Metal base circuit board, and method for producing metal base circuit board

A technology for circuit substrates and manufacturing methods, which is applied in the manufacture of metal core circuits, circuit substrate materials, and printed circuit manufacturing, etc., can solve the problems of reduced adhesion of insulating resin layers, etc., and achieve the effects of excellent bending resistance and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0151] In addition, in the following Example 1, when resin varnish a was used, it was marked with "Example 1a", and when resin varnish b was used, it was marked with "Example 1b". The same applies to other Examples and Comparative Examples.

[0152] (production of resin paint a)

[0153] A phenoxy resin having a bisphenol F skeleton and a bisphenol A skeleton (manufactured by Mitsubishi Chemical Corporation, 4275, with a weight average molecular weight of 6.0×10 4 , ratio of bisphenol F skeleton to bisphenol A skeleton=75:25) 22.0 parts by mass, bisphenol F epoxy resin (manufactured by DIC Corporation, 830S, epoxy equivalent 170) 10.0 parts by mass, bisphenol A epoxy resin ( Mitsubishi Chemical Corporation, 1001, epoxy equivalent 475) 15.0 parts by mass, 2-phenylimidazole (2PZ manufactured by Shikoku Chemicals Co., Ltd.) 1.0 parts by mass, γ-glycidoxytrimethylsilane as a silane coupling agent ( KBM-403 (manufactured by Shin-Etsu Silicone Co., Ltd.) 2.0 parts by mass, aluminu...

Embodiment 2~5 and comparative example 1~8)

[0159] The aluminum plate was treated according to the treatment conditions in Tables 1-3, washed with acetone, and dried to obtain an aluminum test plate.

[0160] (reference example)

[0161] An aluminum plate with a thickness of 1 mm and an aluminum plate of 10 cm in width and height was used as a substrate. The surface of the substrate was polished with sandpaper (#1500), washed with acetone, and dried to obtain an aluminum test panel.

Embodiment 6~8)

[0163] An aluminum plate with a thickness of 1 mm and an aluminum plate of 10 cm in width and height was used as a substrate. As the ultraviolet irradiation device, a low-pressure mercury lamp (manufactured by OAK Corporation, wavelength: 185nm, radiation intensity 5.0mW / cm was used) 2 ). One side of the substrate was irradiated with ultraviolet light according to the treatment conditions in Table 4 to obtain an aluminum test plate.

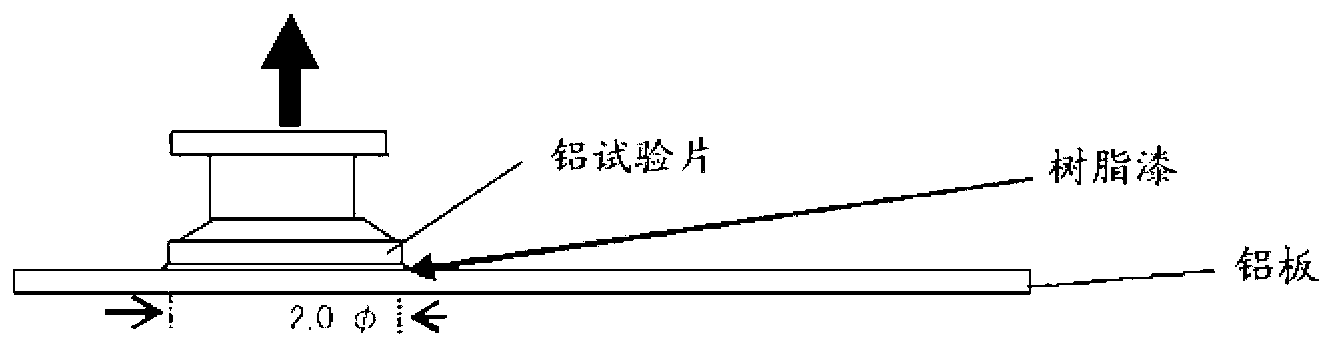

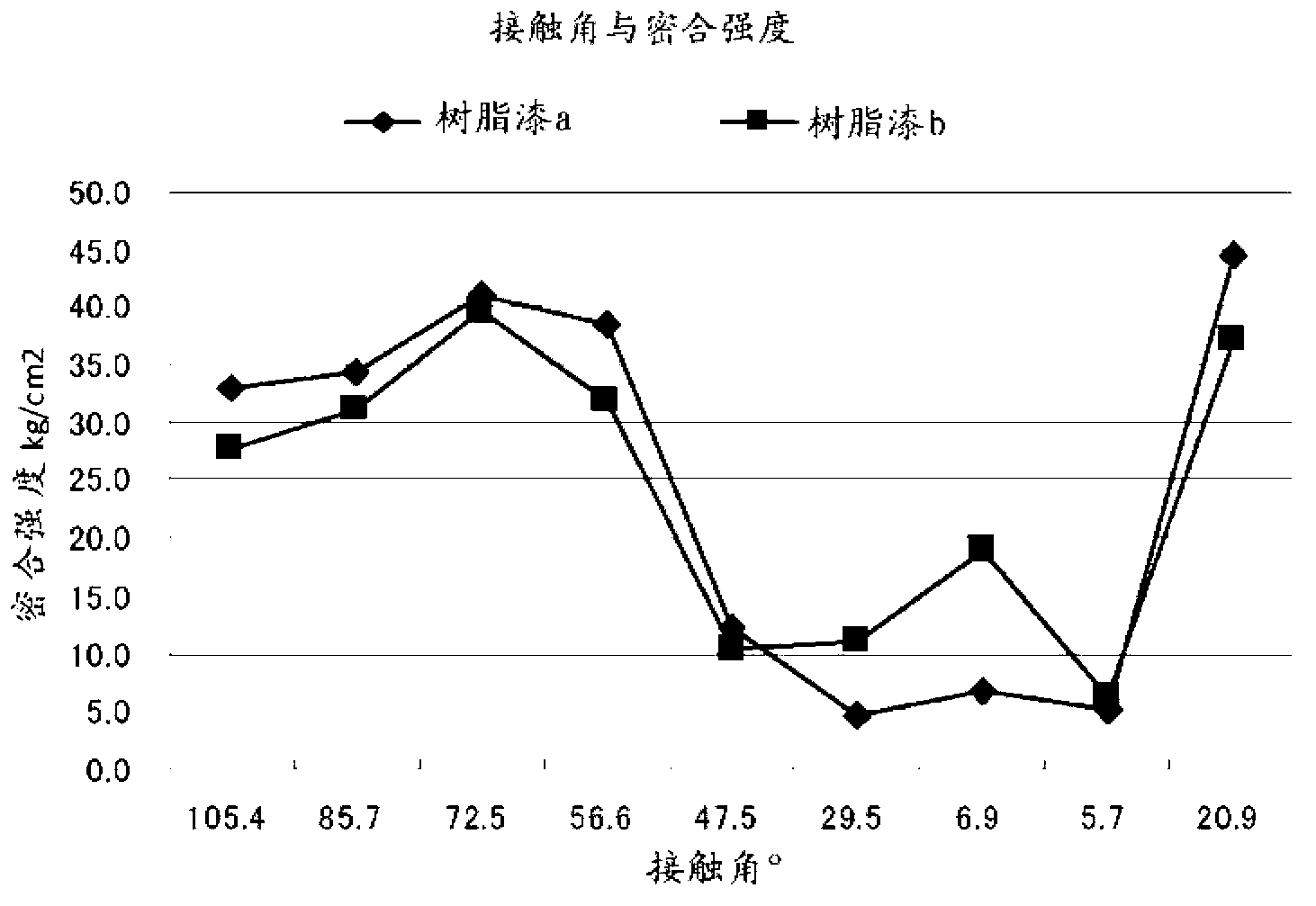

[0164] Each of the following evaluations was performed by the following measuring method about the aluminum test plate obtained from each Example, the comparative example, and the reference example. The evaluation results are shown in Tables 1 to 4. The relationship between contact angle and adhesion strength is as follows: image 3 shown. In addition, the relationship between processing conditions and adhesion strength is as follows: Figure 4 shown.

[0165] a. Contact angle with water

[0166] According to JIS R3257, the average of 5 po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com