Photocuring-thermocuring composite ink, application and circuit board containing photocuring-thermocuring composite ink

A composition and light-curing technology, applied in the direction of ink, application, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

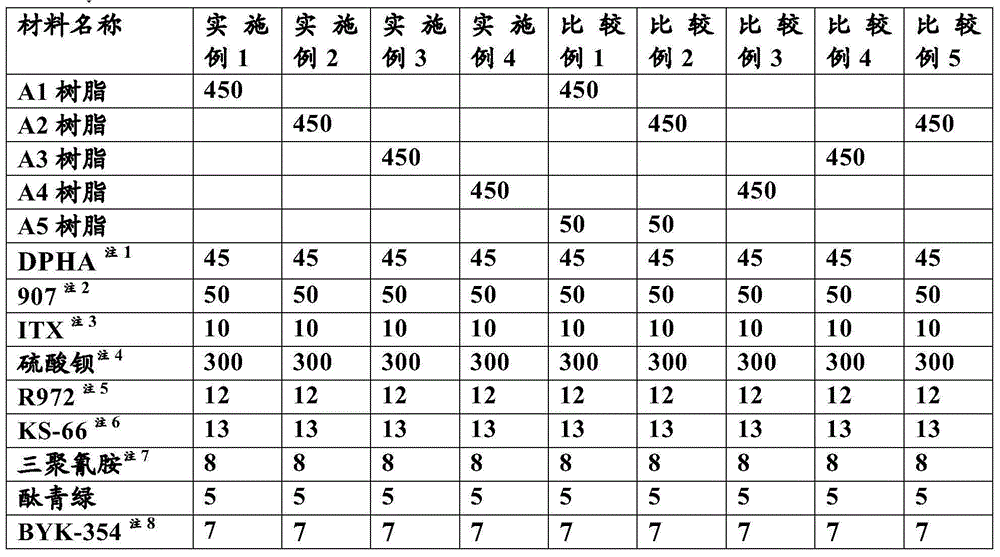

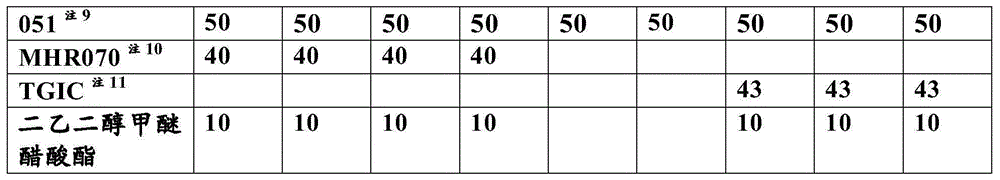

Examples

Embodiment 1

[0078] According to the material ratio listed in Example 1 of Table 1, accurately weigh various materials into the container, use a high-speed disperser, stir and disperse at a speed of 500 rpm for 15 minutes, and then grind the composition with three rollers Machine milled three times to make the composition finer than 15 microns. The viscosity of the above composition was determined to be 200 dPa.s / 25°C.

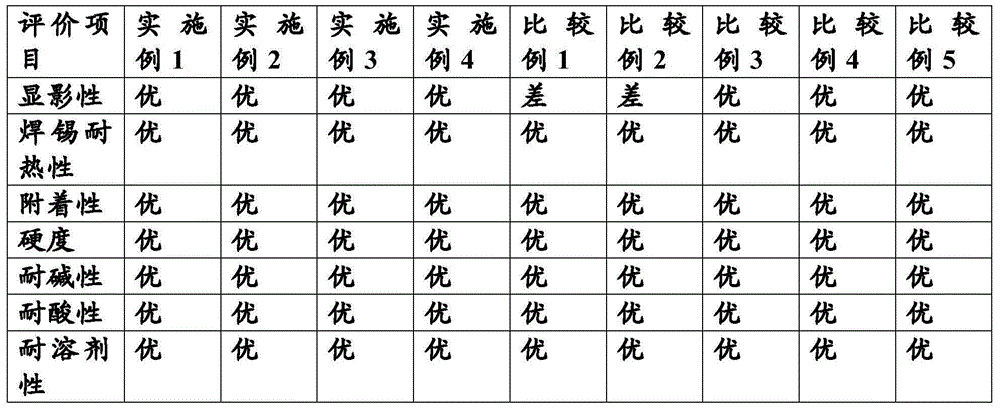

[0079] The developability, solder heat resistance, adhesion, hardness, solvent resistance, acid resistance, and alkali resistance of the composition were evaluated.

[0080] Developability: Using the process of screen printing, the composition ink of Example 1 was coated on three clean circuit board substrates with conductive lines made through 43T nylon mesh, marked as B11 / B12 / B13, respectively. Make the dry film thickness of the coating 25-30 microns, in a constant temperature oven at a temperature of 75 ℃, dry B11 for 60 minutes, B12 for 70 minutes, and B13 for 80 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com