Ink-free laser printing machine

A laser printer and laser printing technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large volume, large limitations, and inability to completely eliminate them, and achieve simple and compact structure, easy maintenance and movement, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment:

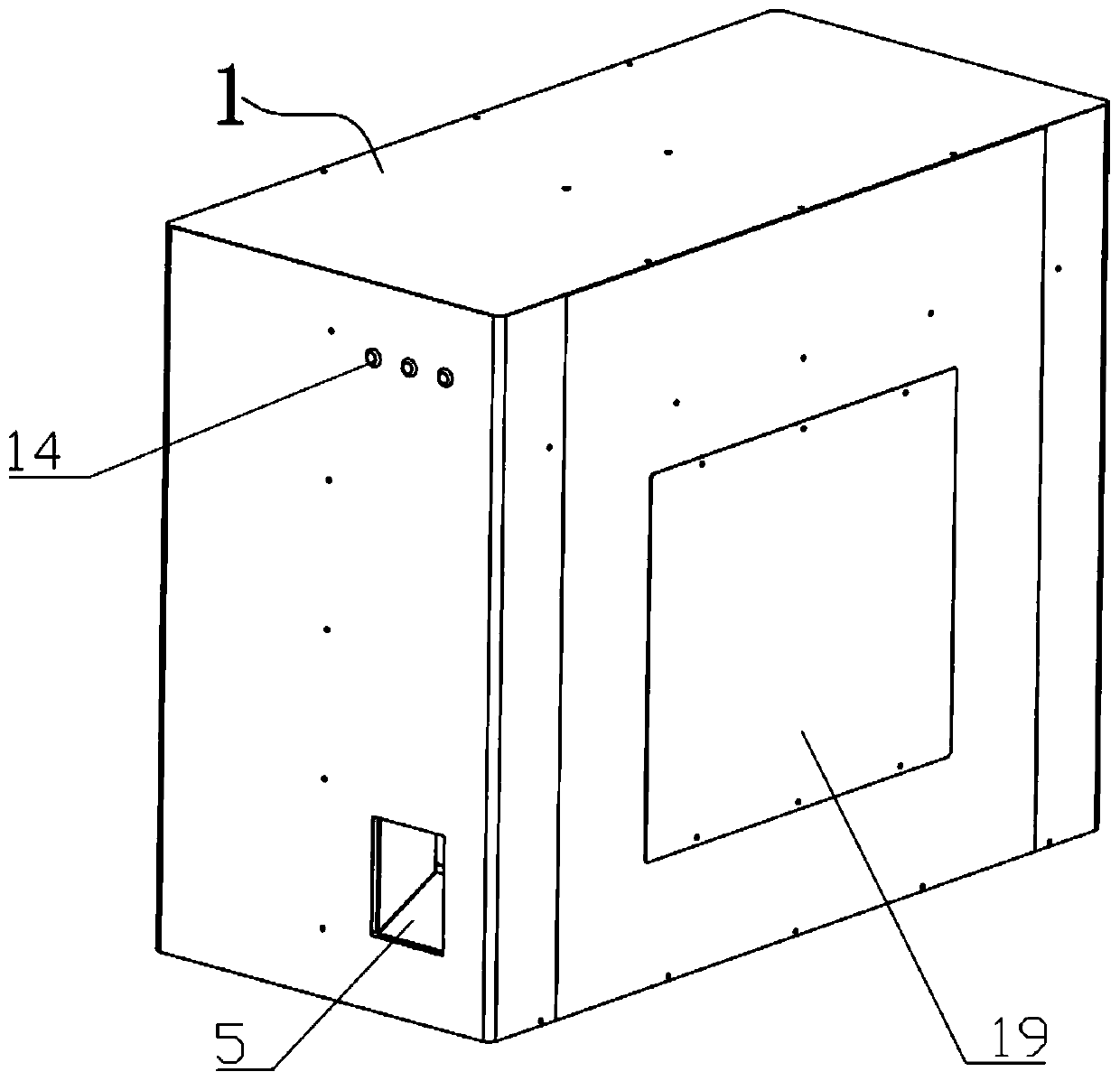

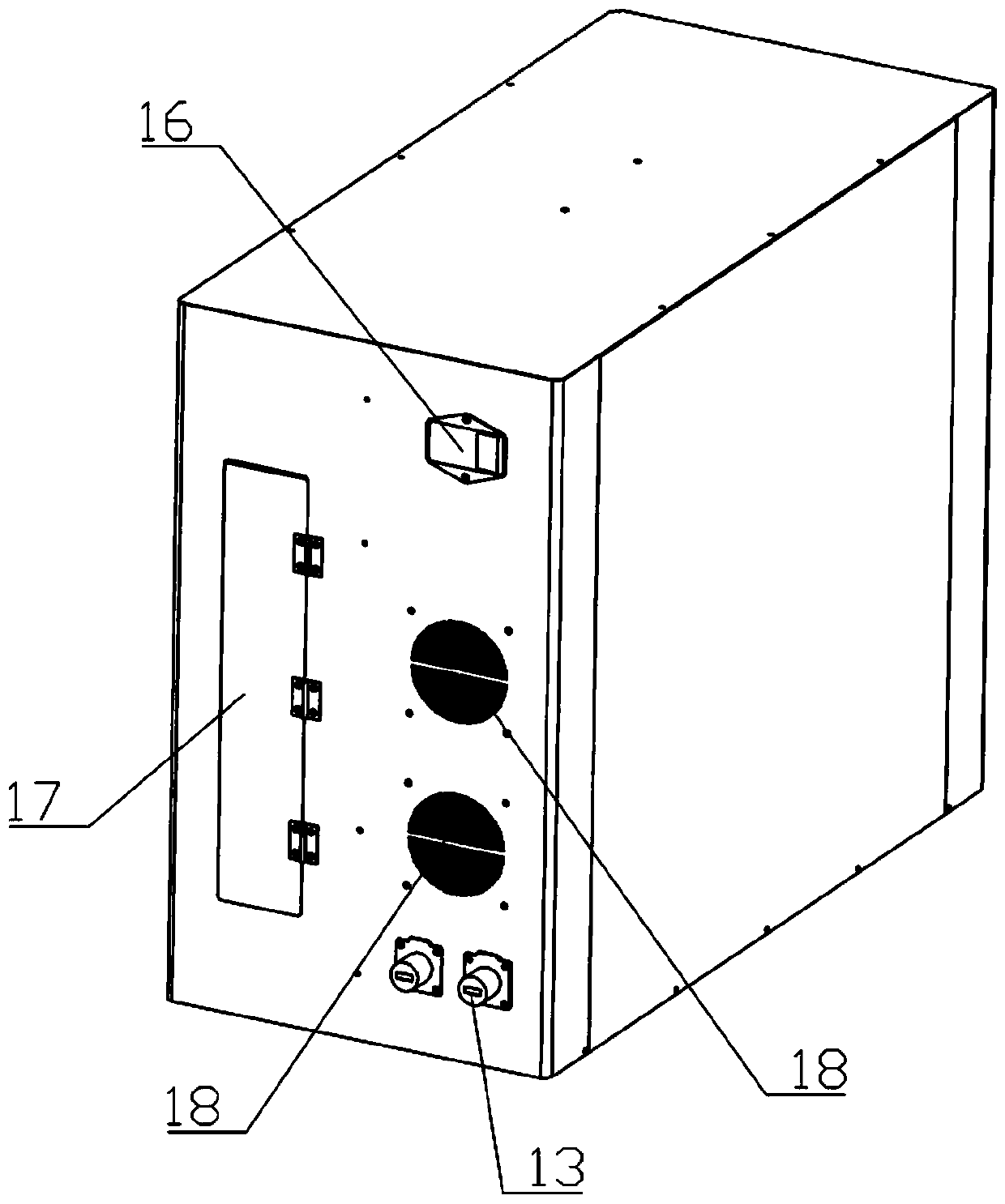

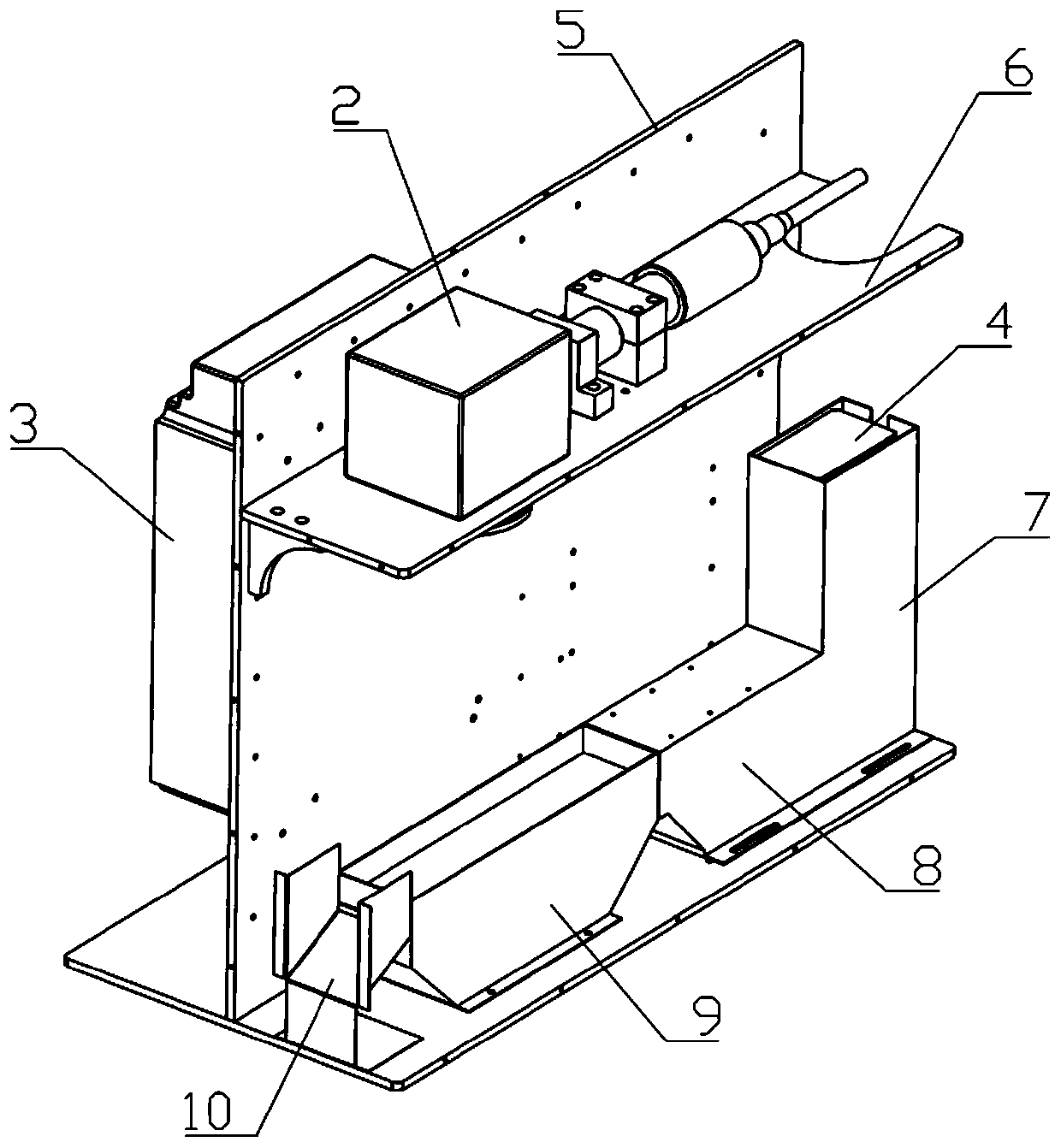

[0023] Such as Figure 1-Figure 5 As shown, a kind of inkless laser printer of the present invention is used for carrying out laser printing to the surface of plastic card 4, comprises: installation box 1; The plastic card feeding module that is arranged in installation box 1; The laser printing module above the plastic card feeding module. The laser printing module includes a printing scanning head 2 and a laser source 3 connected to the printing scanning head 2. The printing scanning head 2 is used to generate radiation that is transmitted from the plastic card feeding module to the printing scanning module. The laser on the plastic card 4 below the head 2, the wavelength of the laser is 1670nm; it is set in the installation box 1 and is used to control the control module that the printing scanning head 2 performs laser irradiation according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com