Preparation method of polyurethane resin for single-component steaming and boiling resistant composite ink

A technology of polyurethane resin and retort resistance, applied in the field of polyurethane, can solve the problems of high toxicity of curing agent, difficult to store, inconvenient to use, etc., and achieves the effects of good adhesion fastness, good dispersion and good retort resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

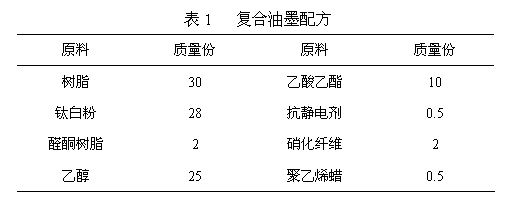

[0021] Example 1: Add 131.5g of adipic acid, 56.4g of dimer acid, and 188.9g of 2-methyl-1,8 octanediol into a four-necked flask, stir and raise the temperature in a nitrogen environment, when the reactants are melted, add 0.030g of tetrabutyl titanate, react at 170°C for 3h, then heat to 230°C to react to an acid value of 8.76mgKOH / g, reduce pressure to below 0.02MPa, react at 240°C to an acid value of 0.35mgKOH / g, stop For the reaction, the measured hydroxyl value is 56.64 mgKOH / g. Cool down to 40°C, then add 88.9g IPDI, 11.3g IPDI trimer, 0.041g dibutyltin dilaurate, heat up to 70°C to react until the mass fraction of isocyanate groups in the system is 4.87%, cool to room temperature, add 340.0g acetic acid Ethyl ester, 793.3g ethanol, 41.8g IPDA, 2.0g WD-52, 0.9g ethanolamine were reacted at 35°C for 2h to obtain a product with a solid content of 30%, a viscosity of 970mPa·s / 25°C, and a number average molecular weight of 42215.

Embodiment 2

[0022] Example 2: Add 173.0g azelaic acid, 45.1g dimer acid, 99.8g neopentyl glycol, 31.8g dipropylene glycol into a four-necked flask, stir and raise the temperature in a nitrogen environment, when the reactants are melted, add 0.028g of tetrabutyl titanate, react at 170°C for 3h, then heat to 230°C to react to an acid value of 7.98mgKOH / g, reduce pressure to below 0.02MPa, react at 240°C to an acid value of 0.32mgKOH / g, stop For the reaction, the measured hydroxyl value is 66.12 mgKOH / g. Cool down to 40°C, then add 89.0g HMDI, 13.1g IPDI trimer, 0.038g dibutyltin dilaurate, heat up to 70°C to react until the mass fraction of isocyanate groups in the system is 3.73%, cool to room temperature, add 314.2g acetic acid Ethyl ester, 733.2g ethanol, 29.2g IPDA, 2.0g KH-792, 1.9g di-n-butylamine, react at 35℃ for 2h to obtain the product, solid content 30%, viscosity 1050mPa·s / 25℃, number average molecular weight 44075 .

Embodiment 3

[0023] Example 3: Add 178.0g of sebacic acid, 67.7g of dimer acid, and 139.8g of 3-methyl-1,5 pentanediol into a four-necked flask, stir and raise the temperature in a nitrogen environment, when the reactants are melted, add 0.031g of tetrabutyl titanate, react at 170°C for 3h, then heat to 230°C to react to an acid value of 8.82mgKOH / g, reduce pressure to below 0.02MPa, react at 240°C to an acid value of 0.38mgKOH / g, stop For the reaction, the measured hydroxyl value is 55.49 mgKOH / g. Cool down to 40°C, then add 83.0g IPDI, 12.5g IPDI trimer, 0.042g dibutyltin dilaurate, heat up to 70°C to react until the mass fraction of isocyanate groups in the system is 4.29%, cool to room temperature, add 339.5g acetic acid Ethyl acetate, 792.2g ethanol, 36.9g IPDA, 1.9g WD-53, 1.2g diethanolamine were reacted at 35°C for 2h to obtain a product with a solid content of 30%, a viscosity of 1250mPa·s / 25°C, and a number average molecular weight of 49935.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com