Patents

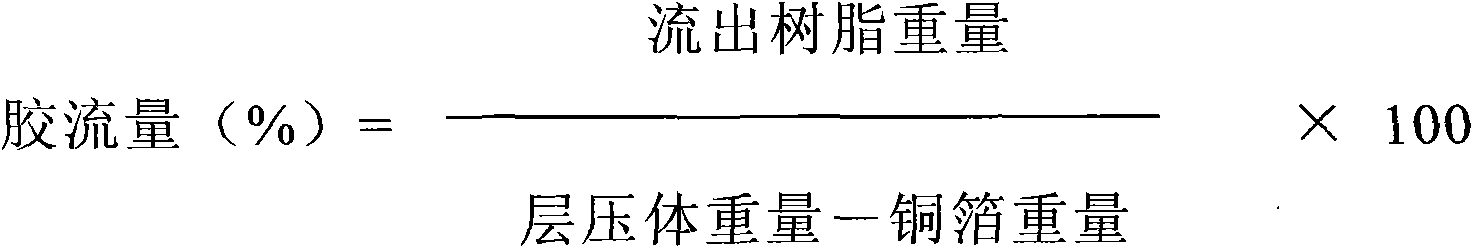

Literature

66results about How to "Excellent soldering heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photocuring/thermosetting inkjet composition and printed wiring board using same

The invention provides a photocurable and thermosetting composition for inkjet, which contains: (A) a monomer having an acryl group or a methacryloyl group and a thermosetting functional group in the molecule; (B) a weight average molecular weight of 700 or less of the photoreactive diluent and (C) photopolymerization initiator other than the component (A), and the viscosity of the composition is 150 mPa·s or less at 25°C. The composition is used to directly draw a solder resist pattern on a printed circuit board with an inkjet printer, and is cured once by irradiating active energy rays, and then further heated and cured.

Owner:TAIYO HLDG CO LTD

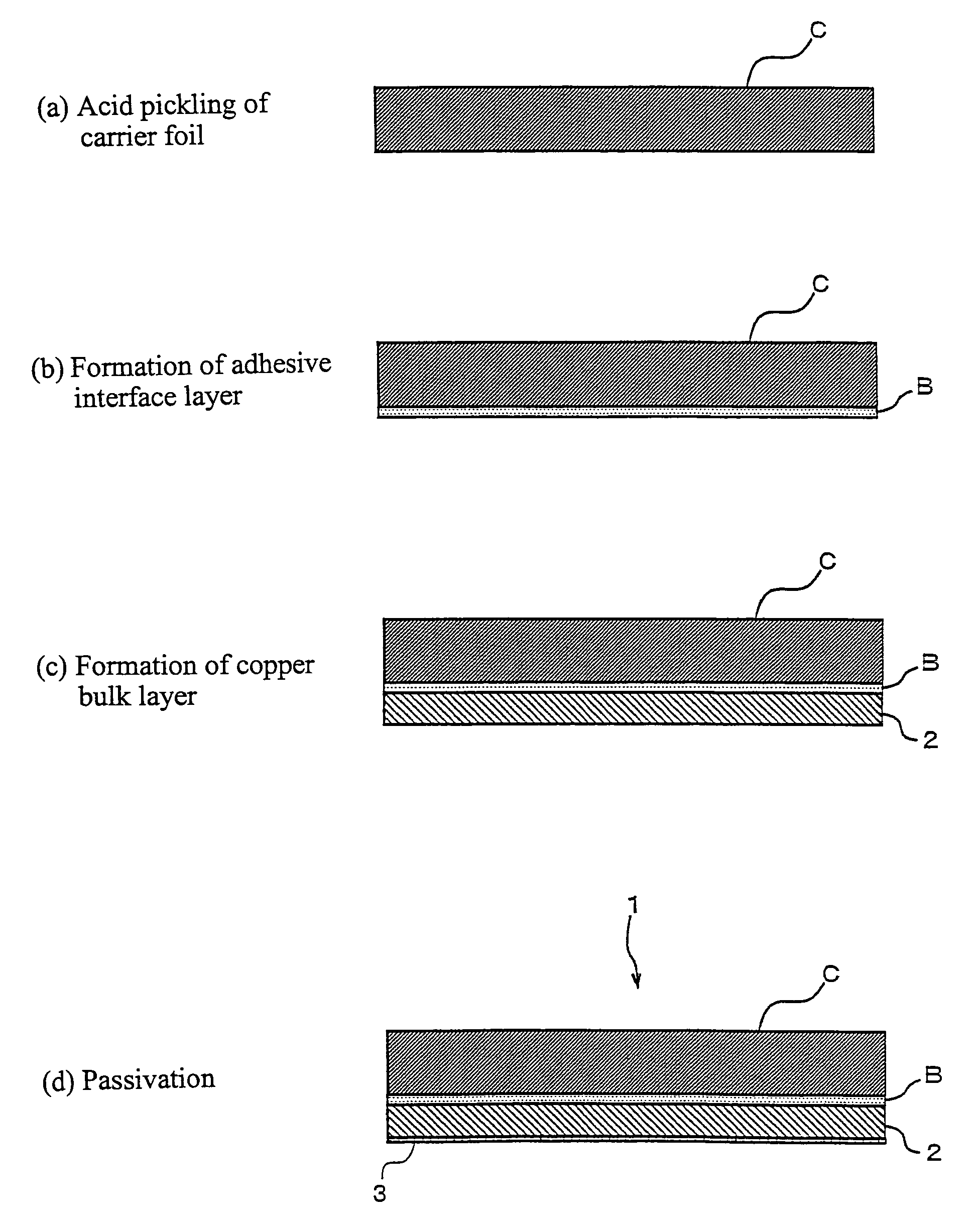

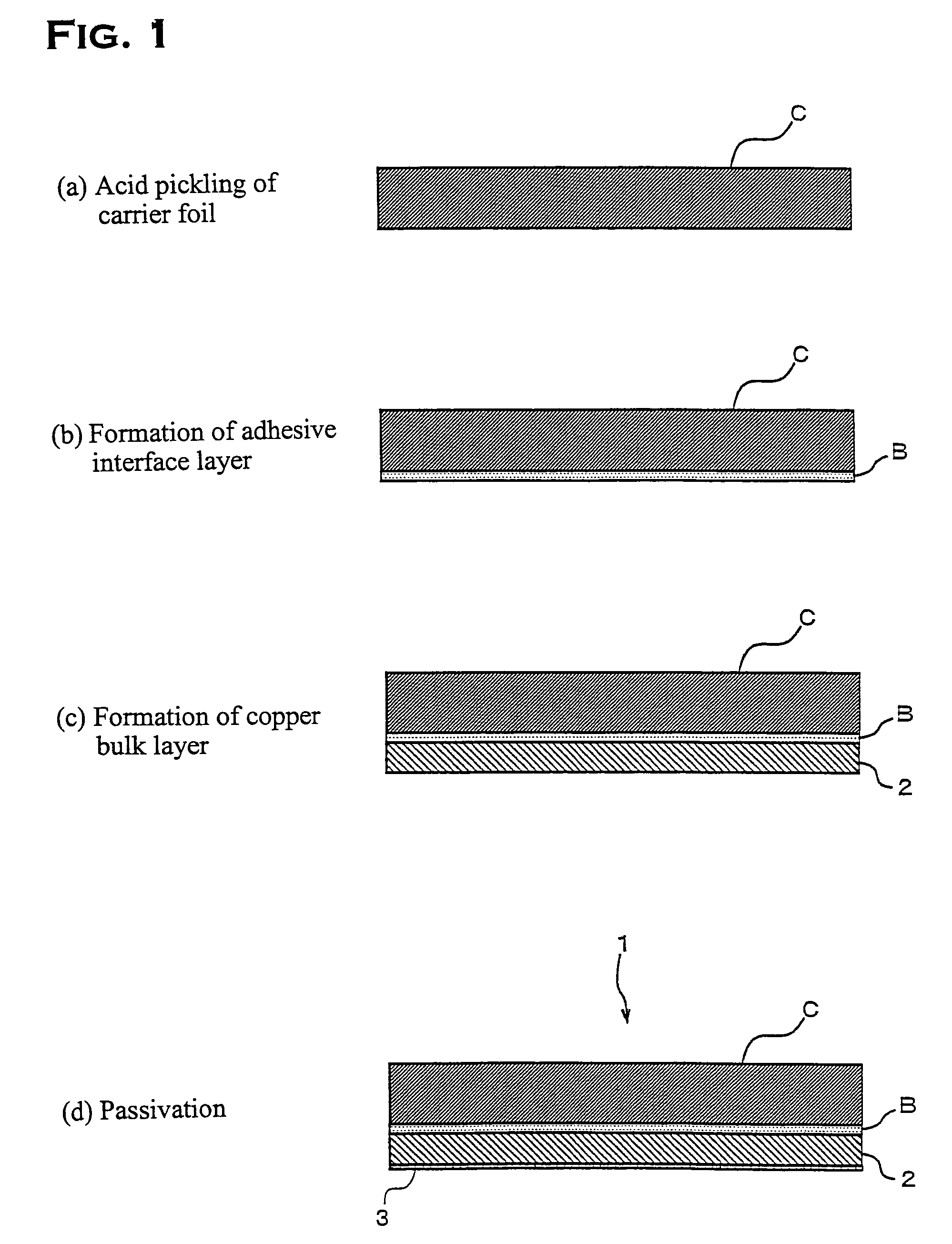

Electrodeposited copper foil with carrier foil

ActiveUS7691487B2Improve adhesion strengthGood chemical resistanceInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentInterface layerCopper foil

The present invention provides electrodeposited copper foil with a carrier foil which permits the formation of finer-pitch circuits and also enables the multilayer process to be easily performed to meet the requirements for recent printed wiring boards. According to the invention, there is provided electrodeposited copper foil with a carrier foil in which an adhesive interface layer is formed on a surface of the carrier foil and an electrodeposited copper foil layer is formed on the adhesive interface layer, which is characterized in that the electrodeposited copper foil layer is provided with a passivated layer formed without performing roughening treatment as nodular treatment and that a nickel-zinc alloy consisting essentially of 50 to 99% nickel by weight and 50 to 1% zinc by weight is adopted as the passivated layer.

Owner:MITSUI MINING & SMELTING CO LTD

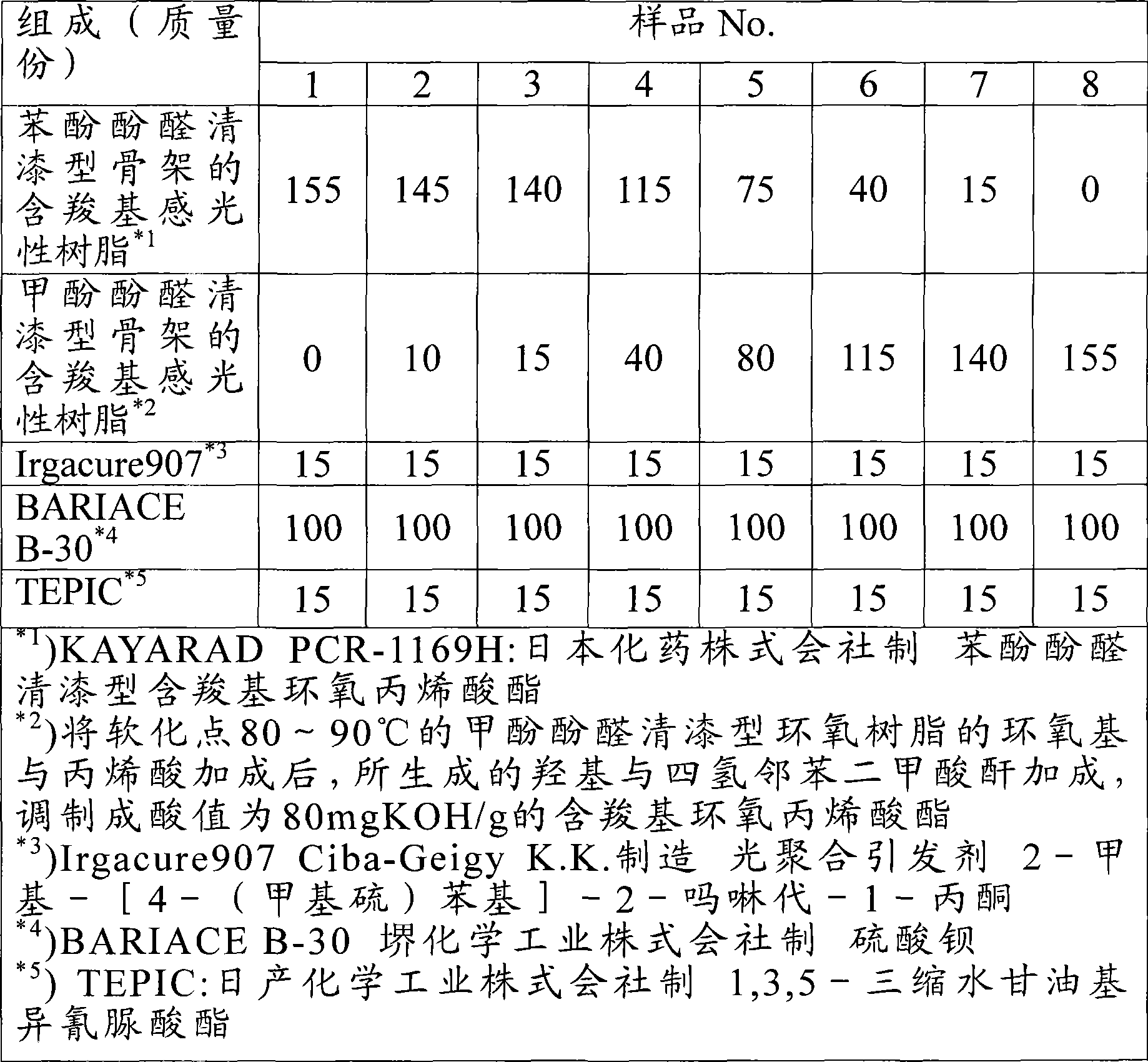

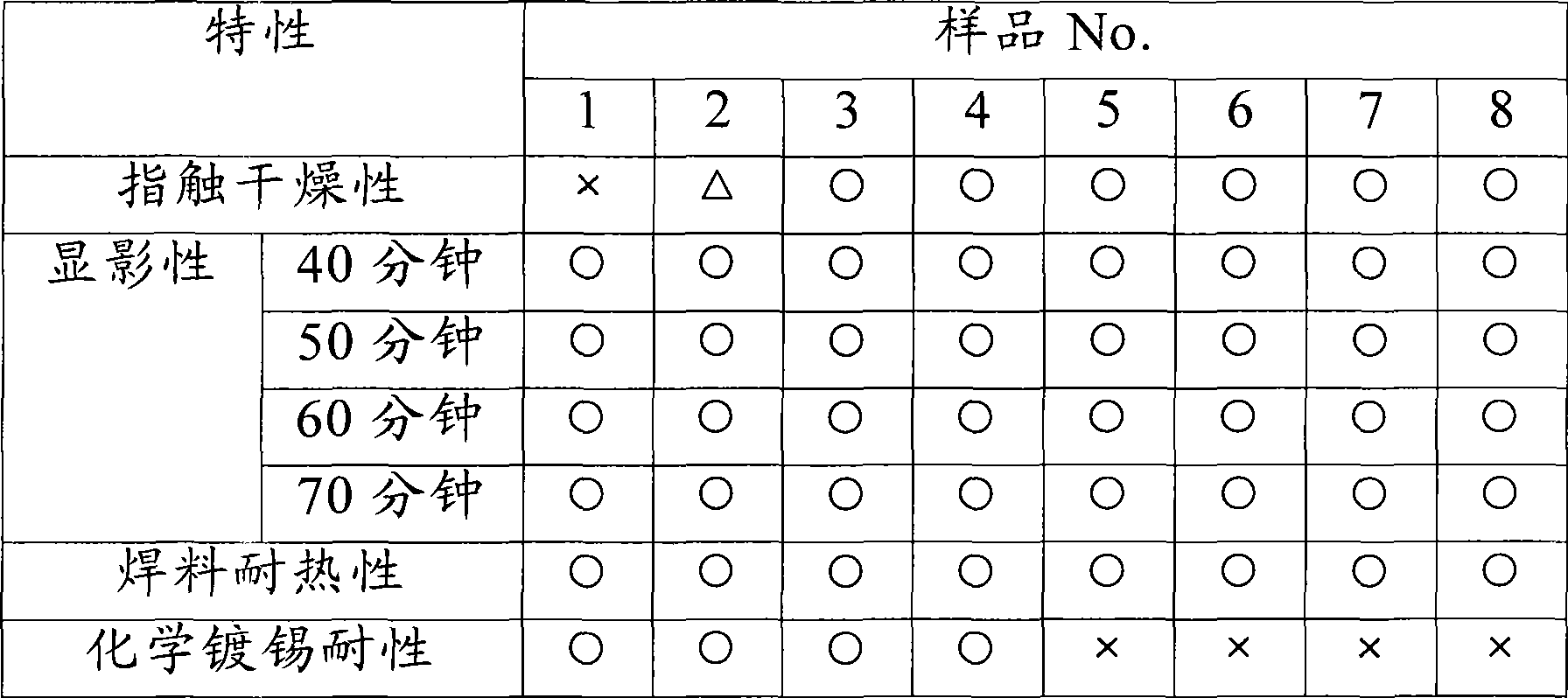

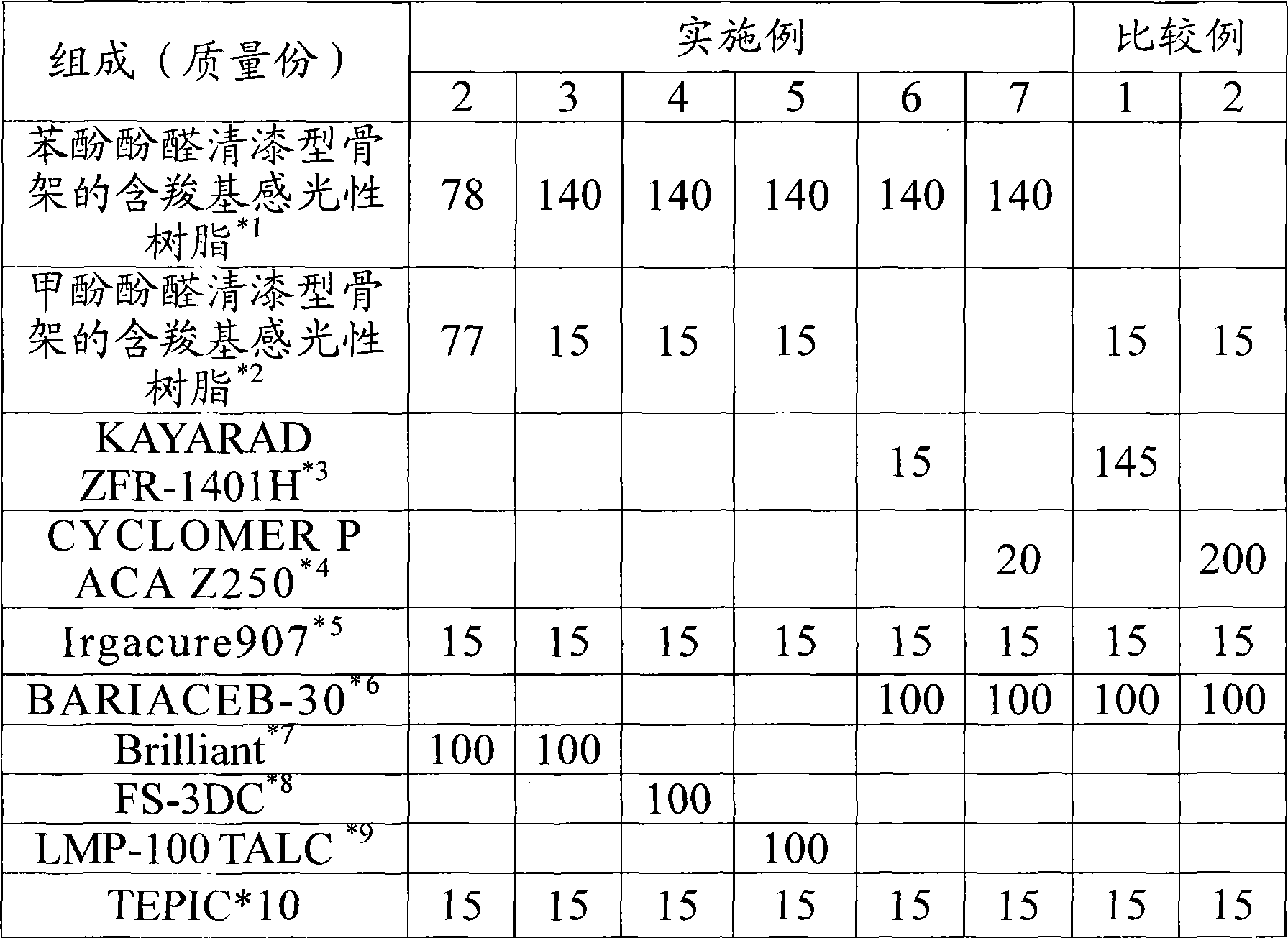

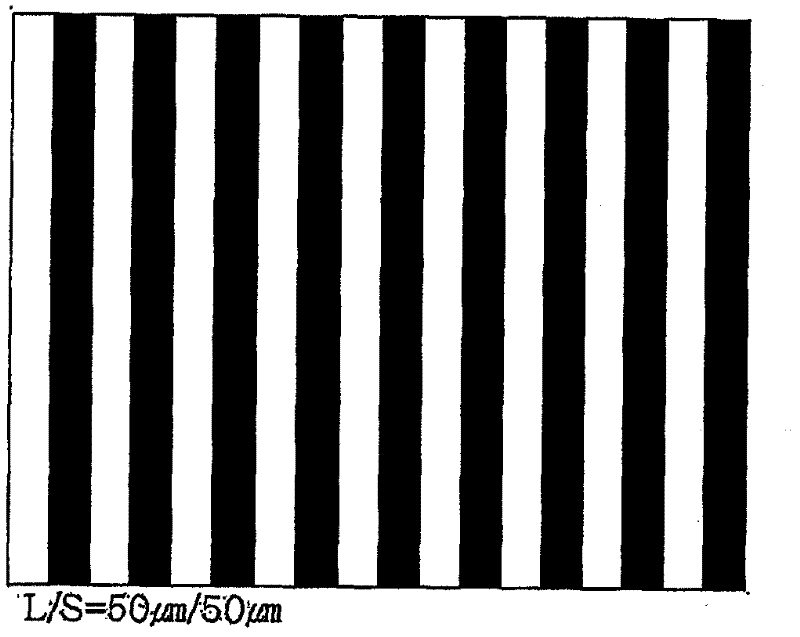

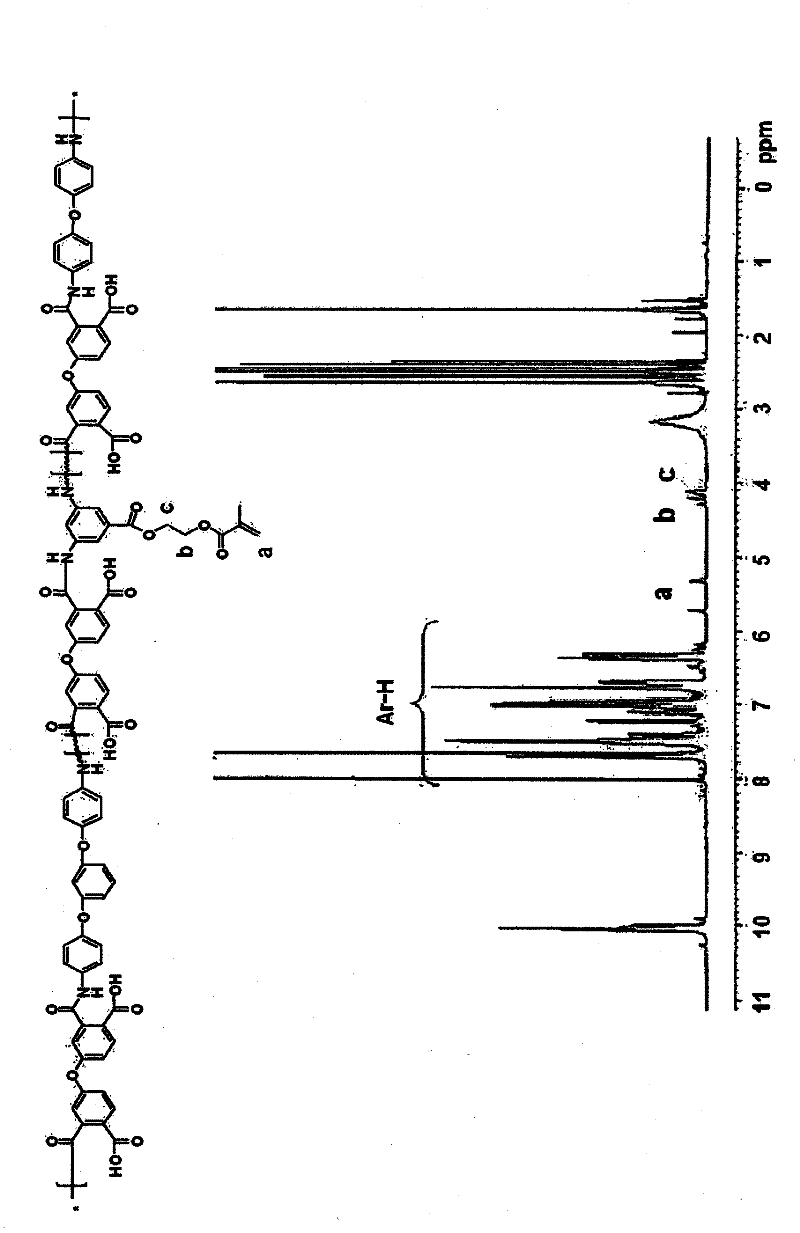

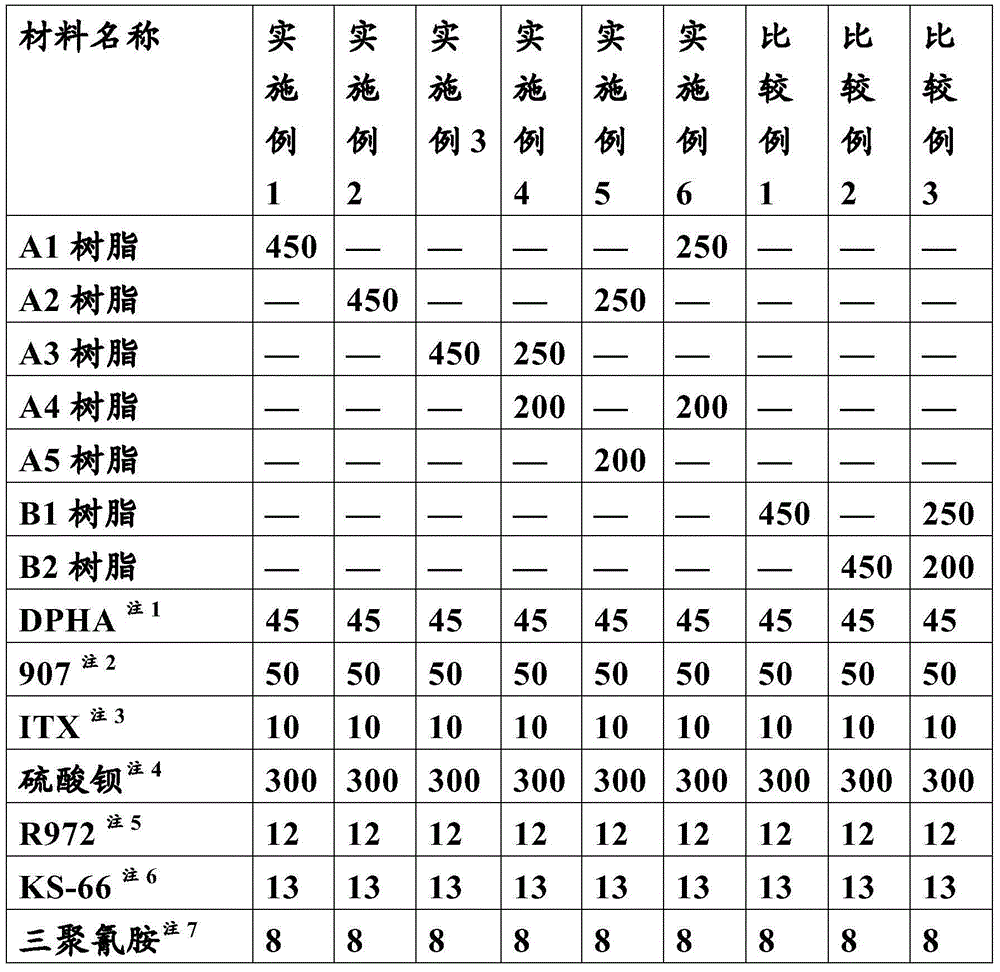

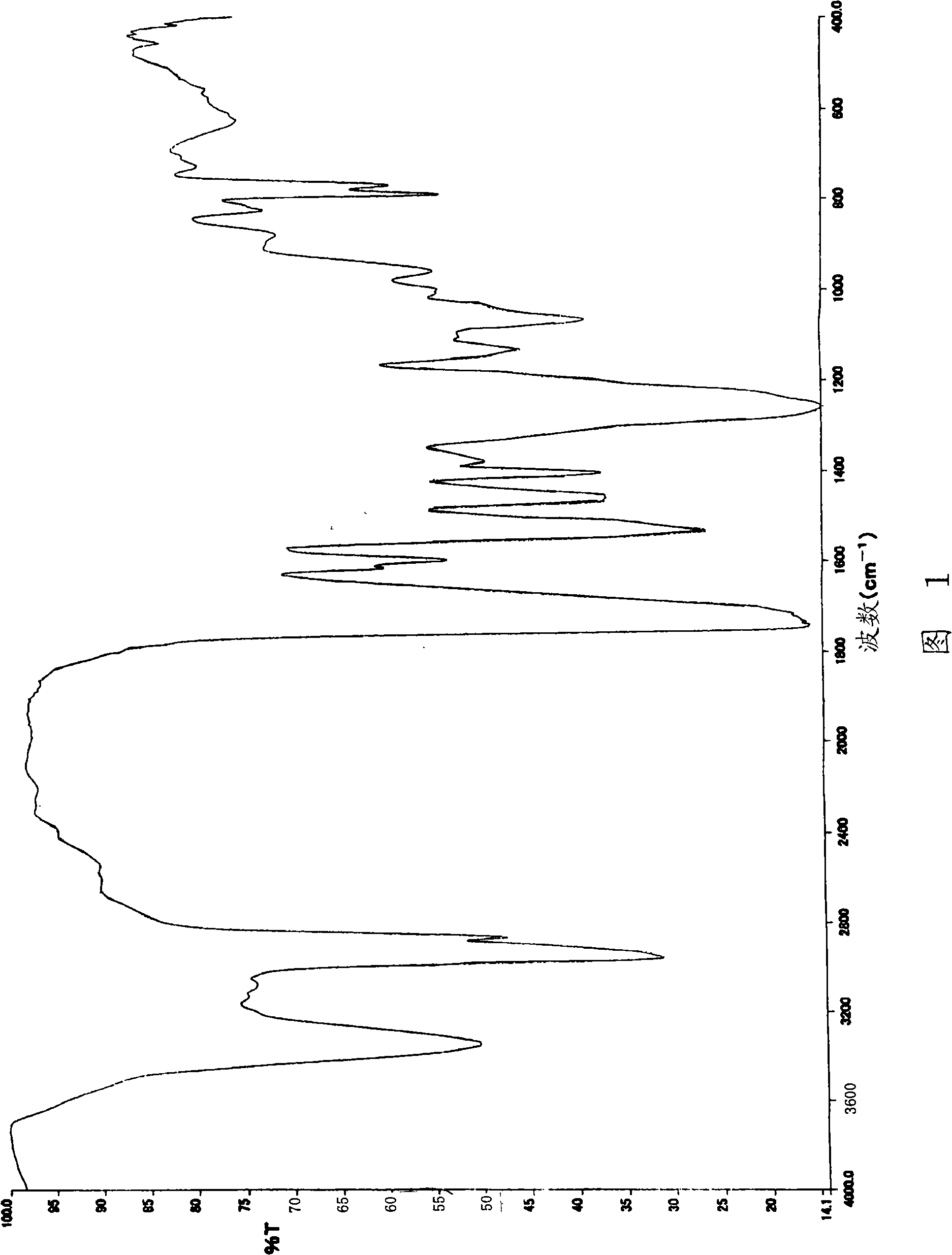

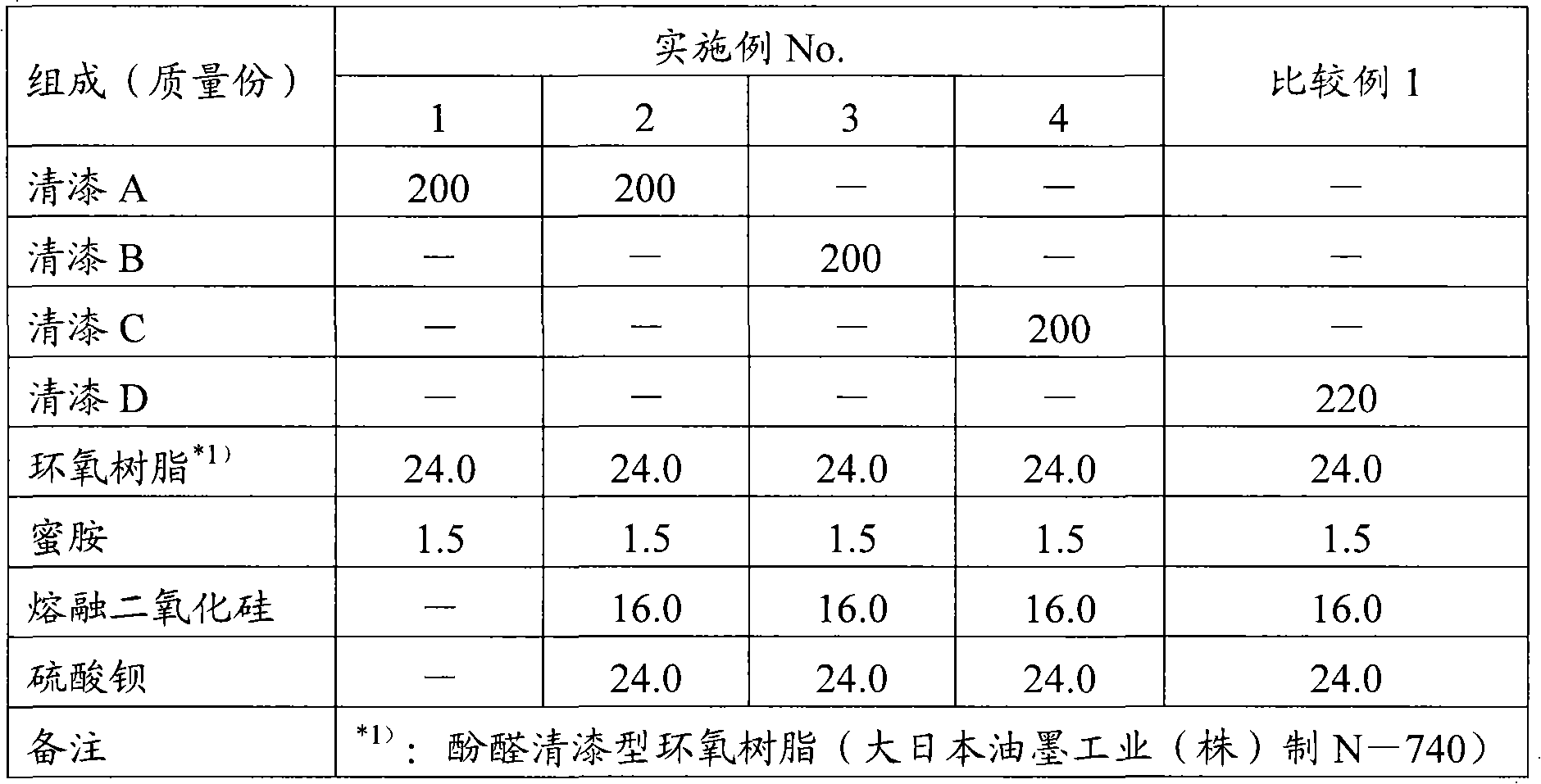

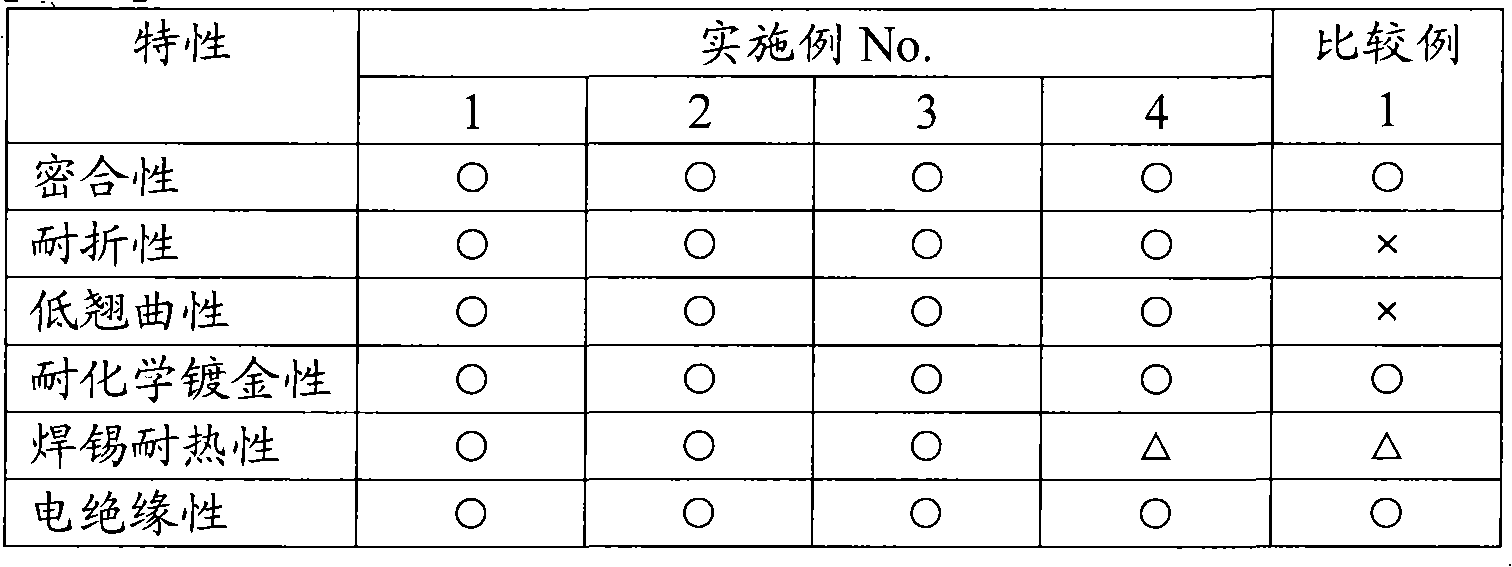

Photo-cured and heat-cured resin composition and pcondensate thereof

ActiveCN101393394AImprove curing effectExcellent soldering heat resistancePhotomechanical apparatusPrinted circuit manufactureTinningEpoxy

The invention provides a light curing and thermal curing resin composition which can not produce the problem of touch drying deterioration, and form curing coating pattern with good chemical tinning resistance, curing material, and printed circuit board formed of solder mask made of the curing material. The light curing and thermal curing resin composition comprises (A) carboxyl containing photosensitive resin obtained from the reaction between the reaction product of phenol phenolic varnish type epoxy resin and unsaturated monocarboxylate and saturated or unsaturated multi-anhydride, (B) other carboxyl containing photosensitive resin except for (A), (C) photopolymerization initiator, (D) diluent, and (E) thermal curing composition, the ratio of (A) and (B) is 50 to 95:50 to 5 (mass ratio). Moreover, (F) curing accelerant is comprised, or barium sulfate and / or silicon dioxide is used as inorganic filler.

Owner:TAIYO INK MFG

Novel polyamic acid, polyimide, photosensitive resin composition comprising same, and dry film produced from the composition

ActiveCN102361913AHigh resolutionExcellent test toleranceCircuit artworks manufacturePhotosensitive materials for photomechanical apparatusImidePolymer science

The present invention relates to a polyamic acid comprising a thermopolymerizable or photopolymerizable functional group, to a photosensitive resin composition which can form a high-resolution pattern, and which has a superior property of being developable with an aqueous alkaline solution, and which can provide a cured coating film having excellent flexibility, adhesion properties, soldering-heat resistance, and pressure cooker test (PCT) resistance, and to a dry film produced from the composition.

Owner:LG CHEM LTD

Photosensitive resin composition, cured product thereof, and method for producing photosensitive resin

InactiveCN101535896AIncrease photosensitivityImprove flexibilityPolyurea/polyurethane coatingsPrinted circuit manufactureResistPolyol

Disclosed is a photosensitive resin composition containing a carboxyl group-containing photosensitive urethane resin (A), a photopolymerization initiator (B) and a photosensitive ethylenically unsaturated group-containing compound (C). This photosensitive resin composition is characterized in that the carboxyl group-containing photosensitive urethane resin (A) is a resin obtained by reacting a hydroxy group in a hydroxy group-containing urethane prepolymer (c) with an acid anhydride group in an acid anhydride group-containing compound (d). The hydroxy group-containing urethane prepolymer (c) is obtained by reacting a carboxyl group in a carboxyl group-containing urethane prepolymer (a), which is obtained by reacting a polymer polyol (e), a carboxylic acid compound (f) having two hydroxy groups in a molecule and a diisocyanate compound (g) as essential ingredients, with an epoxy group or an oxethane group in a compound (b) having an epoxy group or an oxethane group and an ethylenically unsaturated group. This photosensitive resin composition is excellent in sensitivity to an active energy ray and enables to form a fine pattern. A cured coating film of the photosensitive resin composition is excellent in flexibility, insulating property, adhesion, solder heat resistance, coating film resistance and flame retardance, and is thus suitably used for a photosolder resist.

Owner:TOYO INK SC HOLD CO LTD

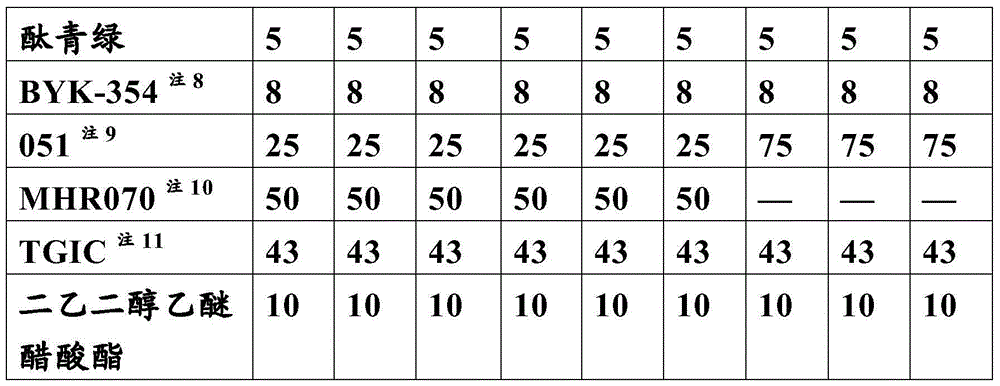

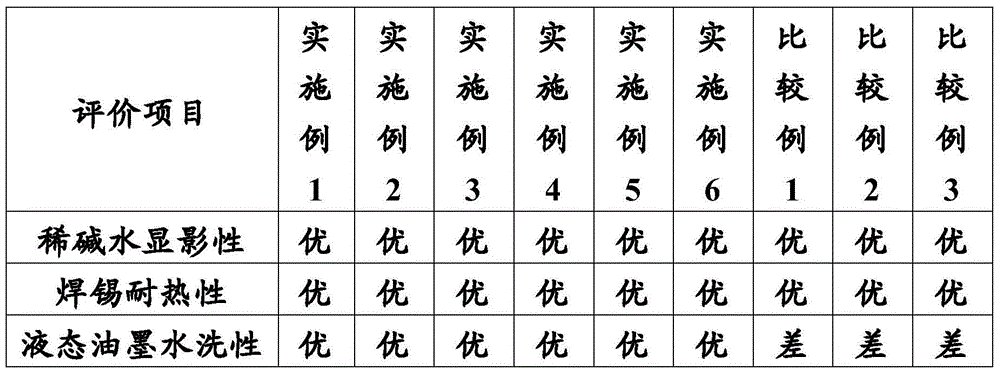

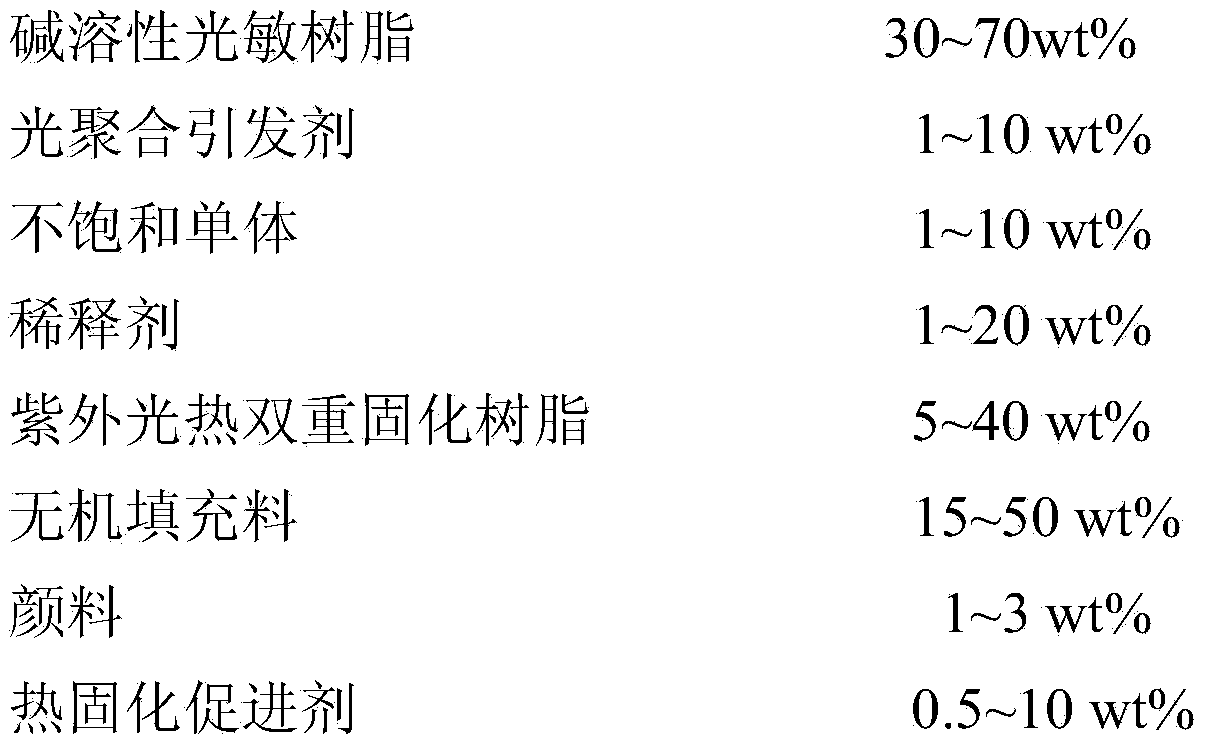

Printing ink composition with water-soluble solvent, application of printing ink composition, and printed circuit board

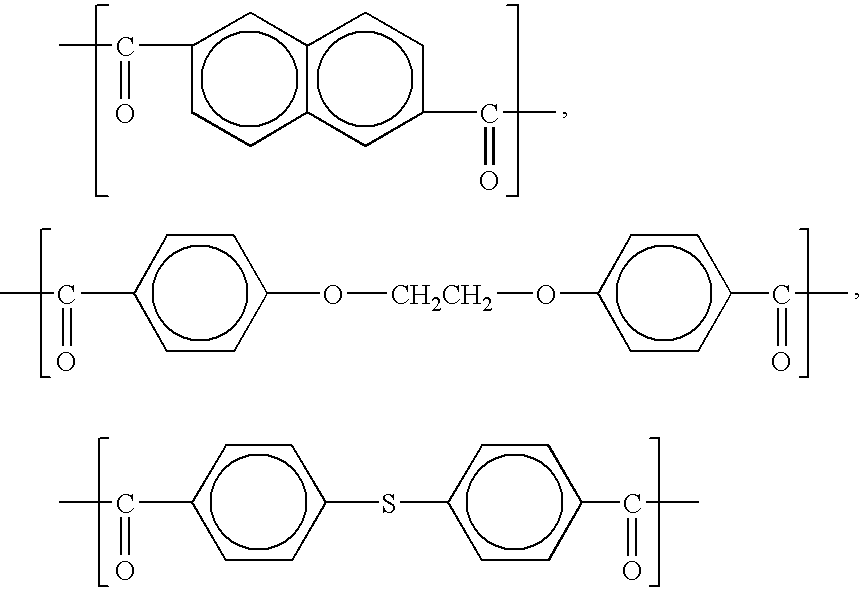

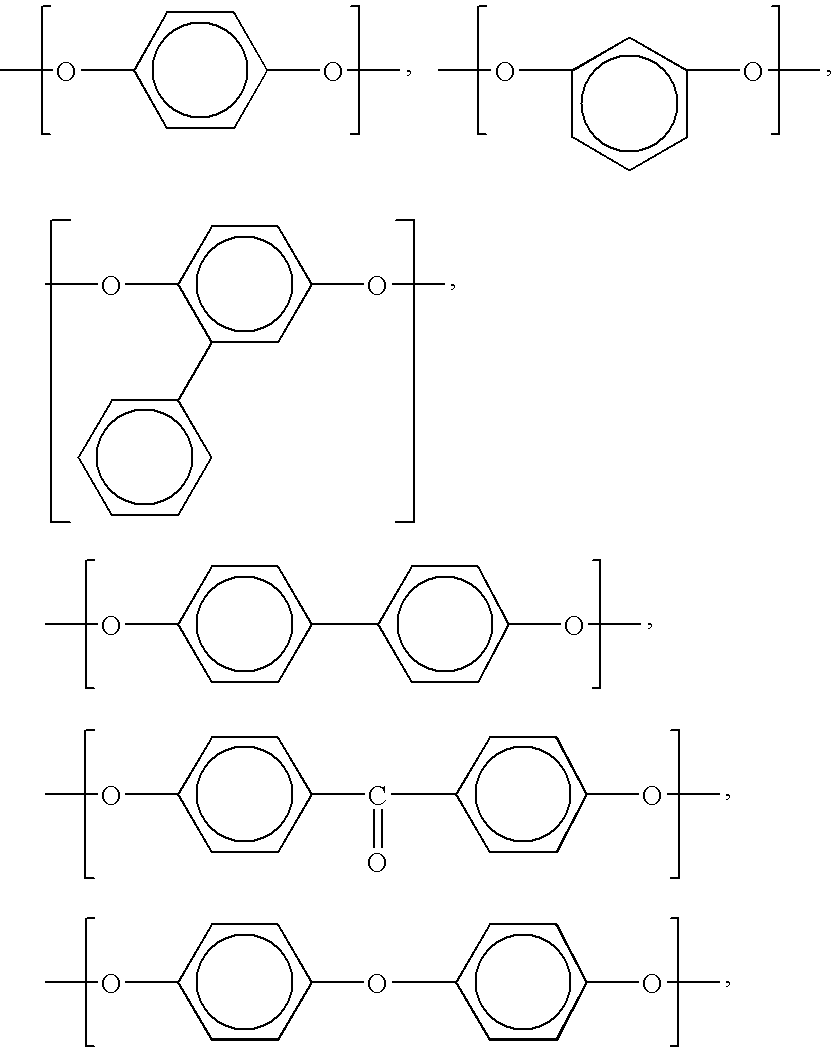

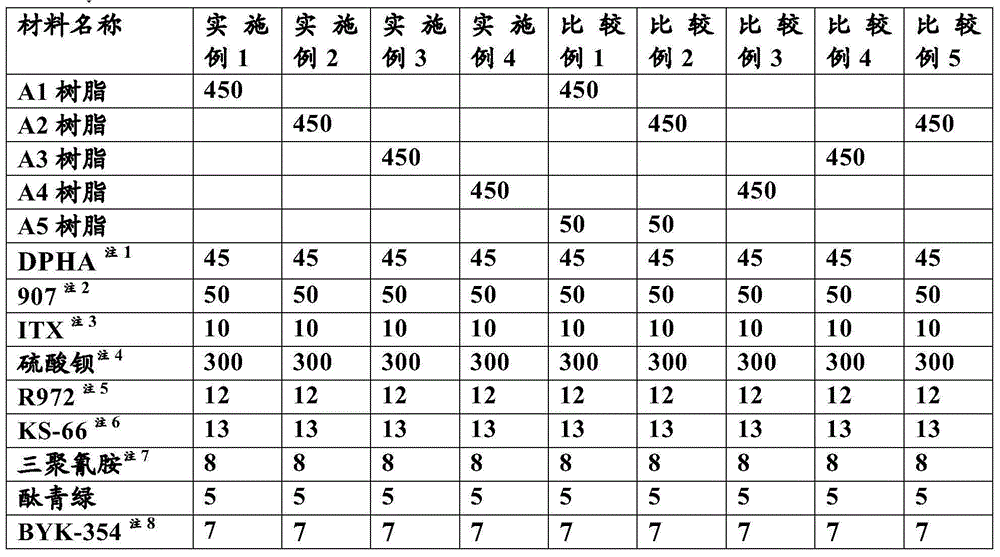

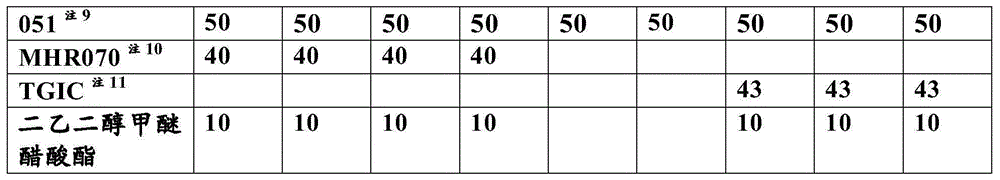

ActiveCN104974594AExcellent soldering heat resistanceImprove washing effectPrinted circuit detailsInksEpoxyPolymer science

The invention relates to a printing ink composition with a water-soluble solvent, an application of the printing ink composition, and a printed circuit board. The printing ink composition comprises the following components: A) a photo-cured dilute-alkaline-water developable resin containing carboxyl and an unsaturated double bond, B) an unsaturated monomer, C) a water-soluble solvent, D) epoxy resin, E) an epoxy curing accelerator, F) a photopolymerization initiator, and optional G) a filling material, H) a pigment, and I) an antifoaming agent, a dye, a thermopolymerization inhibitor, an adhesive force promoter, a dispersant, a coupling agent, a fire retardant, a leveling agent, an anti-oxidant and / or a thixotropic agent. The printing ink composition is applied to holes of a circuit board, has excellent properties, such as hot-soldering-tin resistance, developability, and washing resistance of a liquid composite, and can be widely applied as an insulated solder-resisting protective material for the holes of the circuit board.

Owner:深圳市容大感光科技股份有限公司 +1

Ultraviolet-thermal dual-cured resin, anti-welding ink containing resin, and application of resin

ActiveCN103788342AIncrease photosensitivityLow photosensitivityPrinted circuit detailsInksUltravioletCarboxylic acid

The invention discloses ultraviolet-thermal dual-cured resin, anti-welding ink containing the resin, and an application of the resin. The resin is obtained as follows: multifunctional epoxy resin containing two or more pieces of epoxy acetylene and monocarboxylic acid containing an unsaturated group are subjected to ring-opening addition to obtain a middle product, and the middle product and saturated or unsaturated anhydride are subjected to ring-opening addition; the equivalent weight of an epoxy group is 0-1,000g / eq; the equivalent weight of vinyl is 0-1,000g / eq. A printed circuit board is coated with the anti-welding ink in a silk-screen printing mode to form a welding resistant coating layer and then the welding resistant coating layer is subjected to ultraviolet exposure, development and thermal curing. The ultraviolet-thermal dual-cured resin disclosed by the invention can realize the ultraviolet-thermal dual-curing, and is excellent in physical and chemical performance, low in toxicity, and environmentally-friendly; the anti-welding ink containing the resin is high in photo-electric sensitivity; the ultraviolet-thermal-cured coating layer is high in precuring operation tolerance level, soldering heat resistance, adhesive force and chemical resistance.

Owner:JIANGSU KUANGSHUN PHOTOSENSITIVITY NEW MATERIAL

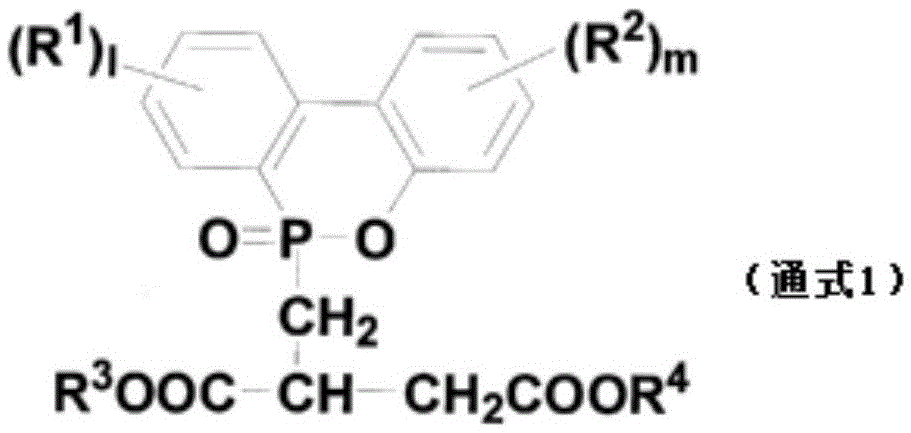

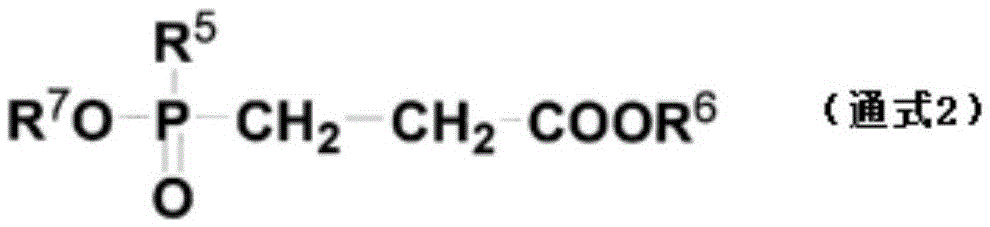

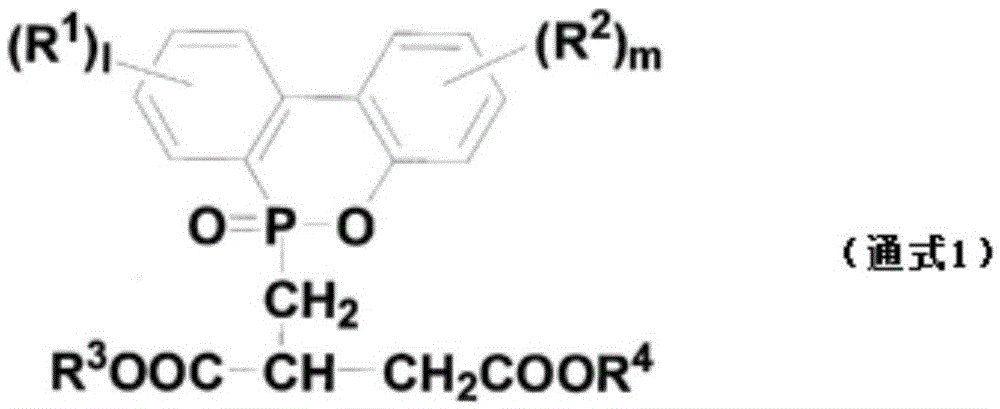

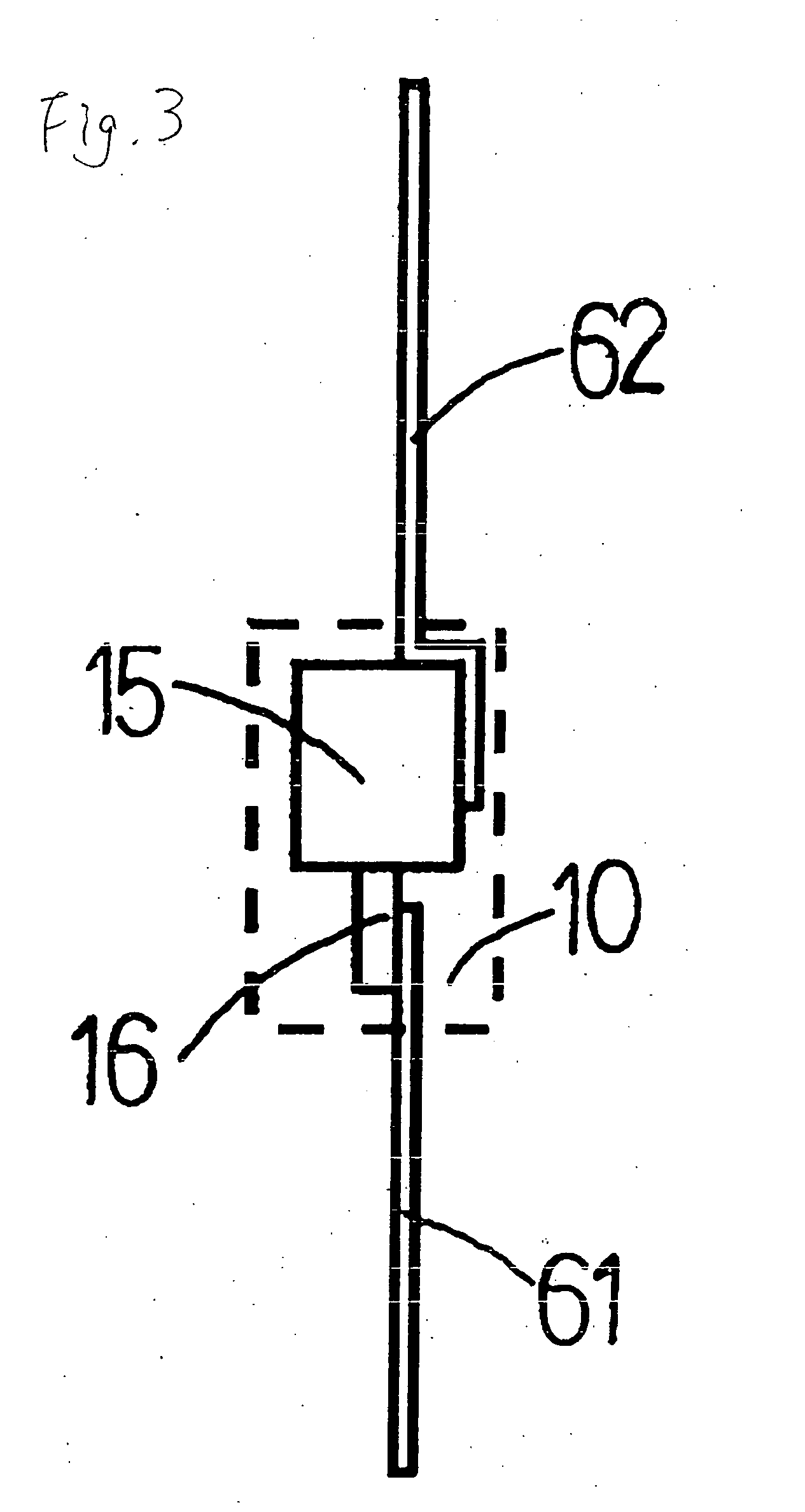

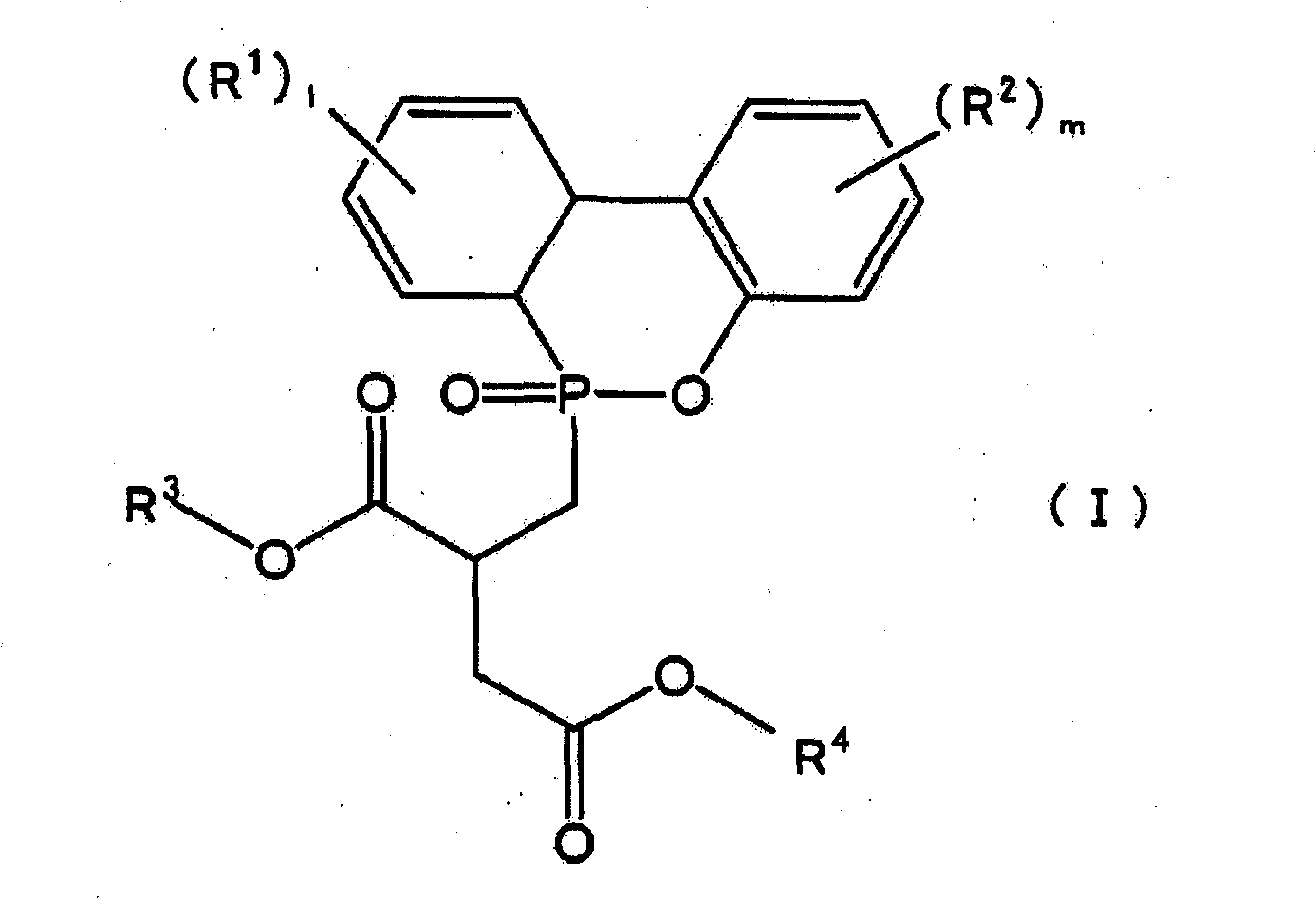

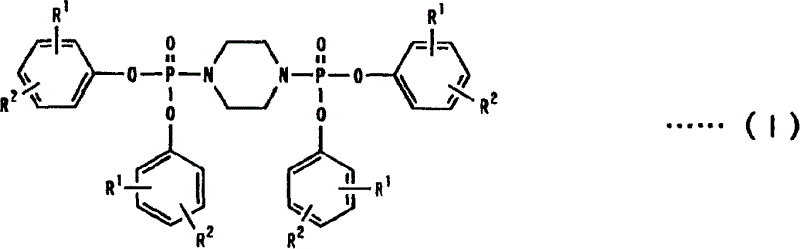

Polyurethane resin composition and adhesive composition, laminate, and printed wiring board using same

ActiveCN105492534AExcellent insulation reliabilityImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntimonyHydrocarbon

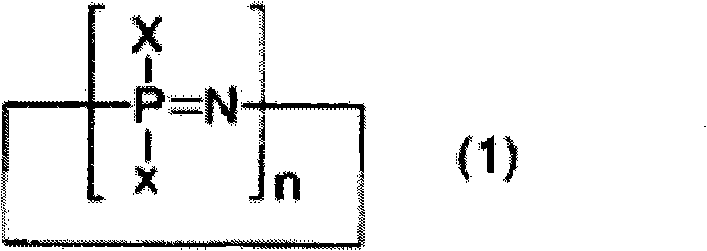

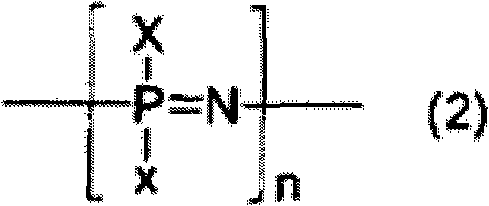

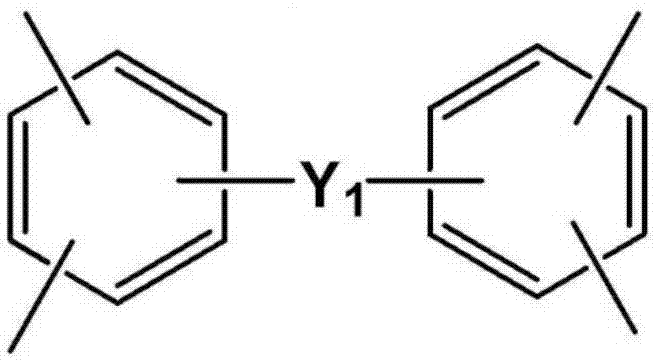

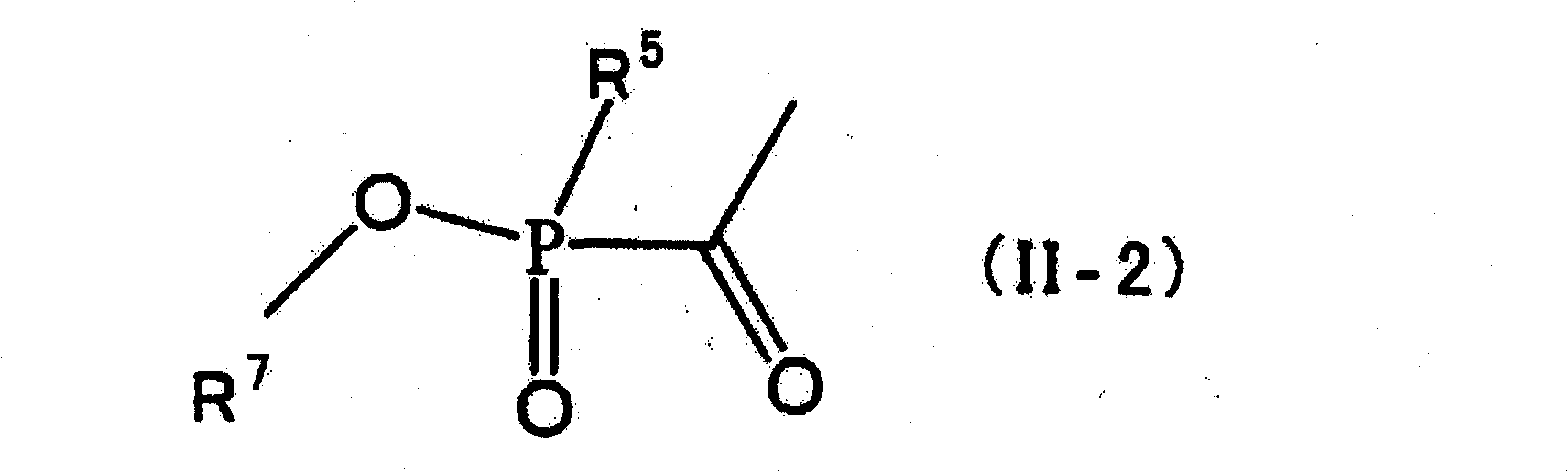

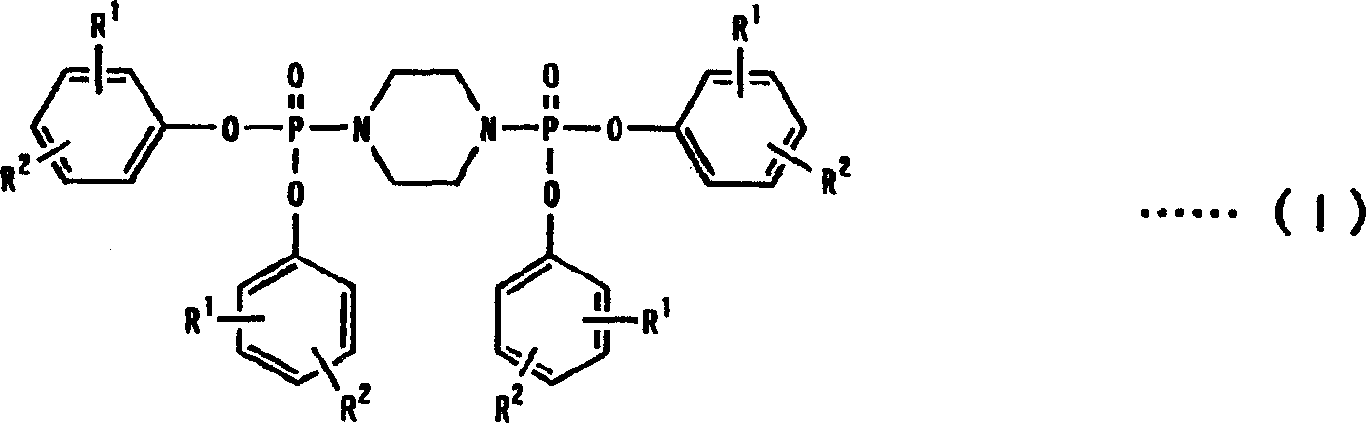

The present invention provides a polyurethane resin composition having high adhesiveness to various plastic films and metals, high moist heat resistance that can even accommodate soldering after humidification, and excellent flame retardancy without using any halogen or antimony, and an adhesive composition, laminate, and printed wiring board that use the polyurethane composition. A polyurethane resin composition containing a polyurethane resin (A) that satisfies (1)-(3) and an epoxy resin (B). (1) Includes a polyester polyol containing a phosphorus compound residue represented by general formula (1) or general formula (2) as a structural component; (2) an acid value (unit: Eq / 106 g) of from 50 to 1000; (3) a urethane group concentration (unit: Eq / 106 g) of from 100 to 600 (R1 and R2 are each independently a hydrogen atom or hydrocarbon group, R3 and R4 are each independently a hydrogen atom, hydrocarbon group, or hydroxy group-substituted hydrocarbon group, and l and m are integers of 0 to 4.) (R5 is a hydrogen atom or hydrocarbon group, and R6 and R7 are each independently a hydrogen atom, hydrocarbon group, or hydroxy group-substituted hydrocarbon group.)

Owner:TOYO TOYOBO CO LTD

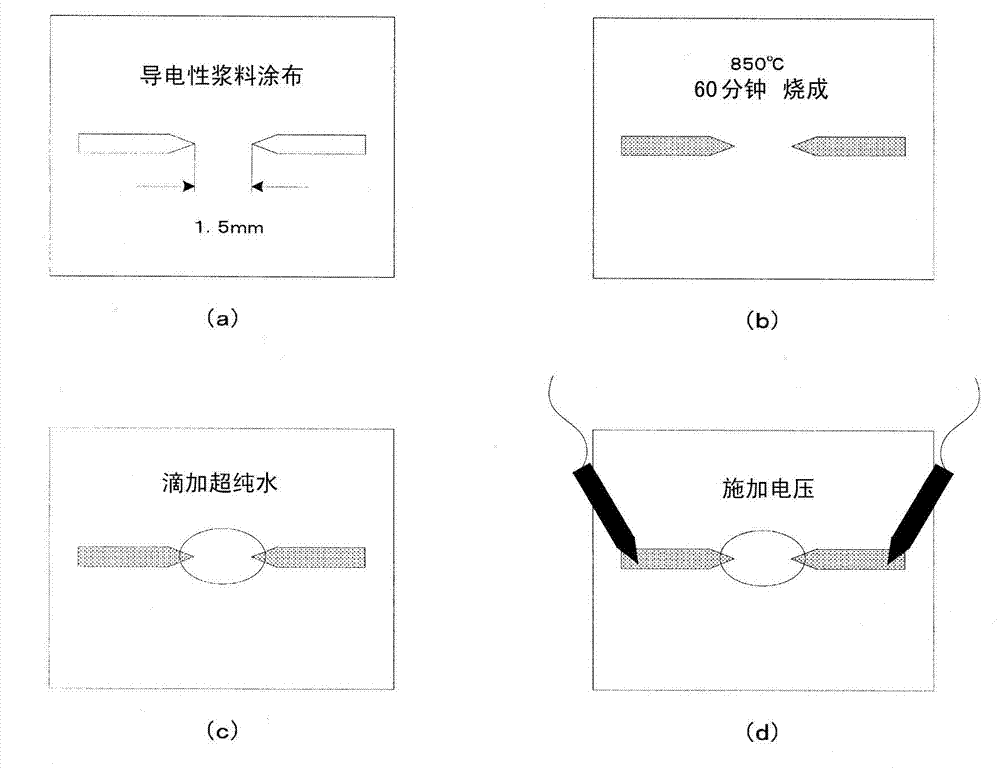

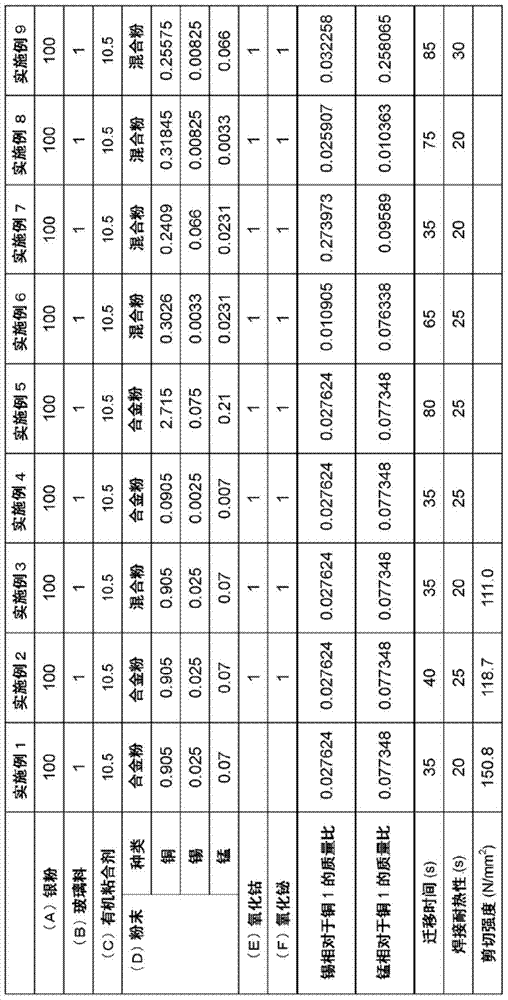

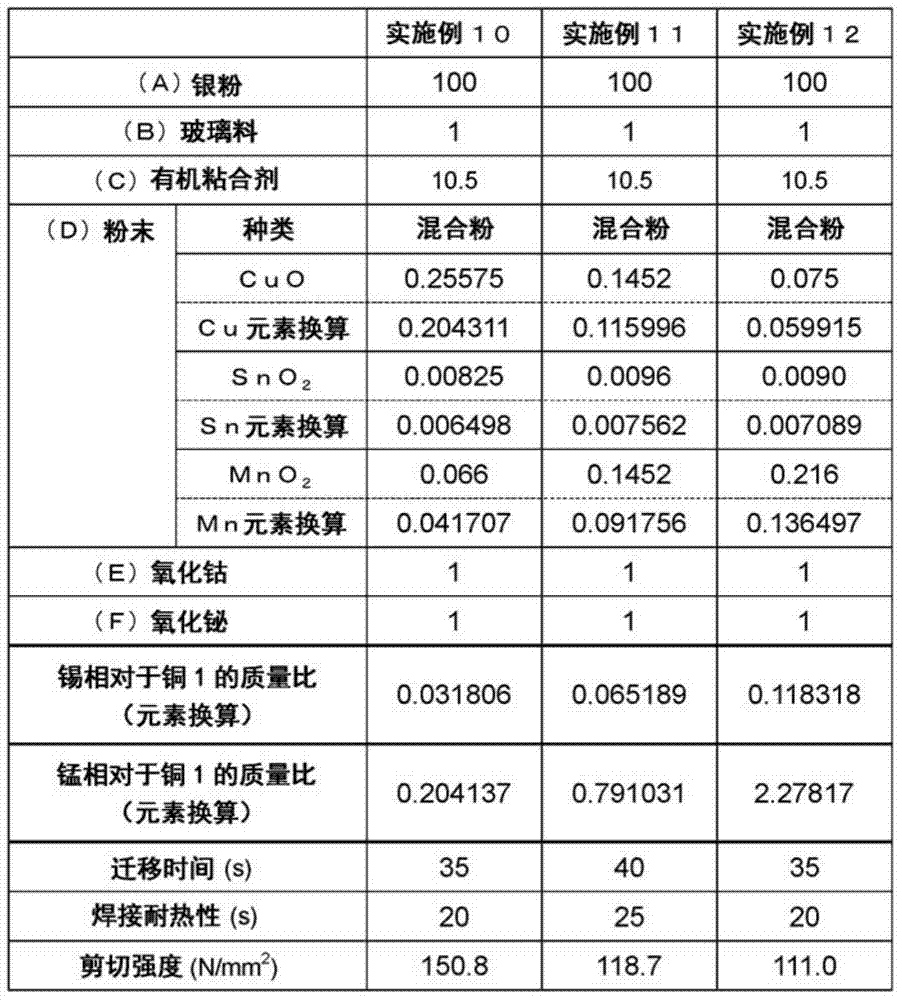

Electroconductive paste

InactiveCN104737238AExcellent electromigration resistanceExcellent soldering heat resistanceConductive layers on insulating-supportsPrinted circuit aspectsFritHeat resistance

Provided is a sintered-type electroconductive paste having excellent electromigration resistance, solder heat resistance, and adhesion to substrates. This electroconductive paste comprises: (A) silver powder; (B) glass frit; (C) an organic binder; and (D) a powder including copper, tin, and manganese. This electroconductive paste preferably comprises 0.1-5.0 parts by mass of said powder (D) per 100 parts by mass of said silver powder (A).

Owner:NAMICS CORPORATION

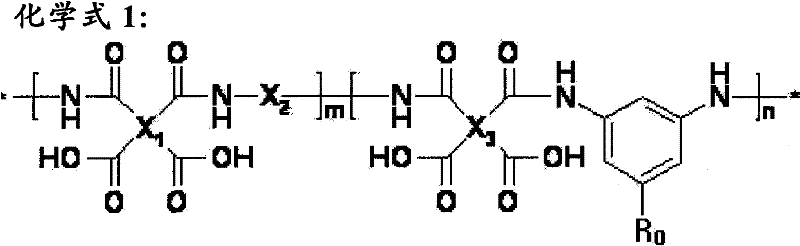

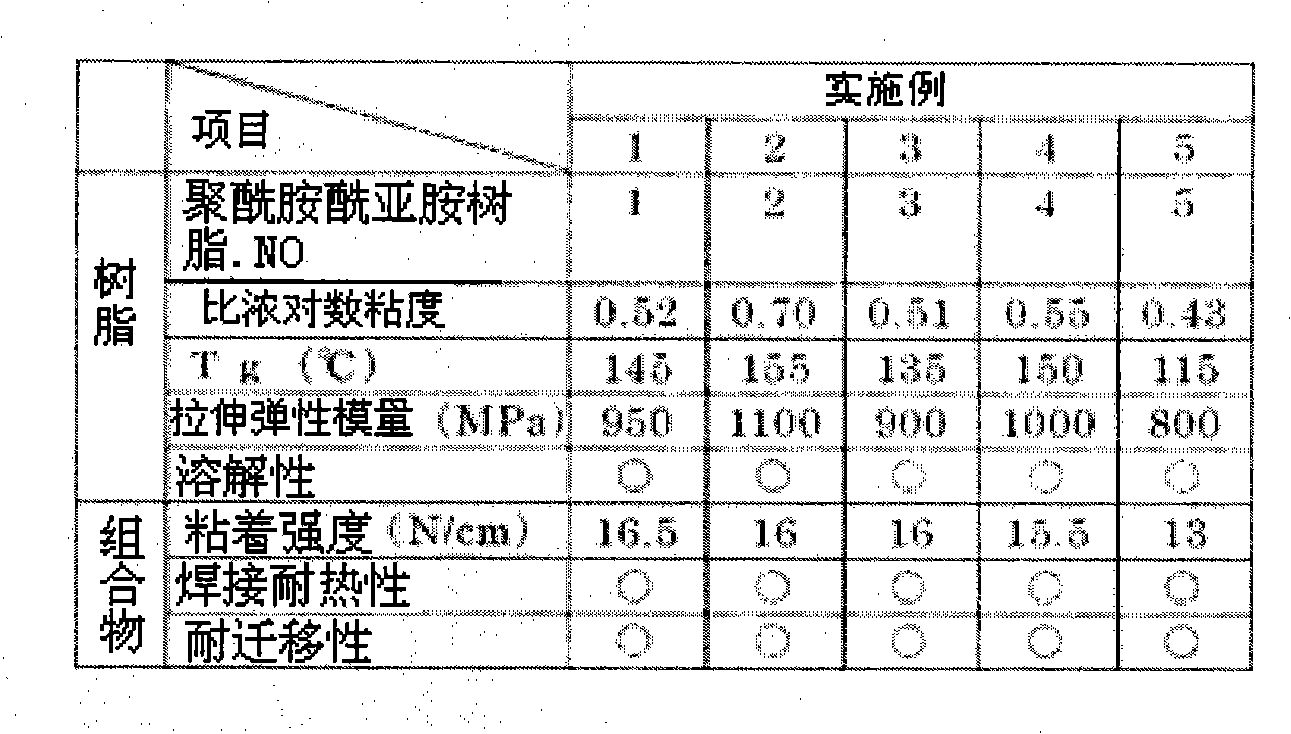

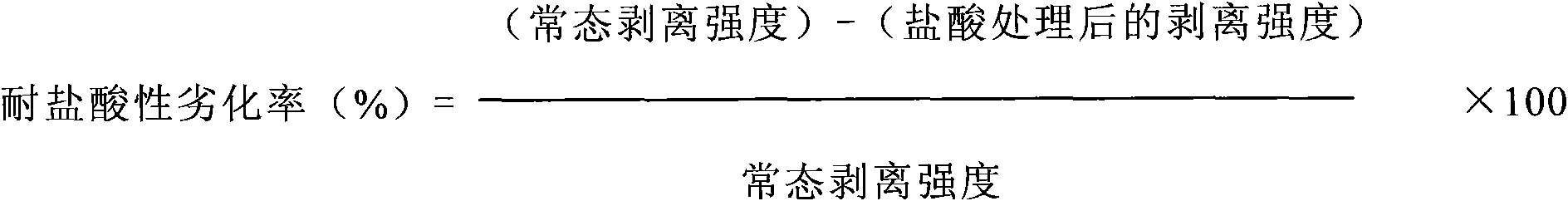

Polyamide resin, resin composition thereof, flame-retardant adhesive composition and adhesive sheet made of said composition, coverlay film, and printed wiring board

ActiveCN102171263AImprove flame retardant performanceExcellent soldering heat resistanceFilm/foil adhesivesPolyureas/polyurethane adhesivesSolubilityCarbon number

Provided is a polyamide resin that simultaneously satisfies requirements for heat resistance, adhesivity, insulation reliability, and solvent solubility, and that is ideal for heat-resistant adhesives for printed wiring board applications. Also provided is a flame-retardant non-halogen adhesive composition made from ingredients that are soluble in general-purpose solvents, and which not only demonstrates stable characteristics but also demonstrates excellent flame-retardancy, solder heat resistance, adhesivity, and electric insulating properties when used for flexible printed wiring boards, for example. Disclosed is a polyamide resin characterized in that the polyamide resin is obtained by reacting acid components (a) to (c) given below and a diisocyanate or diamine having an aromatic ring, and in that when the total of all the acid components of said polyamide resin is 100 mol%, the ratios of the respective acid components are 3 to 10 mol% (a), 10 to 80 mol% (b), and 10 to 87 mol% (c). (a) An acrylonitrile-butadiene rubber having carboxyl groups at both ends; (b) An aliphatic dicarboxylic acid with a carbon number of 4 to 12; (c) A polycarboxylic acid anhydride with an aromatic ring.

Owner:TOYOBO MC CORP

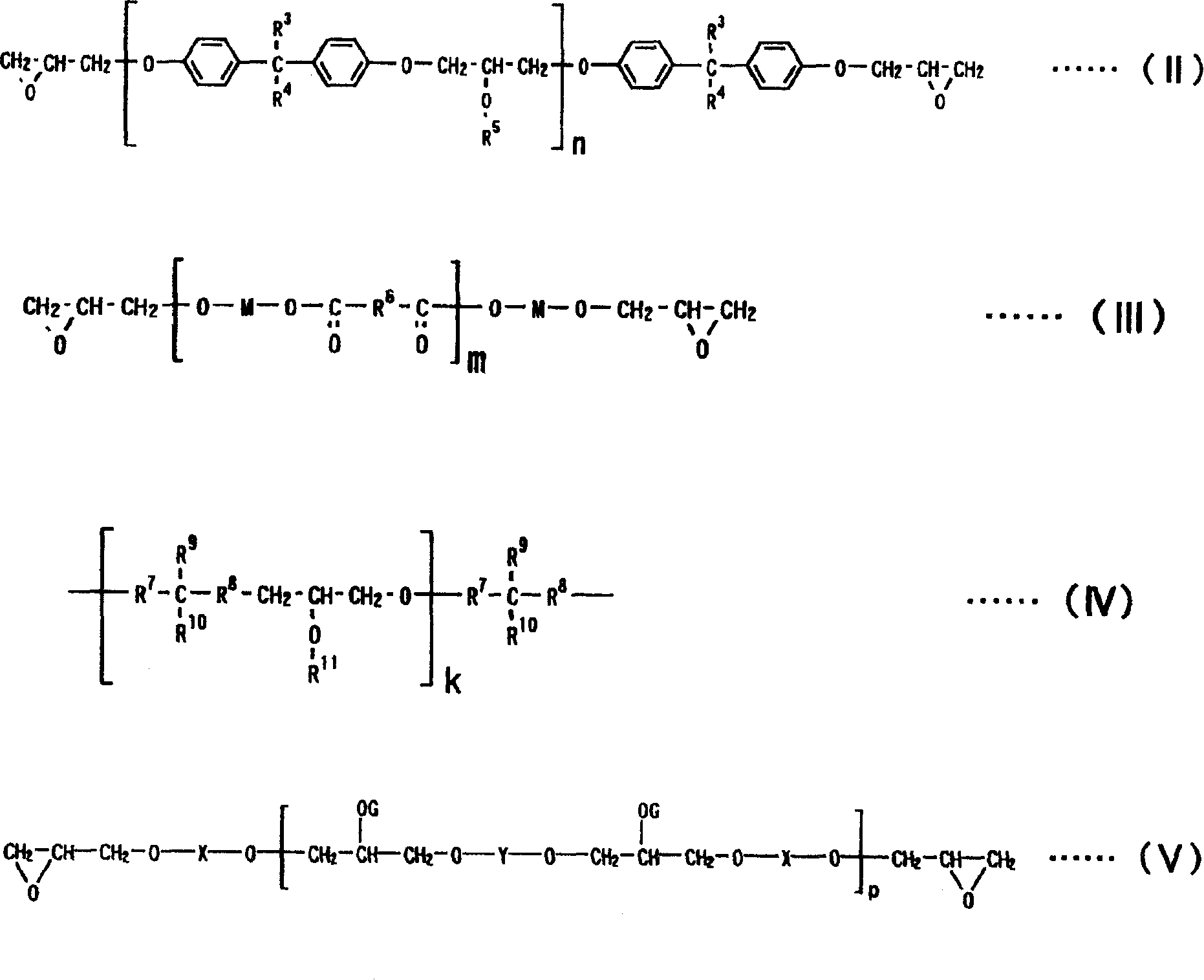

Photosensitive composition, method for forming pattern, and permanent pattern

InactiveCN101116035AExcellent soldering heat resistanceImprove folding resistanceSemiconductor/solid-state device manufacturingPolyurea/polyurethane coatingsHeat resistanceDiol

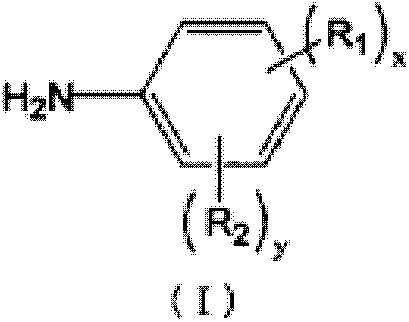

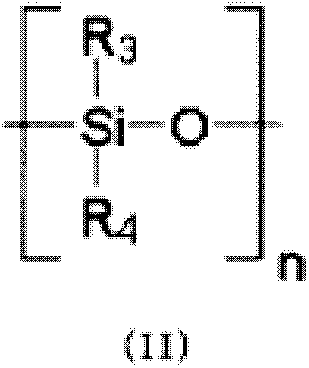

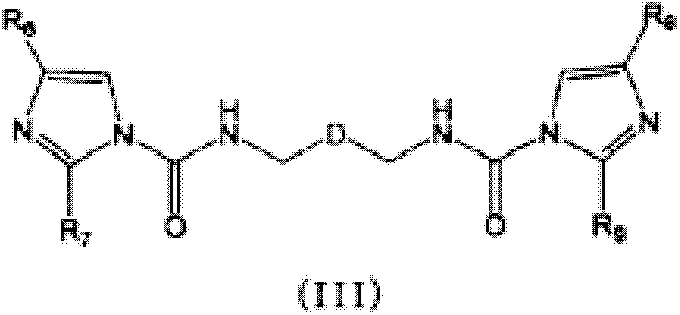

The object of the present invention is to provide a photosensitive composition, a method for forming a pattern, and a permanent pattern. The flexibility is greatly improved, and it is suitable for the manufacture of flexible printed circuit boards. Therefore, the photosensitive composition contains at least (A) a polyurethane resin having a carboxyl group, (B) a polymerizable compound, (C) a photopolymerization initiator, and (D) a thermal crosslinking agent, and the (A) polyurethane resin having a carboxyl group The resin is preferably a form obtained by reacting a diisocyanate compound represented by the following structural formula (I) and a diol compound represented by either the following structural formula (II) or the following structural formula (III).

Owner:FUJIFILM CORP

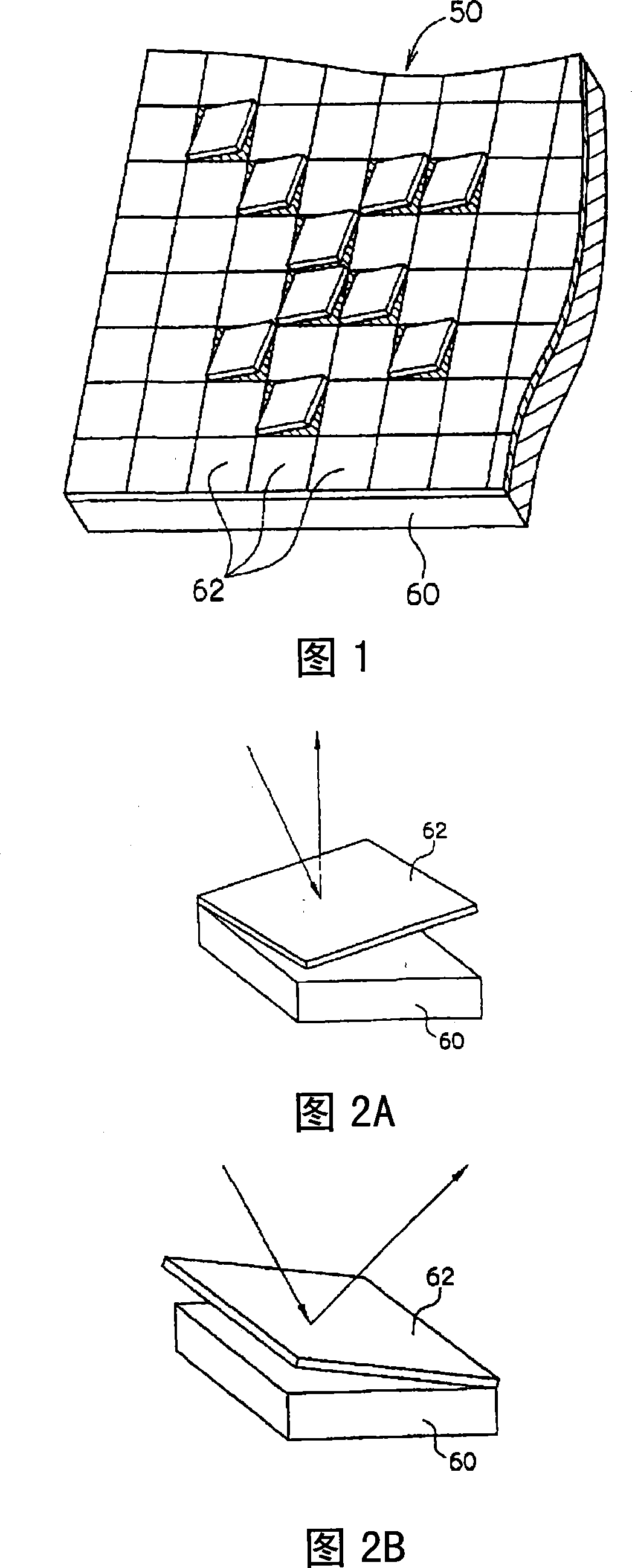

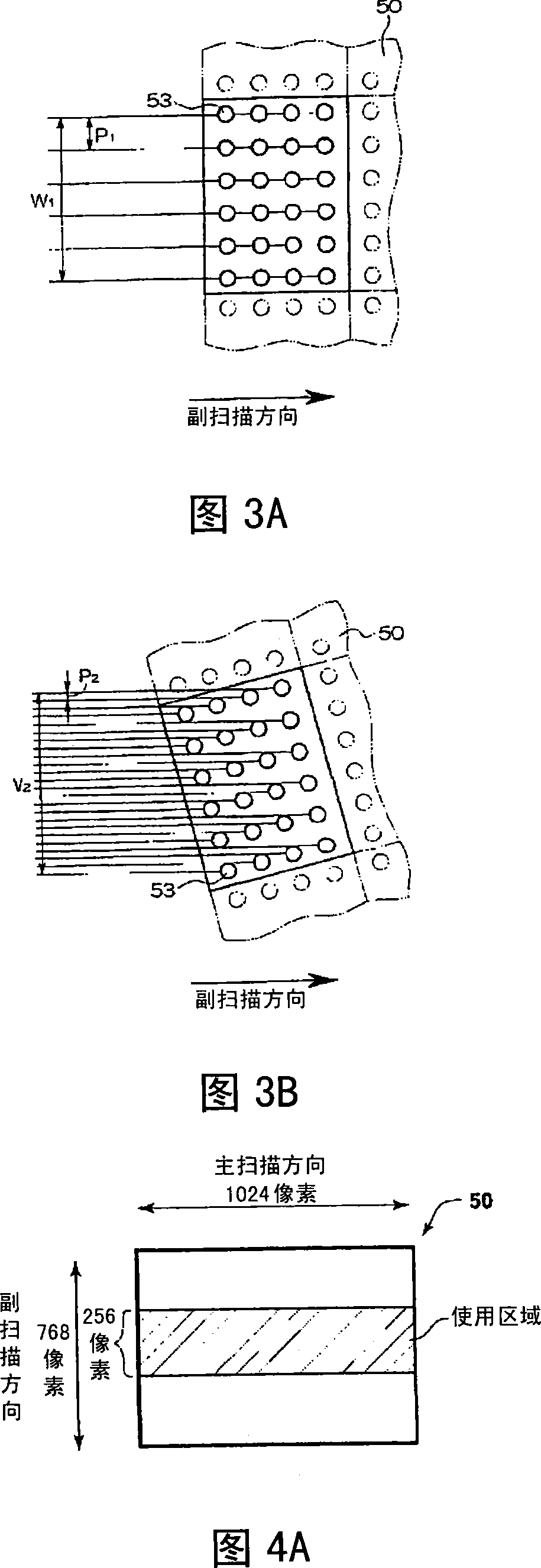

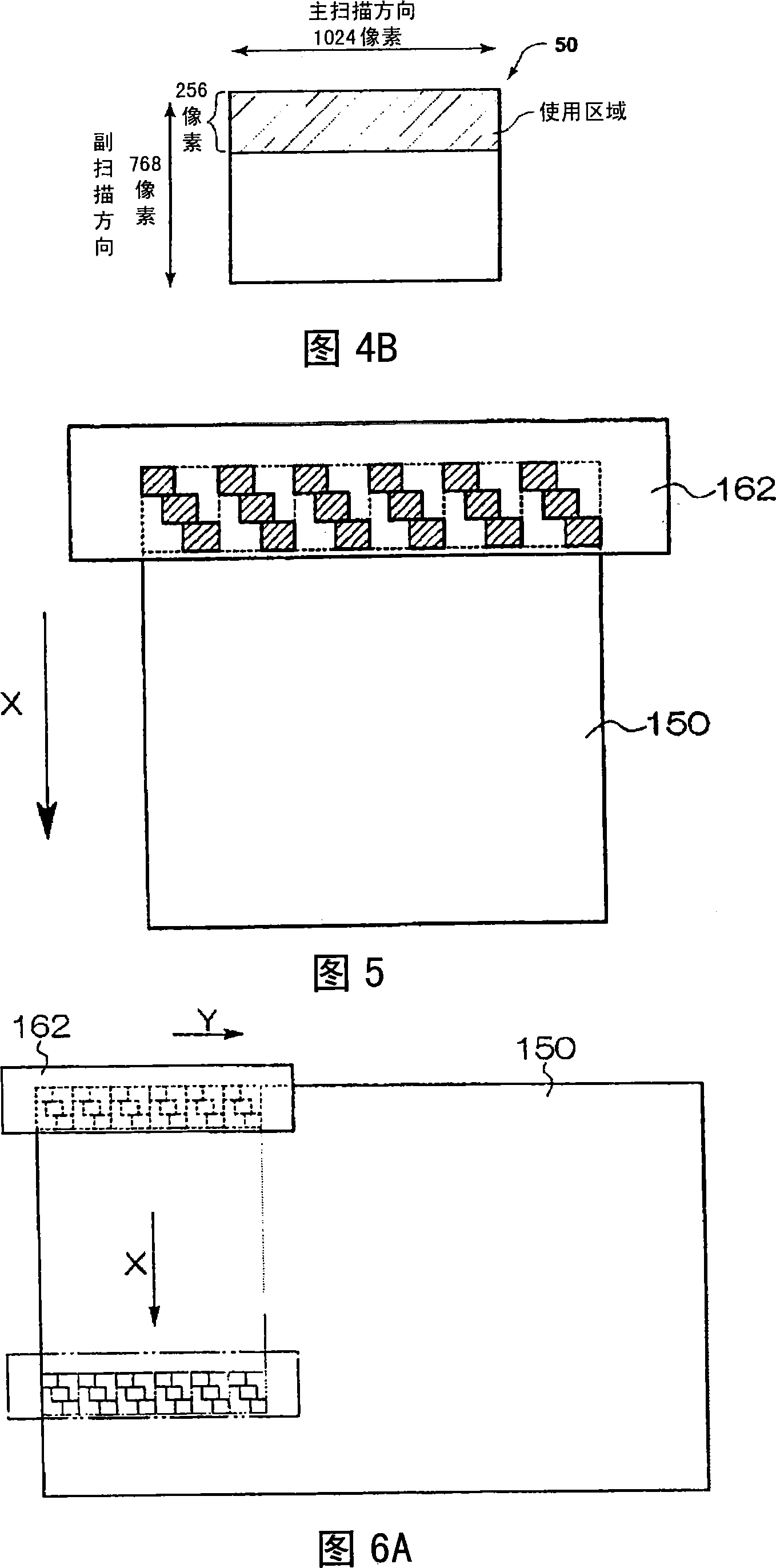

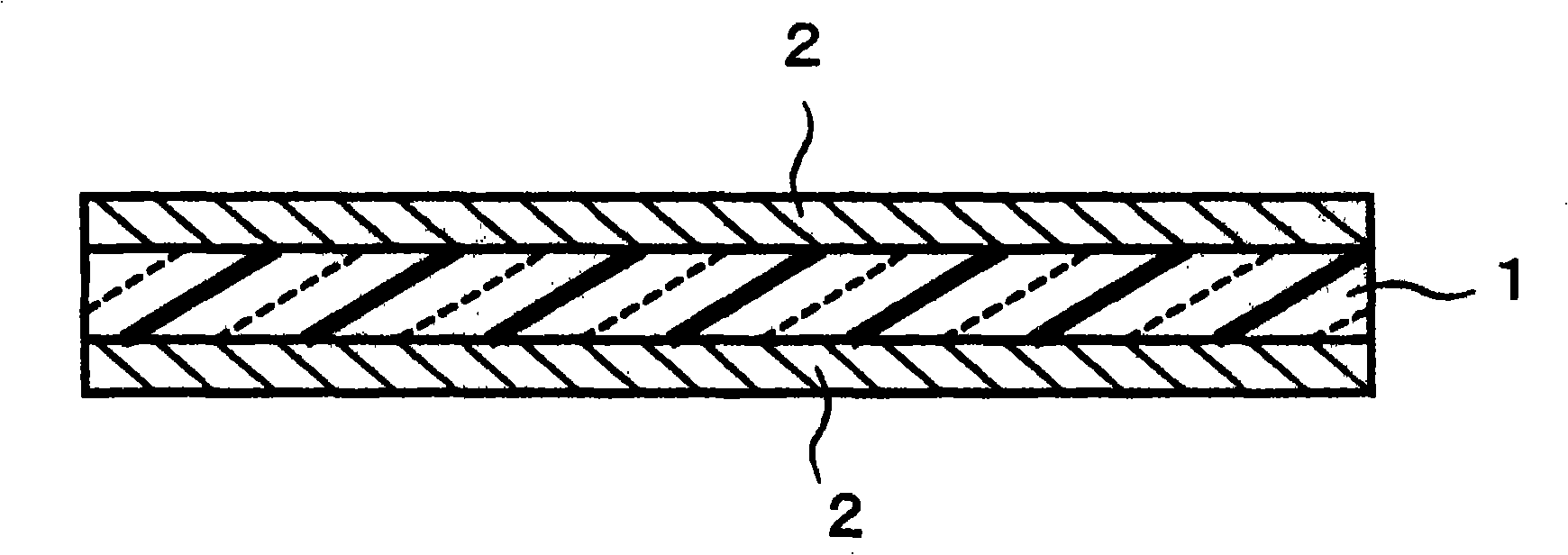

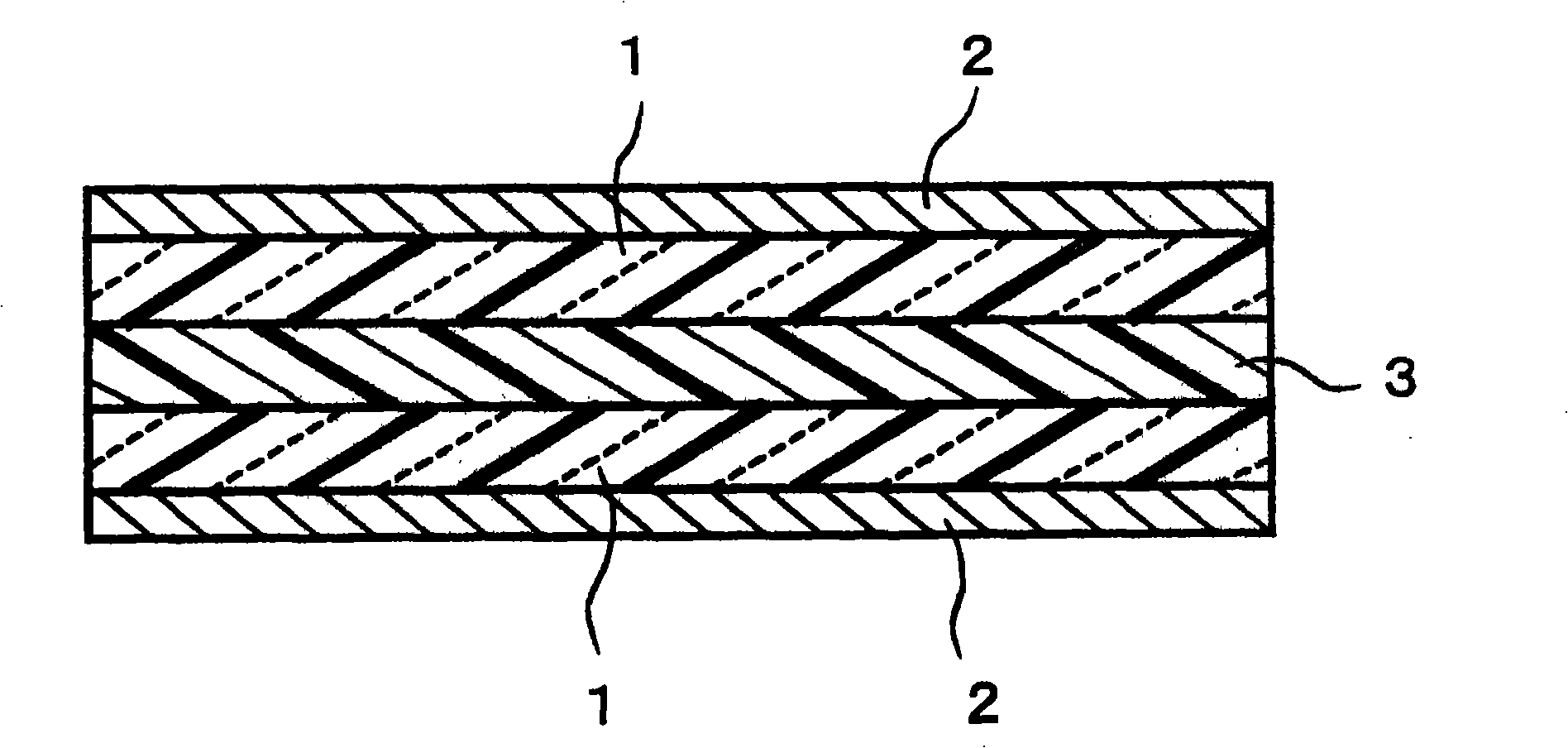

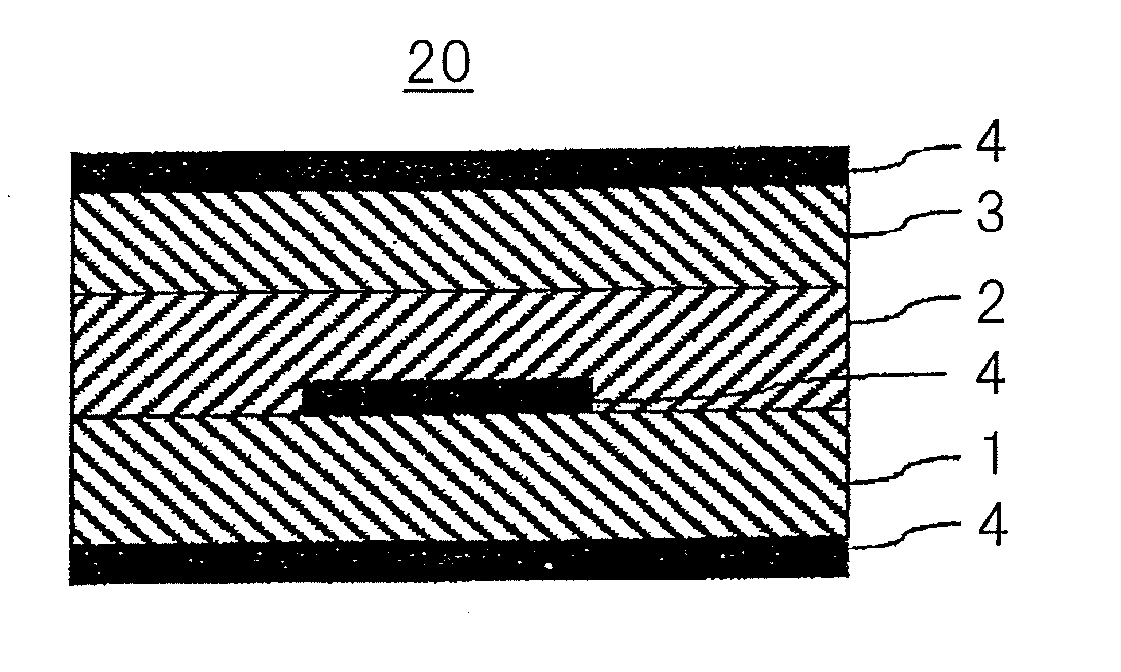

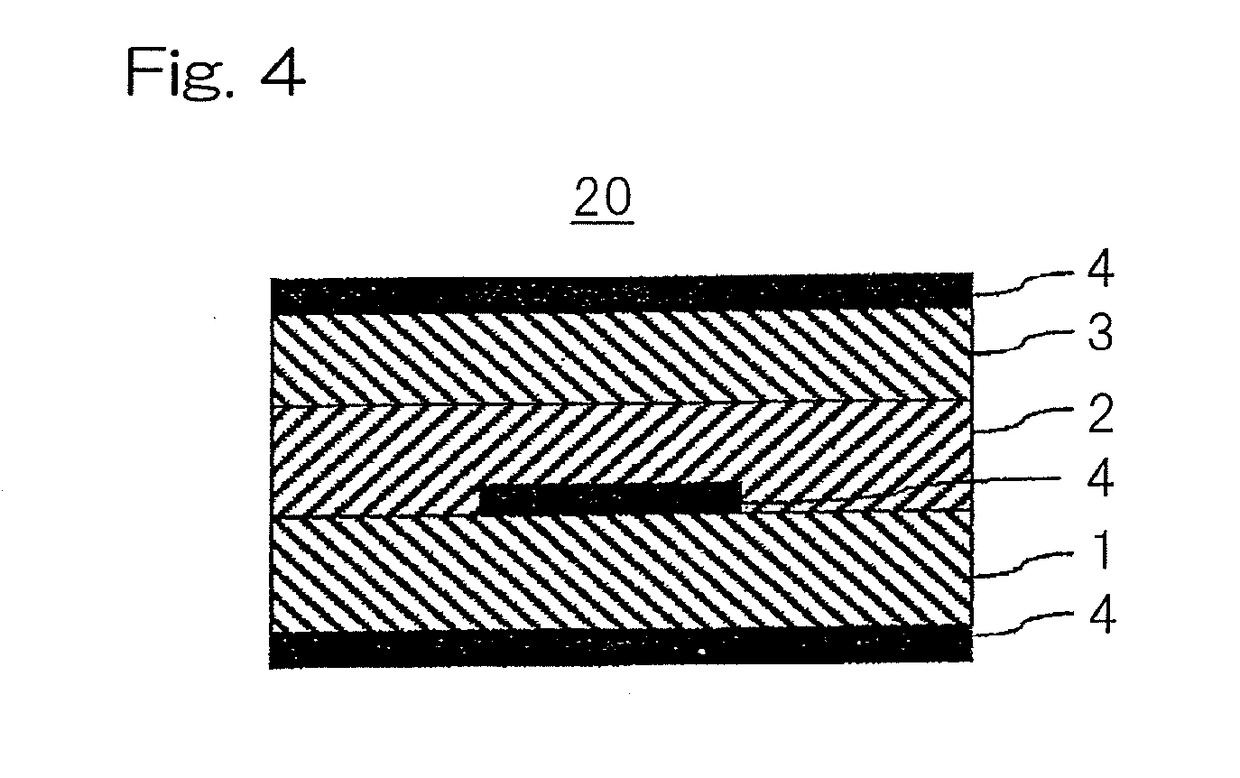

Flexible laminate having thermoplastic polyimide layer and method for manufacturing the same

InactiveCN101410248AExcellent Adhesive StrengthGood migration resistanceMetal layered productsChemistryMetal foil

Disclosed is a flexible laminate comprising a metal foil layer / a thermoplastic layer or / and a conductive circuit layer / a thermoplastic polyimide layer, which is obtained by bonding a metal foil layer or a conductive circuit layer to at least one side of a thermoplastic polyimide layer. In this flexible laminate, the thermoplastic polyimide layer is made of a thermoplastic polyimide resin film or sheet which is obtained by melt-extruding a thermoplastic polyimide resin. Alternatively, the thermoplastic polyimide layer is made of a biaxially stretched thermoplastic polyimide resin film or sheet. Such a flexible laminate can be easily produced by a lamination method wherein a thermoplastic polyimide resin film (1) and a metal foil (2) or a conductive circuit layer (4) are bonded by heat and pressure, and has excellent heat resistance, electrical characteristics and mechanical strength inherent in polyimides. When a biaxially stretched thermoplastic polyimide resin film or sheet is used, the flexible laminate can be improved in dimensional stability and solder heat resistance.

Owner:KURASHIKI BOSEKI KK +1

Bonding agent composition, bonding agent tablet using same and its uses

ActiveCN101268163AHigh bonding strengthGood storage stabilityFilm/foil adhesivesPolyureas/polyurethane adhesivesEpoxyPolyamide

Disclosed is an adhesive composition (I) characterized by containing a polyurethane polyurea resin (A) having a weight average molecular weight of 80,000-250,000 and an acid number of 3-25 mgKOH / g and an epoxy resin (B). The polyurethane polyurea resin (A) is obtained by reacting a urethane prepolymer (d) having an isocyanate group, a polyamino compound (e) and a monoamino compound (f) under the conditions stated below. The urethane prepolymer (d) having an isocyanate group is obtained by reacting a polyol compound (a), an organic diisocyanate (b) and a diol compound (c) having a carboxyl group. (i) The ratio between isocyanate groups of the urethane prepolymer (d) having an isocyanate group and amino groups of the polyamino compound (e) and the monoamino compound (f), namely amino groups / isocyanate groups is from 0.8 / 1 to 0.999 / 1 (molar ratio). (ii) The ratio of amino groups of the polyamino compound (e) in the 100 mol% of the total of the amino groups of the polyamide compound (e) and the amino groups of the monoamino compound (f) is 90.0-97.0 mol%.

Owner:TOYO INK SC HOLD CO LTD

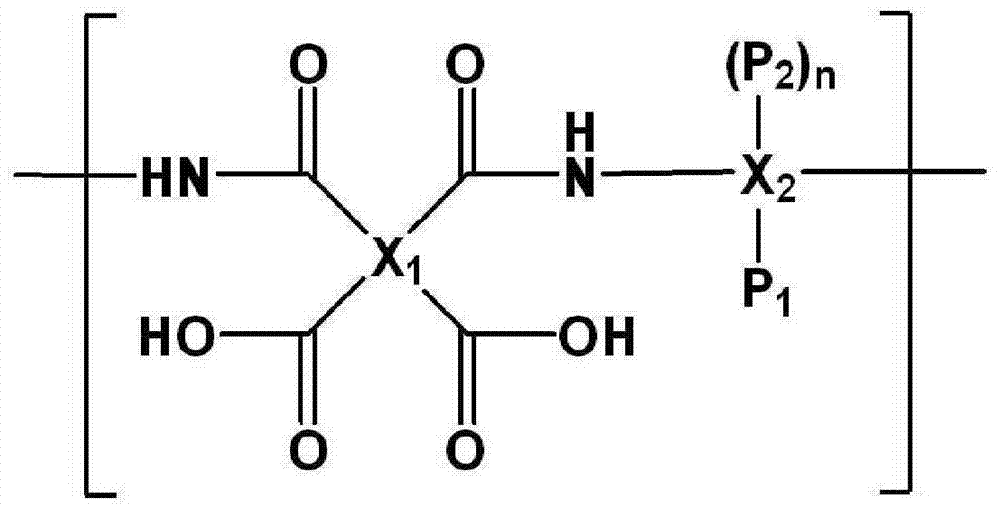

Resin composition, and printed wiring board, laminated sheet, and prepreg using same

InactiveCN103328577AHigh glass transition temperatureExcellent thermal expansionPrinted circuit aspectsSynthetic resin layered productsHeat resistanceOrganic group

A resin composition containing: (a) a maleimide compound having at least two N-substituted maleimide groups in each molecular structure, and (b) a silicone compound having at least one reactive organic group in each molecular structure; and a printed wiring board, a laminated sheet, and a prepreg using the resin composition. A resin composition exhibiting excellent heat resistance and low thermal expansion, and a printed wiring board, a laminated sheet, and a prepreg using the resin composition can be provided.

Owner:HITACHI CHEM CO LTD

Surface treated copper foil, surface treated copper foil with very thin primer resin layer, method for manufacturing the surface treated copper foil, and method for manufacturing the surface treated c

ActiveCN101528981AHigh peel strengthImproved chemical resistance degradation ratePrinted circuit aspectsPrinted circuit manufactureCopper foilNickel alloy

This invention provides a surface treated copper foil which, without use of chromium in an antirust treated layer in an electrolytic copper foil, is excellent in good properties after fabrication into a printed wiring board, for example, in peel strength of a circuit and the percentage deterioration in chemical resistance regarding the peel strength. In the surface treated copper foil, an antirust treated layer and a silane coupling agent layer are provided on a face of lamination of an electrolytic copper foil onto an insulating resin base material. The surface treated copper foil is characterized in that the antirust treated layer comprises a nickel alloy layer having a weight thickness of 5 mg / m to 50 mg / m and a tin layer having a weight thickness of 5 mg / m to 40 mg / m stacked in that order and a silane coupling agent layer is provided on the surface of the antirust treated layer. Further, the present invention further provides, for example, a surface treated copper foil with a very thin primer resin layer, characterized in that a very thin primer resin layer having an equivalent thickness of 1 [mu]m to 5 [mu]m is provided on a face of lamination of the surface treated copper foil (not subjected to roughening treatment) on the insulating resin base material.

Owner:MITSUI MINING & SMELTING CO LTD

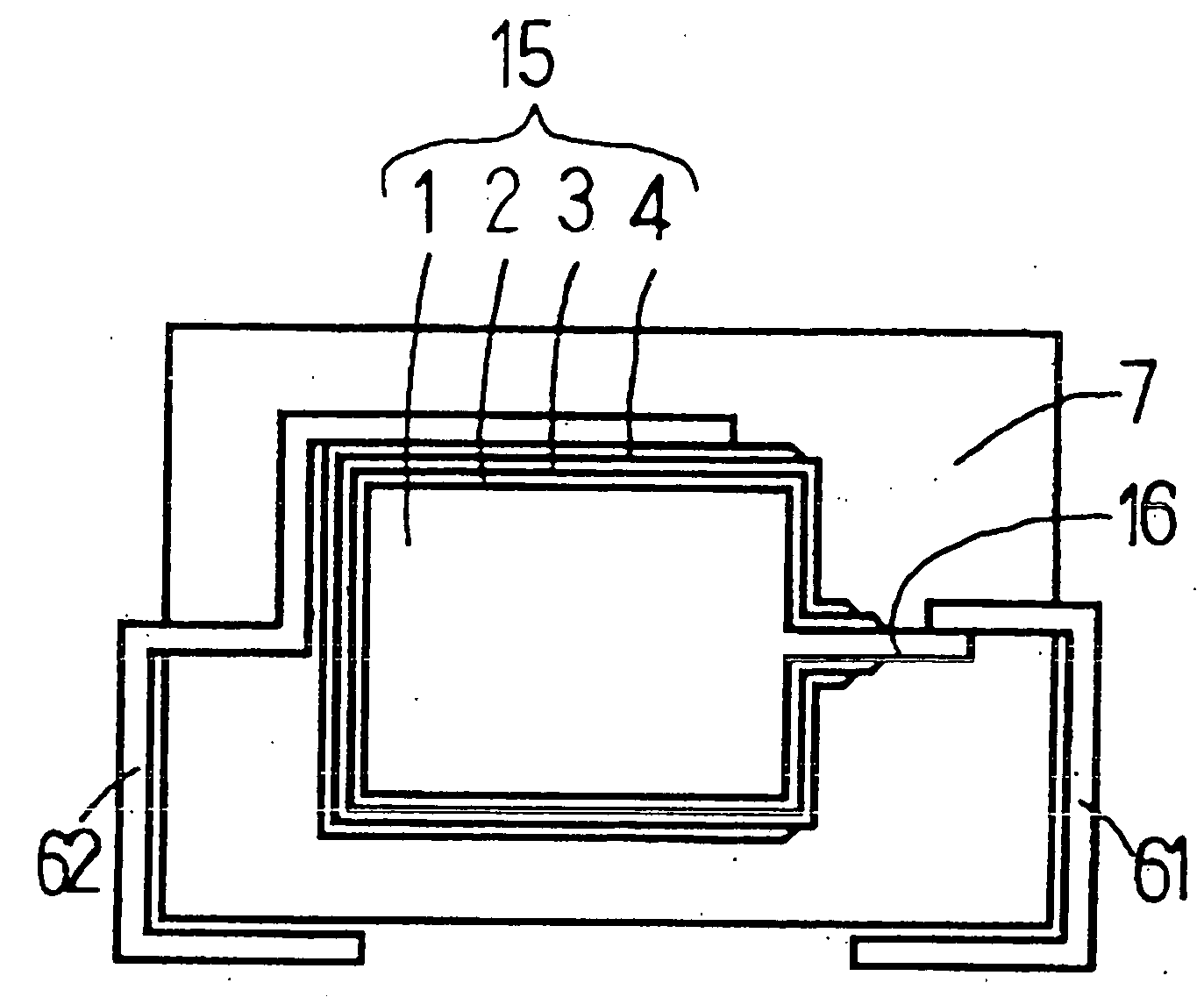

Novel polyamic acid, photosensitive resin composition, dry film and circuit board

ActiveCN103502313AImprove bending performanceImprove rigidityPrinted circuit aspectsPrinted circuit manufactureHeat resistancePolyamic acid

The present invention relates to: a novel polyamic acid in which imidazole is introduced to polymer chains; a photosensitive resin composition containing the polyamic acid which can provide a photosensitive material satisfying the characteristics of excellent flexibility and low stiffness, and has excellent heat resistance and coating resistance; a dry film obtained from the photosensitive resin composition; and a circuit board including the dry film.

Owner:LG CHEM LTD

Carboxyl group-containing polyurethane and thermosetting resin composition using the same

InactiveCN101133096AExcellent substrate adhesionImprove flexibilityPhotomechanical apparatusPolymer sciencePolycarbonate

The present invention relates to a carboxyl group-containing polyurethane obtained by making (a) a polyisocyanate compound, (b) a polycarbonate diol having a molecular weight of 300 to 50,000, (c) a dihydroxy compound having a carboxyl group and, if necessary, (d) a monohydroxy group. Compounds are reacted to obtain a thermosetting composition using the carboxyl group-containing polyurethane, and a paste for forming a film using the thermosetting composition. The thermosetting compositions of the present invention have excellent substrate adhesion, low warpage, plating resistance and solder heat resistance.

Owner:SHOWA DENKO KK

Metal laminate

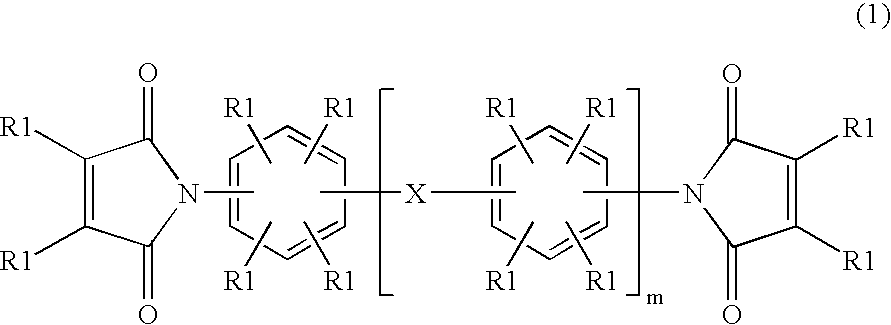

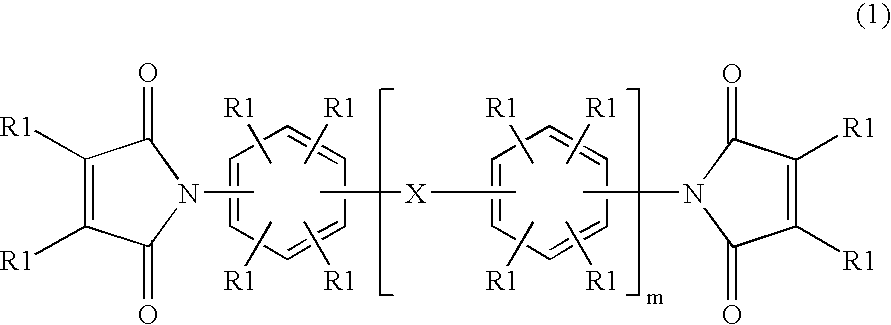

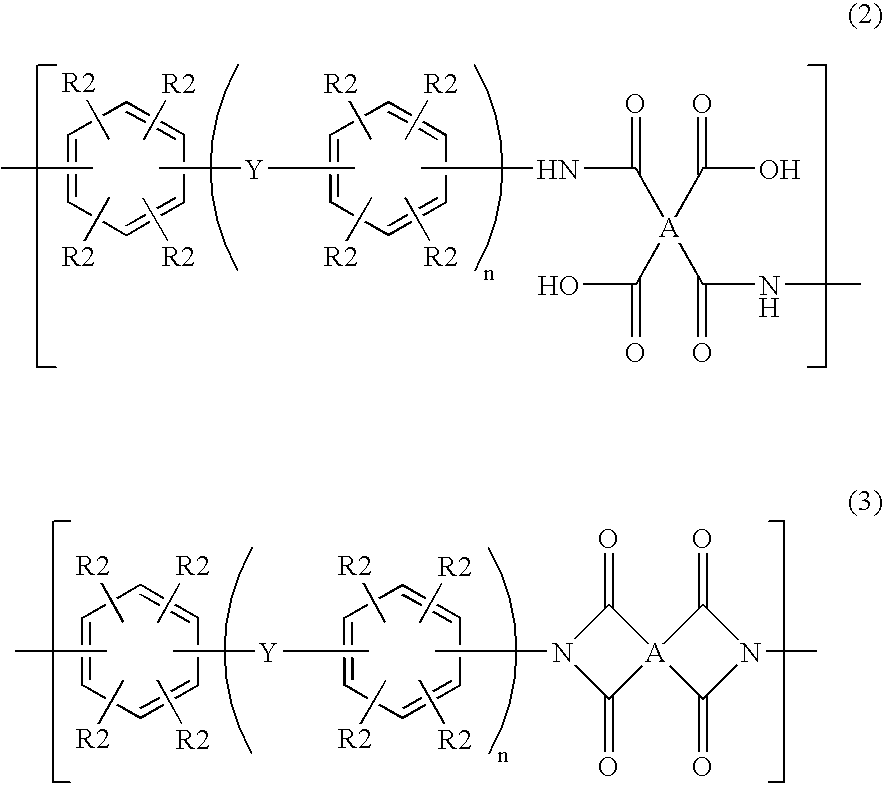

InactiveUS20040096679A1Excellent soldering heat resistanceImprove heat resistanceSynthetic resin layered productsPrinted circuit aspectsCompound aHydrogen atom

A heat resistance resin composition having superb low-temperature adhesiveness and a polyimide / metal laminate which is superior in solder heat resistance and hardly generates swelling when forming a Au-Sn bond or Au-Au bond, which are used for lead-free soldering and COF packaging. A metal laminate comprising a layer comprises a resin composition prepared by compounding a bismaleimide compound represented by the following formula (1) in a polyamic acid and / or a polyimide: wherein m denotes an integer of 0 or more, each X independently represent O, SO2, S, CO, CH2, C(CH3)2, C(CF3)2 or a direct bond and each R1 independently represents a hydrogen atom, a halogen atom or a hydrocarbon group and is independent of any other R1 as to the substitution position on the benzene ring; and a metal foil layer, wherein the layer of the resin composition is formed on at least one surface of the metal foil layer. A resin composition for a metal laminate is also disclosed.

Owner:MITSUI CHEM INC

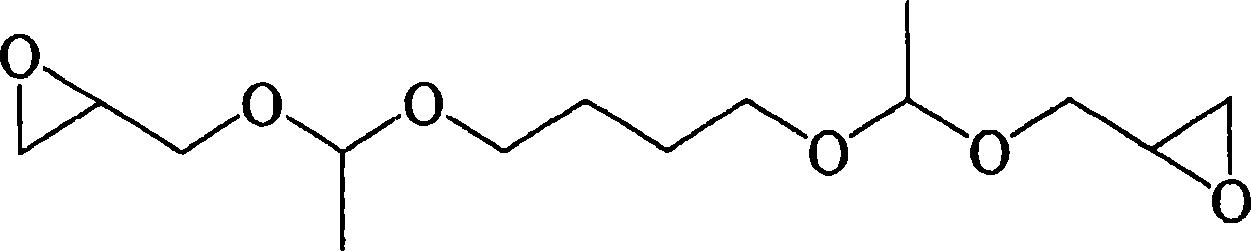

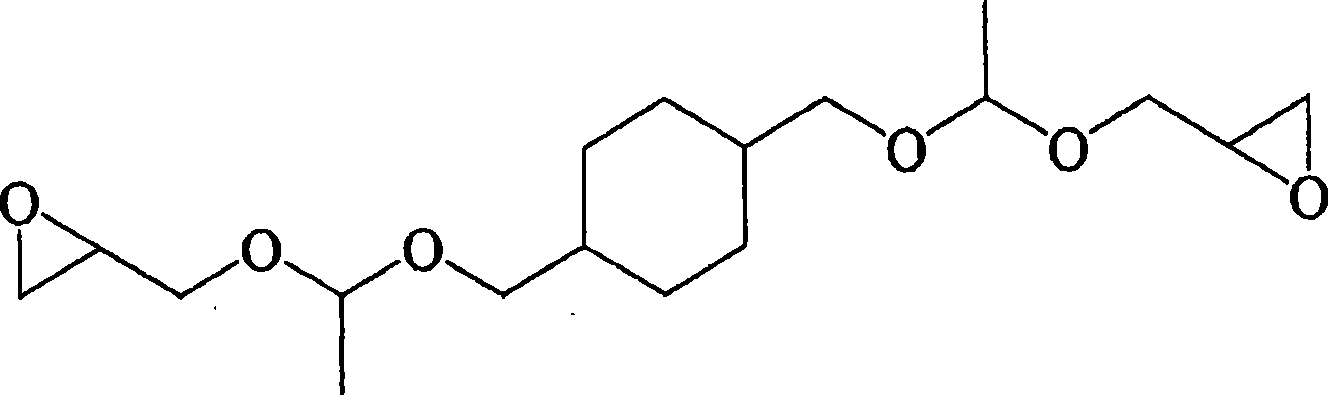

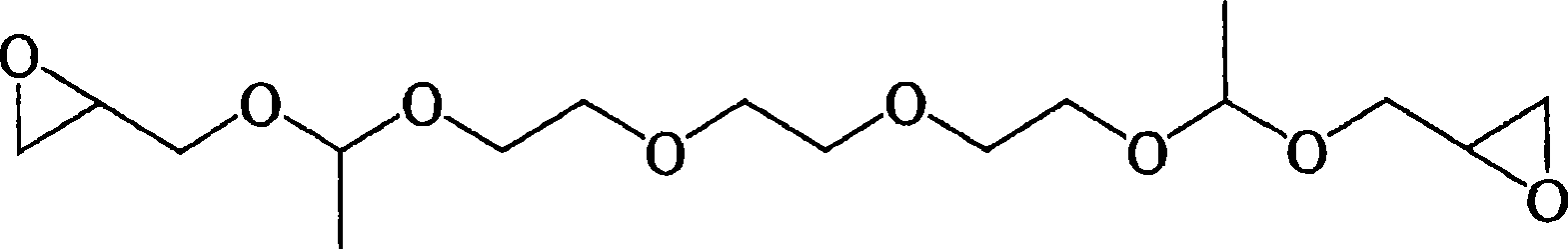

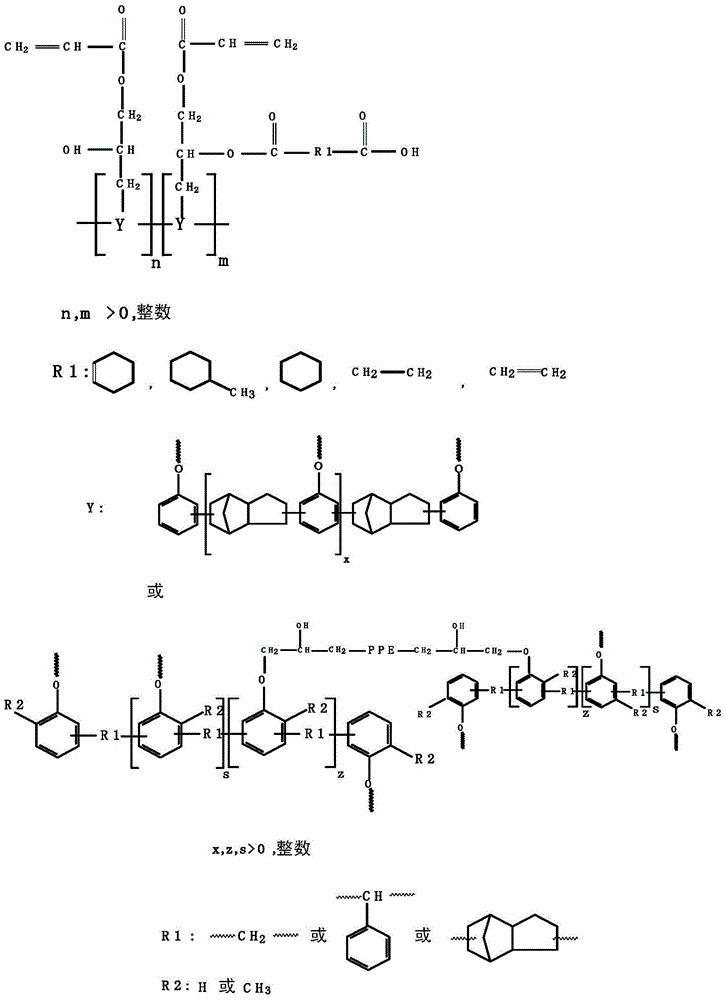

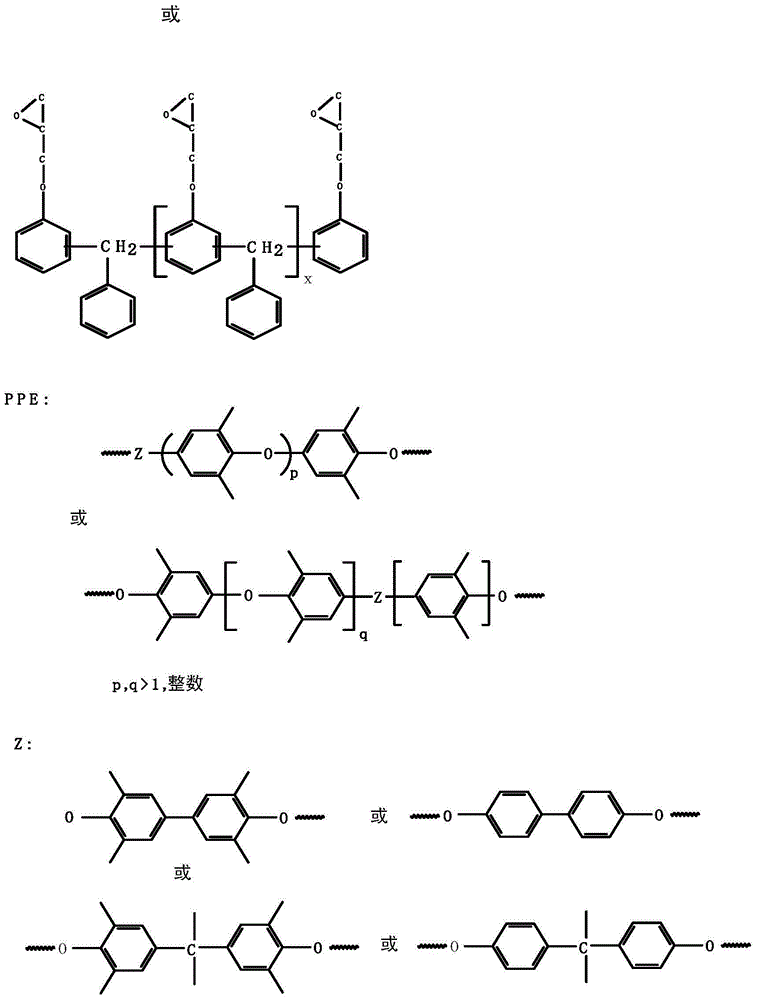

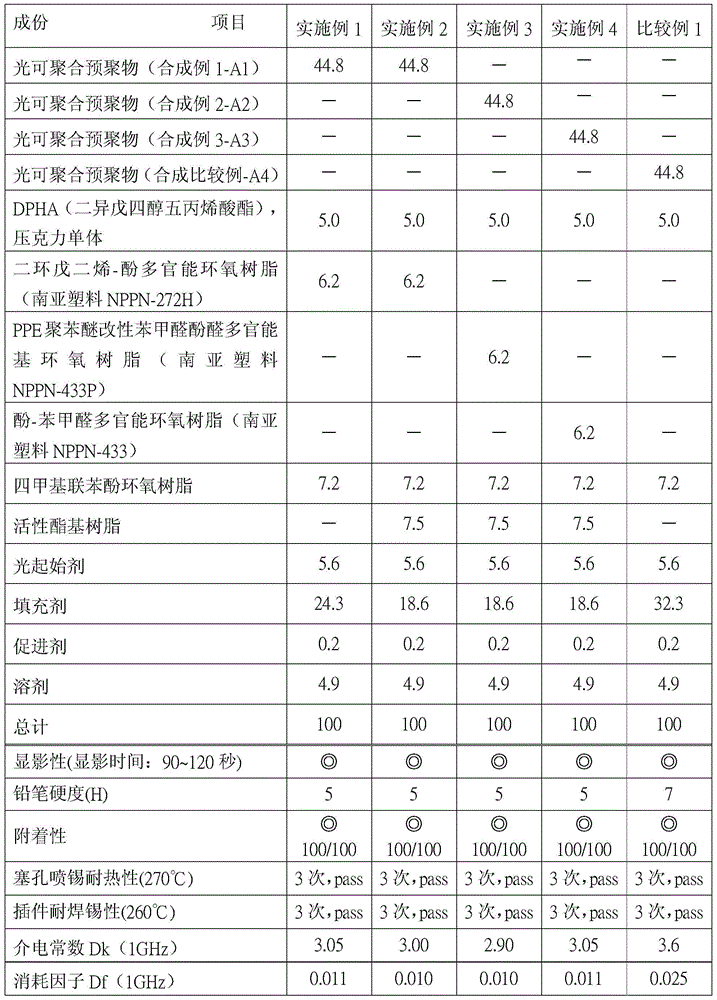

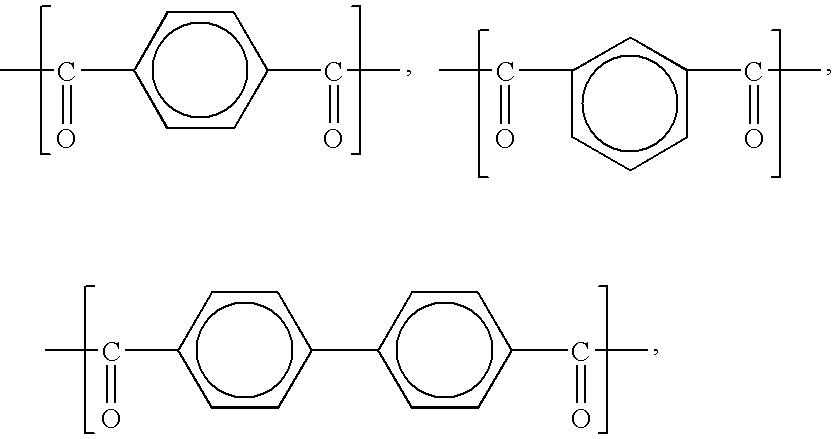

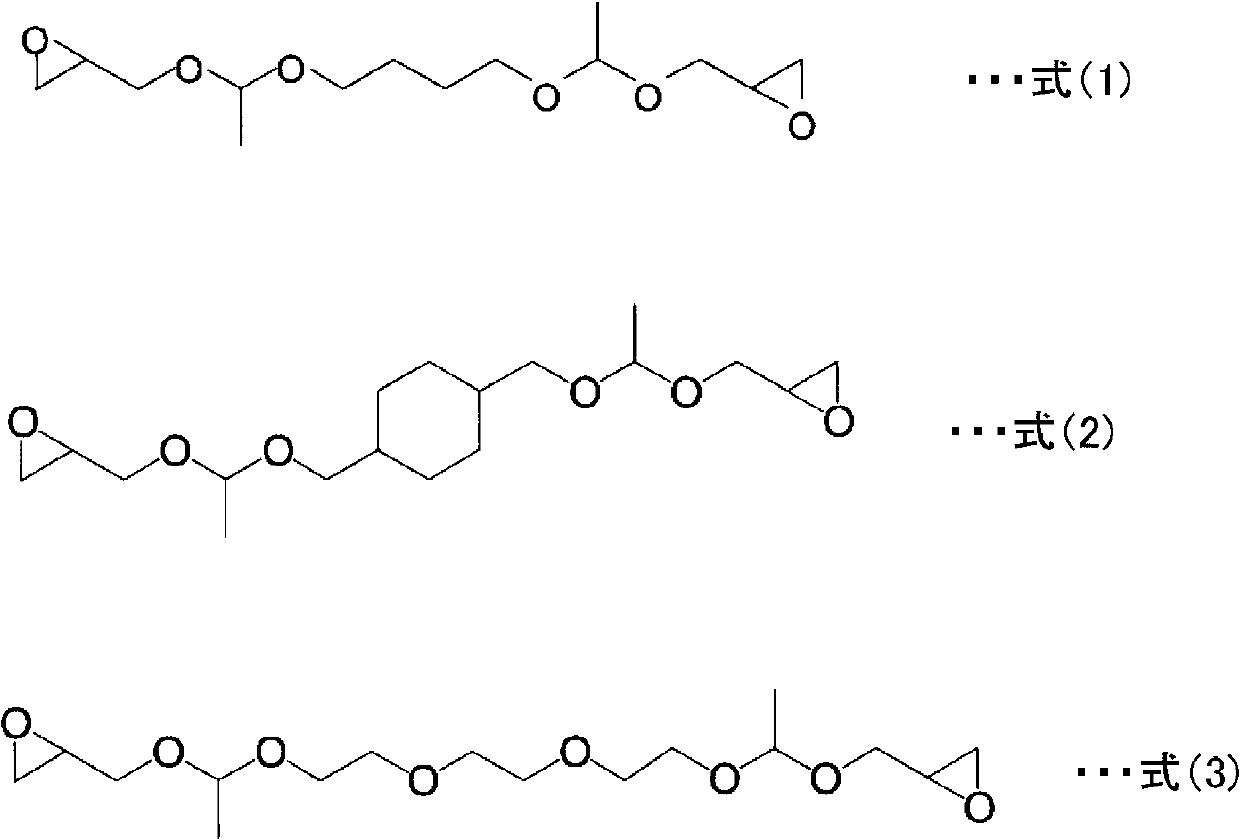

Low-dielectric welding-resistant photoresist ink composition for printed circuit board

The invention provides a welding-resistant photoresist ink composition with the advantages of excellent light hardening force, high alkali wash imaging resolution force and low dielectric constant. The printed circuit board welding-resistant ink prepared by using the composition has the advantages of excellent adherence, solution resistance, electrical characteristics, plating resistance, solder heat resistance, electrical erosion resistance and the like, the dielectric constant Dk of the ink is less than 3.20 (1GHz), and the loss factor Df is less than 0.015(1GHz). The low-dielectric constant welding-resistant photoresist ink composition comprises the following components in percentage by weight: (A) 20-70% of light polymerizable prepolymer (oligomer) shown as a formula (1), wherein the prepolymer is prepared by reacting (a1) dicyclopentadiene-phenol polyfunctional epoxy resin (namely DCPD-phenol polyfunctional epoxy resin) or (a2) polyoxyphenylene modified polyfunctional epoxy resin or (a3) phenol-benzaldehyde polyfunctional epoxy resin or any mixture of two of (a1), (a2) and (a3) with (b) monocarboxylic acid containing a vinyl and then reacting with (c) saturated or insaturated polybasic anhydrides; (B) 0-20% of a light polymerizable vinyl monomer serving as a diluent; (C) 5-30% of an epoxy resin compound comprising (C1) a dicyclopentadiene-phenol polyfunctional epoxy resin (namely DCPD-phenol polyfunctional epoxy resin) or polyoxyphenylene modified polyfunctional epoxy resin or phenol-benzaldehyde polyfunctional epoxy resin or any combination of the three resins, (C2) a tetramethyl diphenol epoxy resin, and (C3) an active ester-based resin; (D) 2-10% of a photo-polymerizatoin initiator; (E) 10-50% of an inorganic filling agent; (F) 0-2.0% of an accelerant; and (G) 10-40% of an organic solvent.

Owner:NANYA PLASTICS CORP

Method for producing aramid laminate

InactiveUS20060127687A1Excellent soldering heat resistanceReduce moisture absorption performanceLiquid crystal compositionsAdhesive processes with surface pretreatmentPolymer sciencePolyamide

A process for preparing an aramid laminate, which comprises impregnating a surface and an interior an aramid paper with a liquid crystal polymer, and laminating a layer comprising an aramid paper and a layer comprising a liquid crystal polymer.

Owner:SUMITOMO CHEM CO LTD

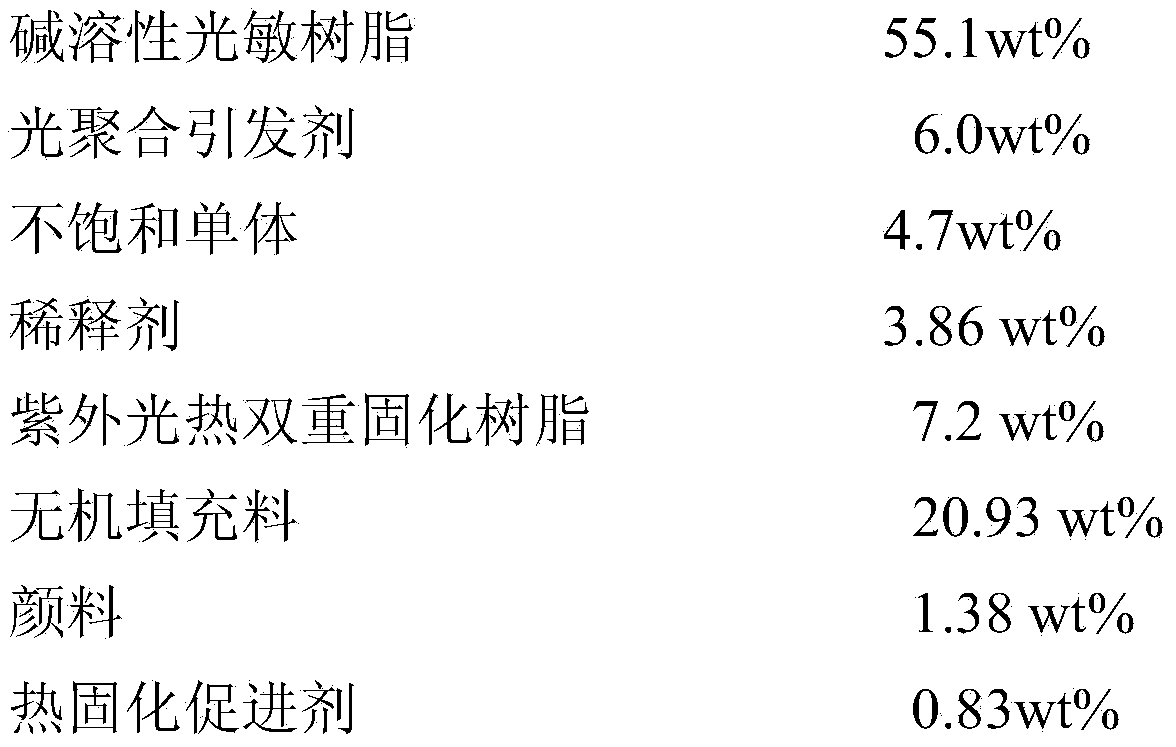

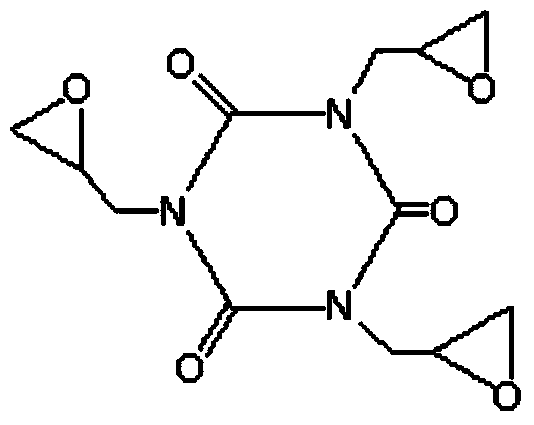

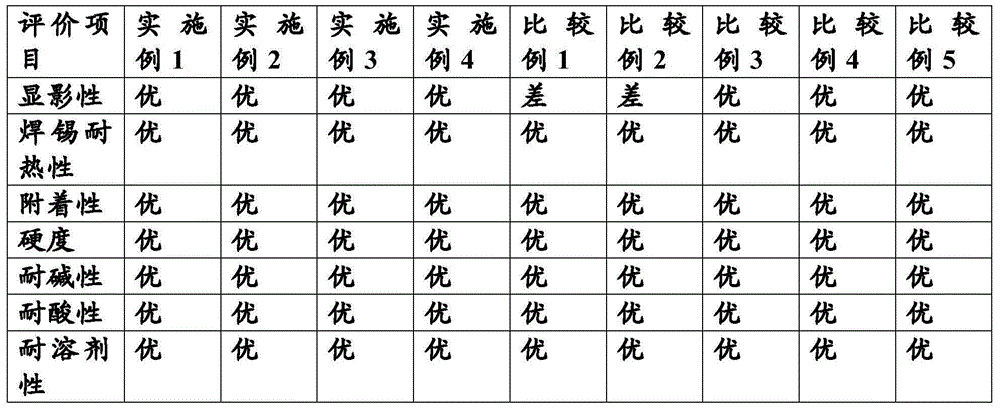

Photocuring-thermocuring composite ink, application and circuit board containing photocuring-thermocuring composite ink

ActiveCN105086605AWide use development processExcellent soldering heat resistancePrinted circuit detailsInksEpoxyAntioxidant

The invention provides photocuring-thermocuring composite ink. The ink comprises the following components: A, 10 to 60% of photopolymerization resin with an molecule containing carboxyl and an unsaturated double bond; B, 2 to 20% of a photopolymerization unsaturated double-bond monomer; C, 0.5 to 20% of hydantoin epoxy resin; D, 2 to 20% of epoxy resin; E, 0.1 to 5% of an epoxy curing accelerator; F, 0.1 to 15% of a photopolymerization initiator; G, 10 to 70% of a filler; H, 0 to 10% of pigment; I, 0.1 to 5% of a defoaming agent; meanwhile, the ink also comprises a leveling agent, an antioxidant, an adhesion promotor, a thixotropic agent and a solvent. The composite ink is applied in printing an insulation solder protectant of a circuit and has good performcances like solder heat resistance, developability, adhesiveness, hardness, alkali resistance, acid resistance, solvent resistance, etc.

Owner:深圳市容大感光科技股份有限公司 +1

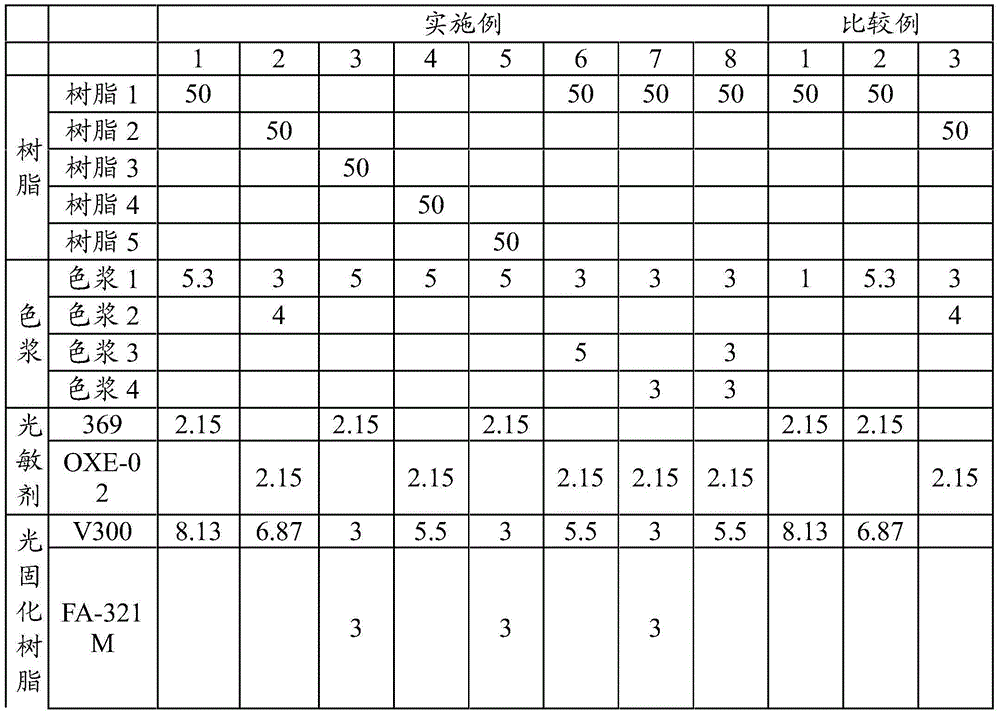

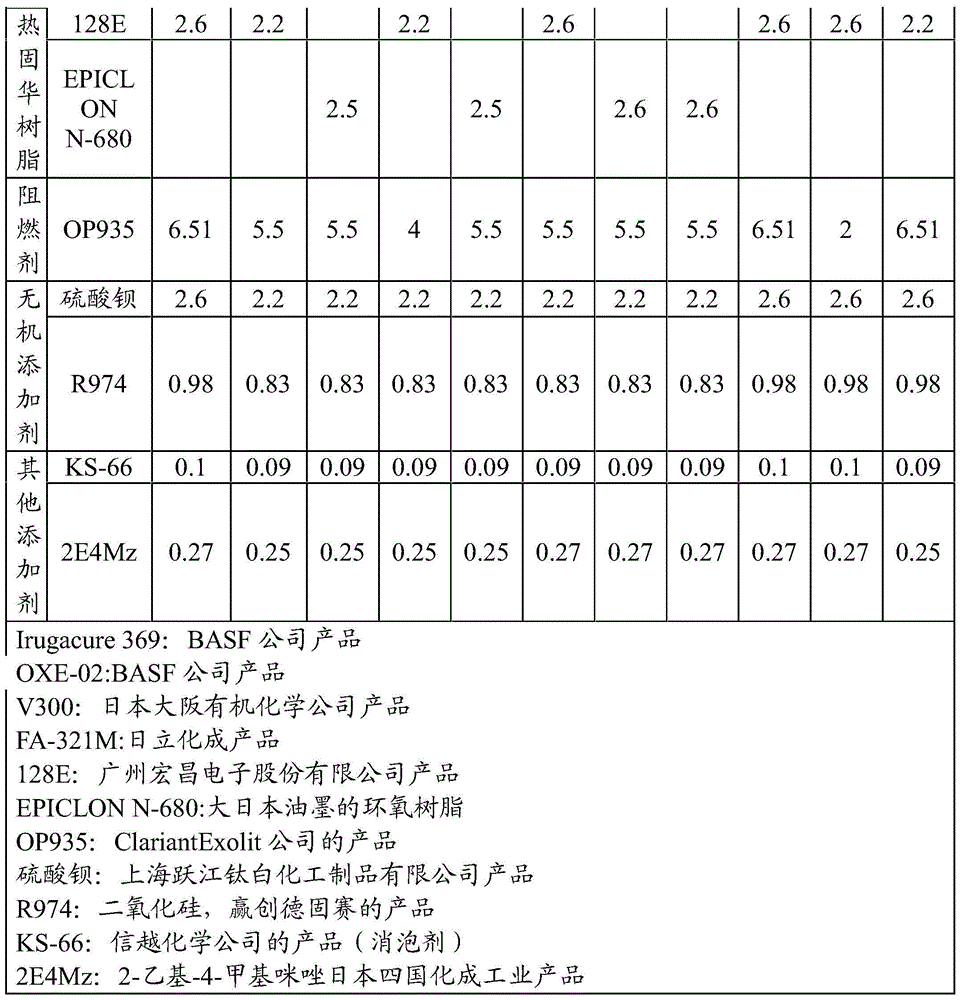

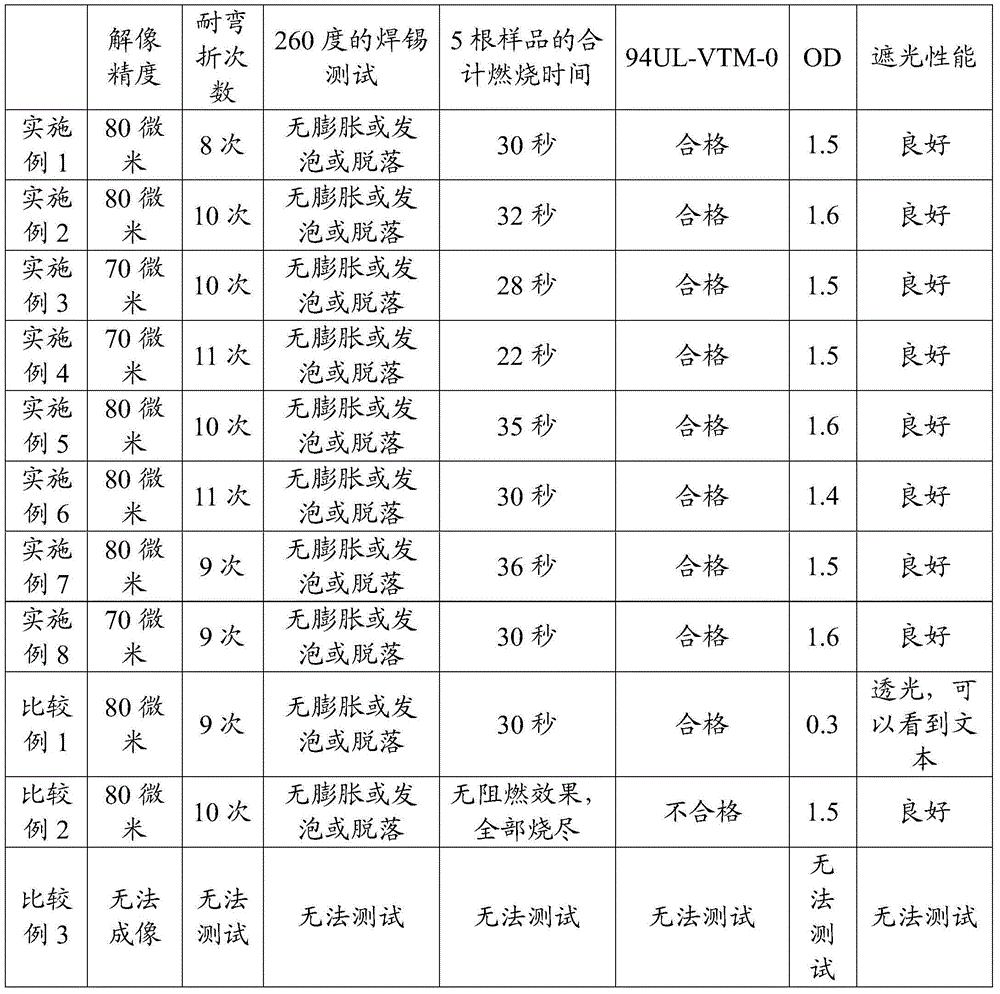

Black photosensitive resin composition and application of black photosensitive resin composition

InactiveCN104536264AImprove machining accuracyGood dimensional stabilityPhotosensitive materials for photomechanical apparatusHeat resistanceAqueous solution

The invention discloses a black photosensitive resin composition and a cured envelope, a dry film and a circuit board which are prepared by using the composition. The black photosensitive resin composition comprises (A) a pigment, (B) a polymer soluble in an alkaline aqueous solution, (C) a photopolymerization initiator, (D) photo-curable resin, (E) heat-cured resin, (F) a flame retardant and (G) inorganic filler. The black photosensitive resin composition disclosed by the invention is rich in flexibility, and excellent in electrical insulation property, solder heat resistance and acid-base resistance property.

Owner:SHANGHAI FUSAITE NEW MATERIAL TECH

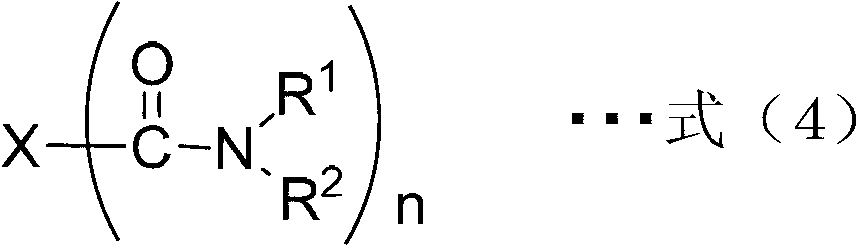

Photosensitive Resin Composition, Cured Product Thereof and Production Method of Printed Circuit Board Using the Same

InactiveUS20070218305A1Abundant flexibilityExcellent soldering heat resistanceNon-fibrous pulp additionPhotosensitive materialsChemistryPrinted circuit board

There are provided a novel photosensitive resin composition, a cured film of which has ample flexibility, and which yields an insulating protective coating having superior soldering heat resistance, thermal degradation resistance and electroless gold plating resistance. The photosensitive resin composition as claimed in the present invention comprises: a photopolymerizeable component containing a urethane acrylate compound (A) and a compound (B) having an ethylenic unsaturated group other than said urethane acrylate compound (A), a thermosetting resin (C), a photopolymerization initiator (D) and a thermal polymerization catalyst (E); wherein, said urethane acrylate compound (A) is the reaction product of an isocyanate compound (a-1) of the following general formula (1): CH2═CH—COO—R—NCO (1) (wherein, R represents a hydrocarbon group having 1 to 30 carbon atoms) with a polyhydroxy compound (a-2).

Owner:SHOWA DENKO KK

Polyurethane resin, heat solidifying resin composition containing the same and its solidifying article

ActiveCN101343345AExcellent adhesionExcellent resistance to chemical gold platingNon-metallic protective coating applicationEpoxyAlcohol

Provided is a polyurethane resin, a thermosetting resin composition including the same and a condensate thereof, forming into a flexible overlay film with excellent sealing performance, flexibility resistance, low warping performance, solder thermal endurance, chemigold plating endurance, electric insulativity and the like, providing a peotective film made of condensate in low cost, a flexible printed plate board of an insulation layer and the like. The polyurethane resin has a phenolic hydroxyl group, preferably has one phenolic hydroxyl group through reacting (a) polyisocyanate, (b) the compound with more than two alcoholic hydroxyl groups and (c) the compound with one alcoholic hydroxyl group and more than one phenolic hydroxyl group to be guided to a terminal. The thermosetting resin composition includes polyurethane resin with the phenolic hydroxyl group and thermoset compound, preferably epoxy resin. Preferably a curing accelerant is included.

Owner:TAIYO HLDG CO LTD

Niobium solid electrolytic capacitor

InactiveUS20050141174A1Maintain good propertiesPrevent degradationLiquid electrolytic capacitorsCapacitor electrodesSolid state electrolyteElectrolysis

A solid electrolytic capacitor constituted by forming a dielectric coating film, a solid state electrolyte layer, and cathode lead-out layer in order on the surface of an anode body comprising niobium or an alloy containing niobium as the main component to an end of which an anode lead member is implanted to construct a capacitor element, connecting the anode lead member with an anode terminal and connecting the cathode lead-out layer, at the same time, with a cathode terminal, and being covered and sealed by a sheath resin, in that the sheath resin is formed by injecting and filling liquid silicone resin and heat curing molding the same.

Owner:SAN DENSHI INDS

Flame-retardant photocurable resin composition, dry film and cured product of same, and printed circuit board using composition thereof

ActiveCN102112920AExcellent adhesionExcellent soldering heat resistancePhotosensitive materials for photomechanical apparatusNon-metallic protective coating applicationPolyesterResist

Disclosed is a flame-retardant photocurable resin composition which has a halogen-free composition and thus places little burden on the environment. The flame-retardant photocurable resin composition has excellent flame retardancy and is capable of forming a cured coating film having excellent flexibility. A dry film and cured product of the composition, and a printed wiring board provided with a flame-retardant cured coating film such as a solder resist obtained by using the composition, dry film or cured product are also disclosed. The flame-retardant photocurable resin composition contains (A) an organic solvent-soluble phosphorus-containing polyester, (B) a carboxyl group-containing resin, and (C) a photopolymerization initiator. Preferably, the carboxyl group-containing resin (B) is a carboxyl group-containing polyurethane resin. Preferably, the flame-retardant photocurable resin composition additionally contains (D) a photopolymerizable monomer or (E) a thermosetting resin. The flame-retardant photocurable resin composition, particularly a flame-retardant photocurable / thermosetting resin composition containing the thermosetting resin (E) can be suitably used as a solder resist.

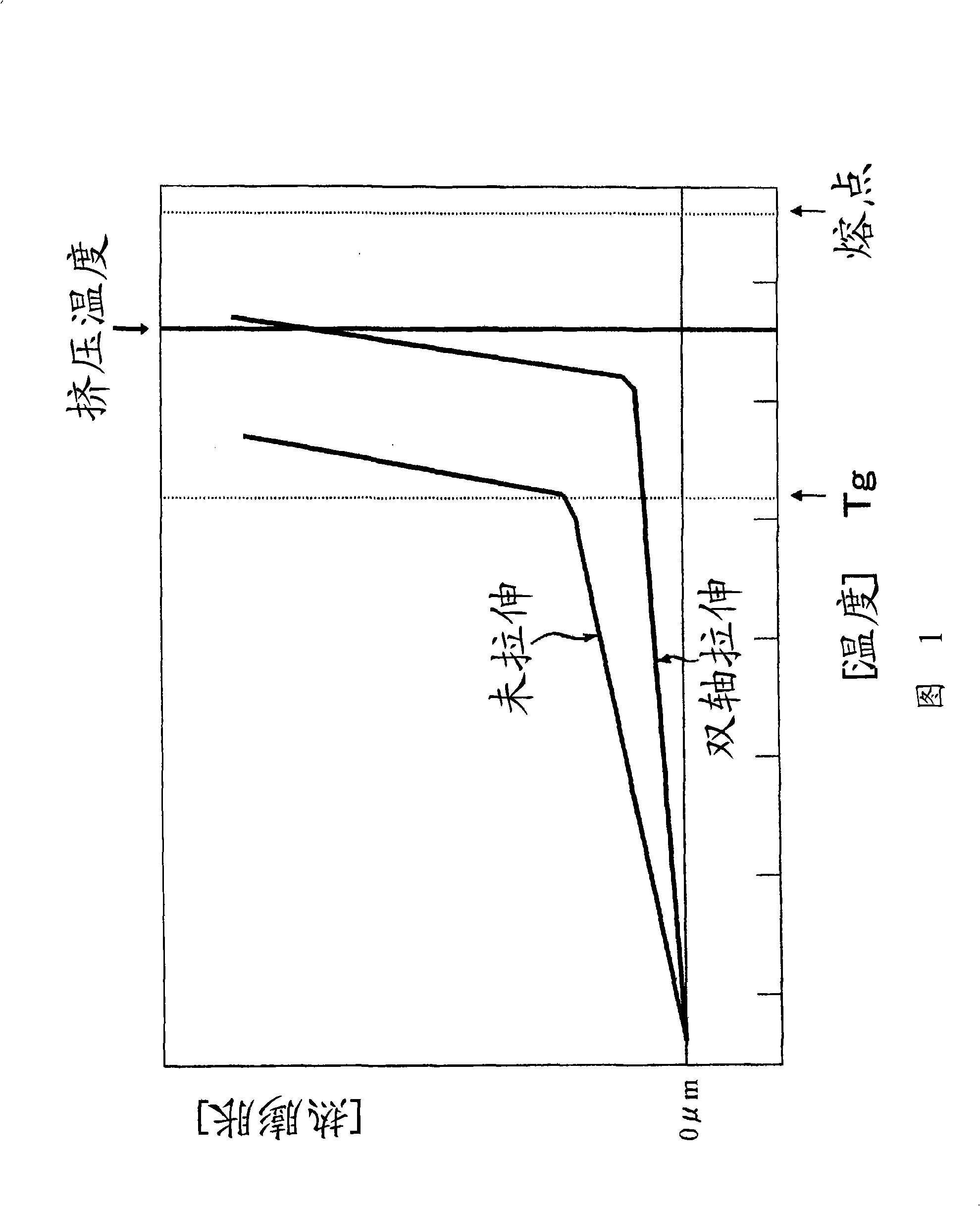

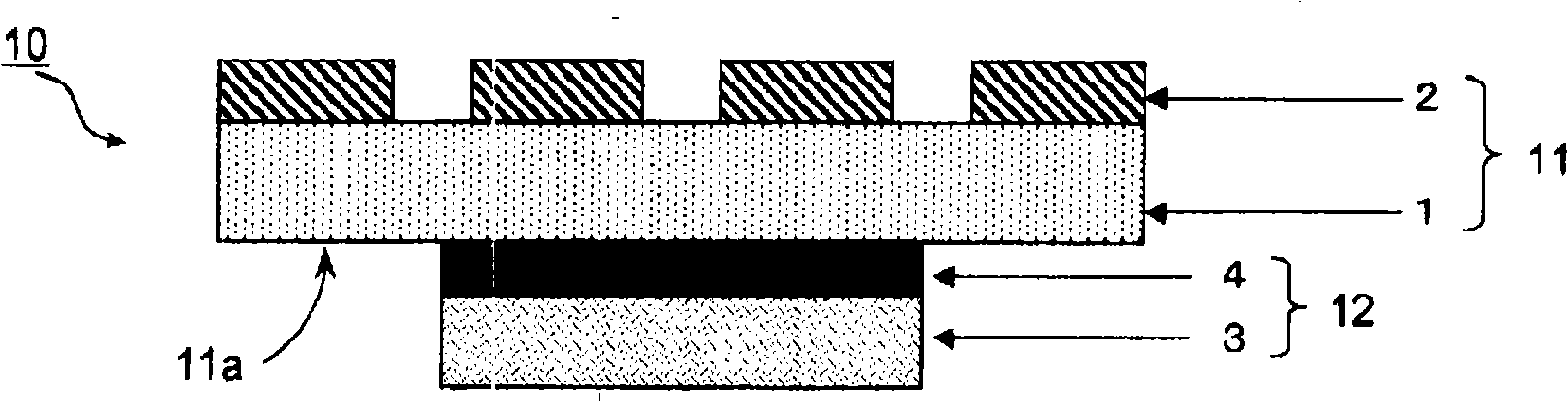

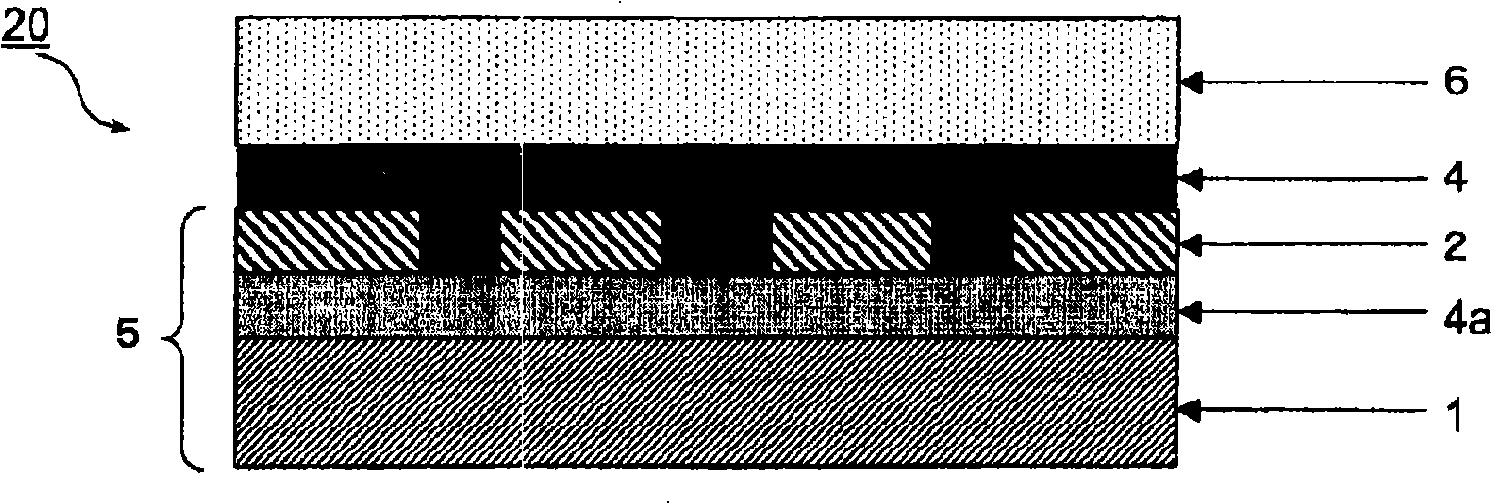

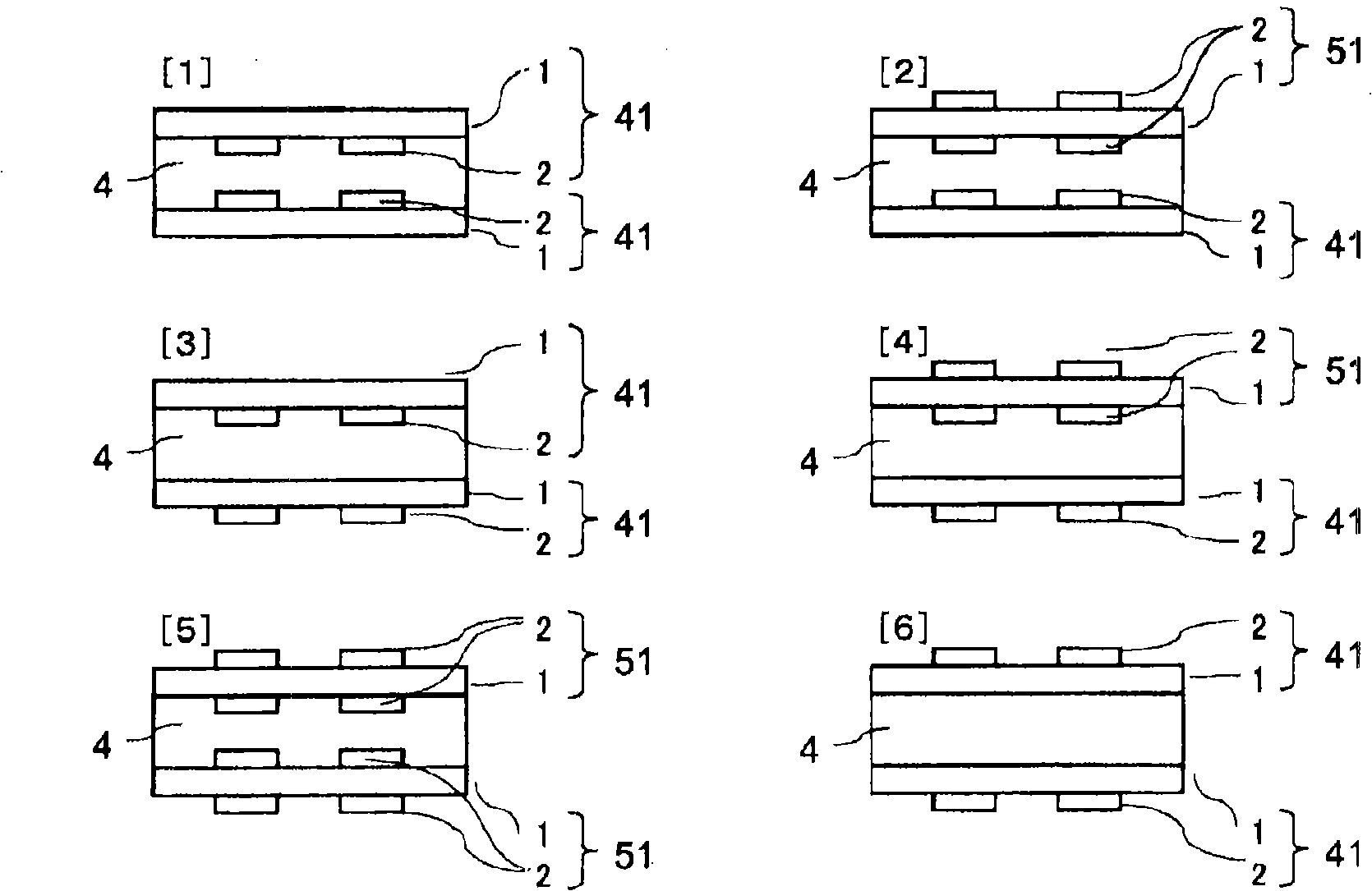

Circuit board and method for manufacturing same

ActiveUS20170238428A1Excellent soldering heat resistanceGood dimensional stabilityLamination ancillary operationsLaminationElectrical conductorHeat resistance

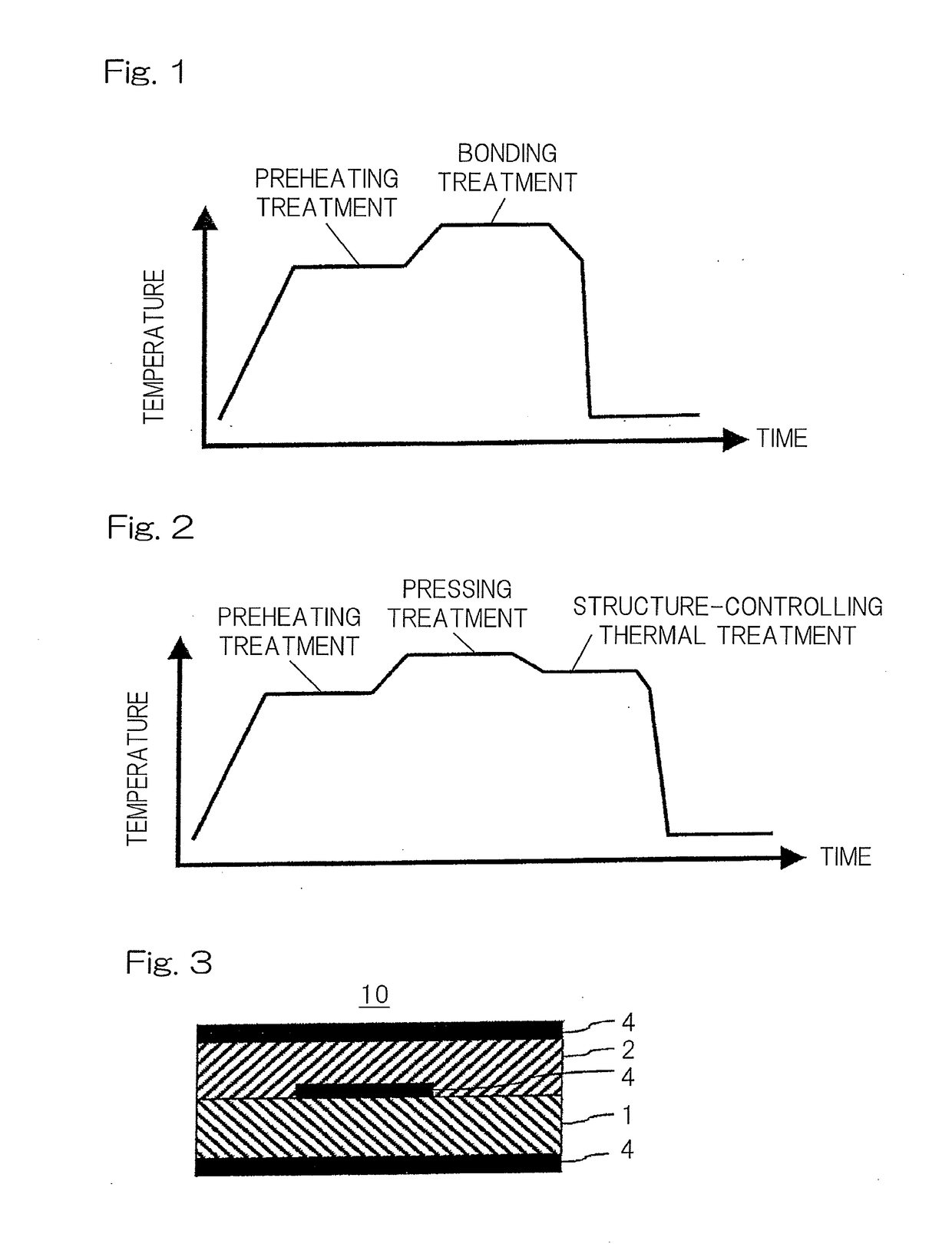

Provided are circuit board excellent in interlayer adhesion and solder heat resistance, and production method thereof. The circuit board is produced by a method including: preparing a plurality of at least one kind of thermoplastic liquid crystal polymer (TLCP) films, forming a conductor layer on one side or both sides of a film in at least one of the films to obtain a unit circuit board, laminating the films containing the unit circuit board to obtain a stacked material, conducting thermo-compression-bonding of the stacked material under pressurization to a first temperature giving an interlayer adhesion to integrate the stacked material, carrying out structure-controlling thermal treatment by heating the integrated stacked material at a second temperature which is lower than the first temperature and is lower than a melting point of a TLCP having a lowest melting point out of the plurality of TLCP films.

Owner:KURARAY CO LTD

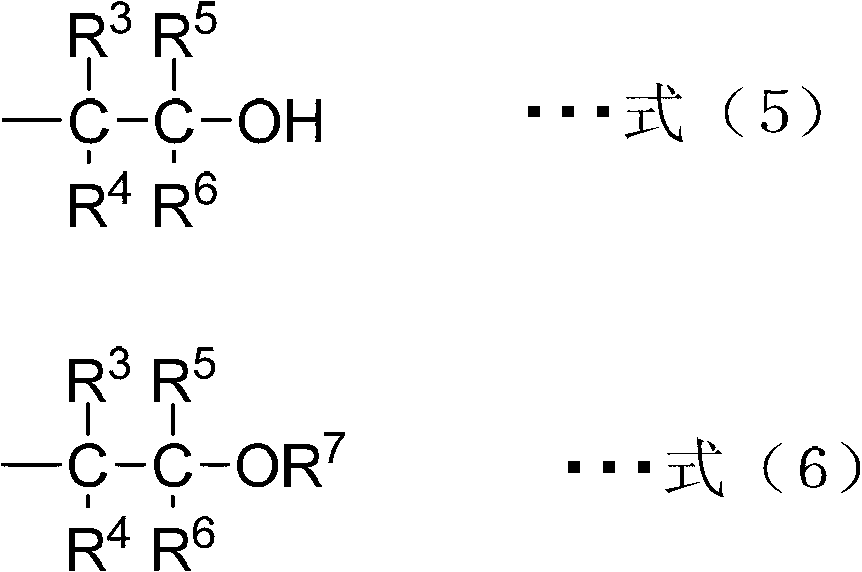

Photosensitive resin composition, cured product thereof, and method for producing photosensitive resin

ActiveCN102854744AIncrease photosensitivityImprove flexibilityInksPhotomechanical exposure apparatusPolymer scienceSide chain

The invention provides a photosensitive resin composition, a cured film of which has excellent flexibility, insulativity, adhesiveness, etc., and is quite suitable to be used as a photosensitive anti-soldering agent. The composition comprises a photosensitive resin (A); at least one compound selected from a compound containing an epoxy group, a non-block isocyanate compound, a block isocyanate compound and a compound containing a beta-hydroxyalkylamide; and a photopolymerization initiator. The photosensitive resin (A) is prepared in the following ways, in which a resin (c) containing a hydroxyl group on a side chain is prepared by using an epoxy compound (a) having at least two epoxy groups in one molecule and a phenolic compound (b) having at least two phenolic hydroxyl groups in one molecule, then a resin (e) containing a carboxyl group is prepared by using the resin (c) and a polybasic anhydride (d), and then the photosensitive resin (A) is prepared by using the resin (e) and an epoxy group or an oxetane group in a compound (f) having the epoxy group or the oxetane group and having a vinyl unsaturated group.

Owner:TOYO INK SC HOLD CO LTD +1

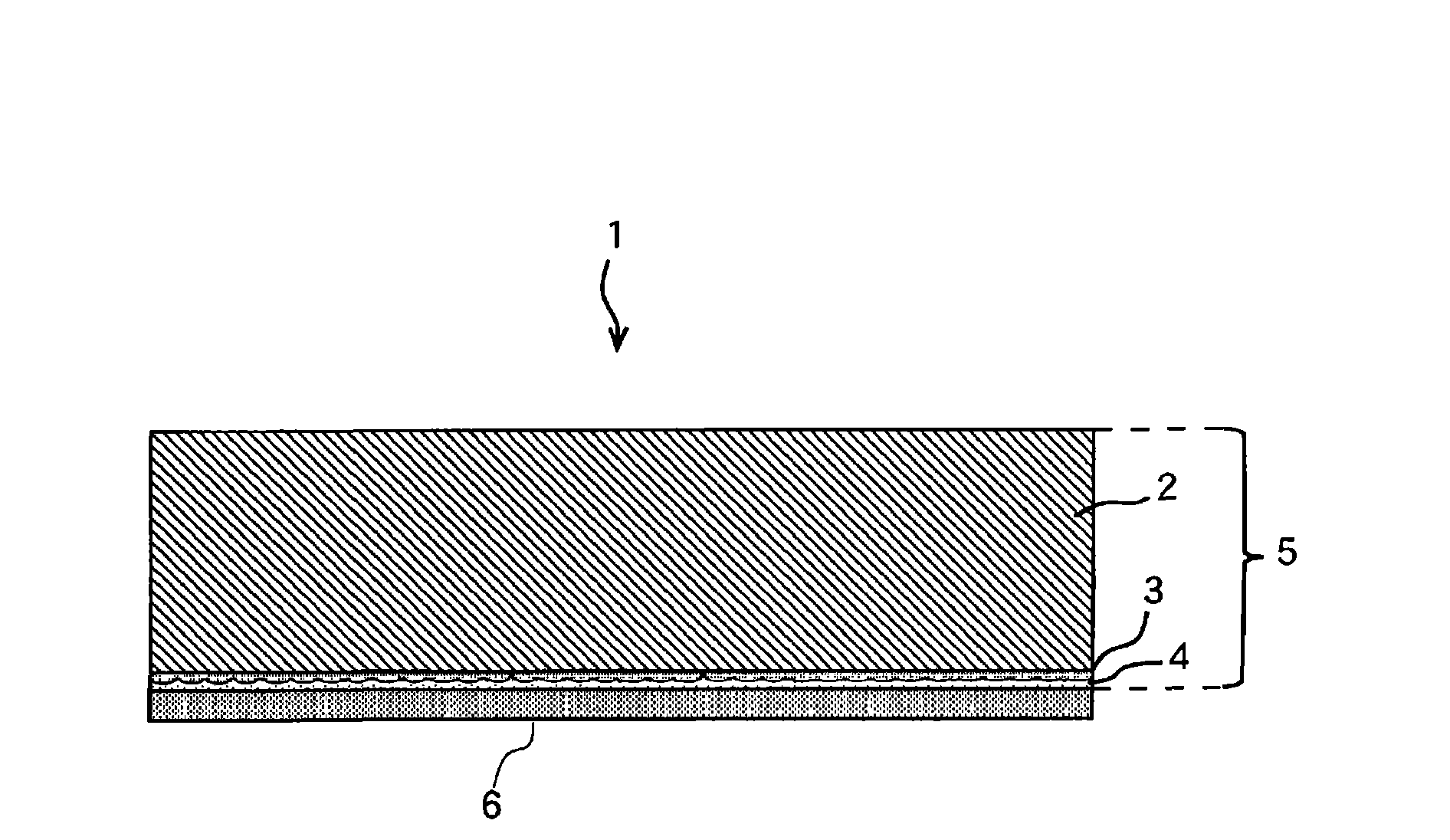

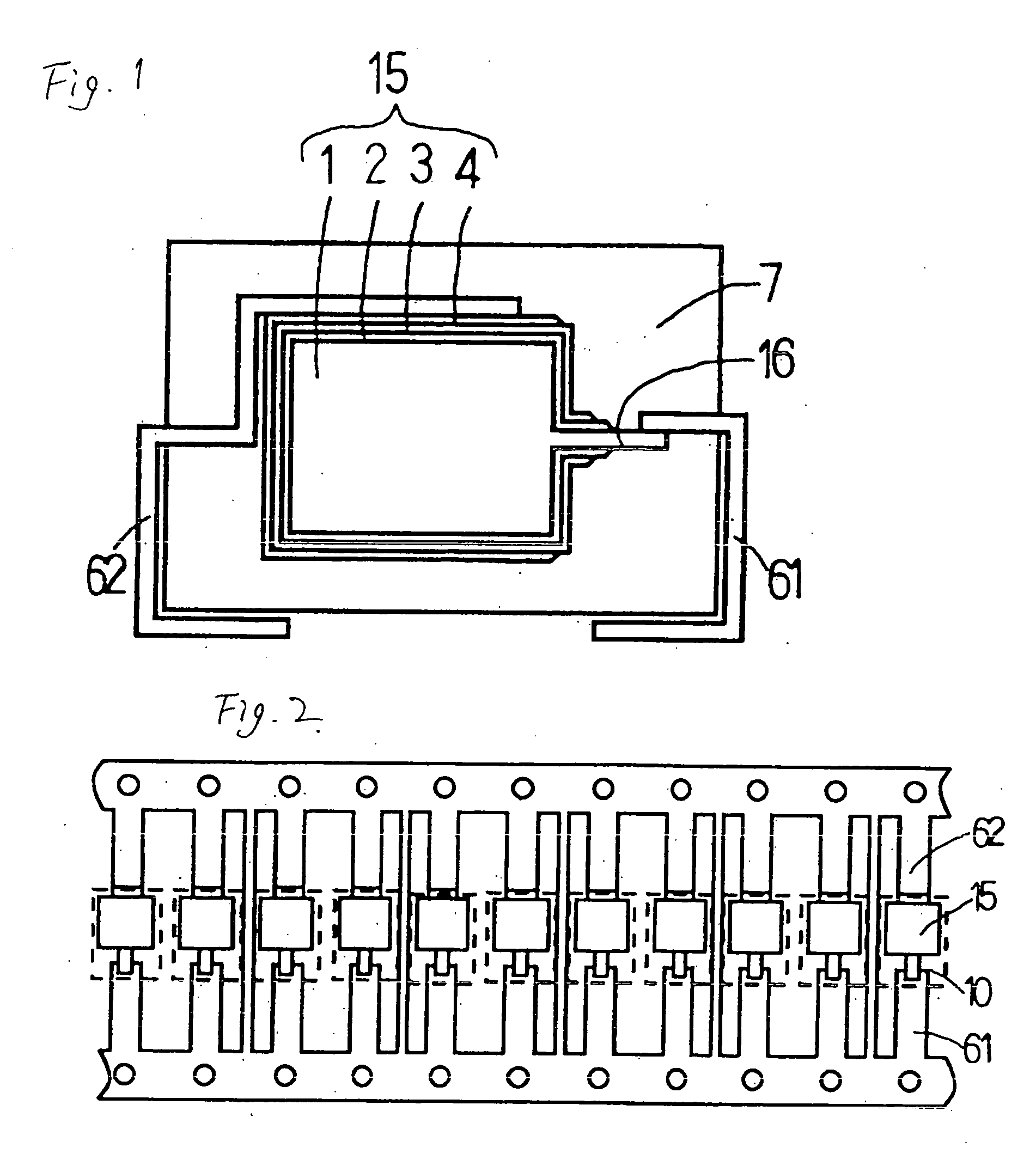

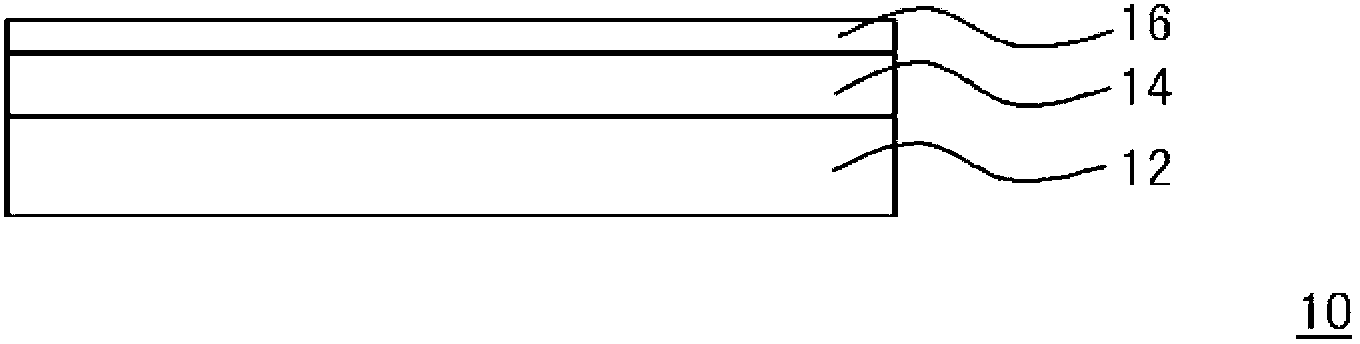

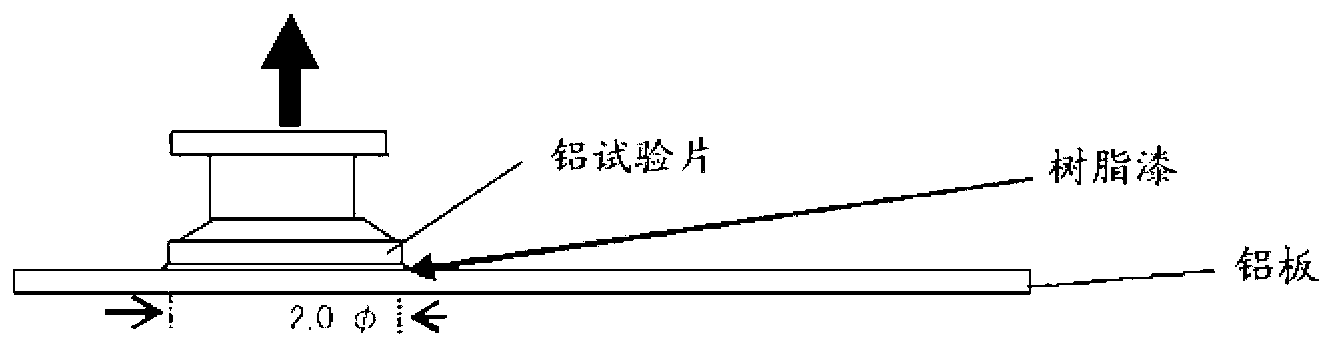

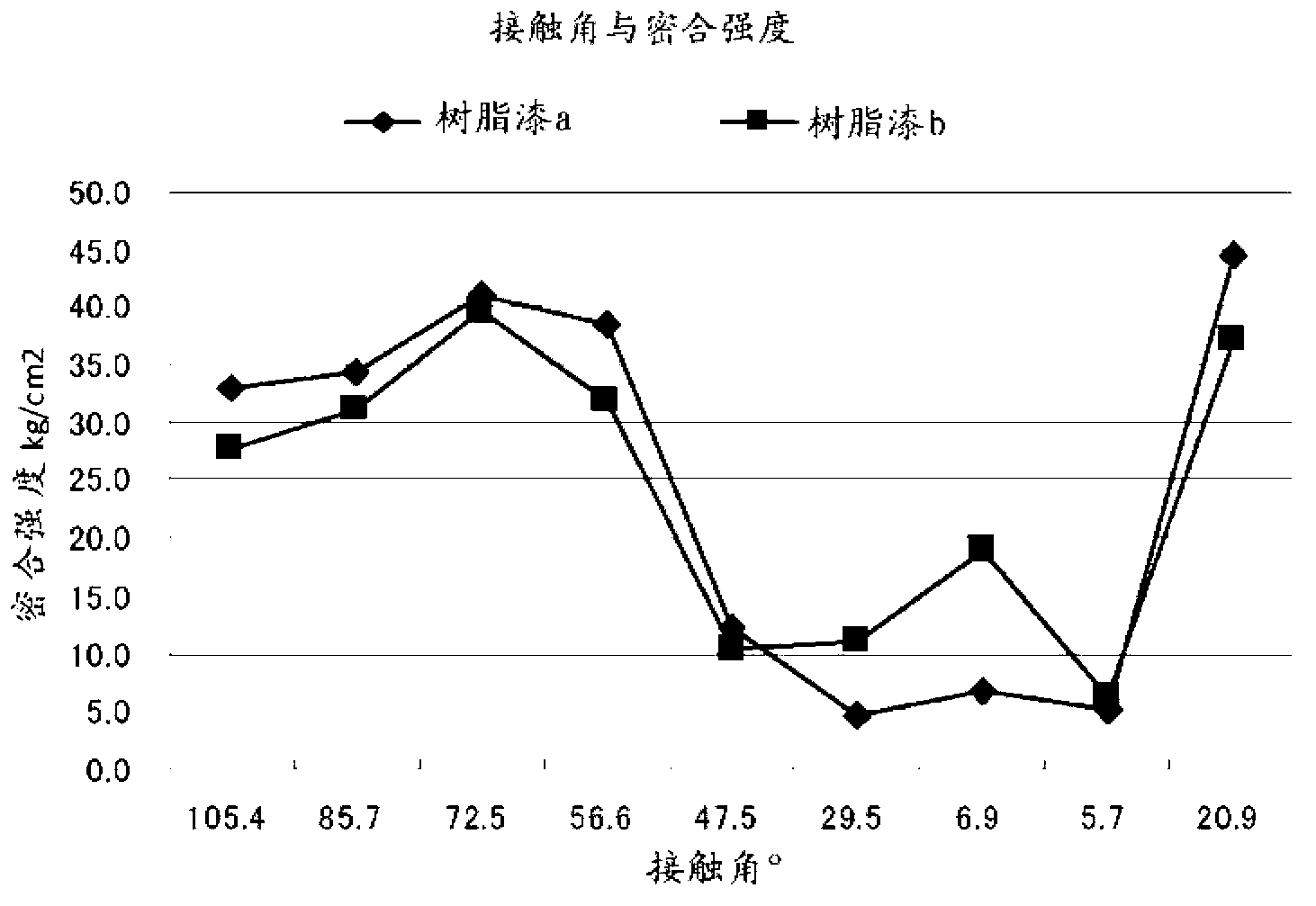

Metal base circuit board, and method for producing metal base circuit board

InactiveCN103283313AExcellent adhesionExcellent soldering heat resistancePrinted circuit aspectsCircuit susbtrate materialsSurface roughnessAluminum substrate

A metal base circuit board (10) is laminated with an aluminum substrate (12), an insulating resin layer (14), and a metal layer (16) in said order. The surface of the aluminum substrate (12) is brought into contact with water having a temperature of 50 to 80 DEG C for 0.5 to 3 minutes such that the surface roughness (Rz) of the surface of the aluminum substrate (12) is between 3 and 9 [mu]m and the water contact angle thereof is between 50 DEG and 95 DEG .

Owner:SUMITOMO BAKELITE CO LTD

Curable resin comosition and coating film thereof

InactiveCN1680470AExcellent PCT resistanceGood flexibilityPhotomechanical apparatusOhmic-resistance heatingResistHeat resistance

The present invention provides a cured resin composition having low hydrolyzability and halogen-free stable flame-resistance, excellent in solder heat-resistance, chemical resistance, adhesiveness, electric insulation and the like. The invention further provides a cured resin composition and a cured film thereof for a carrier tape and a flexible print circuit board, excellent in flexing resistance and causing little warpage after curing. The photosetting / thermosetting resin composition and the thermosetting composition are useful for a solder resist for print circuit boards, which are characterized in: containing a phosphate acidamine compound. Further, a cured film having the resin composition is also provided.

Owner:TAIYO INK MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com