Ultraviolet-thermal dual-cured resin, anti-welding ink containing resin, and application of resin

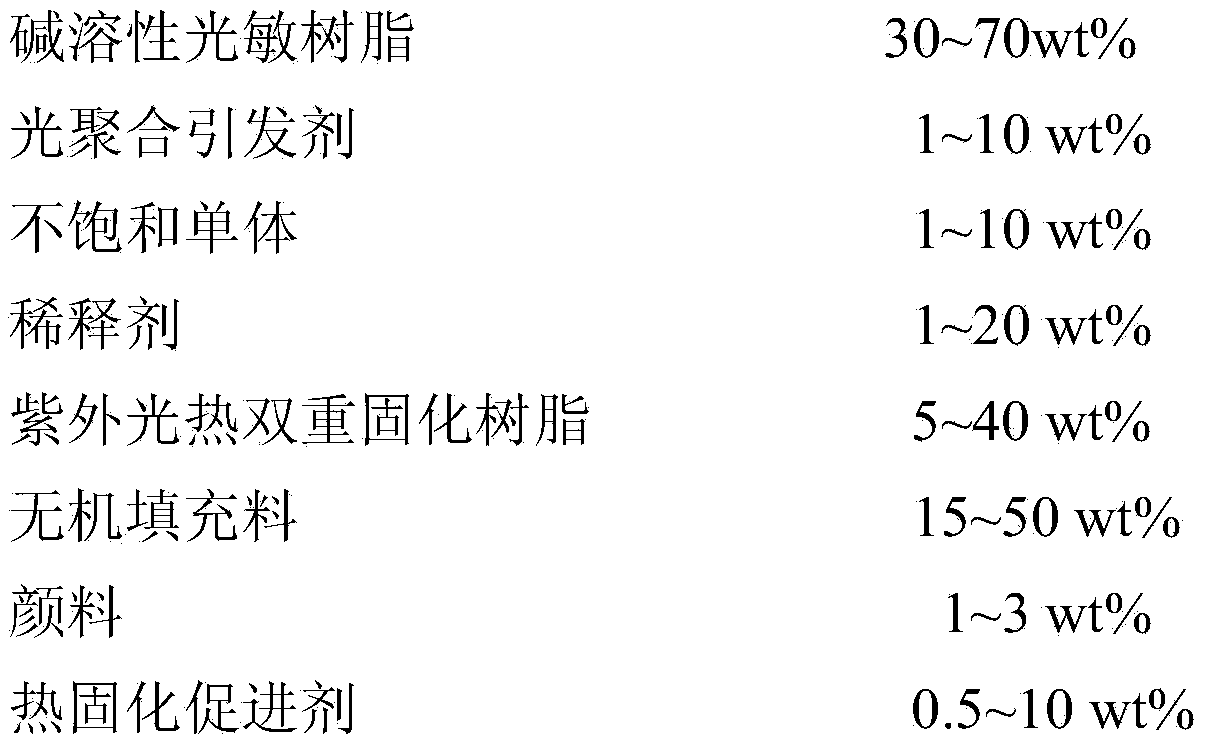

A dual-curing, solder mask ink technology, used in inks, applications, household appliances, etc., can solve the problems of slow progress of TGIC substitutes, and achieve the effect of superior physical and chemical comprehensive properties, high solid content, and excellent pre-baking operation latitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

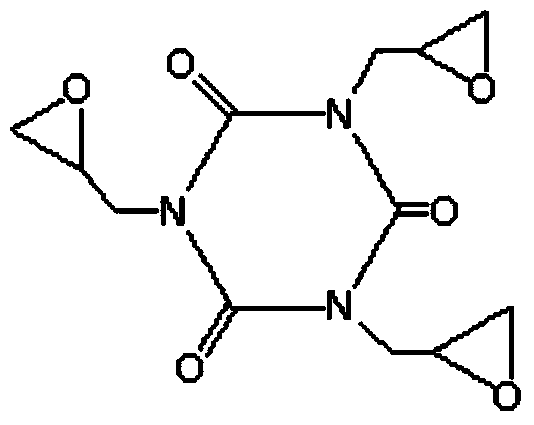

Method used

Image

Examples

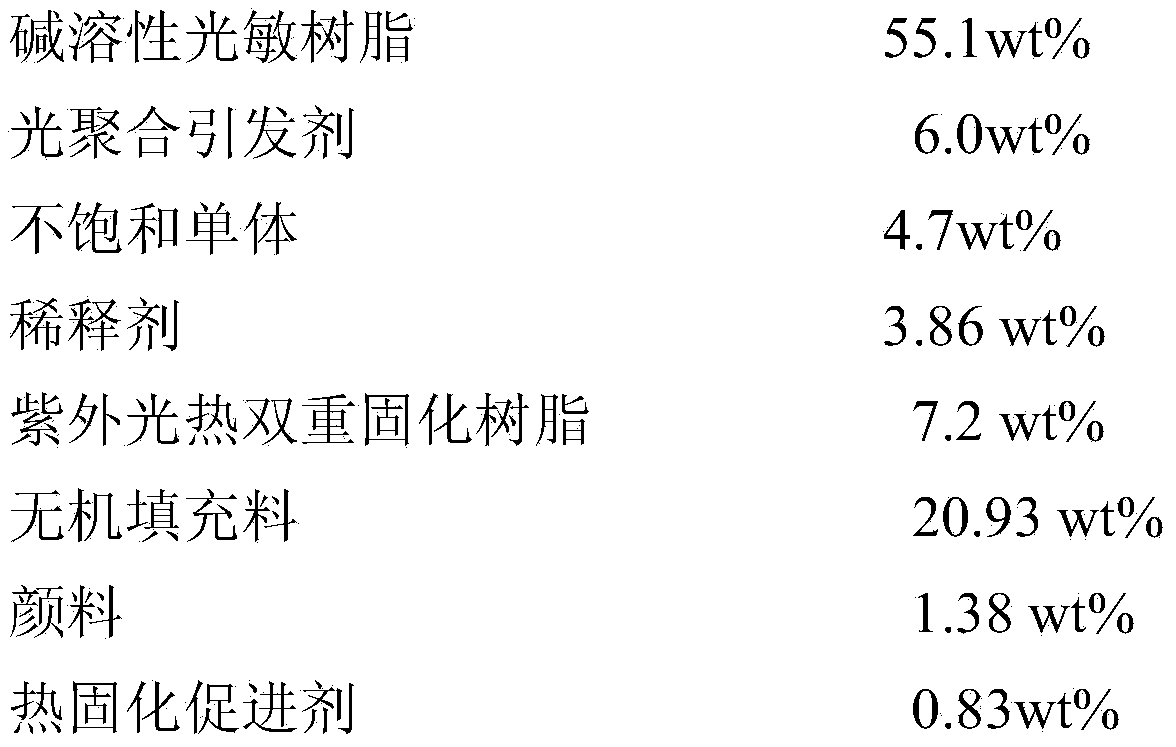

Embodiment 1

[0050] Novolac epoxy resin (manufactured by Changchun Chemical Industry, PNE-177, epoxy equivalent 177) 1320g, diethylene glycol ethyl ether acetate 220g, (meth)acrylic acid 161g, triphenylphosphine 1.8g, p-hydroxyanisole 0.6 g, added to a four-neck flask equipped with a stirrer, heated to 85-130°C and reacted for 8 hours until the acid value was less than 0.5 mgKOH / g. Lower the temperature to 80°C, add 53g of tetrahydrophthalic anhydride, and react at 90-120°C for 5 hours until the acid value is less than 0.2mgKOH / g, and the UV-photothermal dual-curing resin A is obtained.

Embodiment 2

[0052] Novolac epoxy resin (manufactured by Changchun Chemical Industry, PNE-177, epoxy equivalent 177) 1320g, diethylene glycol ethyl ether acetate 220g, (meth)acrylic acid 306g, triphenylphosphine 1.8g, p-hydroxyanisole 0.6 g, added to a four-neck flask equipped with a stirrer, heated to 85-130°C and reacted for 8 hours until the acid value was less than 0.5 mgKOH / g. Lower the temperature to 80°C, add 100g of tetrahydrophthalic anhydride, and react at 90-120°C for 5 hours until the acid value is less than 0.2mgKOH / g, and the UV-photothermal dual-curing resin B is obtained.

Embodiment 3

[0054] Novolac epoxy resin (manufactured by Changchun Chemical Industry, PNE-177, epoxy equivalent 177) 1320g, diethylene glycol ethyl ether acetate 220g, (meth)acrylic acid 376g, triphenylphosphine 1.8g, p-hydroxyanisole 0.6 g, added to a four-neck flask equipped with a stirrer, heated to 85-130°C and reacted for 8 hours until the acid value was less than 0.5 mgKOH / g. Cool down to 80°C, add 129g of tetrahydrophthalic anhydride, and react at 90-120°C for 5 hours until the acid value is less than 0.2mgKOH / g, and UV-light-thermal dual-curing resin C is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com