Low-dielectric welding-resistant photoresist ink composition for printed circuit board

An ink composition, a technology of the composition, applied in the directions of ink, application, household appliances, etc., can solve the problem of inability to obtain electronic signal transmission characteristics and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

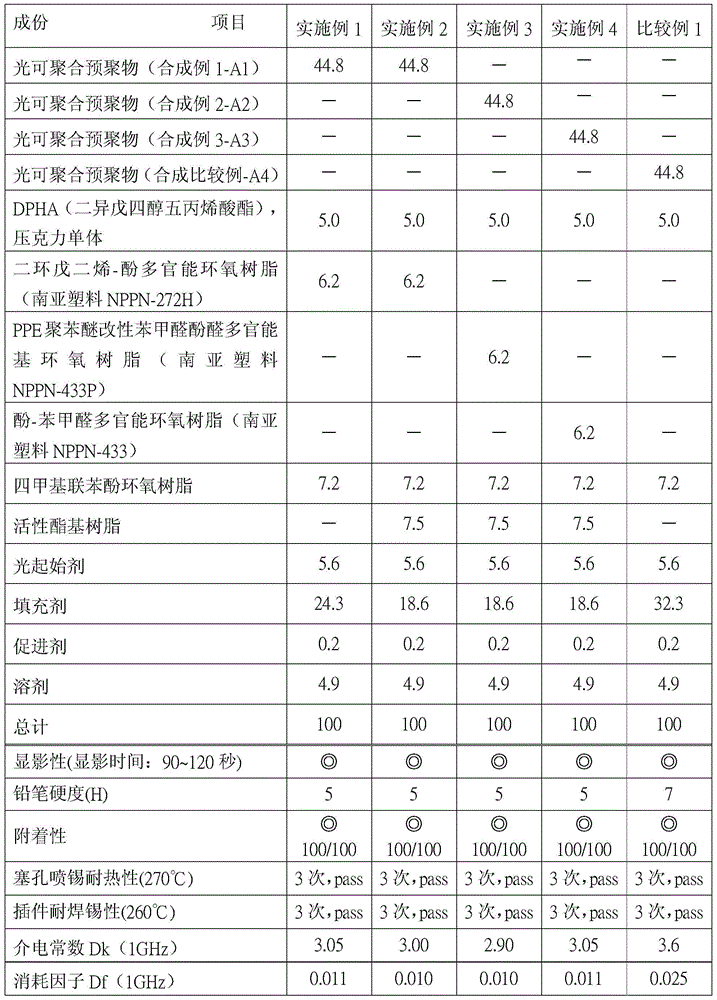

Examples

Synthetic example 1

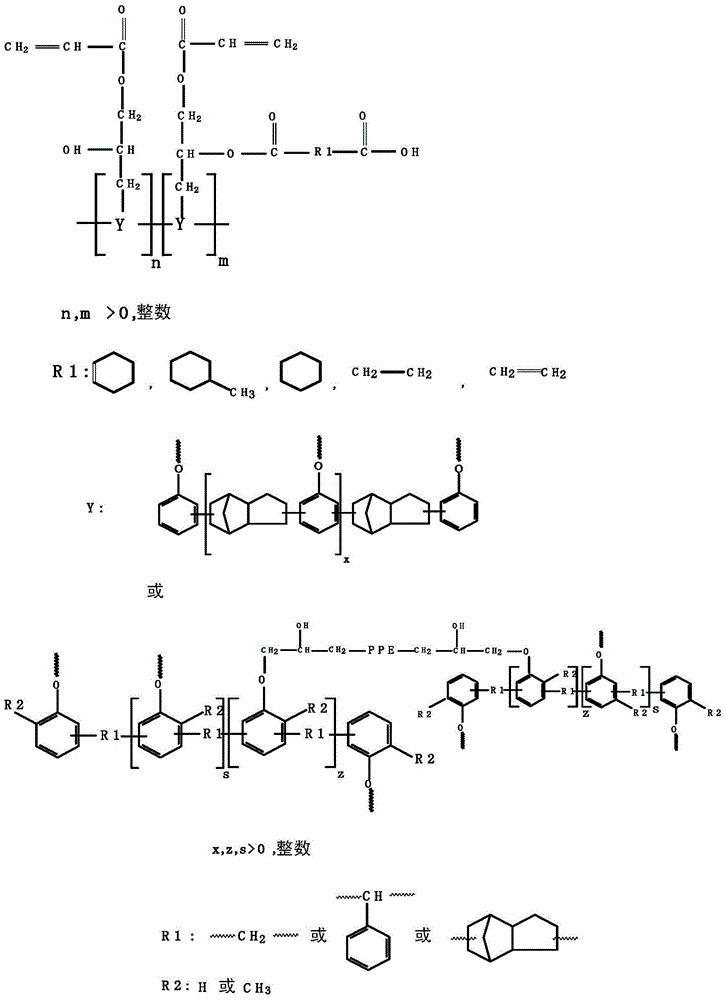

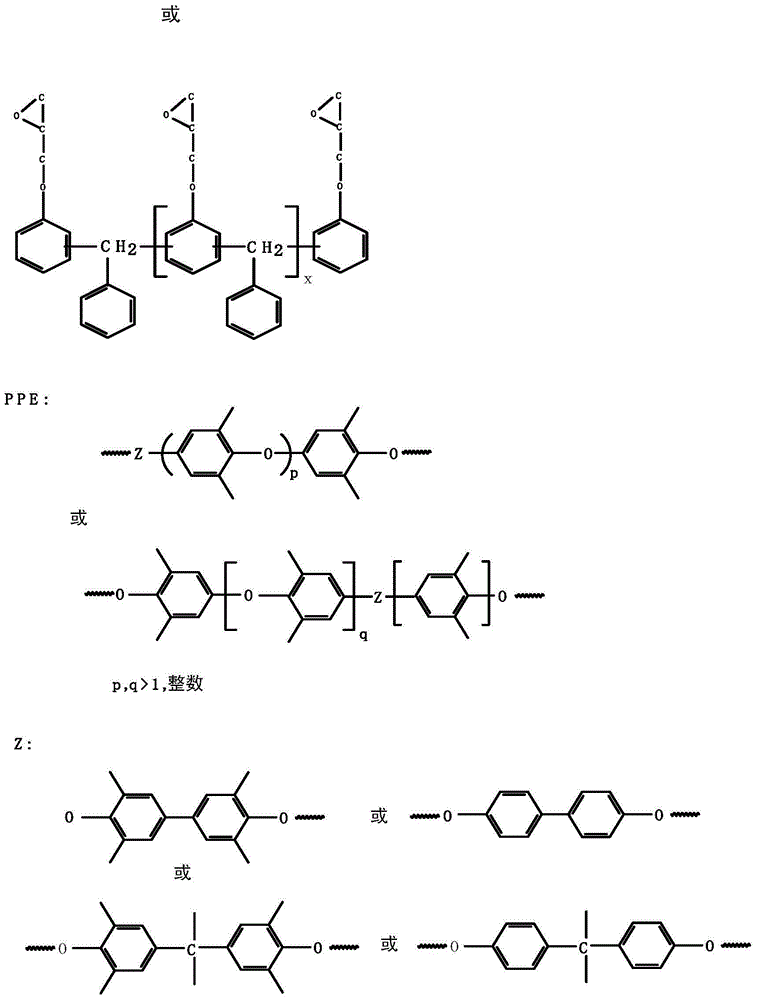

[0037] Synthesis Example 1: Photopolymerizable prepolymer (oligomer)-A1

[0038] Add 1000g of dicyclopentadiene-phenol polyfunctional epoxy resin (Nanya Plastics Company, NPPN-272H, epoxy equivalent 272g / eq) into 390g solvent KA, heat to 100°C, add 4.5g triphenylphosphorus and 1.0 g Hydroquinone HQ, stir to dissolve and then add 265g acrylic acid AA dropwise to the aforementioned solution for reaction. The reaction time is 90 minutes, and the temperature is 95°C. After the addition, the temperature is raised to 120°C for maturation reaction and maturation reaction Time 12 hours. When analyzing acid value <1mgKOH / g, then add 380g of tetrahydrophthalic anhydride THPA, and 390g of solvent I-150, react for 5 hours at a reaction temperature of 110°C, add 55g of solvent KA and I-150 each, and dilute to a solid part of 65 ﹪The photopolymerizable prepolymer A1 is obtained, the acid value is 60mgKOH / g, and the weight average molecular weight Mw is 1839.

Synthetic example 2

[0039] Synthesis Example 2: Oligomer-A2

[0040] Add 1000g of polyphenylene ether modified benzaldehyde phenolic multifunctional epoxy resin (NPPN-433P, EEW316g / eq) from Nanya Plastics Co., Ltd., add 378g of solvent KA, heat up to 100℃, add 4.0g of triphenylphosphorus and 1.0g of p-benzene Diphenol HQ, after stirring and dissolving, 227g acrylic acid AA was added dropwise to the aforementioned solution for reaction, the dropping time was 90 minutes, the dropping temperature was 95°C, the dropping was completed, and the maturing was 12 hours, and then tetrahydrophthalic anhydride THPA was added. 327g, reacted with 378g of I-150 solvent for 5 hours at a reaction temperature of 110°C, add 41g each of solvent KA and I-150, dilute to a solid content of 65% to obtain photopolymerizable prepolymer A2, analyze the acid value of 77mgKOH / g, the weight average molecular weight Mw 1872.

Synthetic example 3

[0041] Synthesis Example 3: Oligomer-A3

[0042] Add 1000g of phenol-benzaldehyde polyfunctional epoxy resin (Nanya Plastics Company's brand NPPN-433, EEW230g / eq) into 405g solvent KA, heat to 100°C, add 5.4g triphenylphosphorus and 1.0g hydroquinone HQ After stirring and dissolving, 312g of acrylic acid AA was added dropwise to the aforementioned solution for reaction. The reaction time was 90 minutes, and the temperature was 95°C. After the addition, the temperature was raised to 120°C for maturation reaction. The maturation reaction time was 12 hours. When analyzing acid value <1mgKOH / g, then add 450g tetrahydrophthalic anhydride THPA, and 405g solvent I-150, react for 5 hours at a reaction temperature of 110℃, add 71g each of solvent KA and I-150, and dilute to a solid part of 65 ﹪The photopolymerizable prepolymer A3 is obtained, the acid value is 59mgKOH / g, and the weight average molecular weight Mw is 2267.

[0043] Synthesis comparative example: photopolymerizable prepolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com