Manufacturing technology of two-piece-type steel high-performance zip-top cans

A production process and technology of pop-top cans, which are applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problem of unable to meet the diversified requirements of the beverage industry and the diversification of consumption habits, and achieve enhanced filling. Adaptability and corrosion resistance, enhanced environmental adaptability, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

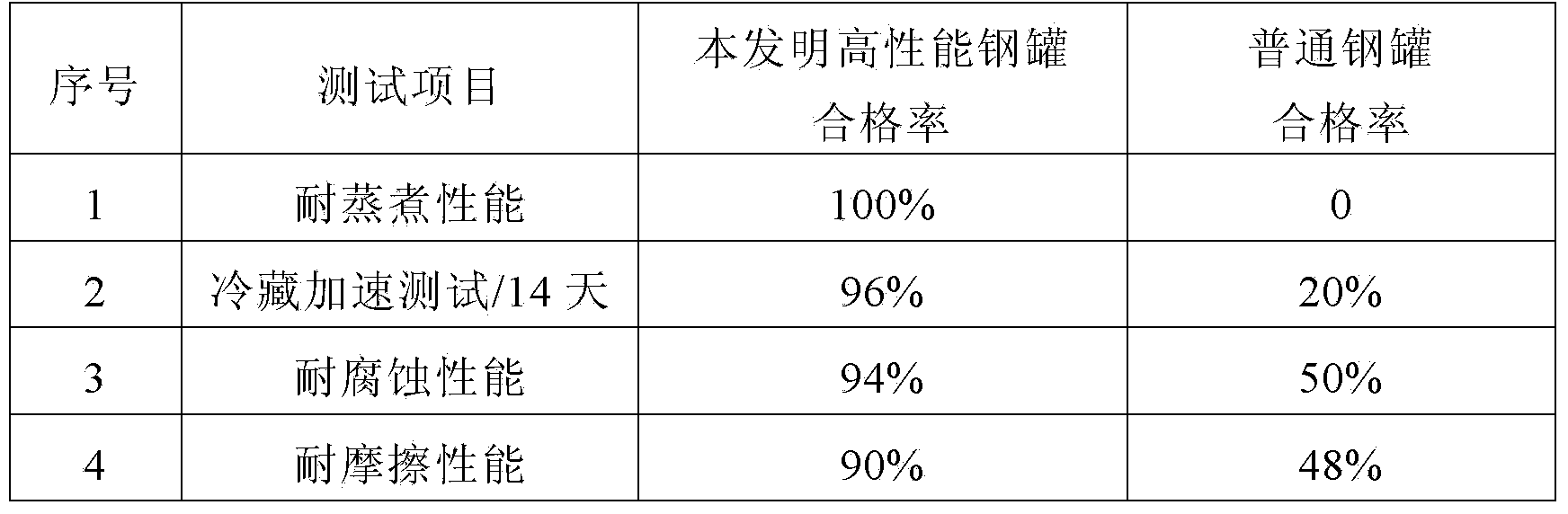

[0036] Embodiment (production 202 steel tanks)

[0037] The previous process is carried out according to the production process of ordinary 202 steel tanks. After the steel tanks go through the necking and flanging process, they will reach the inlet end of the bottom coating equipment through the lifting conveyor belt. About 50 cans are taken as test tanks, and the magnetic conveyor belt is sucked by the test tanks. Drive it into the bottom coating equipment, adjust the height gap between the soft coating roller and the conveyor belt, the gap value is 114.7±0.5mm, so as to ensure that the bottom edge paint completely covers the bottom part of the tank, and after passing the UV curing lamp, the bottom coating reaches the surface dry, magnetic The conveyor belt drives the test tank through the air-cooled part, reducing the temperature of the bottom edge to 65±5°C; the magnetic conveyor belt transfers the test tank to the ordinary conveyor belt, and enters the subsequent process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com