Re-emulsifiable resin powder, aqueous emulsion and adhesive composition using same

A resin powder, re-emulsification technology, applied in the direction of unsaturated alcohol copolymer adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of insufficient physical properties, etc., and achieve excellent retort resistance , Excellent temperature and water resistance

Inactive Publication Date: 2008-11-26

THE NIPPON SYNTHETIC CHEM IND CO LTD

View PDF13 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, this re-emulsifiable resin powder is not currently used as an adhesive for wood parts or wooden materials requiring water resistance because of insufficient physical properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

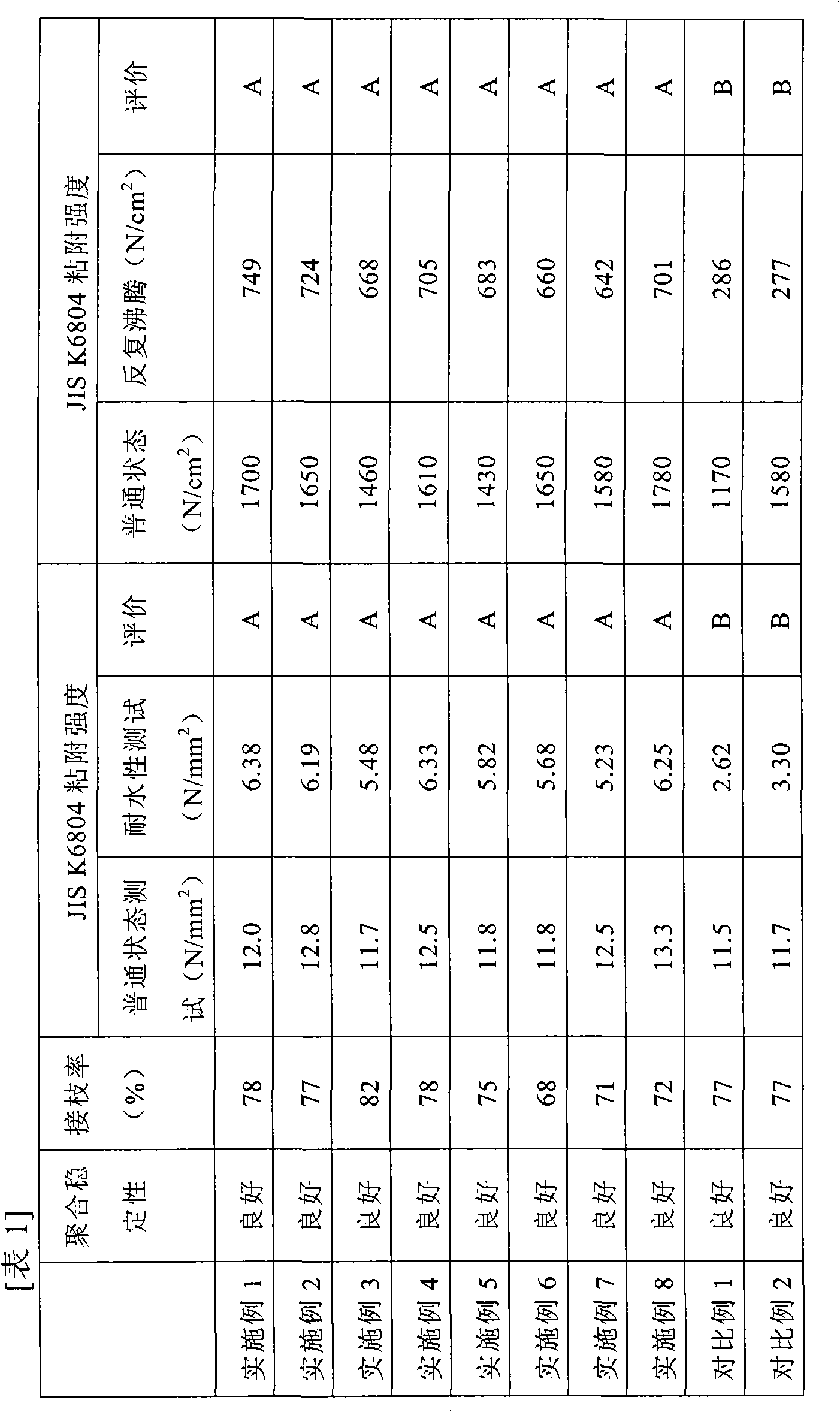

Embodiment

preparation Embodiment 1

preparation Embodiment 2-8

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

Disclosed is a re-emulsifiable resin powder which is characterized in that the physical properties after being re-emulsified in water are substantially the same as those of the emulsion from which the resin powder is formed. A film formed by using an emulsion obtained by re-emulsifying such a re-emulsifiable resin powder is improved in water resistance. Specifically disclosed is a re-emulsifiable resin powder obtained from an aqueous synthetic resin emulsion which is dispersion-stabilized by a polyvinyl alcohol resin, wherein a hydrophobic monomer having a solubility in water at 20 DEG C of 0.1% or less is contained, as a copolymerizable monomer for constituting the aqueous synthetic resin, in an amount of not less than 30% by weight relative to the total weight of the copolymerizable monomers.

Description

Re-emulsifiable resin powders, aqueous emulsions and adhesive compositions comprising these technical field The invention relates to a re-emulsifiable resin powder obtained by drying an aqueous synthetic resin emulsion. More specifically, the present invention relates to a re-emulsifiable resin powder from which a film formed from an aqueous emulsion is excellent in water resistance, warm water resistance and retort resistance. The re-emulsifiable resin powder can be used in various applications including, inter alia, adhesives for wood parts or wooden materials or for paper and the like, inorganic finishing materials, coatings, and for hydraulic materials such as A mixture of cement and gypsum. Background technique Re-emulsifiable resin powders are prepared by drying (eg, spray drying) aqueous synthetic resin emulsions. Since the re-emulsifiable resin powder is in powder form, it is easier to handle than aqueous synthetic resin emulsions that are mainly packaged in jars...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L29/04C08J3/12C09J129/04C09J151/06C09J175/04

CPCC08L51/003C08F2/22C08F257/02C08F265/00C08F265/04C08F291/00C08G18/6212C08G18/6229C08G18/6237C08G2170/80C08L51/06C09J151/003C09J151/06C08L2666/02

Inventor 菅谷护西桥洋一郎岩崎宽之

Owner THE NIPPON SYNTHETIC CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com