Solvent-free two-component polyurethane cooking adhesive and preparation method thereof

A two-component polyurethane, solvent-free technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of easy delamination and low peel strength, and achieve high peel strength and cooking resistance. Good performance, the effect of improving temperature resistance and medium resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

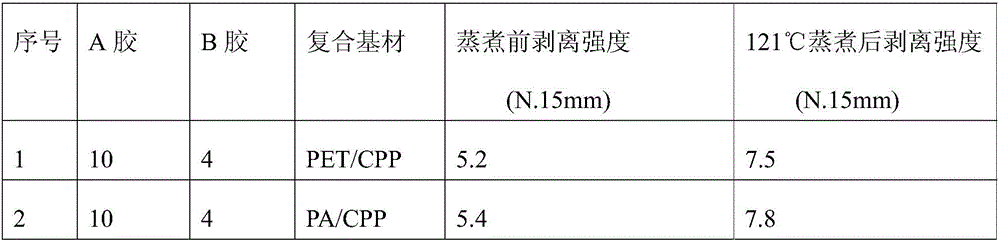

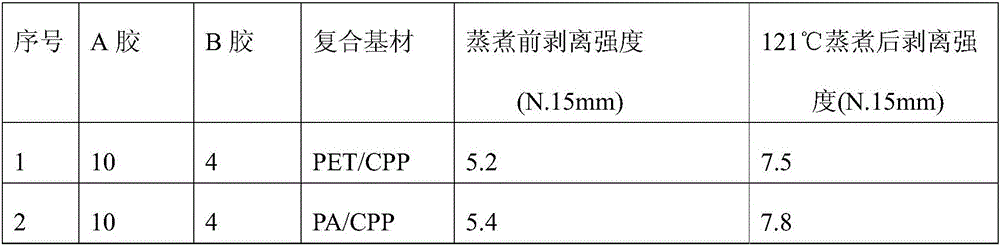

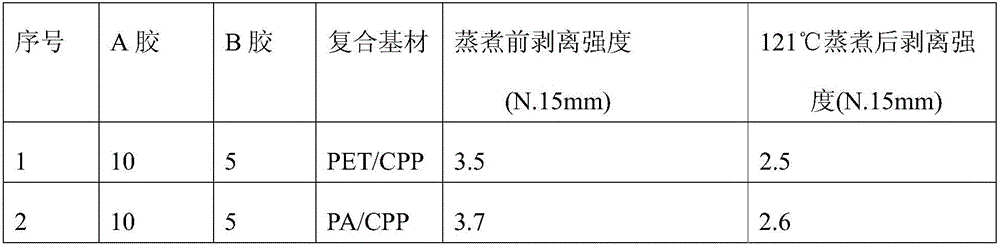

[0031] Embodiment 1: A kind of solvent-free two-component polyurethane cooking adhesive is made up of A glue and B glue, and wherein, A glue is to be formed by the reaction of polyester polyol, liquefied MDI and polyether polyol, and B glue is to be made of containing Composed of polyether polyol with bisphenol A structure, coupling agent and castor oil, the important ratio of glue A and glue B is 10:4~5.

[0032] In the above-mentioned solvent-free two-component polyurethane cooking glue, the polyester polyol is formed by polycondensation of a small molecular dibasic acid and a dibasic alcohol, and the small molecular dibasic acid is adipic acid, isophthalic acid Formic acid, sebacic acid, terephthalic acid, a mixture of one or two of phthalic anhydride, preferably isophthalic acid, adipic acid or sebacic acid; the dihydric alcohol is ethylene glycol , diethylene glycol, neopentyl glycol, 1,2 propanediol, methylpropanediol, glycerin, cyclohexanedimethanol, 1,4-butanediol, 1,6...

Embodiment 2

[0051] Preparation of glue A:

[0052] (1) Preparation of polyester polyol:

[0053] In a four-necked flask equipped with a thermometer, a stirrer, a spherical cooler, and a nitrogen-sealed tube, add 270 g of isophthalic acid, 172 g of diethylene glycol, 329 g of sebacic acid, 117 methyl propylene glycol, neopentyl 203g diol, and 0.2-0.25g tetrabutyl titanate catalyst, stir well, then slowly raise the temperature to 160°C, react at 160°C-230°C for 14 hours, take a sample to measure the acid value, if the acid value is less than 25mgKOH / g , then the esterification is qualified. After the esterification is qualified, the polycondensation reaction is carried out. At a temperature of 220-230°C, vacuumize at -0.1Mpa for 5 hours to obtain a polyester multi-polymer with an acid value ≤ 1mgKOH / g and a hydroxyl value of 112mgKOH / g. alcohol.

[0054] (2) Preparation of glue A:

[0055] 200g of the polyester polyol obtained after the above-mentioned esterification and polycondensation...

Embodiment 3

[0064] Preparation of glue A:

[0065] (1) Preparation of polyester polyol:

[0066] In a four-necked flask with a thermometer, a stirrer, a bulb cooler, and a nitrogen sealed tube, add 270 g of isophthalic acid, 172 g of diethylene glycol, add 118.5 g of adipic acid and 164.5 g of sebacic acid, Methylpropanediol 117, neopentyl glycol 203g, and 0.25g tetrabutyl titanate catalyst, stir evenly, then slowly raise the temperature to 160°C, react at 160°C-230°C for 14 hours, take a sample to measure the acid value, if the acid If the esterification value is less than 22mgKOH / g, the esterification is qualified. After the esterification is qualified, the polycondensation reaction is carried out. At a temperature of 220-230°C, vacuumize at -0.1Mpa for 5 hours to obtain an acid value of ≤1mgKOH / g and a hydroxyl value of 117mgKOH / g of polyester polyols.

[0067] (2) Preparation of glue A:

[0068] 200g of the polyester polyol obtained after the above-mentioned esterification and pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com