Surface treated copper foil, surface treated copper foil with very thin primer resin layer, method for manufacturing the surface treated copper foil, and method for manufacturing the surface treated c

A technology of surface treatment and manufacturing method, applied in thin material treatment, superimposed layer plating, printed circuit manufacturing, etc., can solve the problems of improper analysis method and misjudgment, and achieve the effect of good fit and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

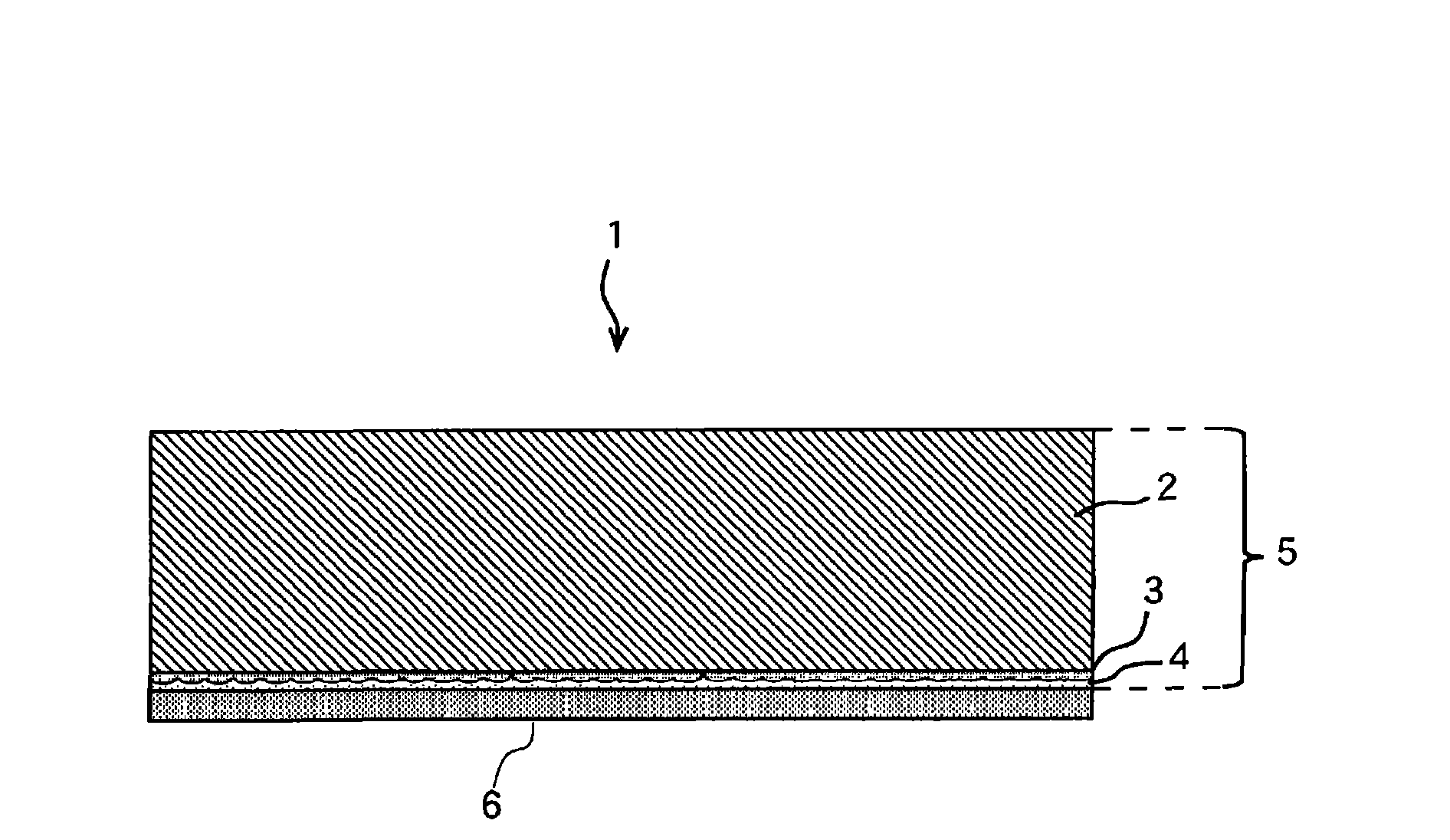

[0095] (Manufacture of surface-treated copper foil)

[0096] In Example 1, the surface of the rough surface (surface roughness Ra=0.64 μm, Rzjis=3.0 μm) of an untreated electrolytic copper foil (hereinafter referred to simply as “untreated foil”) with a thickness of 18 μm was roughened to prevent Rust treatment, silane coupling agent treatment, made of surface treated copper foil. It should be noted that the antirust treatment layer is composed of a nickel-molybdenum alloy layer and a tin layer. The steps will be described in detail below.

[0097] Cleaning treatment: First, the untreated foil is pickled to remove grease and surface oxide film to make it clean. As the pickling solution at this time, a dilute sulfuric acid solution having a sulfuric acid concentration of 100 g / L and a liquid temperature of 30° C. was used, dipped in the dilute sulfuric acid solution for 30 seconds, and then washed with water.

[0098] Roughening treatment: cathodically polarize the untreated...

Embodiment 2

[0114] (Manufacture of surface-treated copper foil)

[0115] In Example 2, roughening treatment, antirust treatment, and silane coupling agent Treatment to make surface treated copper foil. It should be noted that the antirust treatment layer is composed of a nickel-zinc alloy layer and a tin layer. The steps will be described below, but since the cleaning treatment and the roughening treatment are the same as those in Example 1, their descriptions will be omitted.

[0116] Antirust treatment: In Example 2, a nickel-zinc alloy layer was formed on the surface of the above-mentioned rough surface using the nickel-zinc electrolyte solution and the tin electrolyte solution shown below, and then a tin layer was formed. Table 1 summarizes the production conditions for forming the nickel-zinc alloy layer and the tin layer at this time. Then, the nickel weight thickness, the zinc weight thickness, and the tin weight thickness of the rough surface of the produced surface-treated cop...

Embodiment 3

[0123] (Manufacture of surface-treated copper foil)

[0124] In Example 3, roughening treatment, antirust treatment, and silane coupling agent treatment were performed on the rough surface (surface roughness Ra = 0.64 μm, Rzjis = 3.0 μm) of the same 18 μm thick untreated foil as in Example 1 , made of surface-treated copper foil. It should be noted that the antirust treatment layer is composed of a nickel-molybdenum-cobalt alloy layer and a tin layer. The steps will be described in detail below, but since the cleaning treatment and the roughening treatment are the same as those in Example 1, their descriptions will be omitted.

[0125] Antirust treatment: Using the nickel-molybdenum-cobalt alloy electrolyte solution and the tin electrolyte solution shown below, a nickel-molybdenum-cobalt alloy layer was formed on the surface of the rough surface, and then a tin layer was formed. Table 1 summarizes the detailed manufacturing conditions for forming the nickel-molybdenum-cobalt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com