Polyurethane resin, heat solidifying resin composition containing the same and its solidifying article

A technology of polyurethane resin and resin composition, applied in the field of solder heat resistance and resistance, to achieve the effect of low cost and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

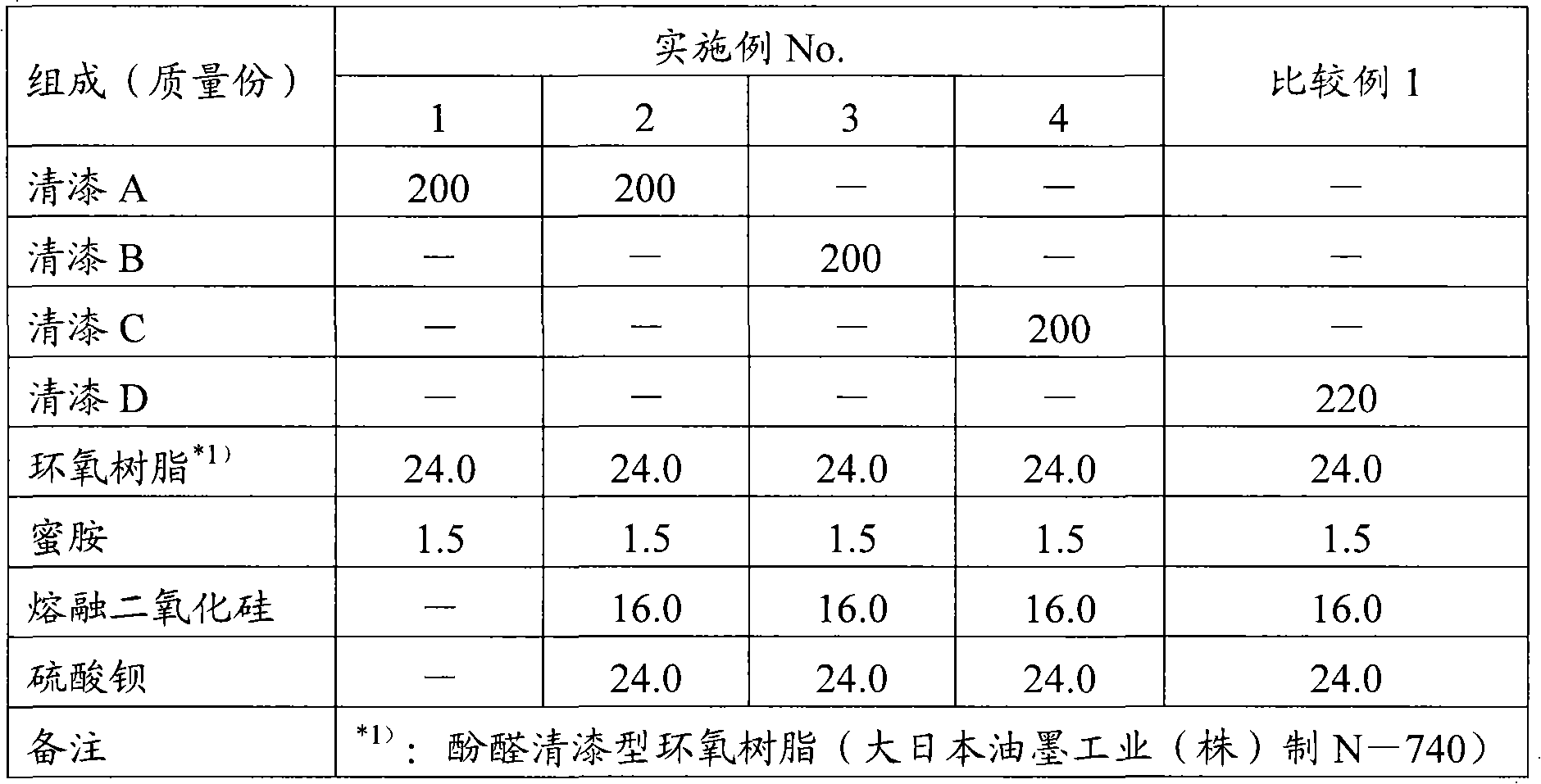

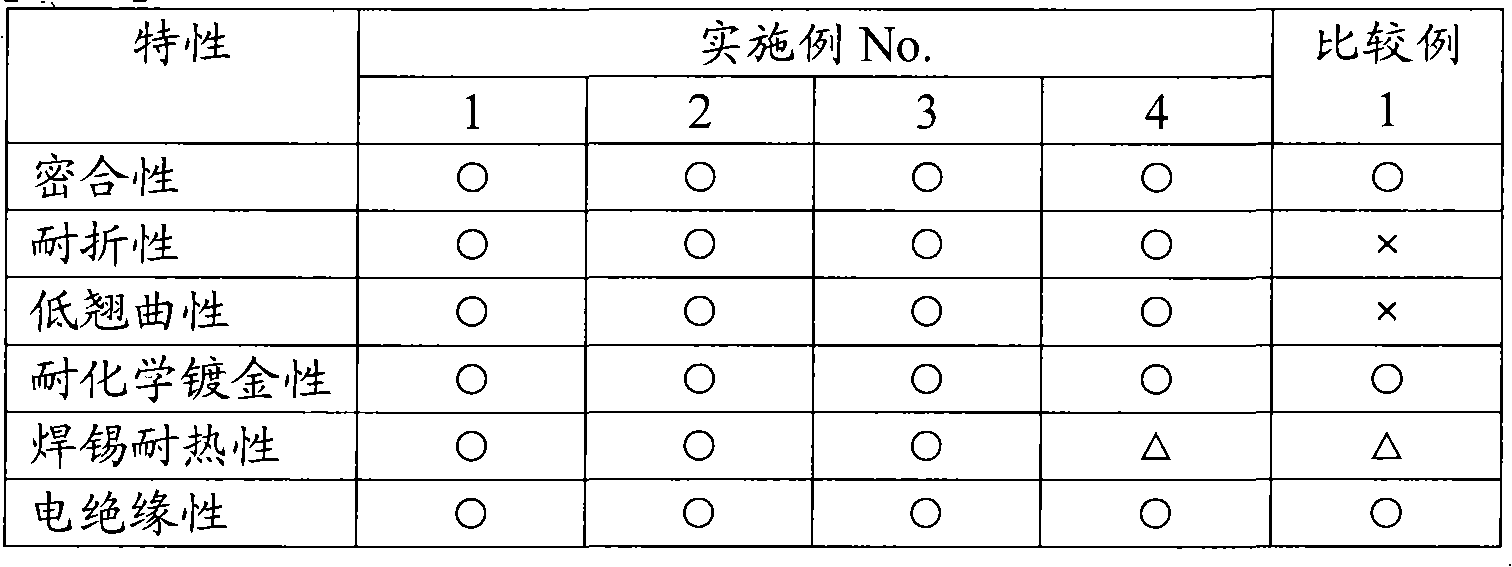

[0053] The present invention will be specifically described below by showing Examples and Comparative Examples. In addition, the following "parts" and "%" are mass standards unless otherwise stated.

Synthetic example 1

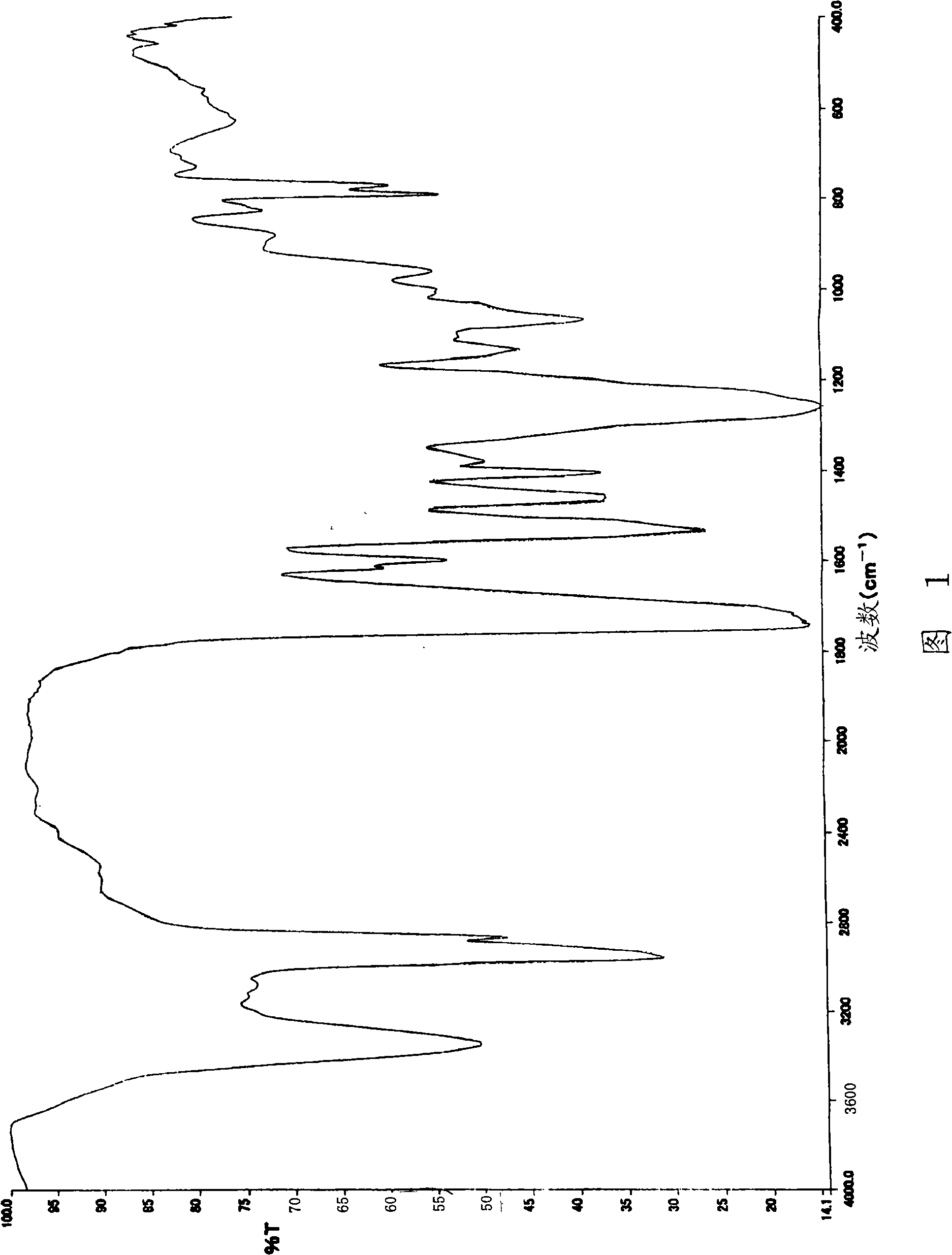

[0055] A polycarbonate diol derived from 1,5-pentanediol and 1,6-hexanediol (Ube Industries, Ltd. Co., Ltd., PCDL800, number average molecular weight 800) 360 g (0.45 mol), dimethylol butyric acid 81.4 g (0.55 mol), and a compound having one alcoholic hydroxyl group and one or more phenolic hydroxyl groups in one molecule Hydroxyphenethyl alcohol 22.1g (0.16mol). Next, add 187.9 g (1.08 mol) of toluene diisocyanate as polyisocyanate, heat to 60°C while stirring, stop heating, and heat again when the temperature in the reaction vessel begins to drop, continue stirring at 80°C, The absorption spectrum confirms the absorption spectrum of the isocyanate group (2280cm -1 ) disappears and the reaction is terminated. Next, carbitol acetate was added so that the solid content would be 50% by weight, and a viscous liquid polyurethane resin (varnish A) having a phenolic hydroxyl group containing a diluent was obtained. The acid value of the solid content of the obtained polyurethane ...

Synthetic example 2

[0057] A polycarbonate diol derived from 1,5-pentanediol and 1,6-hexanediol (Ube Industries, Ltd. Co., Ltd., PCDL800, number average molecular weight 800) 360 g (0.45 mol), dimethylol butyric acid 81.4 g (0.55 mol), and a compound having one alcoholic hydroxyl group and one or more phenolic hydroxyl groups in one molecule Hydroxyphenethyl alcohol 22.1g (0.16mol). Next, add 83.5 g (0.48 mol) of toluene diisocyanate and 111.6 g (0.60 mol) of trimethylhexamethylene diisocyanate as polyisocyanate, heat to 60 ° C while stirring, stop heating, and the temperature in the reaction vessel When it starts to decrease, heat again, continue to stir at 80°C, and confirm the absorption spectrum of the isocyanate group (2280cm -1 ) disappears and the reaction is terminated. Next, carbitol acetate was added so that the solid content would be 50% by weight, and a viscous liquid polyurethane resin (varnish B) having a phenolic hydroxyl group containing a diluent was obtained. The acid value o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com