Angle-adjustable scraper device for printing and dyeing mechanism of flat screen printing machine

A technology of flat screen printing and scraper device, which is applied to screen printing machines, printing machines, rotary printing machines, etc., which can solve the problems of time-consuming, unreachable angles, laborious and other problems, and achieve obvious effects, convenient operation, and improved adjustment angles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

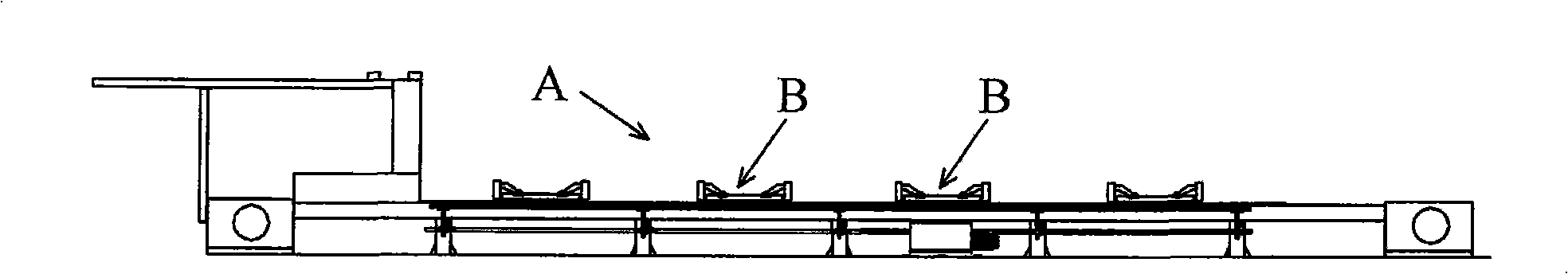

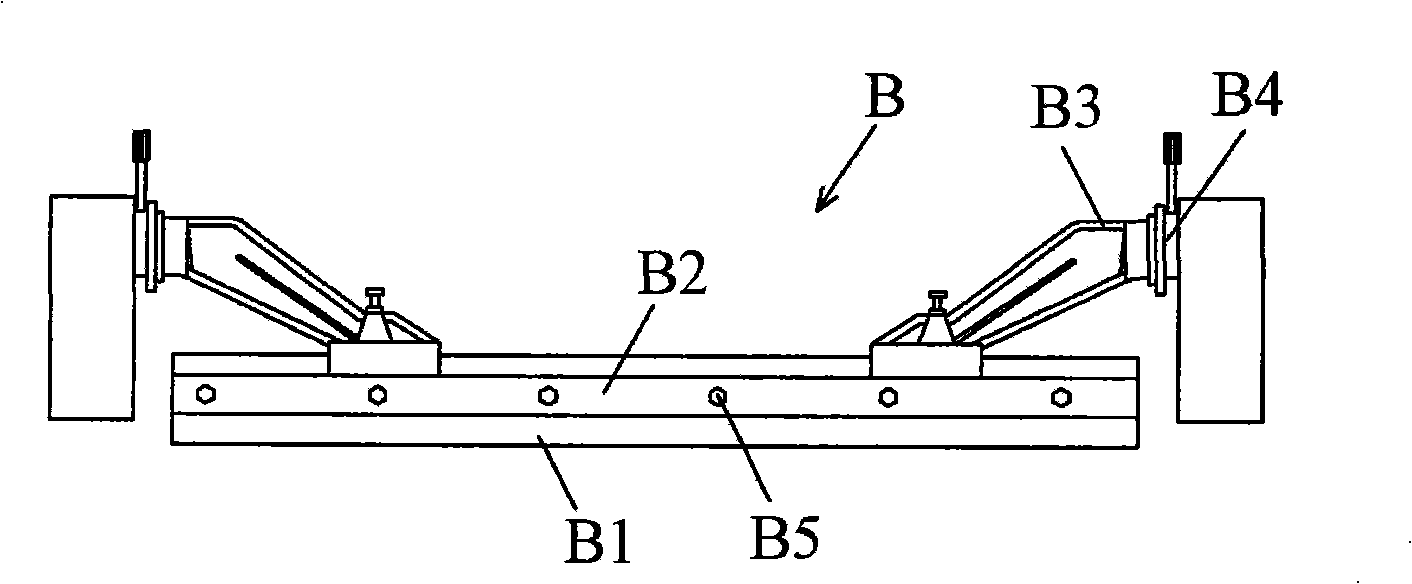

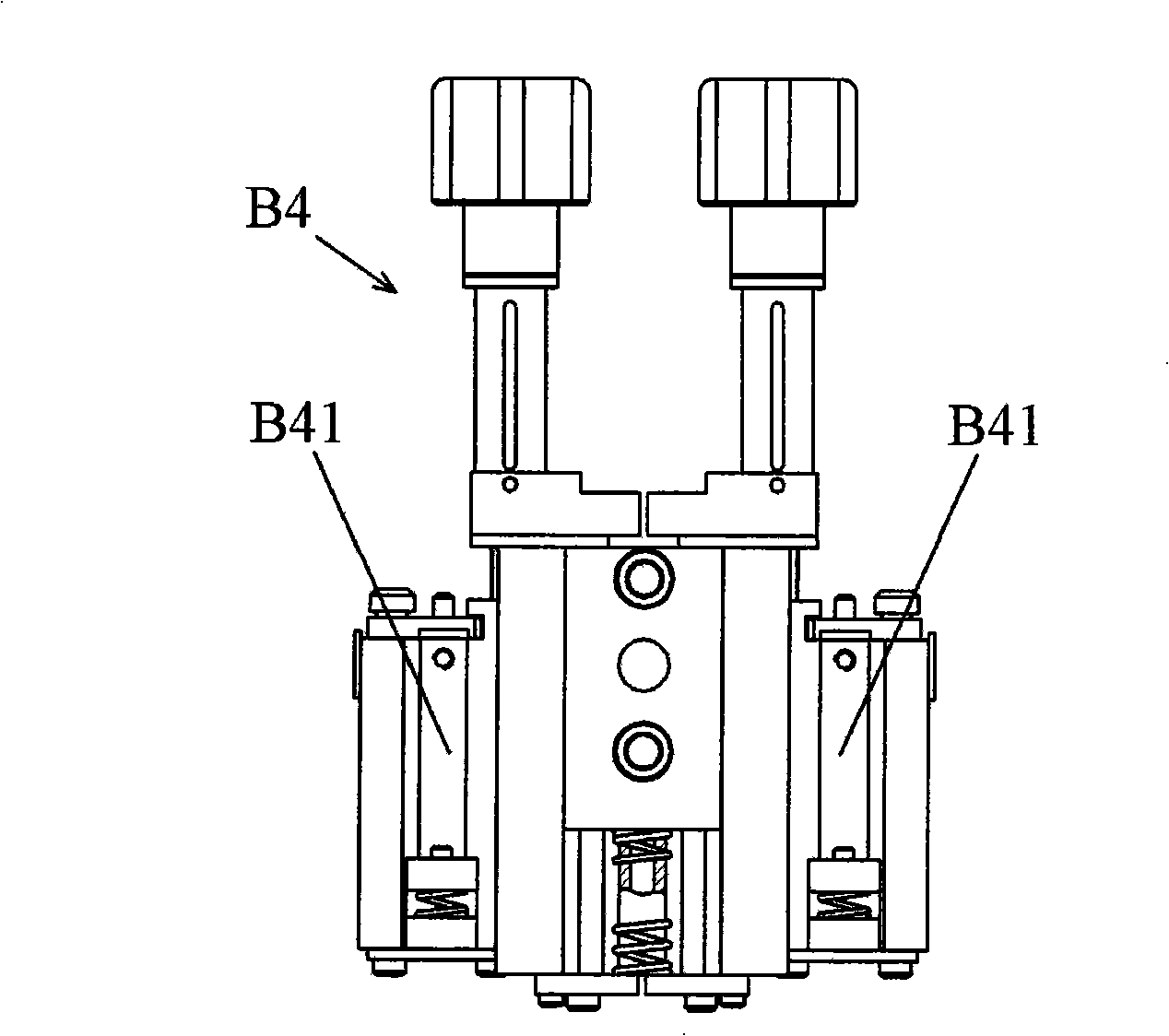

[0027] Example 1, see Figure 4~6 , the flat screen printing machine printing and dyeing mechanism angle adjustable scraper device, the scraper 1 is fixedly connected to the scraper frame 2, the scraper frame 2 is fixedly connected to the sliding arm 3, the sliding arm 3 is fixedly installed on the sliding arm seat 4, and the control slider 5 is fixedly connected with an adjusting disc 6, and an arc-shaped T-slot guide rail 62 is formed on the adjusting disc 6, and a T-shaped guide post 41 is provided on the corresponding slide arm seat 4, and the T-shaped guide post 41 is inserted into the arc-shaped T-slot In the guide rail 62 , a bayonet 61 is formed on the adjusting disk 6 , the spring positioning pin 7 is fixedly installed on the folded portion 42 on the slide arm seat 4 , and the latch 71 of the spring positioning pin 7 is locked in the bayonet 61 .

[0028] The bayonet socket 61 on the described adjusting disc 6 is divided into three scales, one at 15 degrees.

[0029]...

Embodiment 2

[0033] Example 2, see Figure 7-11 , the adjusting disc 6 is composed of three plates, the plate 6a with the bayonet and the two plates 6b, 6c are fixedly connected together with screws 63, the two plates 6b, 6c are connected with the groove 6a1 on the plate 6a with the bayonet 61 An arc-shaped T-slot guide rail 62 is formed. This is more conducive to the installation of the present invention.

[0034] Working principle: pull up the pin 71, directly pull the sliding arm 3 to adjust to the angle to be used, then put down the pin 71, the pin 71 is directly inserted into the bayonet 61, and the required printing effect can be achieved without replacing any spare parts, which is very convenient.

[0035] Under the condition of the same height adjustment, the pressure of the scraper 1 is increased, and the effect is very obvious in the case of light and fine patterns and large surface patterns that require a large scraper pressure. It breaks through the traditional printing machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com