Water-based paint for surface of pop-top can and preparation method of water-based paint

A technology for water-based coatings and cans, applied in the direction of coatings, etc., can solve the problems of insufficient retort resistance and wear resistance, and achieve the effect of excellent retort resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

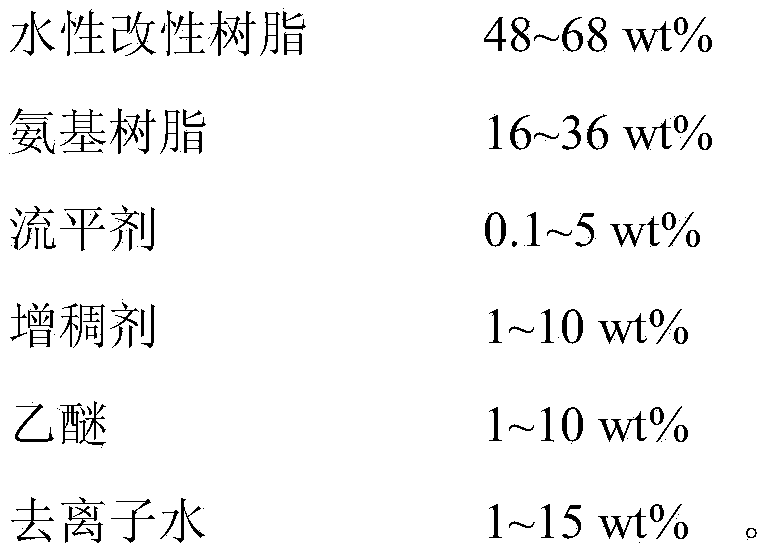

Method used

Image

Examples

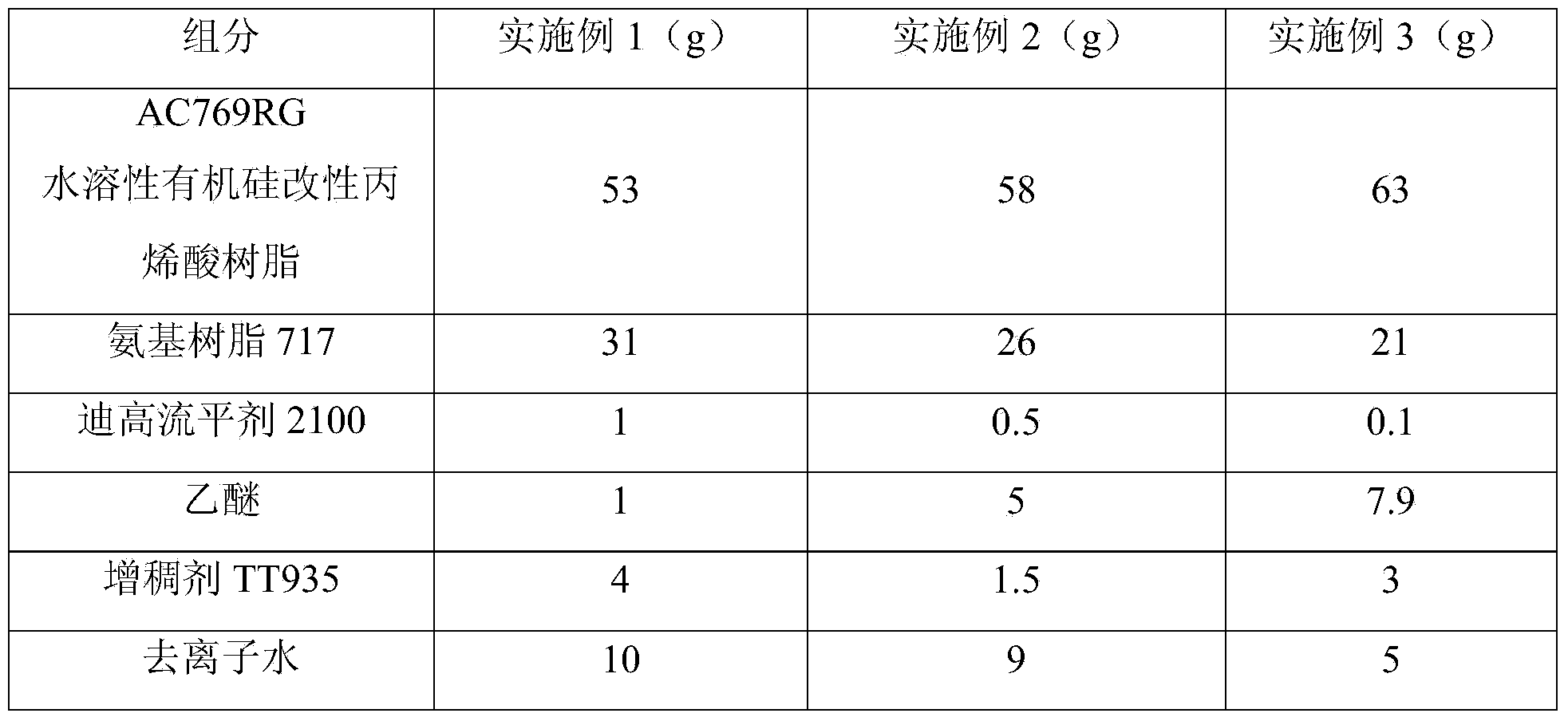

Embodiment 1~3

[0020]

[0021] 2. Preparation of water-based paint: water-based modified resin (AC769RG water-soluble silicone modified acrylic resin), amino resin (amino resin 717), leveling agent (Digo leveling agent 2100), thickener (thickener TT935 ), diethyl ether and deionized water were mixed and stirred for 30-50 minutes.

[0022] 3. Construction process: First, stir the prepared paint for 30 minutes, and let it stand for 20 minutes until the bubbles are completely eliminated; then place the prepared sample, start the paint roller coating device, and coat the film, and pass through the drying tunnel for 150-160 ℃, after 30-45 minutes of baking, the desired finished product can be obtained.

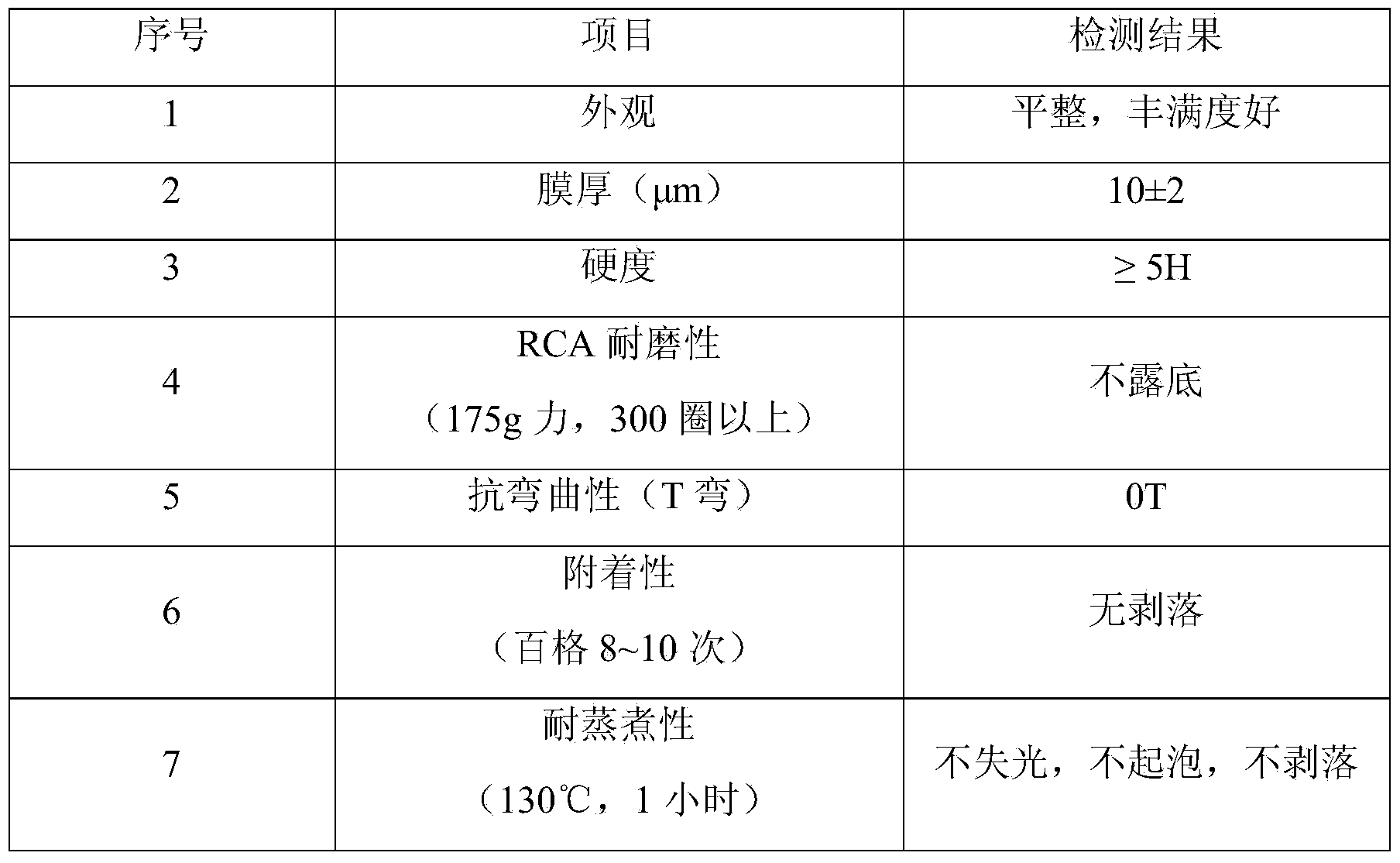

[0023] 4. The finished products prepared in Examples 1 to 3 are subjected to the following tests, and the test technical indicators are shown in the table.

[0024]

[0025] Experimental research found that lack of any one of water-based modified resin (AC769RG water-soluble silicone modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com