Self-crosslinking waterborne wood lacquer emulsion and preparation method thereof

A water-based wood paint, self-crosslinking technology, applied in the direction of coating, can solve problems such as fire hazards, environmental pollution, harm to human health, etc., to achieve the effect of improving hot stickiness and cold brittleness, good UV resistance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

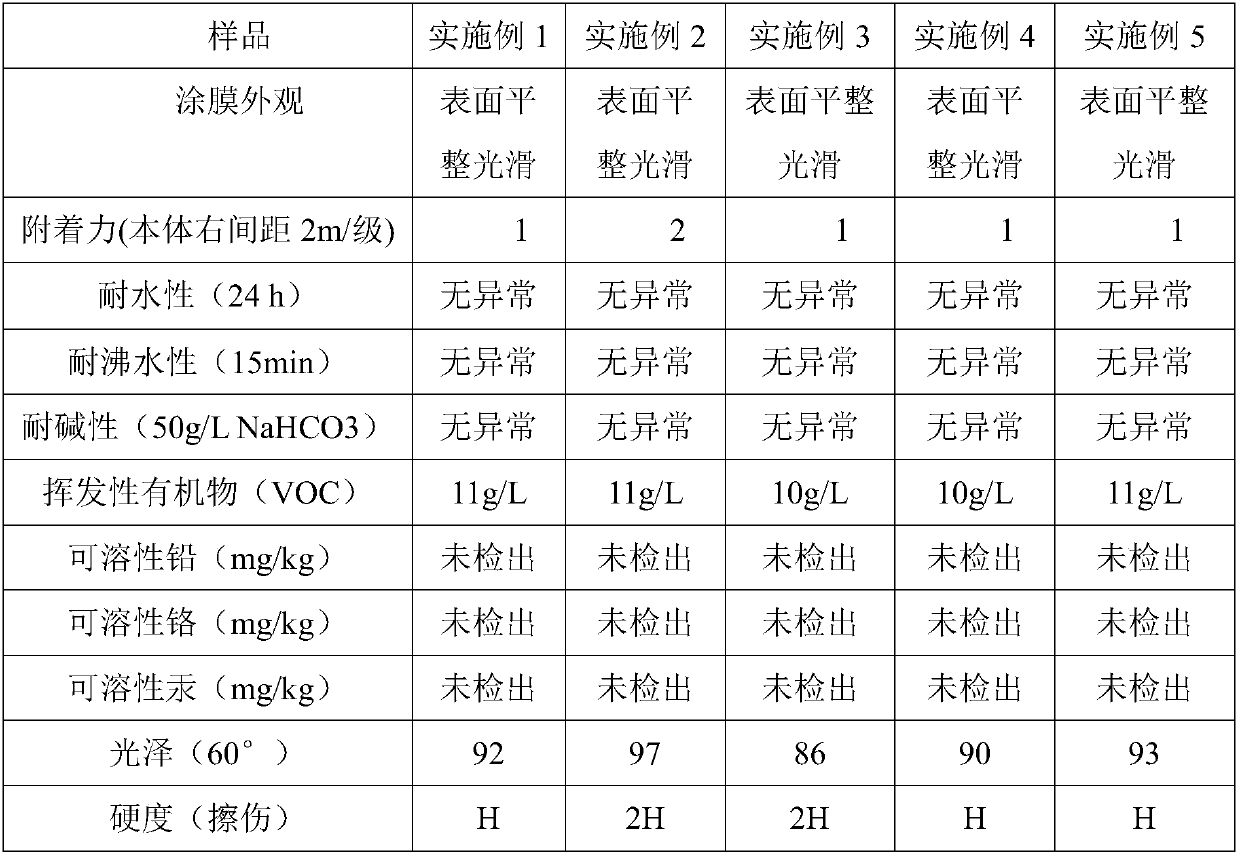

Examples

Embodiment 1

[0023] The self-crosslinking water-based wood paint emulsion of this embodiment includes the following raw materials in parts by weight: 20 parts of modified acrylic emulsion, 25 parts of filler, 3 parts of sodium lauryl sulfate, 2 parts of nonylphenol polyoxyethylene ether, film-forming assistant 2 parts of agent, 1 part of defoamer;

[0024] Among them, the modified acrylic emulsion is a silica sol modified acrylic emulsion and a silicone modified acrylic emulsion according to the mass ratio of 1-3:1.3-2, and the silicone modified acrylic emulsion is a mixture of silane coupling agent, acrylic acid and pure water, Place in an ultrasonic disperser with a frequency of 35khz, a power of 500w, and ultrasonically disperse for 5 minutes to obtain a silicone-modified acrylic emulsion; the method for modifying the acrylic emulsion with silica sol is: disperse nano-silica particles in deionized water at high speed, Obtain silica sol, then add acrylic acid, disperse evenly, obtain sil...

Embodiment 2

[0031] The present embodiment self-crosslinking water-based wood paint emulsion includes the following raw materials in parts by weight: 40 parts of modified acrylic emulsion, 45 parts of filler, 8 parts of sodium lauryl sulfate, 6 parts of nonylphenol polyoxyethylene ether, film-forming assistant 5 parts of agent, 3 parts of defoamer;

[0032] Among them, the modified acrylic emulsion is a silica sol modified acrylic emulsion and a silicone modified acrylic emulsion according to the mass ratio of 1-3:1.3-2, and the silicone modified acrylic emulsion is a mixture of silane coupling agent, acrylic acid and pure water, Place in an ultrasonic disperser with a frequency of 40khz, a power of 800w, and ultrasonically disperse for 15 minutes to obtain a silicone-modified acrylic emulsion; the method for modifying the acrylic emulsion with silica sol is: disperse nano-silica particles in deionized water at high speed, Obtain silica sol, then add acrylic acid, disperse evenly, obtain s...

Embodiment 3

[0039] The self-crosslinking water-based wood paint emulsion of this embodiment includes the following raw materials in parts by weight: 30 parts of modified acrylic emulsion, 35 parts of filler, 6 parts of sodium lauryl sulfate, 4 parts of nonylphenol polyoxyethylene ether, film-forming assistant 3 parts of agent, 2 parts of defoamer;

[0040]Among them, the modified acrylic emulsion is a silica sol modified acrylic emulsion and a silicone modified acrylic emulsion according to the mass ratio of 1-3:1.3-2, and the silicone modified acrylic emulsion is a mixture of silane coupling agent, acrylic acid and pure water, Place in an ultrasonic disperser with a frequency of 38khz, a power of 650w, and ultrasonically disperse for 10 minutes to obtain a silicone-modified acrylic emulsion; the method for modifying the acrylic emulsion with silica sol is: disperse nano-silica particles in deionized water at high speed, Obtain silica sol, then add acrylic acid, disperse evenly, obtain si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com