Vacuum aluminum plating ground paperboard and production method thereof

A technology of vacuum aluminum plating and production methods, which is applied in the direction of special paper, chemical instruments and methods, paper/cardboard layered products, etc., can solve the problems of low efficiency, complex process, large solvent volatilization, etc., and achieve simple process and reduce The effect of solvent volatilization and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

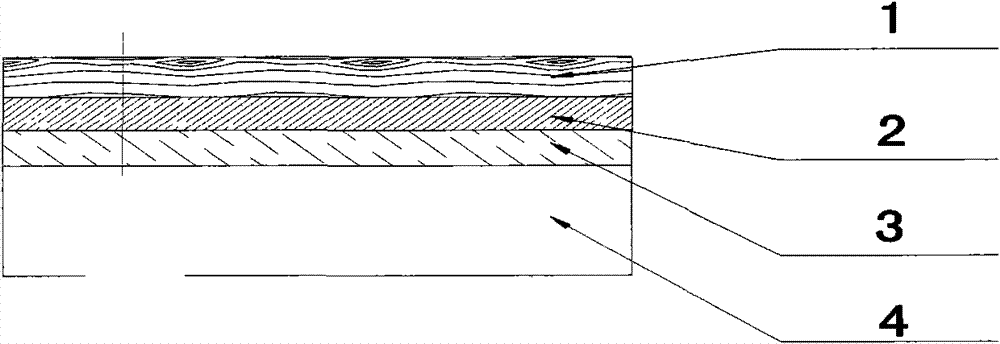

[0043] Reference attached figure 1 , a vacuum aluminized matte cardboard, comprising the bottom paper substrate 4, followed by a matte coating layer 3 and an aluminized layer 2, on which the aluminized layer 2 can be directly offset or gravure printed.

[0044] The above-mentioned production method of vacuum aluminized frosted cardboard comprises the following steps

[0045] (1) At first, make frosted paint mixture;

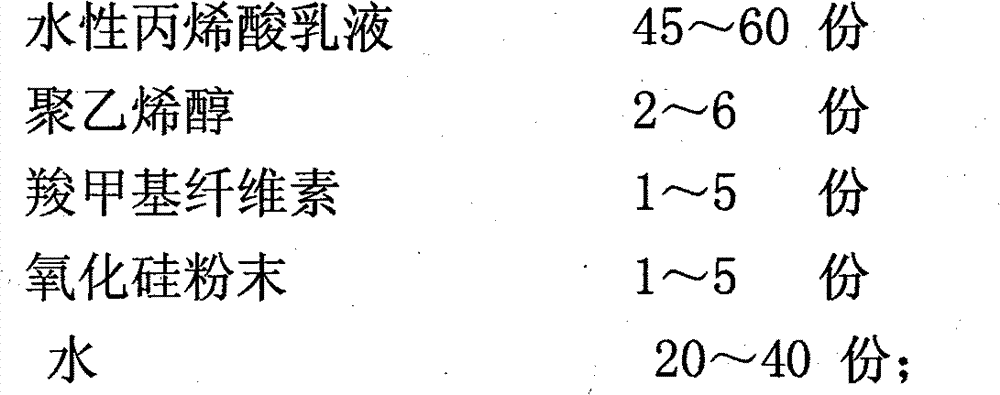

[0046] In a kind of water-containing acrylic emulsion, polyvinyl alcohol, carboxymethyl cellulose composition, the ball mill disperses a kind of nano-scale silicon oxide powder silicon oxide powder (frosting powder) to form a kind of coating mixture with frosting effect, It is an environmentally friendly water-based frosted coating. After curing, some of the particles are wrapped in organic molecules, and some parts are exposed on the surface of the coating, which increases light scattering and achieves a matting effect, thereby forming a matte layer with a fros...

example 2

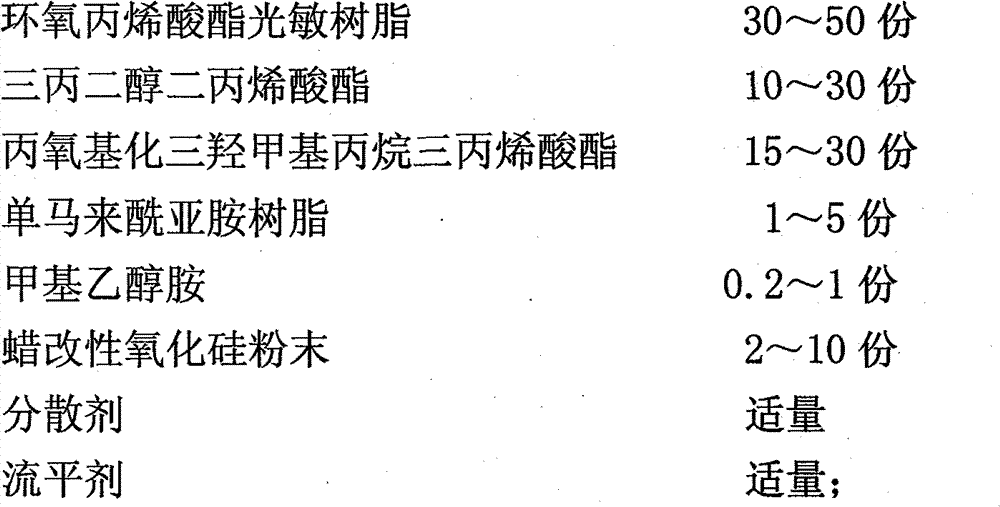

[0057] (1) In a composition containing epoxy acrylate photosensitive resin, tripropylene glycol diacrylate, propoxylated trimethylolpropane triacrylate, monomaleimide resin, methylethanolamine, add a small amount Dispersant and leveling agent, uniformly disperse silicon oxide powder into the composition to form a UV-curable frosted coating.

[0058] The proportioning ratio of each component of the UV-curable frosted paint mixture is:

[0059] Epoxy acrylate photosensitive resin 30-50 parts

[0060] Tripropylene glycol diacrylate 10-30 parts

[0061] Propoxylated trimethylolpropane triacrylate 15-30 parts

[0062] 1-5 parts of monomaleimide resin

[0063] Methylethanolamine 0.2~1 part

[0064] Wax-modified silica powder 2-10 parts

[0065] Dispersants and leveling agents are commercially available products commonly used in the industry in appropriate amounts.

[0066] (2) Coat the UV-curable frosted coating described in (1) with a 200-300 mesh wire roller on a coating mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com