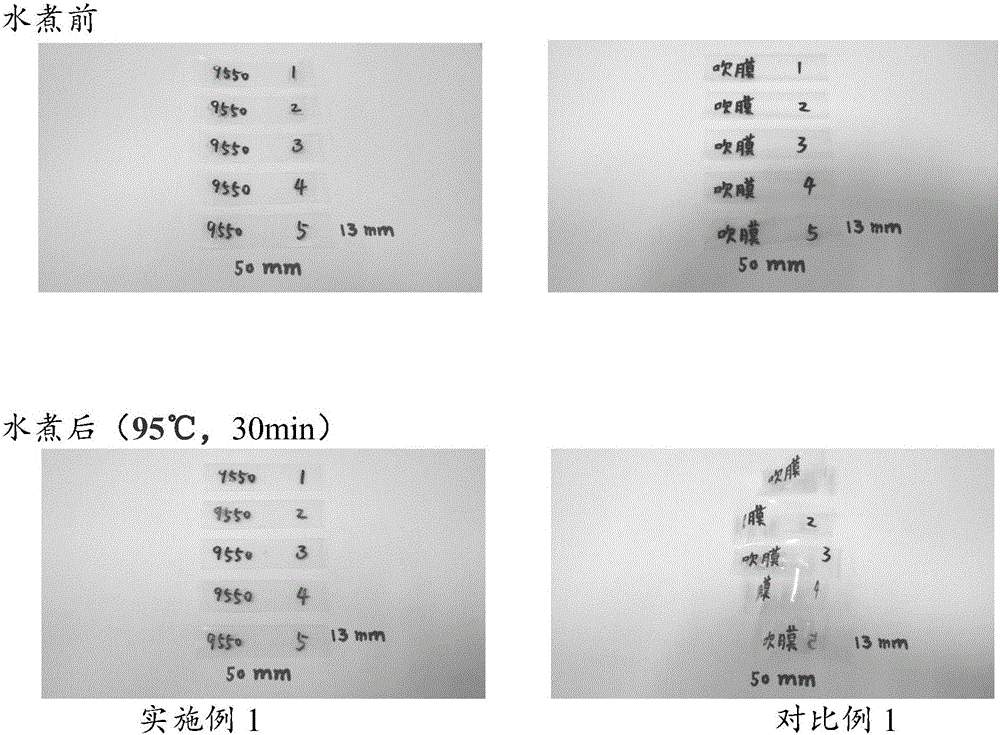

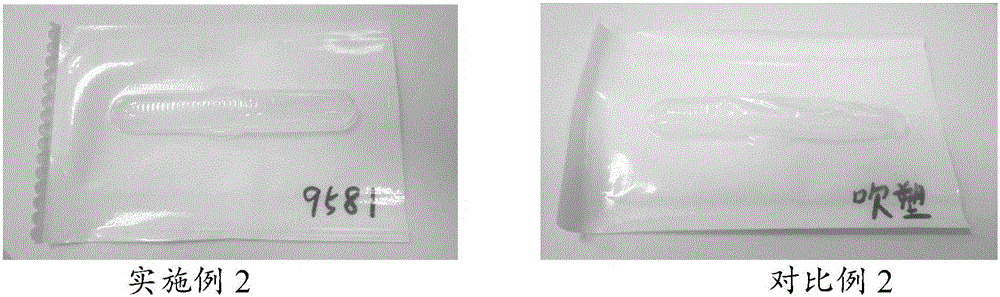

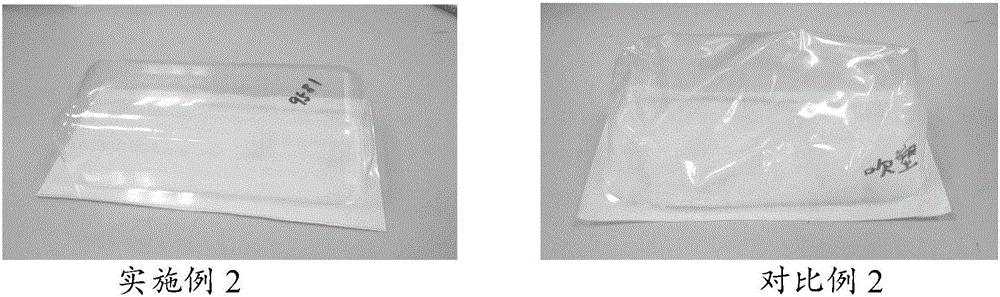

A composite film and cast film technology, applied in the field of composite films, can solve the problems of reducing the barrier properties of composite films, low transparency, unsatisfactory stretch formability and retort resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation method of composite membrane

[0034] In a preferred embodiment, the method of the present invention provides a method for preparing a composite film, comprising the step of laminating at least one layer of cast film and at least one layer of blown film through an adhesive.

[0035] The composite film according to the present invention can be prepared by any appropriate method, for example, by die co-extrusion, film extrusion lamination, adhesive compounding and other methods.

[0036] In order to maximize the advantages of the composite film according to the present invention, the composite film of the present invention can be prepared by, but not limited to, a method comprising the following steps: uniformly coating the adhesive on the casting film, the blown film On the surface to be bonded of the film or both, the surface to be bonded is placed opposite, and the adhesive is cured after rolling and flattening.

[0037] In one embodiment of the present ...

Embodiment

[0047] Some specific implementations of the present invention are explained below in conjunction with examples, so that those skilled in the art can more clearly understand the technical solutions and advantages of the present invention, but do not limit the present invention in any way.

[0048] 1. Materials

[0049] Comparative and Example samples of composite membranes were prepared using the following materials.

[0050]

[0051] 2. Preparation of Composite Membrane

Embodiment 1

[0056] A ReifenHouser SW2200 multilayer coextrusion blown film equipment was used to prepare a PE / PA / EVOH / PA / PE multilayer coextrusion film with a thickness of 58 μm, in which a Bemis adhesive connection layer was used between PE and PA. The die head temperature of the PE layer is 220°C, and the pulling speed is 5.5-8m / min. The die head temperature of the PA layer is 240°C, and the pulling speed is 8-12m / min. The die head temperature of the EVOH layer is 240°C, and the pulling speed is 5-12m / min. The structure of the coextruded film and the composition and thickness of each layer are as follows:

[0057] Raw material composition Thickness (μm) level one PE 23 Second floor Adhesive 2 the third floor PA 2 fourth floor EVOH 4 fifth floor PA 2 sixth floor Adhesive 2 seventh floor PE 23

[0058] Using Taiwan Sanxia DL-S1300 dry compound machine, the PP casting film with a thickness of 60 μm and the first la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com