Preparation method of polyacrylate microgel emulsion and application thereof

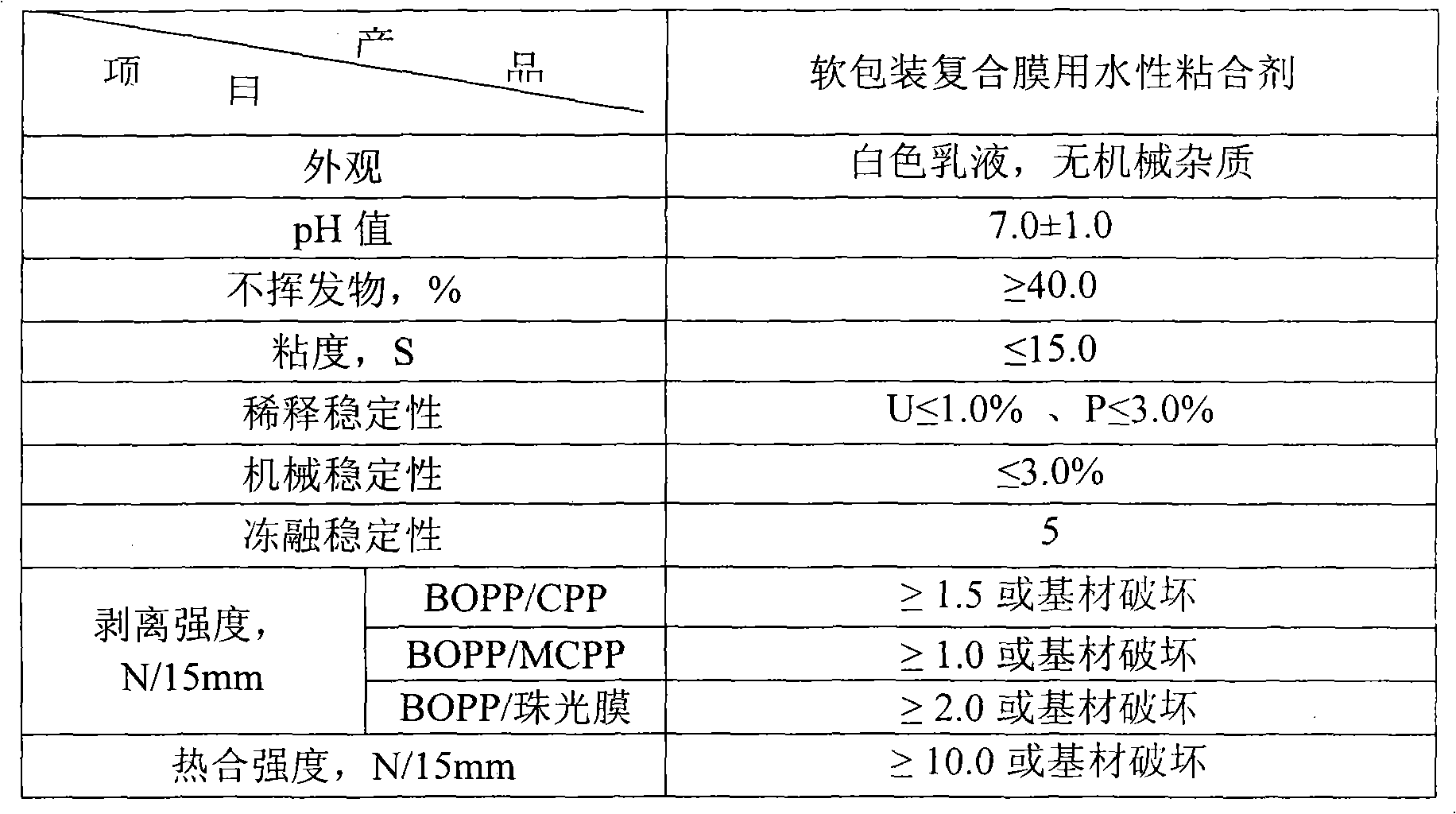

A technology of polyacrylate and microgel, which is applied in the field of polymers, can solve the problems of low peel strength, slow drying speed, and poor medium resistance of composite products, and achieve the effects of improving heat resistance, drying speed, and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present embodiment provides a kind of preparation method of polyacrylate microgel emulsion, it comprises the following steps:

[0054] 1. Pre-emulsification: Weigh 200-250 parts of deionized water, mix 1 / 3-2 / 3 of the total amount of deionized water, 100 parts of mixed monomer (long-chain flexible monomer: 75 parts of butyl acrylate, functional Monomer: 7.2 parts of hydroxyethyl acrylate, 1.2 parts of acrylic acid, 0.3 parts of epoxy monomer, multi-functional monomer: 0.1 part of divinylbenzene), 0.1 part of reactive emulsifier into the emulsification kettle, and stir at high speed , pre-emulsified for 10 to 30 minutes to obtain an emulsion.

[0055] 2. Seed polymerization: Add 20% to 40% of the remaining deionized water and 0.1 part of nonionic emulsifier in the reactor, stir and heat until the temperature reaches 60°C, add initiator a (component: K 2 S 2 o 8 0.12 parts, H 2 (26 parts) When the temperature reaches 75°C, quickly add 20% to 40% of the pre-emulsio...

Embodiment 2

[0062] This embodiment provides a preparation method of polyacrylate microgel emulsion, and its manufacturing steps are basically the same as in Example 1, the difference being that the raw materials of the polyacrylate microgel emulsion prepared in this embodiment consist of:

[0063] Butyl acrylate 75 parts

[0064] 10 parts of hydroxyethyl acrylate

[0065] Acrylic acid 1.5 parts

[0066] Epoxy functional monomer 0.6 parts

[0067] 2 parts divinylbenzene

[0068] Reactive emulsifier 0.15 parts

[0069] Non-ionic emulsifier 0.1 parts

[0070] 220 parts of deionized water

[0071] PH regulator 0.02 parts

[0072] The raw material component of described free radical initiator comprising initiator a, initiator b is:

[0073] K 2 S 2 o 8 0.15 copies,

[0074] h 2 O 7.5 servings

[0075] Initiator b

[0076] 0.15 parts of tert-butyl hydroperoxide

[0077] h 2 O 5 copies

[0078] The effect of this embodiment is the same as that of Em...

Embodiment 3

[0080] This embodiment provides a preparation method of polyacrylate microgel emulsion, and its manufacturing steps are basically the same as in Example 1, the difference being that the raw materials of the polyacrylate microgel emulsion prepared in this embodiment consist of:

[0081] Butyl acrylate 75 parts

[0082] 15 parts of hydroxyethyl acrylate

[0083] Acrylic acid 2.4 parts

[0084] Epoxy functional monomer 0.6 parts

[0085] 0.7 parts of divinylbenzene

[0086] Reactive emulsifier 0.15 parts

[0087] Non-ionic emulsifier 0.1 parts

[0088] 250 parts of deionized water

[0089] PH regulator 0.02 parts

[0090] The raw material component of described free radical initiator comprising initiator a, initiator b is:

[0091] K 2 S 2 o 8 0.15 copies,

[0092] h 2 O 7.5 servings

[0093] Initiator b

[0094] 0.15 parts of tert-butyl hydroperoxide

[0095] h 2 O 5 copies

[0096] The effect of this embodiment is the same as that of E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com