Double-end spacing stepless adjustable welding tractor for longitudinal joints of plate units

A welding trolley and adjustable technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor adaptability, time-consuming and laborious, high equipment cost, and achieve the effect of convenient maintenance and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-7 The application is described in further detail.

[0042] The embodiment of the present application discloses a welding trolley with steplessly adjustable double-head spacing for longitudinal seams of panel units.

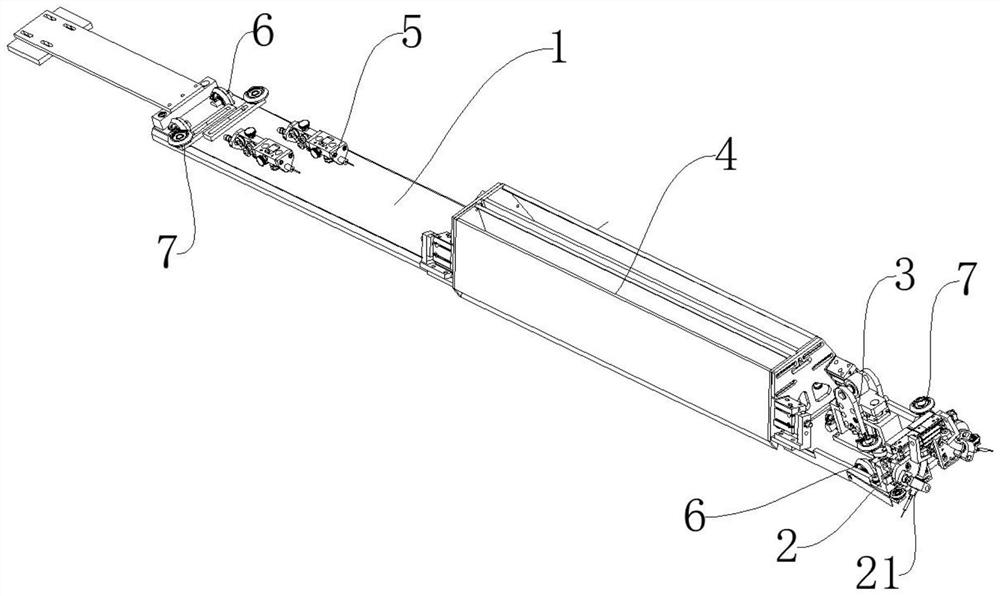

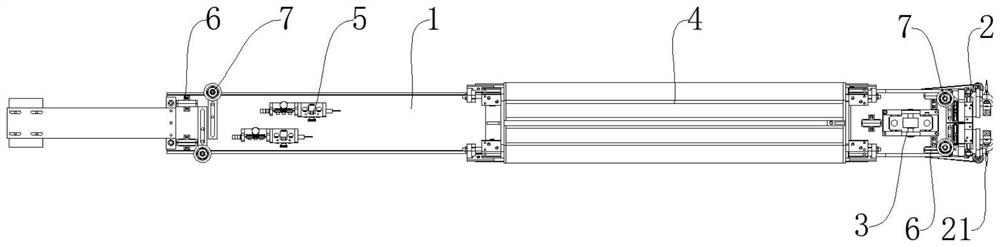

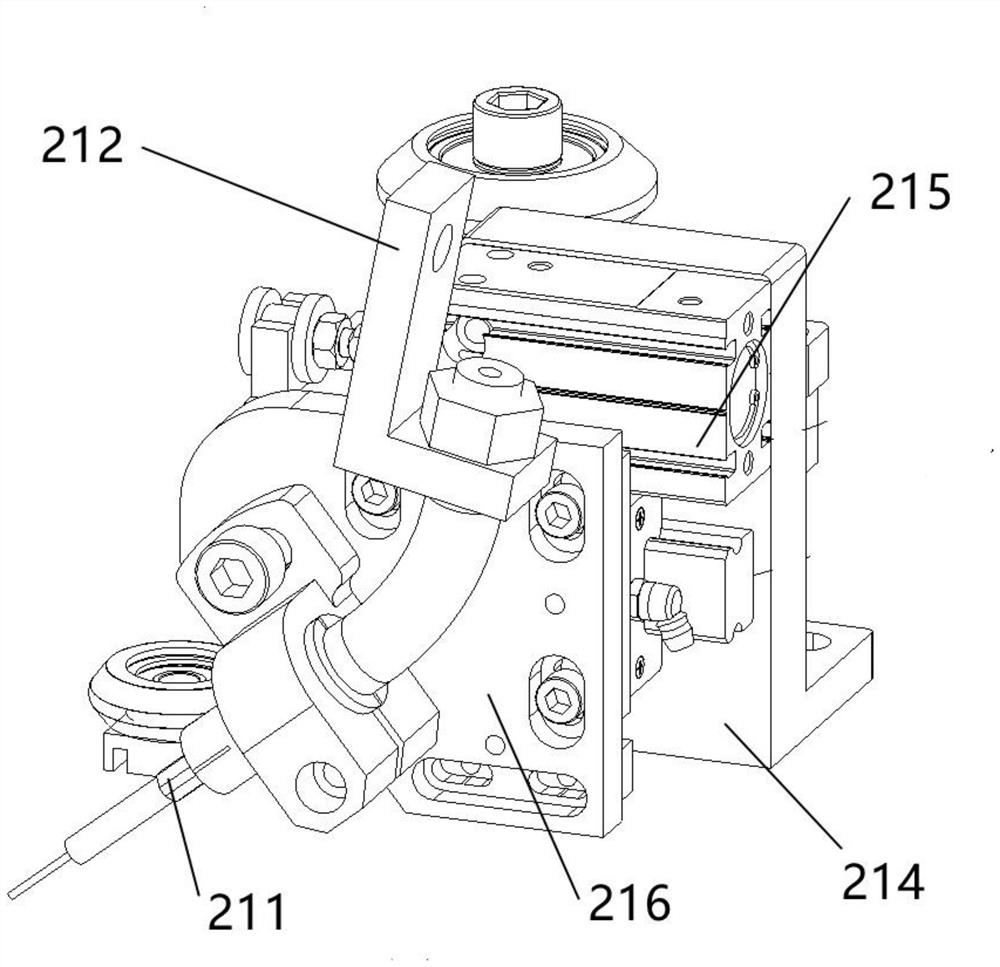

[0043]refer to Figure 1 to Figure 7 , a double-head stepless adjustable welding trolley for the longitudinal seam of the plate unit, including a trolley frame 1, a welding torch head assembly 2, a height support assembly 3, a flux hopper assembly 4 and a wire feeder 5, and a welding torch The head assembly 2, the height support assembly 3, the flux hopper assembly 4 and the wire feeder 5 are sequentially installed on the trolley frame 1;

[0044] The welding torch head assembly 2 is used for welding, and the distance between the welding torch heads of the welding torch head assembly 2 is adjustable;

[0045] The height support assembly is used to tighten the entire welding trolley in the working space during the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com