Adhensive rotary printer

A printing press and rubber wheel technology, applied in the field of self-adhesive rotary printing presses, can solve the problems of single paper feeding, difficult operation, low printing accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

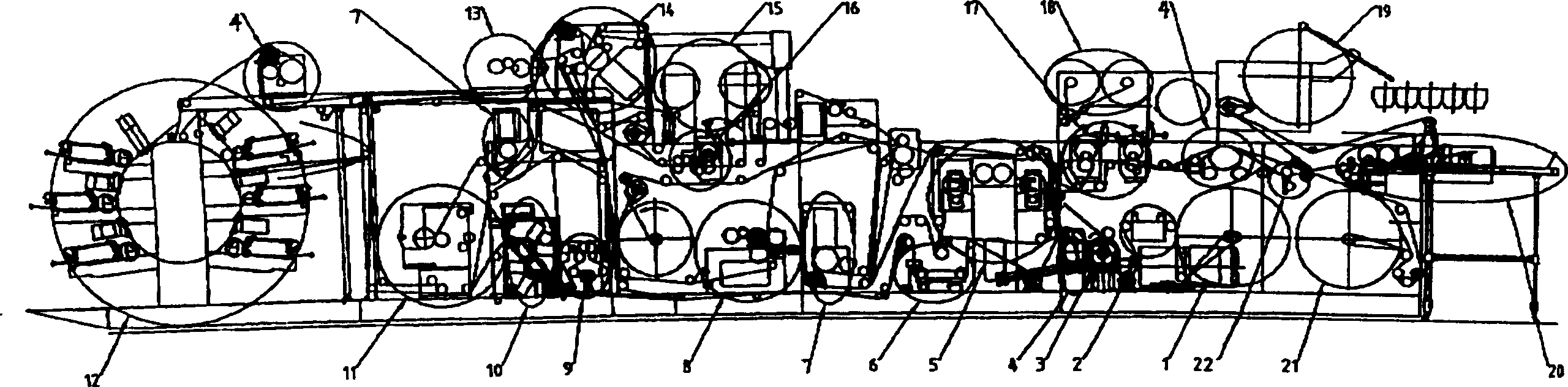

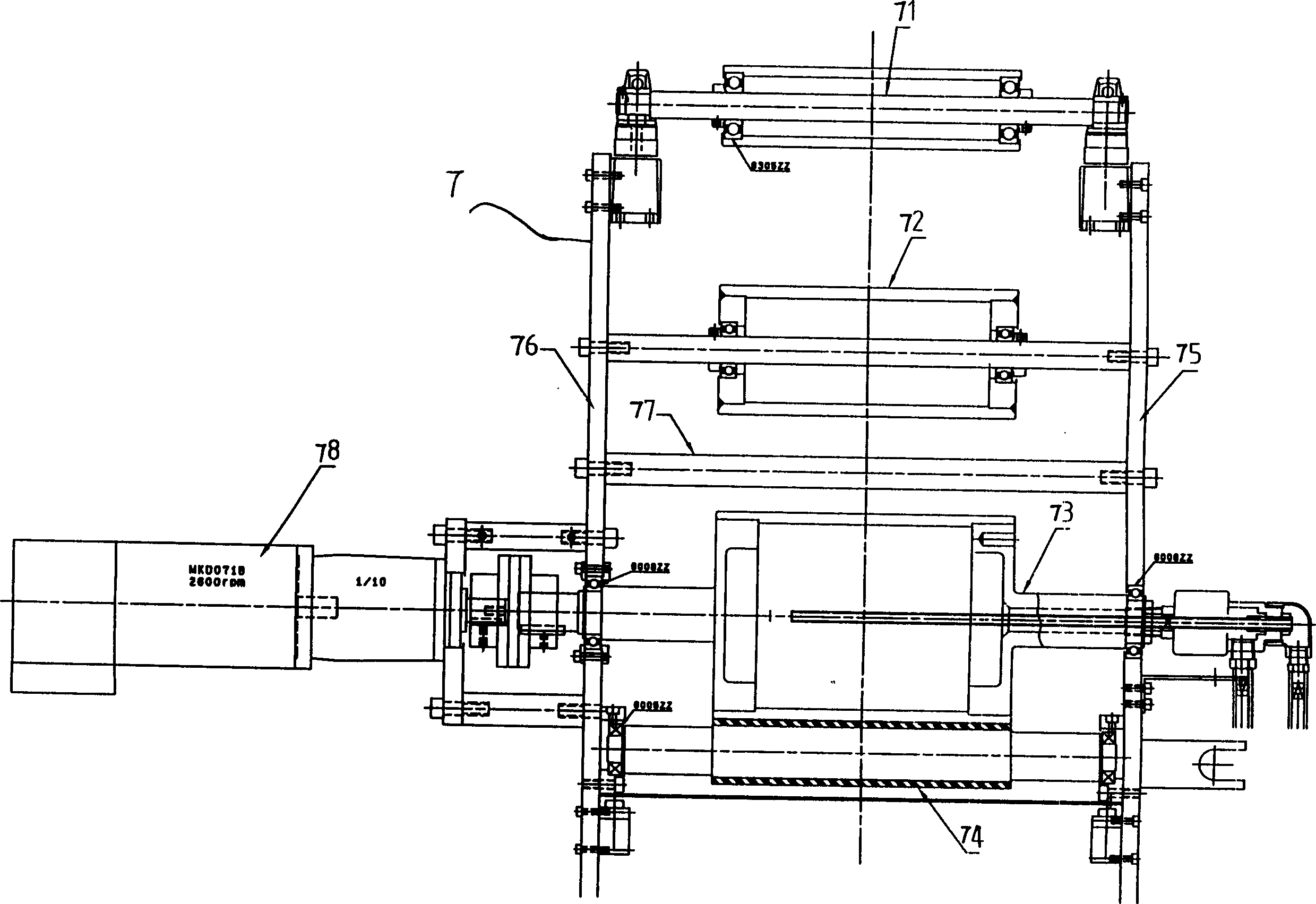

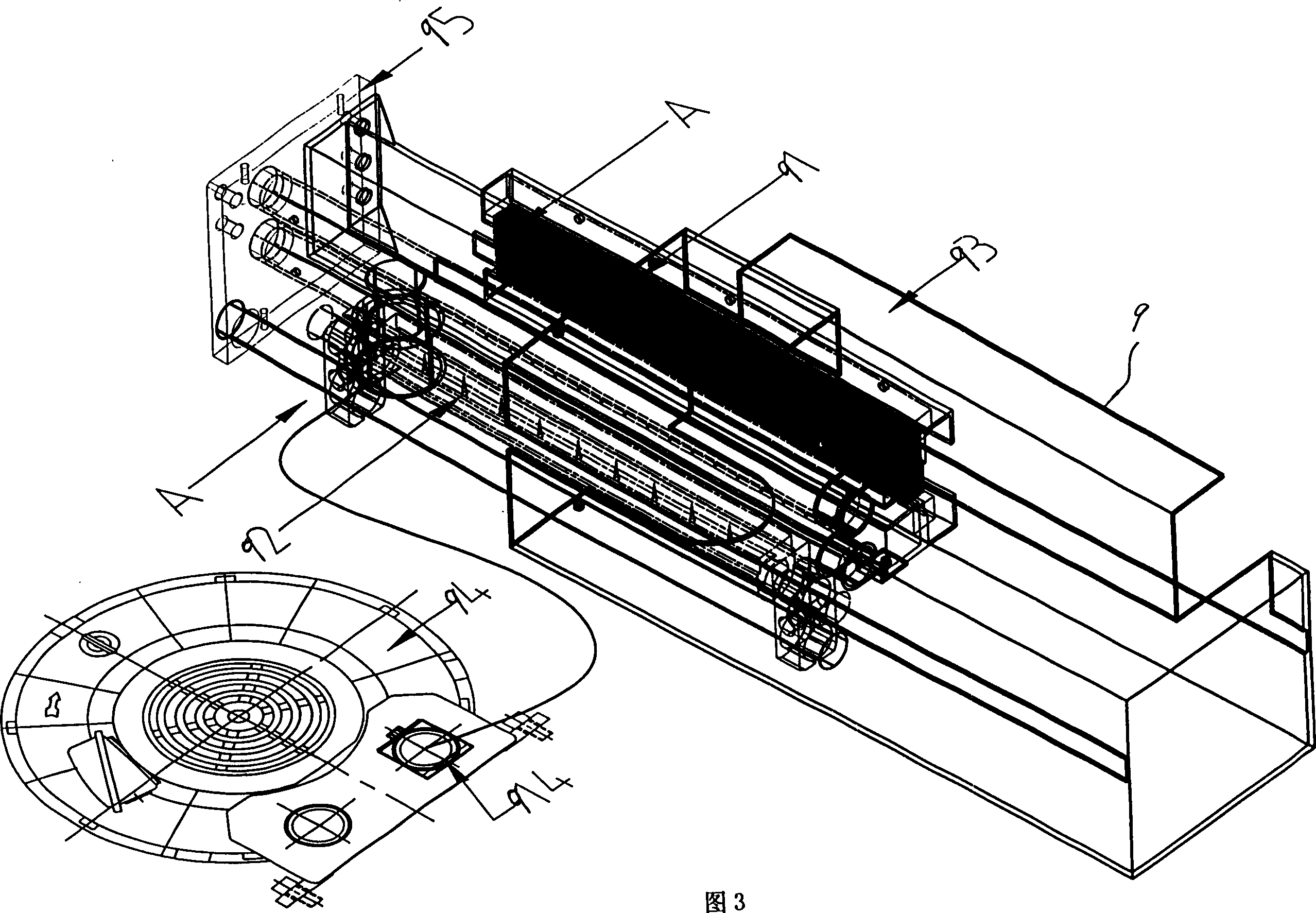

[0024] Such as figure 1 As shown, it is a structural schematic diagram of a self-adhesive rotary printing machine. The self-adhesive rotary printing machine described above consists of a paper feeding unit 1, a paper splicing device 2, a reduction box device 3, an AC servo tension control traction device 4, and a flattening and flattening unit. Device 5, deviation correction device 6, servo motor cooling traction device 7, flexographic printing device 8, paper dust and static electricity removal device 9, corona device 10, screen printing unit 11, satellite letterpress printing unit 12, flexographic printing device 13. Hot stamping film pressing, UV drying and cooling traction device 14, gold foil paper feeding, rewinding shaft 15, hot stamping film cutting device 16, two-cylinder circular film cutting device 17, film covering and peeling part 18, waste discharge roll part 19. Consists of a suction conveying device 20, a rewinding section 21, and a back press-cutting section 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com