Novel manufacturing process of plastic tube and plastic tube manufactured thereby

A manufacturing process and technology of plastic pipes, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of affecting the strength of varnish, low production efficiency, and increased costs, and achieve low production efficiency and production speed Fast, production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention is mainly applied to the surface printing process improvement of all-plastic sheets, and the manufacturing process has been changed. In order to meet the process requirements and the barrier property requirements of the hose, firstly, the inner printing technology is used, combined with the imaging principle of the surface printing, to manufacture plastic hoses. After compounding, the ink layer is in the direction of the surface film of the composite sheet. After the compounding is completed, the pattern of the original manuscript can be reproduced very well. After cutting, the surface is printed with varnish, which can achieve more Good printing effect.

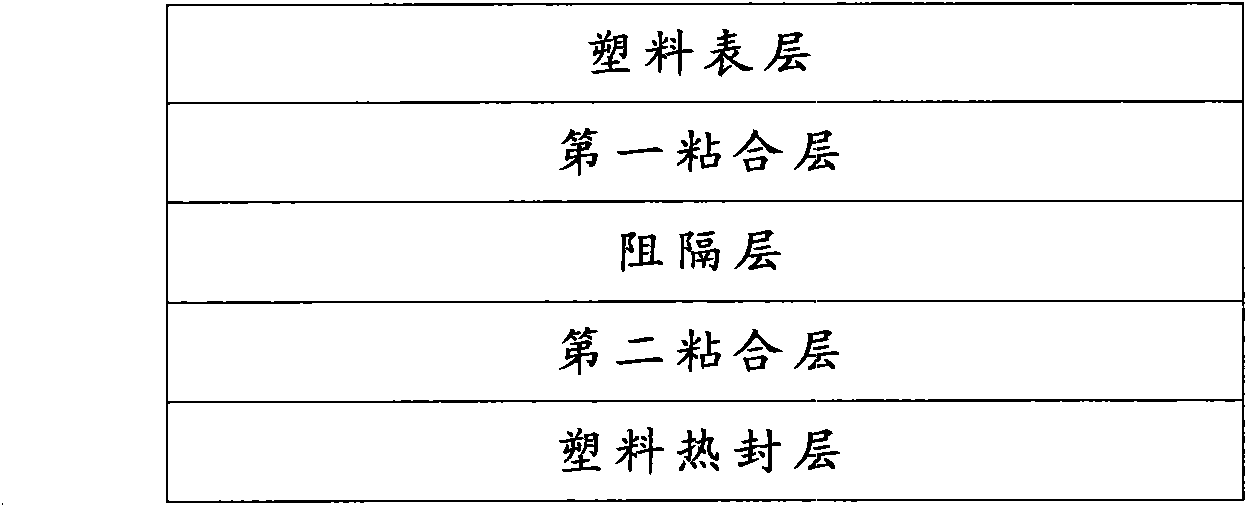

[0022] Such as figure 1 As shown, the structure of the plastic hose includes from outside to inside: the first layer is a plastic surface layer, which is a thermoplastic polyethylene film layer; the second layer is a first adhesive layer, which is a transparent adhesive resin layer; the third layer It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com