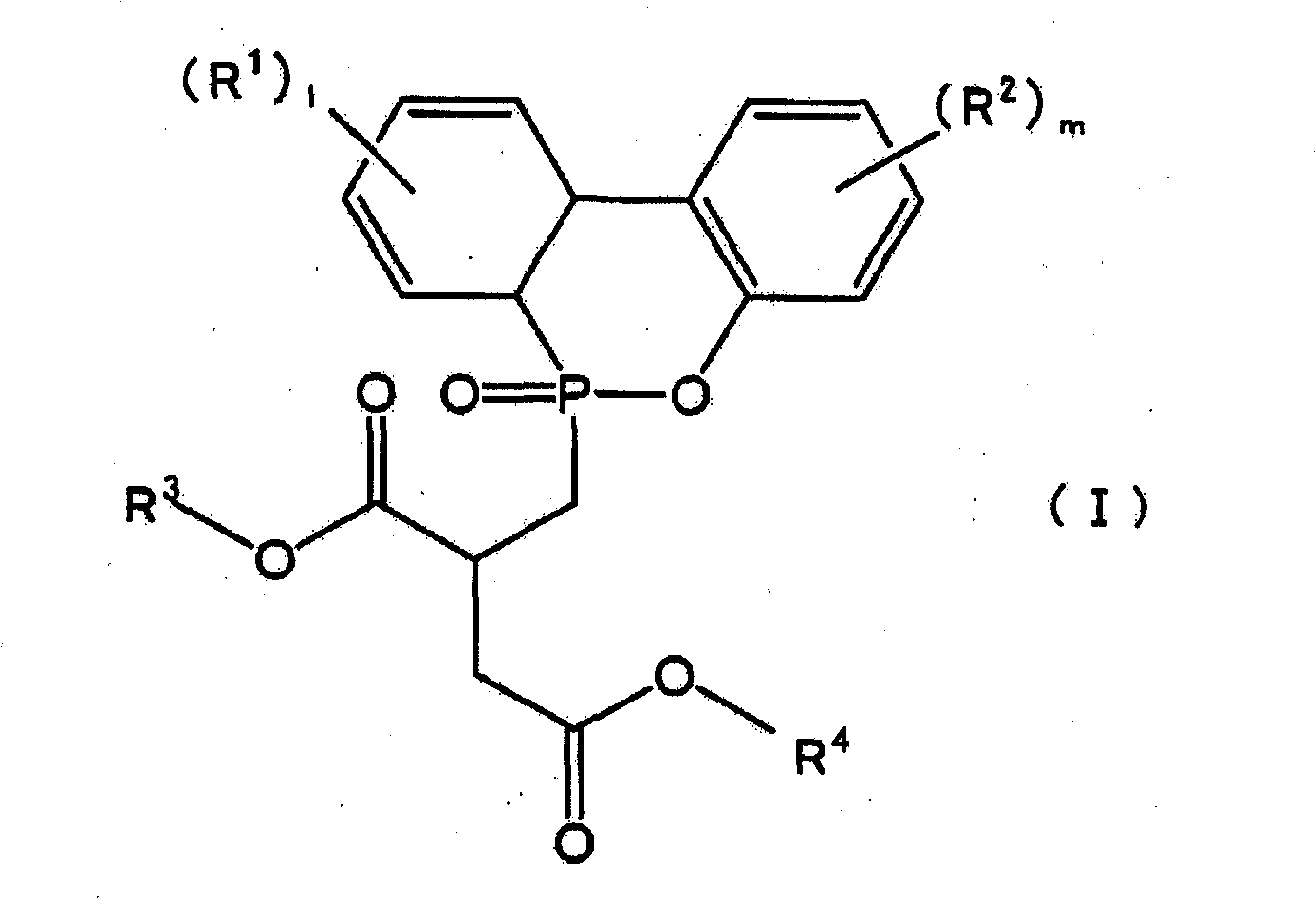

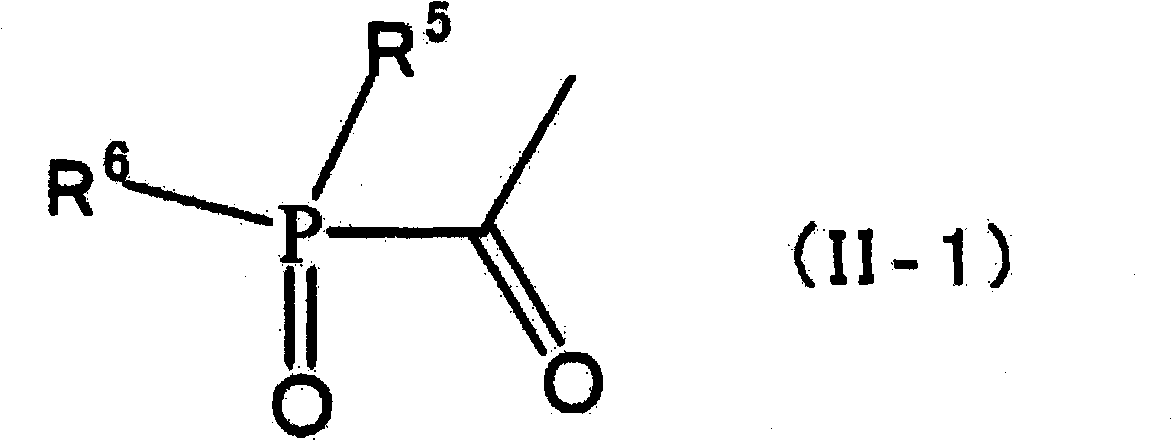

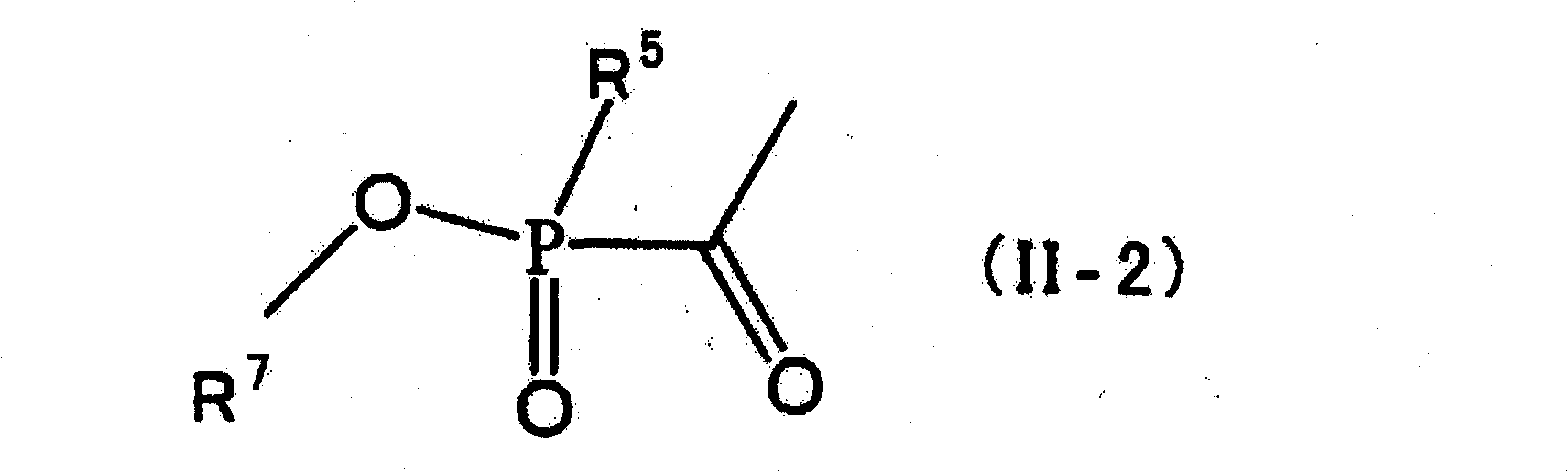

Flame-retardant photocurable resin composition, dry film and cured product of same, and printed circuit board using composition thereof

A light-curable resin, flame retardant technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., to achieve the effect of low environmental load and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1、2

[0166] The components shown in Table 1 were blended in the proportions (parts by mass) shown in Table 1, pre-mixed with a mixer, and then kneaded with a 3-roll mixer to prepare a photocurable thermosetting resin composition for solder resist . Here, the degree of dispersion of the obtained photocurable thermosetting resin composition was evaluated by particle size measurement using GRIND METER manufactured by ERICHSEN, and was 15 μm or less.

[0167] [Table 1]

[0168]

[0169] performance evaluation

[0170]

[0171] A circuit pattern substrate with a copper thickness of 35 μm was ground with a polishing roller, then washed with water and dried, and then coated with the photocurable thermosetting resin composition of the aforementioned examples and comparative examples on the entire surface by the screen printing method, and heated at 80° C. Dry in a hot air circulation drying oven for 30 minutes. After drying, use an exposure device (HMW-680-GW20) equipped with a met...

Embodiment 4

[0204] Dilute the photocurable thermosetting resin composition prepared according to the same combination as in Example 1 with methyl ethyl ketone, apply it on the carrier film and heat and dry to form a resin composition layer with a thickness of 20 μm, and use a hot air dryer at 80°C to Let dry for 30 minutes. Further, a cover film was bonded thereon to obtain a dry film. Thereafter, the cover film was peeled off, and this was bonded to the patterned polyimide film substrate using a laminator. Use an exposure device (HMW-680-GW20) equipped with a metal halide lamp to expose the solder resist pattern on the substrate at an optimal exposure amount, peel off the carrier film, and then use 1wt% Na at 30°C 2 CO 3 The aqueous solution was developed for 60 seconds under the condition of a spray pressure of 0.2 MPa to obtain a substrate on which a resist pattern was formed. Thereafter, heat curing was performed for 60 minutes in a hot air drier at 150° C. to prepare a test substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com