Efficient cleaning silk-screen printing device

A screen printing device and cleaning technology, which is applied to screen printing machines, printing machines, printing machines, etc., can solve the problems of cumbersome steps, unevenness, time-consuming and labor-intensive printing, etc., and achieve the effect of simple and convenient operation, time-saving and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

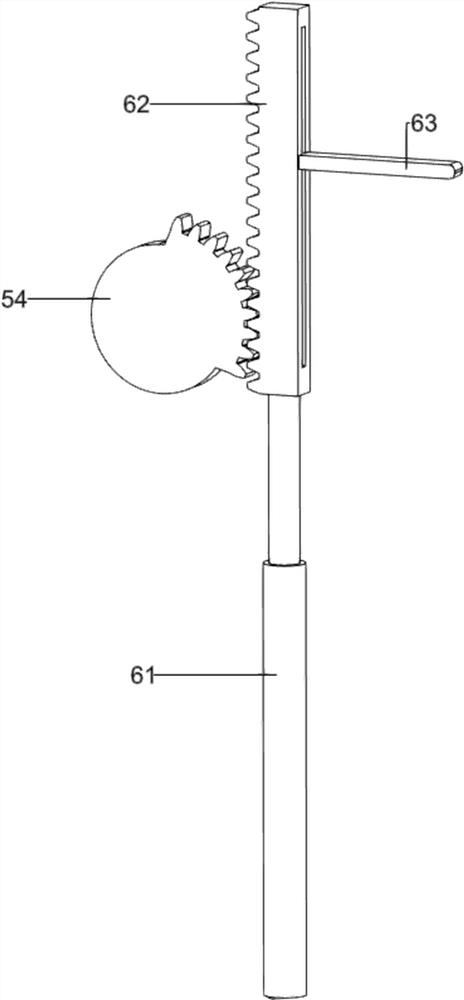

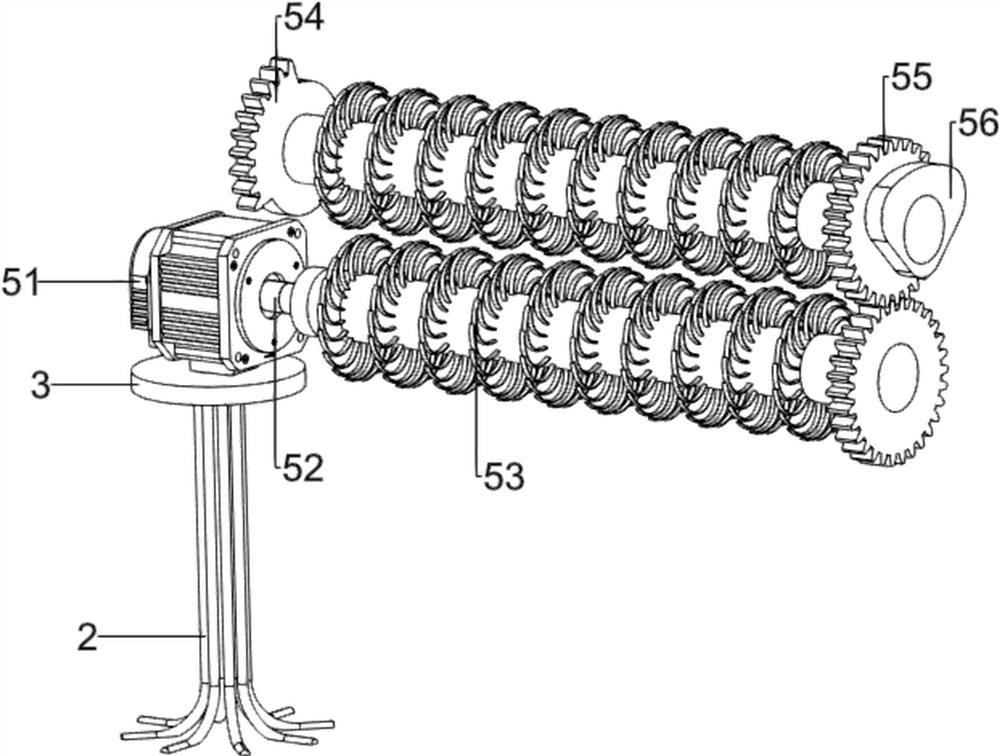

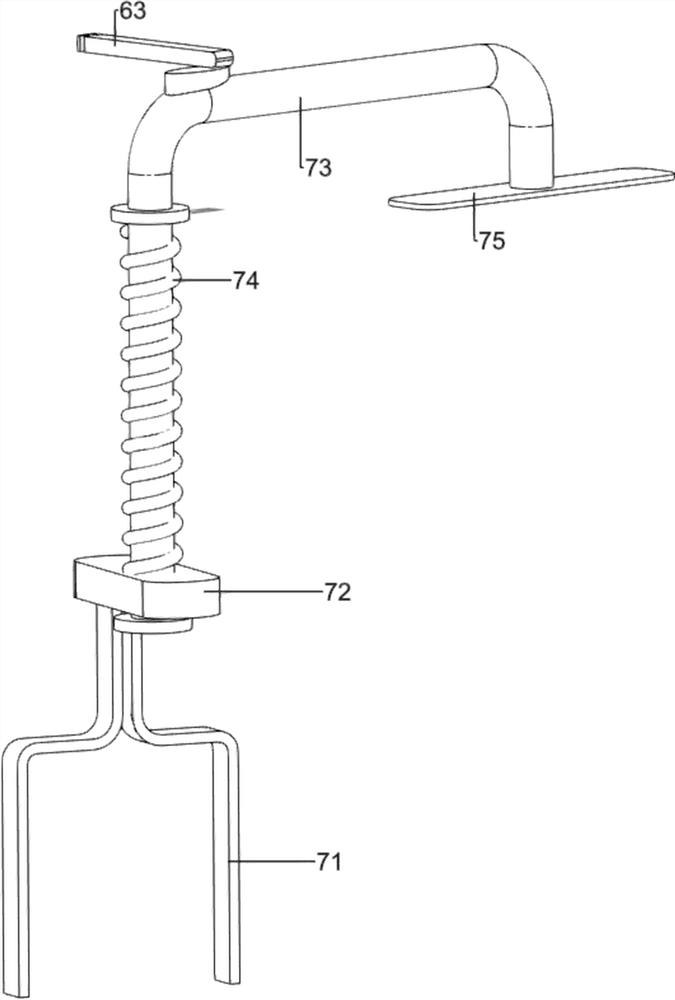

[0074] An efficient and clean screen printing device, such as figure 1 , figure 2 and image 3 As shown, it includes a base plate 1, a first support frame 2, a table plate 3, a feeding mechanism 4, a cleaning mechanism 5, an automatic auxiliary mechanism for printing and pressing 6, and a pressing mechanism 7. The support frame 2, the top of the first support frame 2 is provided with a table board 3, the bottom board 1 is provided with a discharge mechanism 4, the discharge mechanism 4 is provided with a cleaning mechanism 5, the cleaning mechanism 5 is connected with the table board 3, and the bottom board 1 goes forward The left side of the side is provided with an automatic auxiliary mechanism 6 for printing and pressing, and the automatic auxiliary mechanism for printing and pressing 6 cooperates with the cleaning mechanism 5. On the left side of the upper front side of the bottom plate 1, there is a printing and pressing mechanism 7, which is connected with the discharg...

Embodiment 2

[0077] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 7 As shown, the discharge mechanism 4 includes a second support frame 41, a stabilizing frame 42, a support plate 43, a third support frame 44 and a fourth support frame 45, and two second support frames are provided on the front and rear sides of the bottom plate 1. Frame 41, a stabilizer 42 is connected between the bottom of the second support frame 41 on the left and right sides, the inner side of the second support frame 41 is provided with a third support frame 44, and the tops of four third support frames 44 are connected with a support plate 43, The left and right sides of the rear part of the spreader 43 are respectively connected to the two second support frames 41 on the rear side, and the two second support frames 41 on the front side are connected to a fourth support frame 45 on the front side.

[0078] People put the screen on the top of the support plate 43, and...

Embodiment 3

[0086] On the basis of Example 2, such as figure 1 , Image 6 and Figure 7As shown, a sprinkler mechanism 8 is also included. The left side of the bottom plate 1 is provided with a sprinkler mechanism 8. The sprinkler mechanism 8 includes a sixth support frame 81, a water tank 82, a one-way valve 83, a second spring 84 and a shower 85. The bottom plate 1. A sixth support frame 81 is provided in the middle part on the upper left side, and a water tank 82 is provided on the inner side of the upper right part of the upper side of the sixth support frame 81. A check valve 83 is slidably arranged in the middle part of the top side of the water tank 82. The check valve 83 is wound with a first Two springs 84, the top of the second spring 84 is connected with the one-way valve 83, the bottom of the second spring 84 is connected with the water tank 82, and the bottom of the water tank 82 is provided with three showers 85, and the showers 85 are located above the support plate 43.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com