Patents

Literature

35results about How to "Prevent sticking back" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-crosslinking polyacrylate rubber latex, preparation method thereof and water-based paper printing ink

InactiveCN101870793APrevent sticking backFast dryingPaper coatingCoatingsWater basedHydrophilic monomer

The invention discloses self-crosslinking polyacrylate rubber latex, a preparation method thereof and water-based paper printing ink. The self-crosslinking polyacrylate rubber latex is prepared by the following steps: mixing an acrylic ester monomer, a hydrophilic monomer and ADH in a head tank A; mixing water, an emulsifier, the acrylic ester monomer and DAAM in a head tank B; adding water, the emulsifier and polymerizable self-emulsifying functional monomer, stirring the mixture, heating the mixture to 75 DEG C, and dripping a mixture in the head tank A and an initiator to prepare a protective colloid first; dripping the mixture in the head tank B and the initiator at 85 DEG C; and performing a constant-temperature reaction. The water-based paper printing ink is prepared by the following steps: dissolving a phenylethylene-acrylic acid polymer and a pH value regulator in water at 60 DEG C with stirring; adding a pigment and necessary assistant and mixing the mixture to prepare color paste; and uniformly mixing the color paste with the self-crosslinking polyacrylate rubber latex, a surface tension regulator and water. The water-based paper printing ink can be diluted by one or a mixture of two of water and ethanol, can be dried quickly and has high printing adaptability.

Owner:SUN YAT SEN UNIV +1

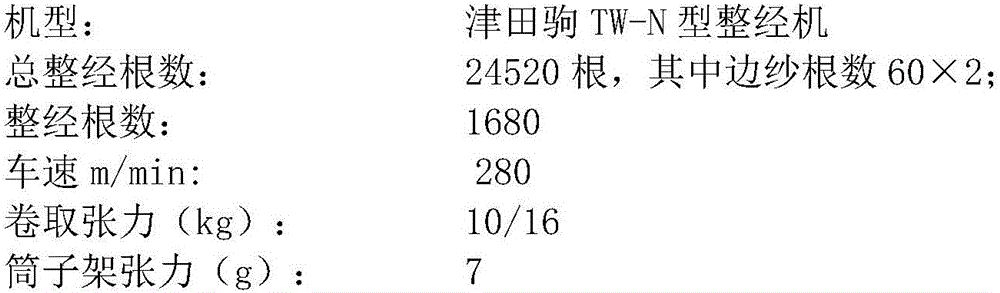

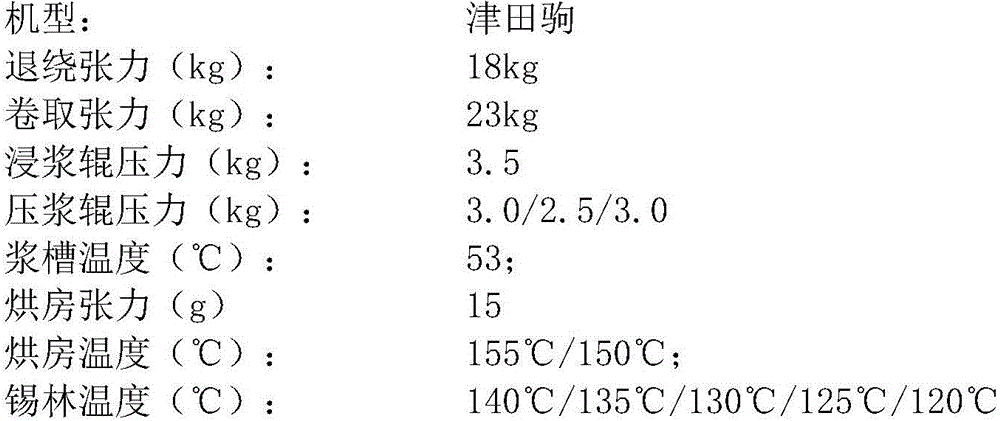

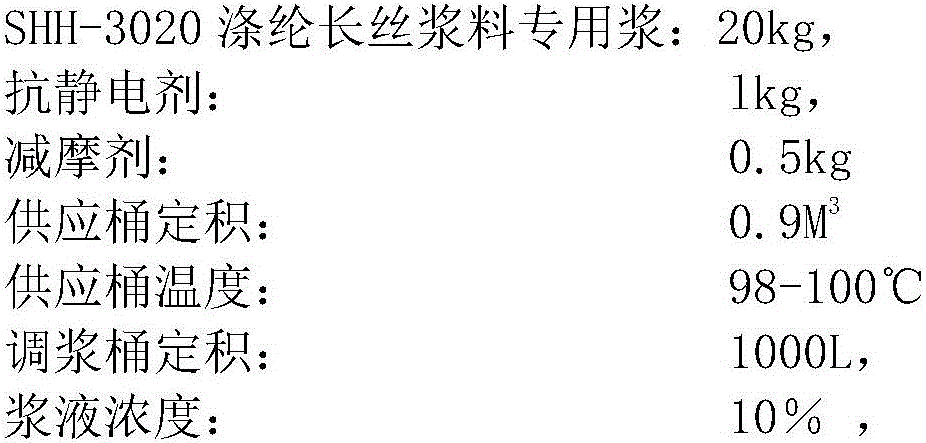

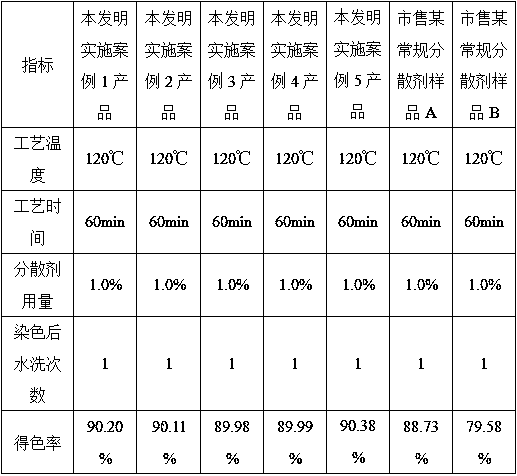

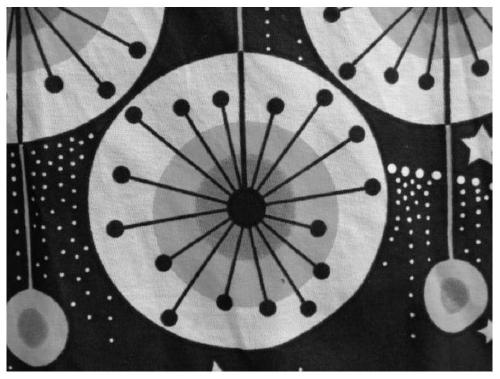

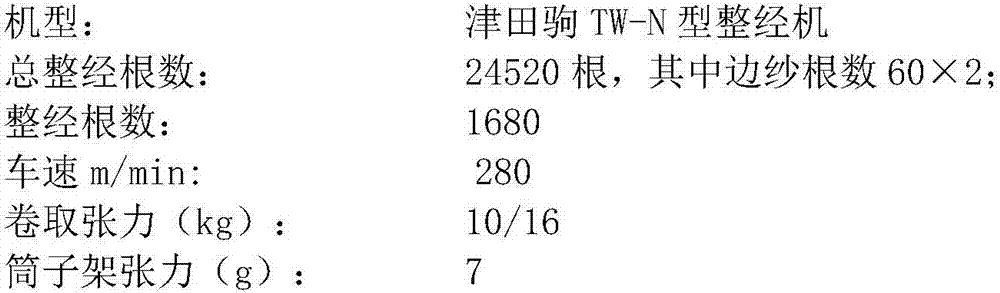

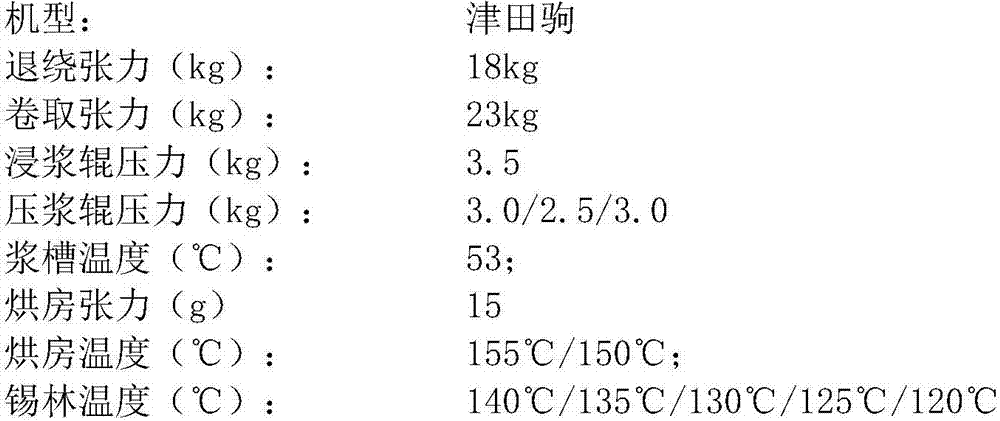

Jacquard acetic acid filament home textile fabric and production method thereof

ActiveCN106012214AGood coloring effectSoft touchHeating/cooling textile fabricsDry-cleaning apparatus for textilesSocial benefitsAcetic acid

The invention provides a jacquard acetic acid filament home textile fabric. Warp is semi-dull polyester filaments with the specification of 50D / 72F, and warp density is 200 pieces per inch. Weft is 75 D acetic acid filaments, and weft density is 96.5 pieces per inch. The structure is a large jacquard fabric. The breadth of the finished product is 160 cm. A production method of the fabric includes the steps that firstly, weaving is conducted, wherein weaving is conducted through warping by means of a warping machine, sizing by means of a filament sizing machine, re-beaming by means of a combining machine, leasing by means of a leasing machine, drafting and weaving by means of a rapier jacquard loom; secondly, dyeing is conducted, wherein dyeing is conducted through unwinding, desizing, dyeing, dewatering, scotching and setting. The fabric is flat, fine, smooth in cloth surface, soft in hand feeling, light, thin, cool, easy to wash, quick to dry, high in color fastness, good in air permeability, gentle and elegant. Reagents of the fabric successfully meet the requirement for comfort and cool of home textile summer quilt fabric of people, and the fabric has high addition value and wide market prospects and is remarkable in economic and social benefit.

Owner:JIANGSU YUEDA HOME TEXTILE

Self-crosslinked polyacrylate latex and preparation method thereof, and water-based paper ink

InactiveCN102304262APrevent sticking backFast dryingPaper coatingCoatingsHydrophilic monomerPolymer science

The invention discloses self-crosslinked polyacrylate latex and a preparation method thereof, and water-based paper ink. The preparation method for the self-crosslinked polyacrylate latex comprises the following steps of: mixing acrylate monomers, hydrophilic monomers and alcohol dehydrogenase (ADH) in a head tank A; mixing water, an emulsifier, acrylate monomers and diacetone acrylamide (DAAM) in a head tank B; adding water, an emulsifier and polymerization self-emulsification functional monomers into a normal-pressure reaction tank, stirring, heating to 75DEG C, dripping a mixture in the head tank A and an initiator, and preparing protective colloid; dripping a mixture in the head tank B and an initiator at 85DEG C; and reacting at constant temperature. The water-based paper ink is prepared by the following steps of: stirring and dissolving styrene-acrylate copolymer, a pH regulator and water at 60DEG C; adding pigments and necessary aids, and mixing to obtain color paste; and uniformly mixing the color paste, the self-crosslinked polyacrylate latex, a surface tension regulator and water. The water-based paper ink can be diluted by one of water and ethanol or a mixture of water and ethanol, and has high drying speed and good printing adaptability.

Owner:SUN YAT SEN UNIV +1

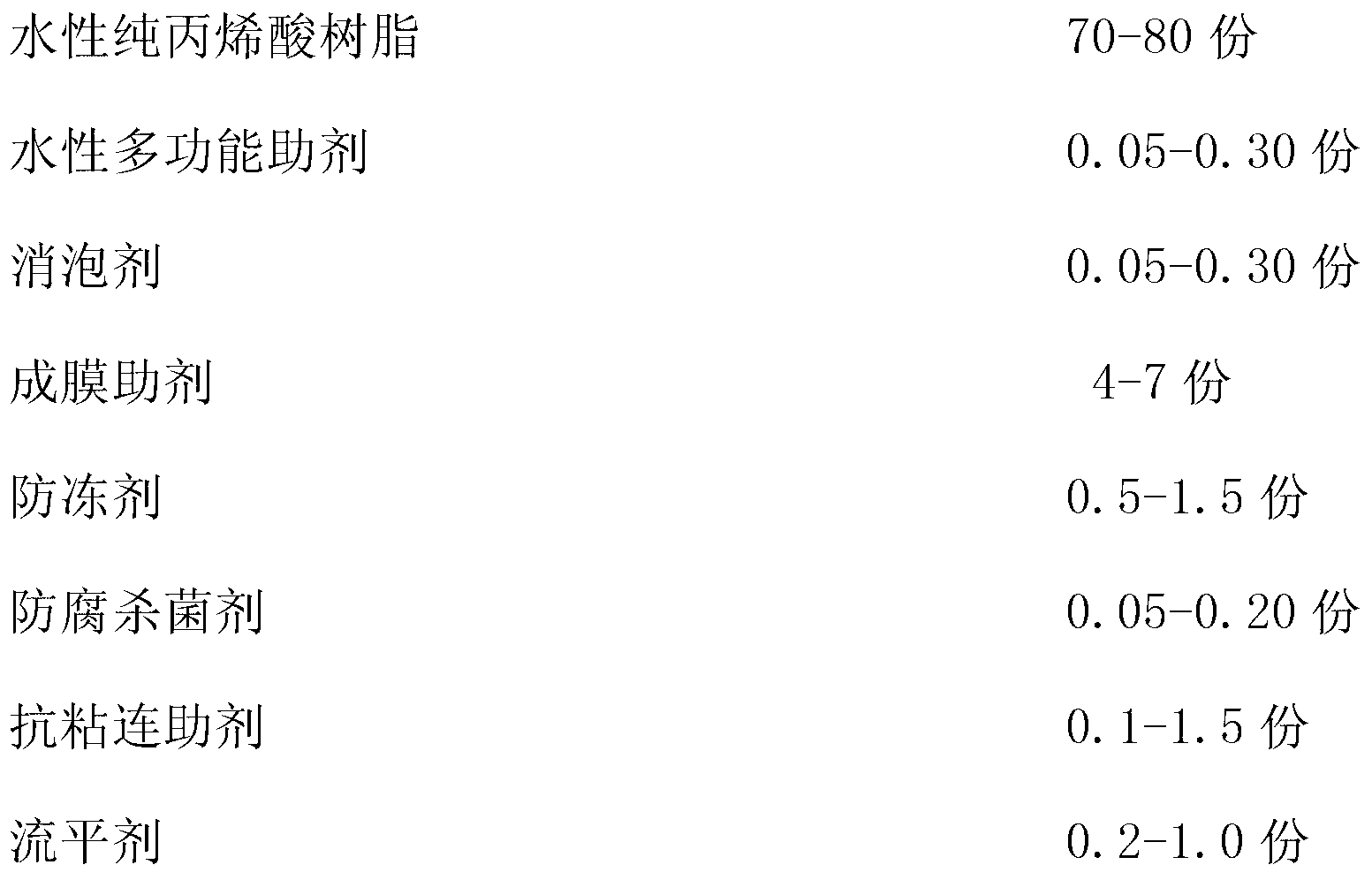

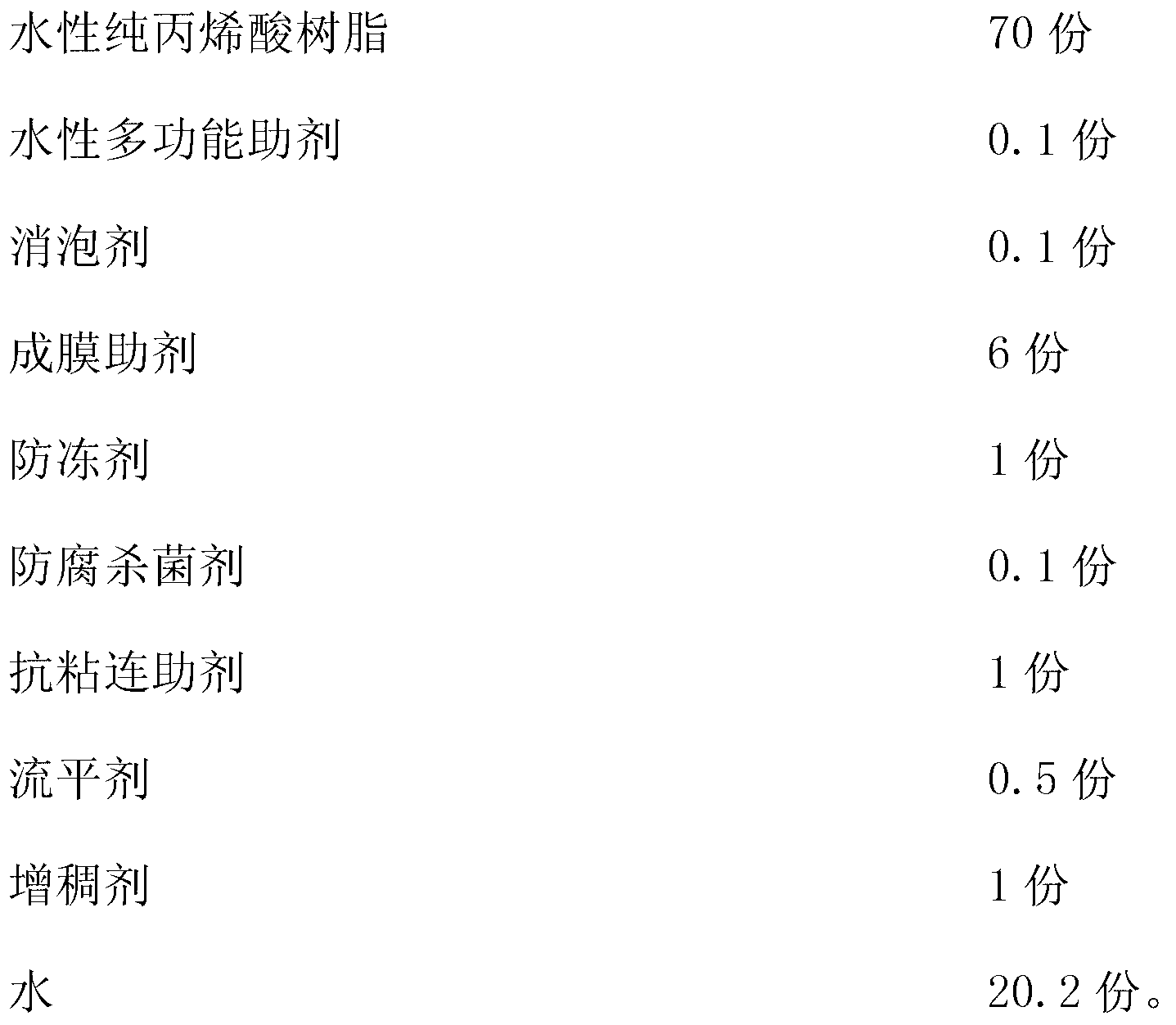

Highly adhesion-resistant aqueous woodenware paint and preparation method thereof

The invention relates to the technical field of woodenware paints, and especially relates to a highly adhesion-resistant aqueous woodenware paint and a preparation method thereof. The highly adhesion-resistant aqueous woodenware paint comprises, by weight, 70-80 parts of an aqueous pure acrylic resin, 0.05-0.30 parts of an aqueous multifunctional assistant, 0.05-0.30 parts of an antifoaming agent, 4-7 parts of a film forming assistant, 0.5-1.5 parts of an antifreeze agent, 0.05-0.20 parts of an anticorrosive bactericide, 0.1-1.5 parts of an adhesion resistant assistant, 0.2-1.0 part of a leveling agent, 0.5-1.7 parts of a thickening agent and 6.5-24.5 parts of water. The highly adhesion-resistant aqueous woodenware paint has a good adhesion resistance, can effectively protect a base material from destroying, has a super strong adhesion with the surface of the base material, can resist superposed 1kg adhesion at 60-80DEG C for 48h in a sealed manner, and has a wide market prospect.

Owner:SKSHU PAINT

Degreasing agent used for dyeing in one bath and with multiple functions

The invention relates to a degreasing agent used for dyeing in one bath and with multiple functions. The degreasing agent is characterized by being composed of the following ingredients by mass percent: 5-20% of fatty alcohol polyoxyethylene ether, 5-20% of modified fatty amine polyoxyethylene ether, 2-10% of a dispersing agent, 5-10% of a solvent, 0.3-1% of polyether modified silyl ether ester and the balance of water. The degreasing agent used for dyeing in one bath and with multiple functions is easy in application and simplified in operation, and only one auxiliary is added. In the aspectof effect, dye dispersing and uniform dyeing effects are better during textile dyeing; besides, the degreasing agent has low foaming property and is easy to clean, degreasing is thorough during one-bath process dyeing of multiple fiber fabrics, removed grease stains are dispersed in dye liquor and can not touch a cloth cover and the inner wall of a dye vat, so that the problems of color tone, color spot, nonuniform dyeing and the like can be effectively avoided, deposition of cation and anion dyes also can be avoided, time, electricity and water are saved at the same time, energy conservationand emission reduction are realized, and economic benefit is effectively improved, so that energy-saving and environmental requirements can be better met.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Bonding wax detergent for semiconductor chips

PendingCN109679790AStrong penetration abilitySpeed up cleaningOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsHydrocarbon solventsWax

The invention discloses a bonding wax detergent for semiconductor chips. The bonding wax detergent is prepared from the raw materials in percentage by mass: 5%-10% of a C8 hydrocarbon solvent or C9 hydrocarbon solvent, 50%-70% of a C10 hydrocarbon solvent or C11 hydrocarbon solvent or C12 hydrocarbon solvent, 5%-10% of a C13 hydrocarbon solvent or C14 hydrocarbon solvent, and 20%-30% of dipropylene glycol dimethyl ether. All the components are matched mutually to completely dissolve components of bonding wax and remove bonding wax and other dirt on the surfaces of the chips, subsequent chemical cleaning operation is omitted, the cleaning process is simple, efficiency is high, the smell is light, and the semiconductor chips and cleaning equipment cannot be corroded.

Owner:DALIAN SANDAAOKE CHEM

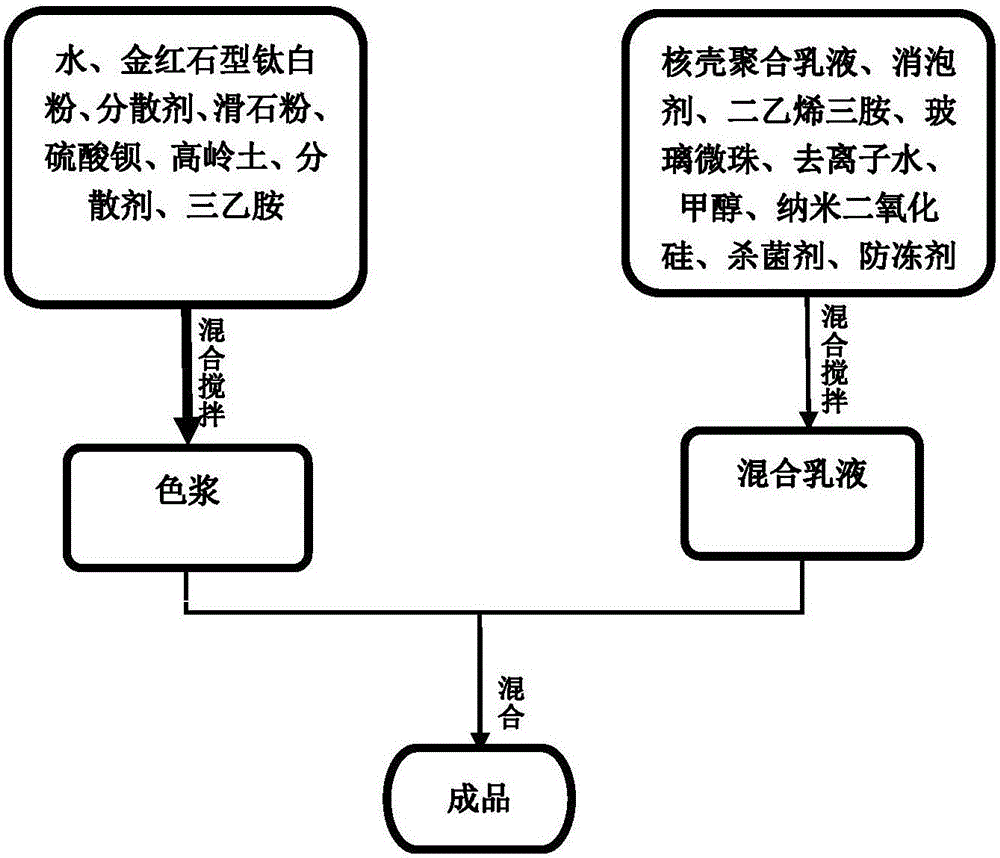

Water-based traffic mark paint and preparation method thereof

The invention relates to a water-based traffic mark paint, which comprises the following components by mass fraction: 8-12% of pigment, 15-30% of a core-shell polymerization emulsion, 2-10% of diethylenetriamine, 10-20% of talcum powder, 10-20% of barium sulfate, 5-25% of kaolin, 1.5-3.5% of a dispersant, 0.5-1.1% of a defoaming agent, 2-4% of triethylamine, 1-3% of methanol, 0.4-0.9% of a bactericide, 1-4% of nano-silica, 5-10% of glass beads, 2%-5% of an antifreezing agent, and the balance deionized water. The water-based traffic mark paint prepared by the method provided by the invention enhances the thickness and ultraviolet resistant ability of the coating, can be applied to construction under the condition of large air humidity, and has fast drying speed.

Owner:广州双桃精细化工有限公司

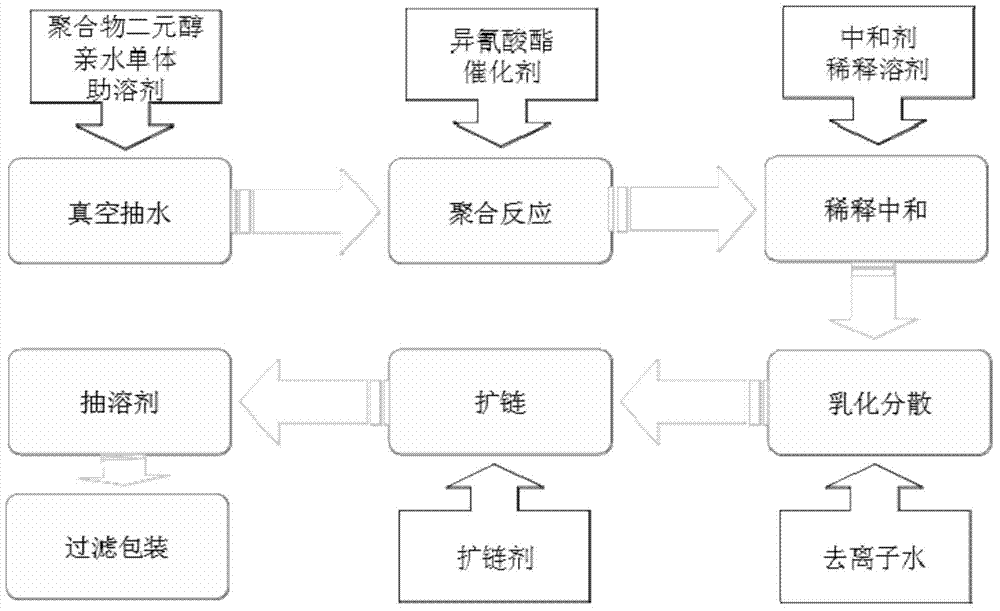

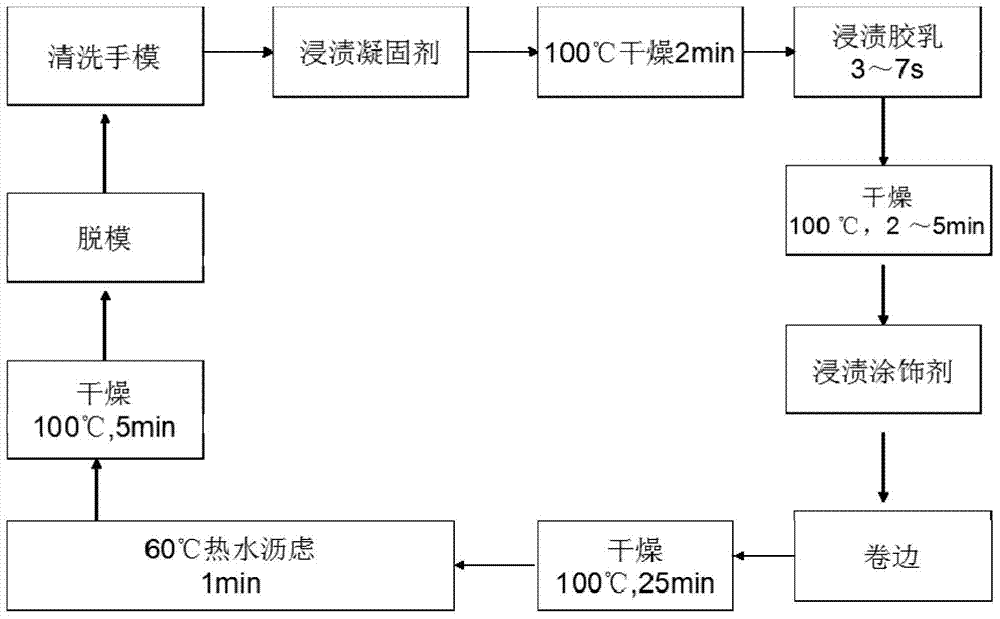

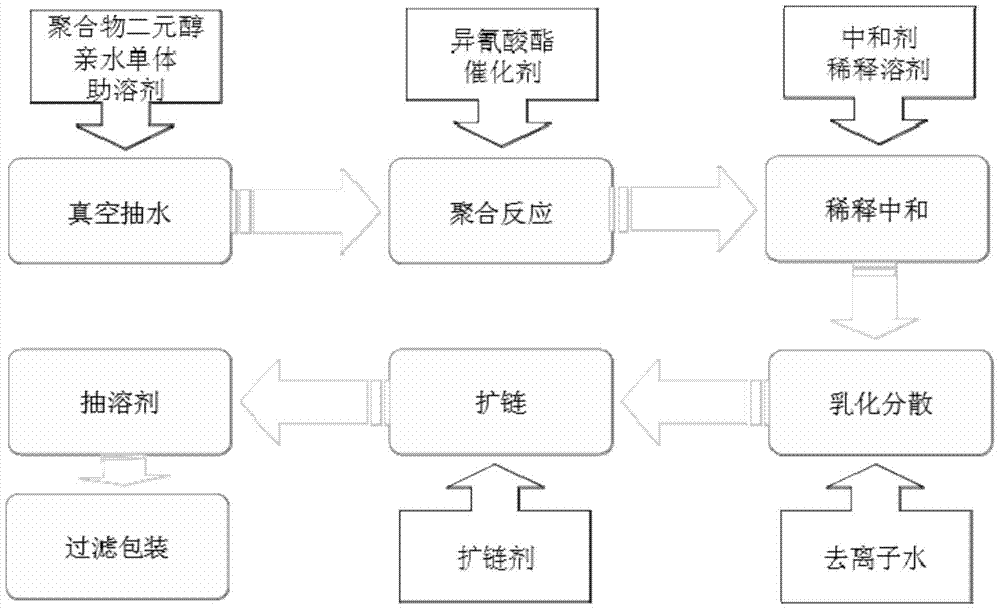

Novel low-modulus waterborne polyurethane material

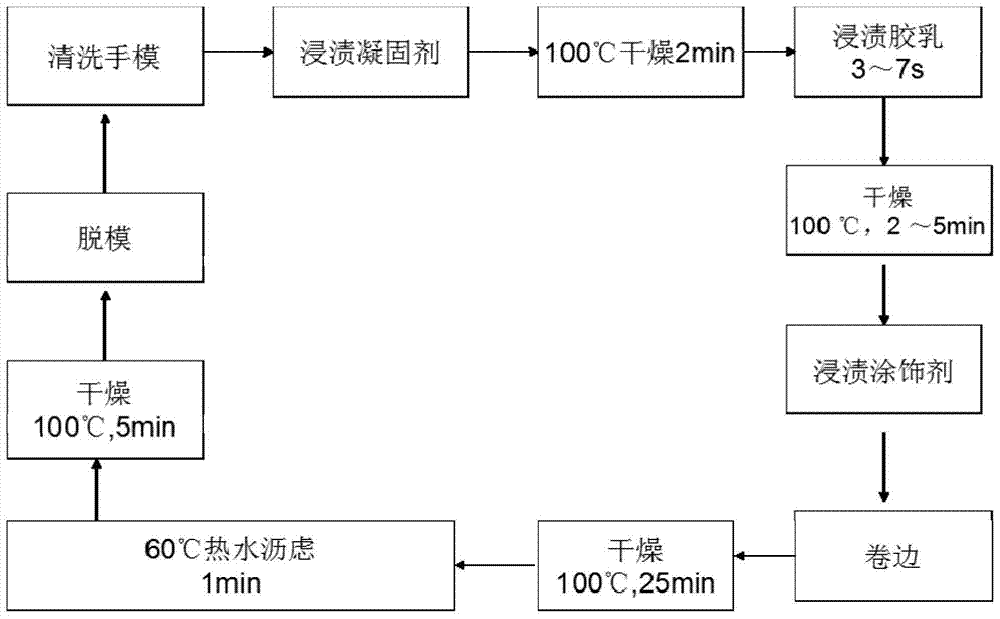

The invention relates to a novel low-modulus waterborne polyurethane material. The material is prepared according to the following steps: step (1), putting polymer diol, a hydrophilic monomer and a cosolvent in a reaction kettle, and dehydrating in vacuum; step (2), cooling the reaction kettle, adding diisocyanate, heating and reacting; step (3), cooling and adding a neutralizing agent and a diluting solvent; step (4), stirring and adding deionized water, stirring continuously, heating, pumping the solvent in vacuum, cooling and filtering to obtain a polyurethane dispersoid, namely obtaining the novel low-modulus waterborne polyurethane material. The polyurethane dispersoid is used for preparing gloves of which the modulus is lower than that of a product prepared by the prior art; the prepared gloves are approximate to a rubber product, easy to wear, soft in hand feeling, good in air permeability, higher than an existing product and the rubber product in breaking strength, better than the existing technical products in rebound resilience and larger than the rubber product in elongation at break; therefore, the novel low-modulus waterborne polyurethane material provided by the invention can be totally used as a potential substitute product for the rubber product in performance.

Owner:山东惠沃盛健康科技有限公司

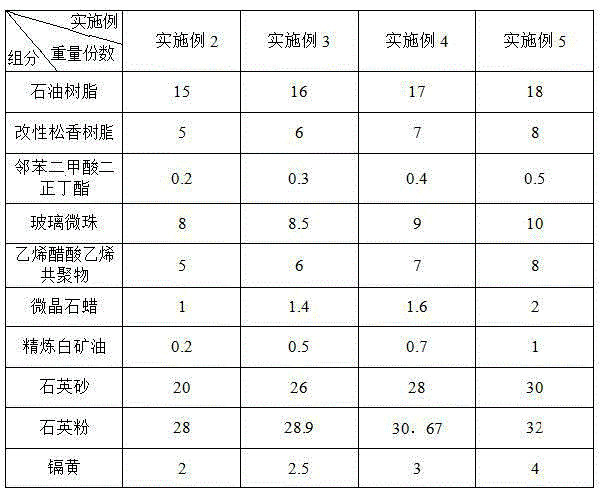

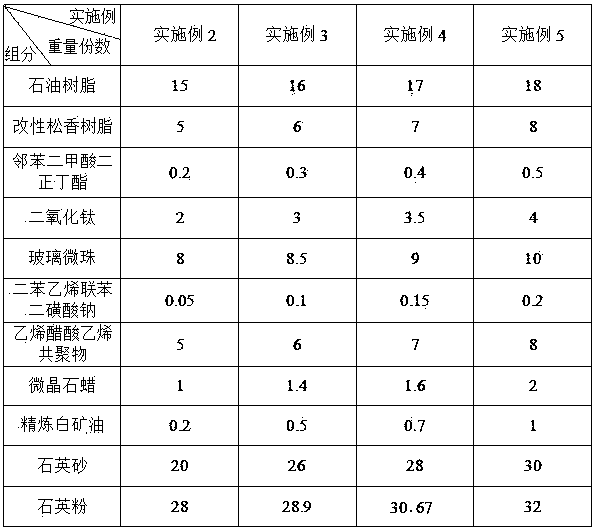

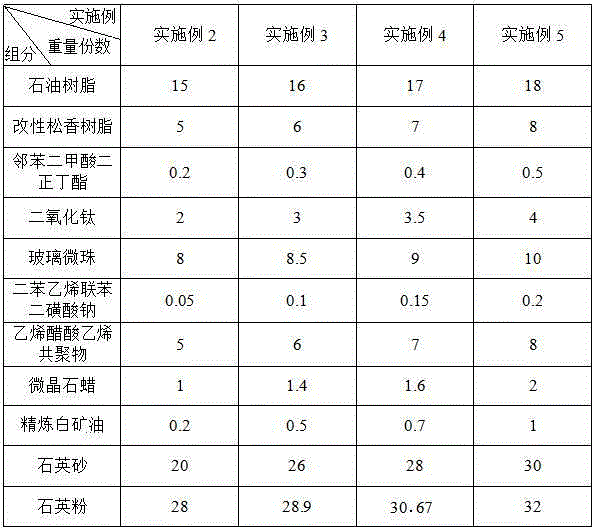

Heat melting high-wear-resistant anti-pollution yellow traffic marking material and preparation method thereof

The invention discloses a heat melting high-wear-resistant anti-pollution yellow traffic marking material and a preparation method thereof. The preparation method is used for preparing the traffic marking material in the technical field of traffics. The heat melting high-wear-resistant anti-pollution yellow traffic marking material comprises the following components: petroleum resin, modified rosin resin, di-n-butyl phthalate, glass beads, an ethylene vinyl acetate copolymer, microcrystalline wax, refined white mineral oil, quartz sand, quartz powder and cadmium yellow. The traffic marking material prepared by using the preparation method not only can be used for improving the wear resistance and anti-pollution capacity of a traffic marking, but also can be used for increasing the adhesive force of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

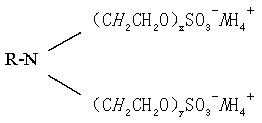

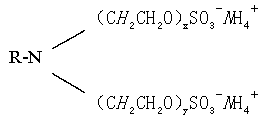

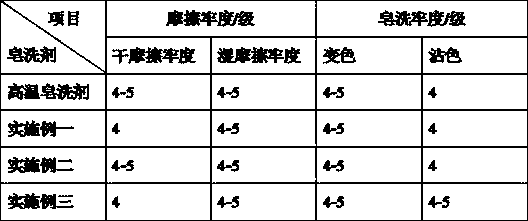

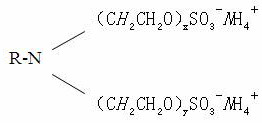

High-efficiency environment-friendly acidic soap washing agent, and preparation method thereof

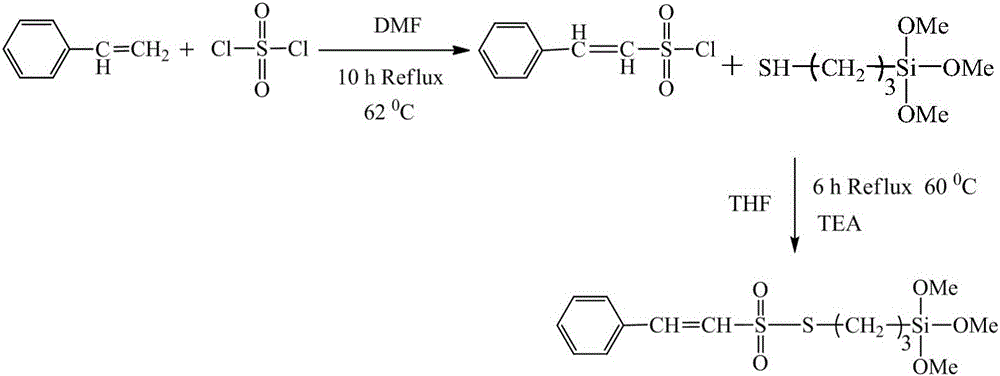

ActiveCN110499218AGood anti-staining effectStrong dispersion abilityCationic surface-active compoundsOrganic detergent compounding agentsAcrylic acidSulfonic acid ester

The invention belongs to the field of fine chemistry, and more specifically relates to a high-efficiency environment-friendly acidic soap washing agent, and a preparation method thereof. The high-efficiency environment-friendly acidic soap washing agent comprises, by mass, 10 to 30 parts of carboxyalkylthiosuccinic acid, 30 to 50 parts of acrylic acid-2-acrylamido-2-methyl propyl sulfonic acid (AA / AMPS) copolymer 20 to 50 parts of sodium gluconate, 5 to 10 parts of hydrolytic polymaleic anhydride, 0.1 to 2 parts of a surfactant, 0.5 to 10 parts of a complexing agent, and 30 to 50 parts of water. When the high-efficiency environment-friendly acidic soap washing agent is used in cotton and cotton blended fabric reactive dye dying, surface dyeing removing effect is better, and fabric color fastness and brightness are ensured; the high-efficiency environment-friendly acidic soap washing agent contains no nitrogen and phosphorus, and is relatively high in acidity, so that the acid neutralizing process before common soaping can be avoided, waste discharge amount is reduced, human labor is saved, electricity cost is reduced, and better market advantages are achieved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

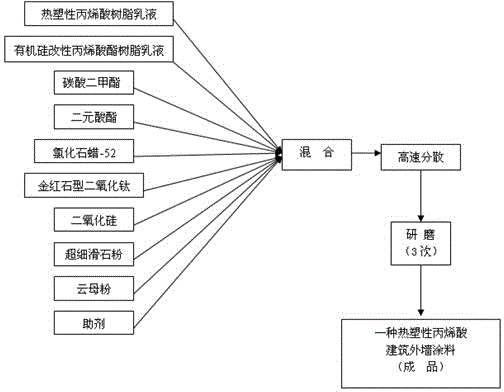

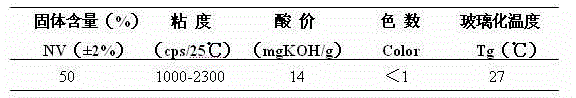

Thermoplastic acrylic building exterior wall coating and preparation method thereof

The invention discloses a thermoplastic acrylic building exterior wall coating and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing a thermoplastic acrylic resin emulsion, an organic silicone modified acrylic resin emulsion, dimethyl carbonate, dibasic acid ester, chlorinated paraffin-52, rutile-type titanium dioxide, fillers and aids in a high-speed dispersion machine in proportion for 15 minutes; milling the mixed material for three times by a sand mill, wherein the material is milled for about 1h at each time, and when the fineness is smaller than 25 microns, the milled material serving as a finished product can be weighed and packaged. The thermoplastic acrylic building exterior wall coating has the advantages of strong adhesive force, strong chemical resistance, acid-base resistance, water resistance, strong solvent resistance, temperature variation resistance, strong weather resistance, strong stain resistance and long service life of a film, and has the characteristics of being environment-friendly, safe, pollution-free and nonhazardous.

Owner:玉渊

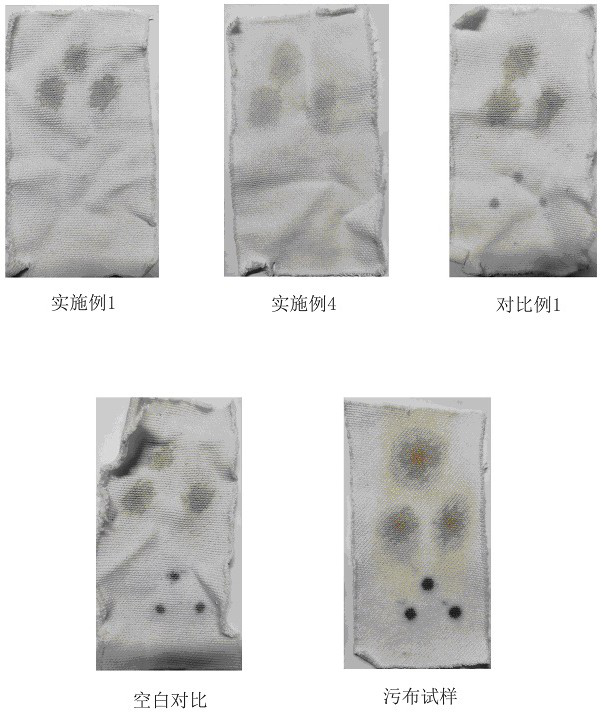

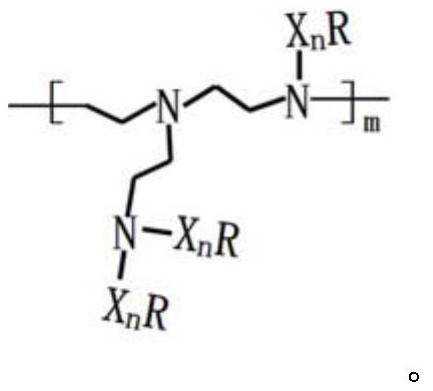

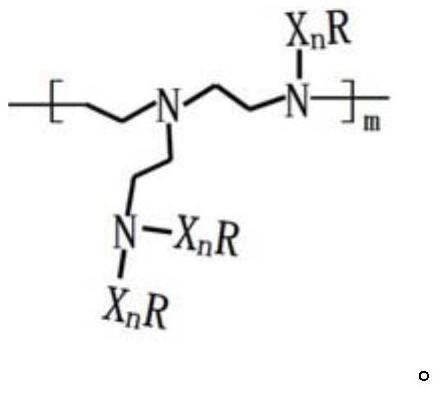

Cation modified printing washing and anti-staining process of cellulose fiber fabrics

PendingCN111549549AImprove solubilityPrevent sticking backDry-cleaning apparatus for textilesDyeing processTextile printerReactive dye printing

The invention belongs to the technical field of textile printing, and in particular relates to a cation modified printing washing and anti-staining process of cellulose fiber fabrics. The process comprises a cation modification process, a reactive dye printing process and a washing process after printing, wherein the cation modification process comprises the steps of padding a modifier, stacking at the room temperature and washing; and the washing process after printing comprises the steps of preparing a washing liquid, washing for the first time-washing with the washing liquid in warm water,washing for the second time-washing with the washing liquid in warm water, washing for the third time-washing with the washing liquid in warm water, and washing in cold water. The process provided bythe invention can effectively prevent the dye back staining and staining and cross-coloring of the cation modified fabrics during the process of washing, which greatly improves the dye utilization rate, and expands the application range of the cation modified process of cellulose fiber fabrics.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Production method of fluoride-free oil-proof paper

InactiveCN111254732AHigh degree of fibrillationImprove compactnessPaper/cardboardChemical/chemomechanical pulpCellulosePolyvinyl alcohol

The invention relates to a production method of fluoride-free oil-proof paper, which comprises the following steps: (1) preparing raw materials which comprise the following components in percentage bymass: 80%-95% of sulfate hardwood pulp and 5%-20% of sulfate softwood pulp; (2) respectively putting the sulfate softwood pulp and the sulfate softwood pulp pulp obtained in the step (1) into a pulper, injecting water for pulping to obtain sulfate softwood paper pulp and sulfate softwood paper pulp, and respectively pumping the sulfate softwood paper pulp and the sulfate softwood paper pulp intoa pulp mixing tank to form mixed paper pulp; (3) sequentially adding aluminum sulfate and alkyl ketene dimer into the slurry mixing tank, and stirring to obtain mixed slurry; and (4) preparing a coating liquid, wherein the coating liquid comprises the following components in percentage by mass: 35%-40% of surface adhesive starch, 30%-35% of polyvinyl alcohol and 25%-35% of sodium carboxymethyl cellulose. The production method is simple in production process and low in production cost, and the prepared fluoride-free oil-proof paper is good in water resistance and oil resistance, non-toxic, harmless, environment-friendly and practical.

Owner:广东通力定造股份有限公司

Acid soaping detergent and preparation method thereof

InactiveCN106929178AImprove anti-stick performanceImprove bindingInorganic/elemental detergent compounding agentsAnionic surface-active compoundsSulfonateAlkylphenol

The invention relates to the field of dyeing auxiliaries, and provides an acid soaping detergent and a preparation method thereof. The acid soaping detergent solves the defects of high water consumption, high APEO (Alkylphenol Ethoxylates) content, and no biodegradability of a soaping detergent in the prior art. The acid soaping detergent comprises a component A and a component B packaged separately, wherein the component A is prepared from the following raw materials in parts by weight: 15 to 20 parts of acrylic acid, 20 to 30 parts of maleic acid, 15 to 20 parts of pyrrolidone, 5 to 10 parts of sodium lignin sulfonate, 5 to 10 parts of docosyl sodium sulfate, 200 to 300 parts of deionized water, 15 to 20 parts of N-cocoyl-L-glutamic acid, and 10 to 20 parts of soapberry extracting solution; the component B is prepared from 10 to 30 parts of microcapsule slow release alkaline assistant.

Owner:石狮市华锐化工贸易有限公司

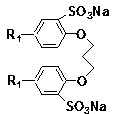

Low-temperature soaping agent for cellulose reactive dye

The invention relates to the technical field of textile printing and dyeing, and provides a low-temperature soaping agent for a cellulose reactive dye. The low-temperature soaping agent is prepared bycompounding a Gemini anionic sulfonate surfactant, polymer and other auxiliary agents, and comprises the following components in percentages by weight: 1-20% of sodium dialkyl diphenyl ether disulfonate, 5-15% of anionic surfactant AOT, 0.1-0.5% of a defoaming agent, 0.1-5% of beta-cyclodextrin, 0.2-2% of sodium polyacrylate, 1-10% of polyvinylpyrrolidone and the balance of deionized water. The soaping agent has the advantages of low foam, strong hard water resistance, remarkable color removal effect in low-temperature soaping at the temperature of 60 DEG C, energy conservation, emission reduction and production cost reduction, and has positive significance for improving the problem of high energy consumption in the printing and dyeing industry.

Owner:苏州新扬新材料科技有限公司

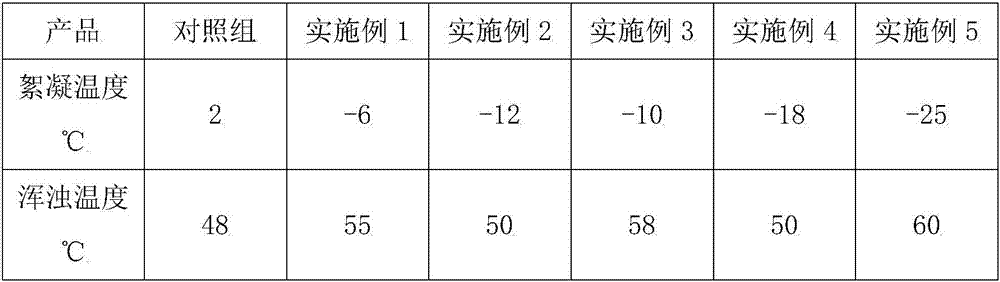

Laundry detergent

InactiveCN106916640AStrong emulsificationKeep the colorNon-ionic surface-active compoundsOrganic detergent compounding agentsCoconut diethanolamideBULK ACTIVE INGREDIENT

The invention discloses a laundry detergent which comprises the following components in parts by weight: 20-30 parts of fatty alcohol polyoxyethylene ether, 10-15 parts of sodium N-lauroylglutamate, 2-5 parts of coconut diethanolamide, 2-10 parts of an anti-condensation agent, 0.2-1 part of a plant essential oil, 0.1-0.3 part of a preservative, and 40-70 parts of deionized water. The laundry detergent has various surfactants and active ingredients compounded, has strong detergency, can maintain the excellent emulsifying capacity on oil stains, and also effectively prevents stains from back dipping; the laundry detergent has excellent biodegradable performance, has the neutral-alkaline pH, and is gentle and does not hurt hands; the laundry detergent has strong stability, can keep a flow state without change at the temperature of -25 DEG C, and also has no delamination and flocculation phenomena at the high temperature of 50-60 DEG C.

Owner:广东得到宝贝科技有限公司

A low modulus waterborne polyurethane material

The invention relates to a novel low-modulus waterborne polyurethane material. The material is prepared according to the following steps: step (1), putting polymer diol, a hydrophilic monomer and a cosolvent in a reaction kettle, and dehydrating in vacuum; step (2), cooling the reaction kettle, adding diisocyanate, heating and reacting; step (3), cooling and adding a neutralizing agent and a diluting solvent; step (4), stirring and adding deionized water, stirring continuously, heating, pumping the solvent in vacuum, cooling and filtering to obtain a polyurethane dispersoid, namely obtaining the novel low-modulus waterborne polyurethane material. The polyurethane dispersoid is used for preparing gloves of which the modulus is lower than that of a product prepared by the prior art; the prepared gloves are approximate to a rubber product, easy to wear, soft in hand feeling, good in air permeability, higher than an existing product and the rubber product in breaking strength, better than the existing technical products in rebound resilience and larger than the rubber product in elongation at break; therefore, the novel low-modulus waterborne polyurethane material provided by the invention can be totally used as a potential substitute product for the rubber product in performance.

Owner:山东惠沃盛健康科技有限公司

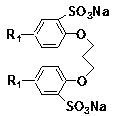

Heat-fused highly-wear-resisting anti-pollution white traffic marking material and preparation method thereof

ActiveCN103951931AGood weather resistanceImprove wear resistanceMicrocrystalline waxMaterials science

The invention discloses a heat-fused highly-wear-resisting anti-pollution white traffic marking material and a preparation method thereof, and the preparation method is used for manufacturing the traffic marking material in the traffic technical field. The heat-fused highly-wear-resisting anti-pollution white traffic marking material comprises the following components: petroleum resin, modified rosin resin, di-n-butyl ortho-phthalate, titanium dioxide, glass bead, stilbene biphenyl sodium disulfonate, ethylene vinyl acetate copolymer, microcrystalline wax, refined white mineral oil, quartz sand and quartz powder. The traffic marking material prepared by adopting the preparation method disclosed by the invention not only can be used for improving the wear resistance and anti-pollution capacity of the traffic marking, but also strengthening the adhesion force of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

Jacquard acetate filament home textile fabric and production method thereof

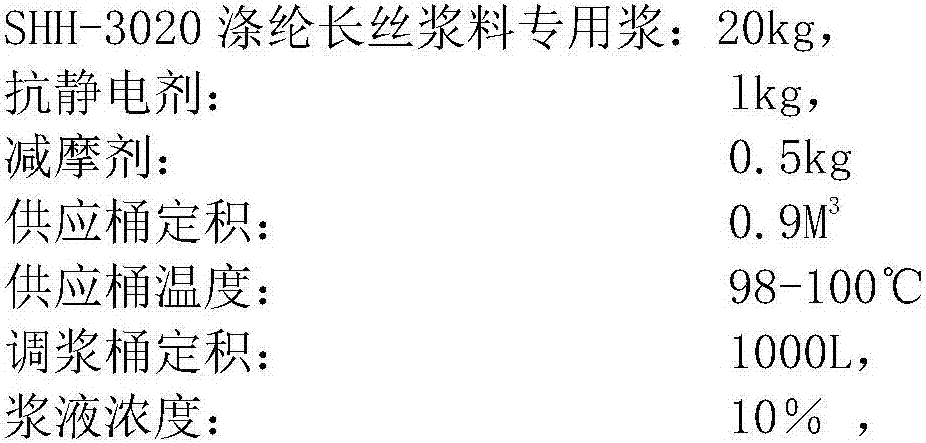

ActiveCN106012214BPrevent sticking backPrevent and reduce plaqueHeating/cooling textile fabricsDry-cleaning apparatus for textilesPolyesterColour fastness

A jacquard acetate filament home textile fabric, the warp is semi-dull polyester filament, 50D / 72F, the warp density is 200 threads / inch; the weft is acetate filament, 75D, the weft density is 96.5 threads / inch; the weave is jacquard fabric. The finished product width is 160cm. The fabric production method includes: 1) weaving: warping with a warping machine → sizing with a sizing machine → paralleling with a warp machine → splitting with a twisting machine → drawing in heald → weaving on a rapier jacquard loom; 2) dyeing: Unwinding → desizing → dyeing → dehydration → opening → setting. The fabric is flat and dense, smooth, soft to the touch, light and cool, easy to wash and dry, strong color fastness, good air permeability, soft and elegant. The successful trial production of this product will further meet people's demand for comfortable and cool home textile summer quilt fabrics. It has high added value and broad market prospects, and has remarkable economic and social benefits.

Owner:JIANGSU YUEDA HOME TEXTILE

Multifunctional degreasing agent for one-bath dyeing and preparation method thereof

InactiveCN112553907AEffective dissolutionGood dispersionFibre typesDyeing processDiethylene glycol monobutyl etherDisperse dye

The invention relates to a multifunctional degreasing agent for one-bath dyeing. The multifunctional degreasing agent is characterized by comprising the following components of fatty alcohol-polyoxyethylene ether, modified fatty amine polyoxyethylene ether, glyceryl ether oleate, fatty alcohol-polyoxyethylene ether, iso-tridecanol polyoxyethylene ether, phenol ether ammonium sulfate, polyether modified silyl ether ester, ethylene glycol monobutyl ether or diethylene glycol monobutyl ether and water. The multifunctional degreasing agent for one-bath dyeing is convenient to apply and simple to operate, and only one auxiliary agent is added. In the aspect of effect, the multifunctional degreasing agent has relatively good disperse dye and level dyeing effects during fabric dyeing, also has low-foaming property, is easy to clean, and can remove oil cleanly when used for dyeing multi-fiber fabrics by a one-bath method, and the removed oil stain is dispersed in dye liquor and does not stickto the cloth surface and the inner wall of a dye vat, therefore, the problems of dyeing defects, color spots, uneven dyeing and the like can be effectively avoided, and the energy-saving and environment-friendly requirements are met.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Textile refining agent containing organic clay

InactiveCN111793974AGood compatibilityEfficient removalInorganic/elemental detergent compounding agentsCationic surface-active compoundsSpinningOrganoclay

The invention discloses a textile refining agent containing organic clay. The textile refining agent is prepared from the following raw materials of, in parts by weight, 7-13 parts of organic nano clay, 3-6 parts of alcohol ether carboxylate, 3-5 parts of fatty acid methyl ester ethoxylate sulfonate, 4-7 parts of alkyl glycoside and 70-80 parts of water. According to the textile refining agent containing organic clay, the oil stain removing effect is better, the cleaning capacity is high, the organic nano clay of the textile refining agent containing the organic clay can effectively remove spinning oil on the surfaces of synthetic fibers and wax and pectin of natural cotton fibers, meanwhile, the natural fibers can be endowed with a better refining capillary effect and whiteness, washed oil stains or macromolecular slurry is prevented from being attached to the fibers, and therefore, an excellent cleaning / desizing effect is achieved.

Owner:司马化工(中国)有限公司

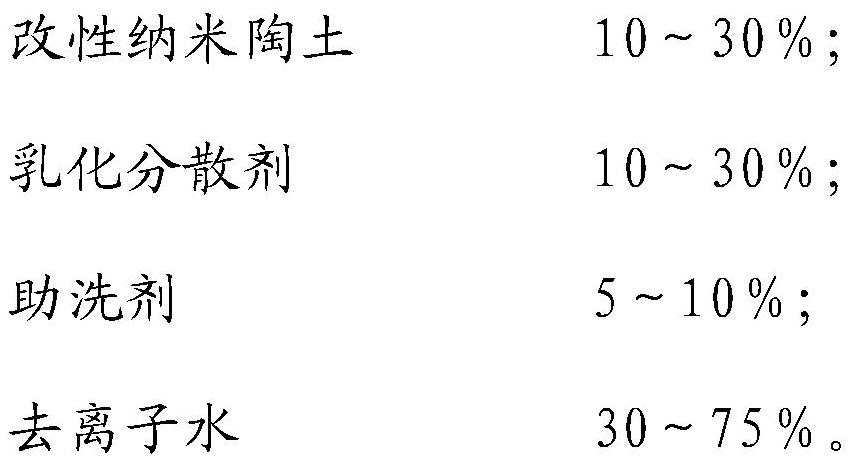

Refining degreaser based on modified nano argil and preparation method of refining degreaser

PendingCN113773917AImprove and enhance the cleaning effect of solubilizationEnhances Solubilizing Cleansing EfficacyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWaxActive agent

The invention discloses a refining degreaser based on modified nano pottery clay and a preparation method of the refined degreaser. The refining degreaser comprises the modified nano pottery clay, an emulsifying dispersant, a builder and deionized water, wherein the modified nano pottery clay is cationic surface active agent modified nano pottery clay. The refining degreaser is used for the pre-treatment degreasing, refining and other procedures of fabric, the emulsifying washing removal ability for impurities such as grease, wax, oily dirt and the like of the fabric (especially the spandex-containing fabric) is significantly improved, it can be ensured that oil drops or dirt do not adhere to the fabric and machines any more, the quality of a processed product is substantially improved, and the COD of a working solution is reduced.

Owner:GUANGDONG ZHAN FENG FINE CHEM CO LTD

A kind of hot-melting high wear-resistant and anti-pollution white traffic marking material and preparation method thereof

The invention discloses a hot-melt high wear-resistant and anti-pollution white traffic marking material and a preparation method thereof, which are used for making traffic marking materials in the field of traffic technology 。 Including the following components: petroleum resin, modified rosin resin, di-n-butyl phthalate, titanium dioxide, glass microspheres, sodium distyrene biphenyl disulfonate, ethylene vinyl acetate copolymer, microcrystalline paraffin, refined white Mineral oil, quartz sand, quartz powder. The traffic marking material prepared by the invention can not only improve the wear resistance and anti-pollution ability of the traffic marking, but also enhance the adhesion of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

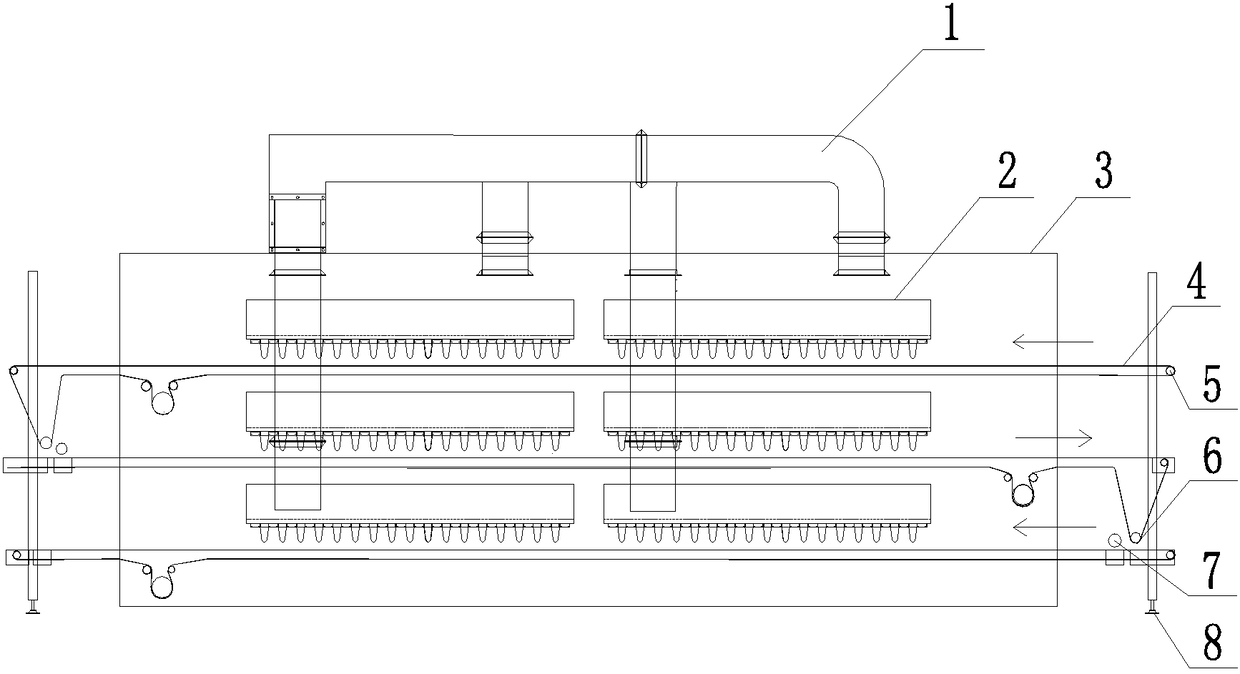

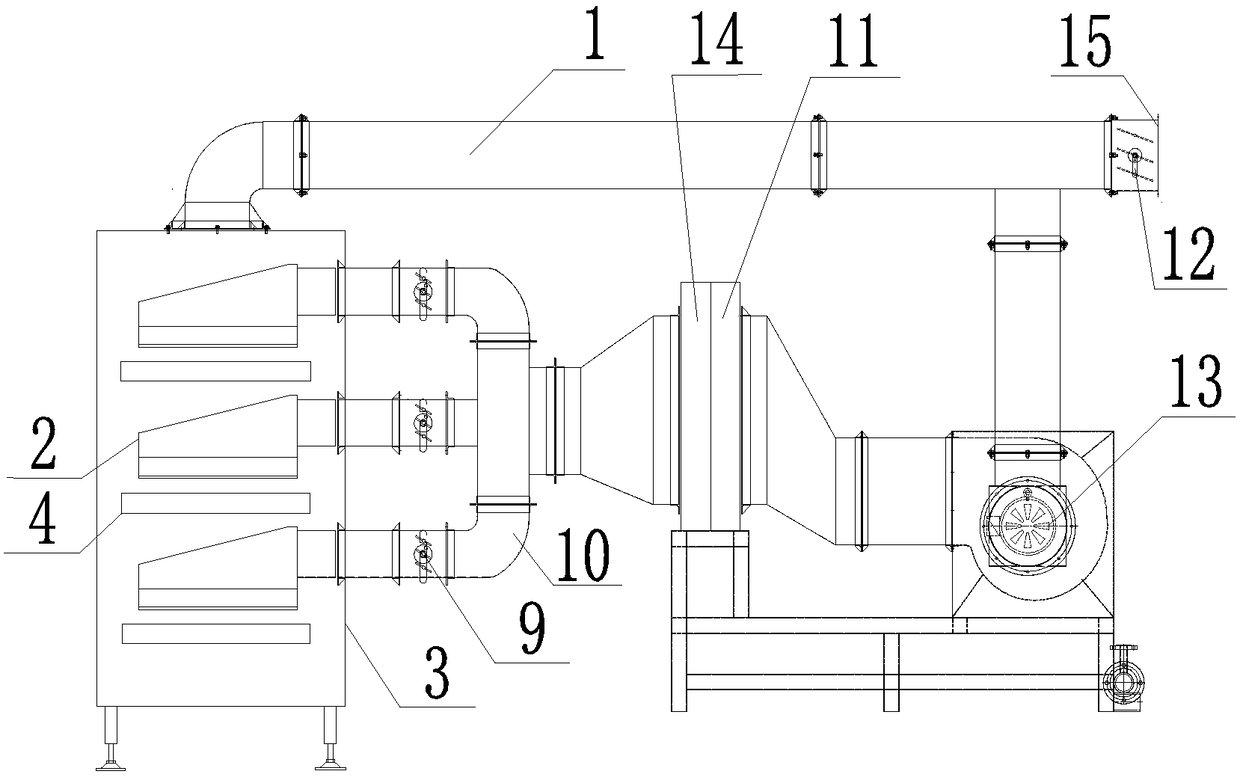

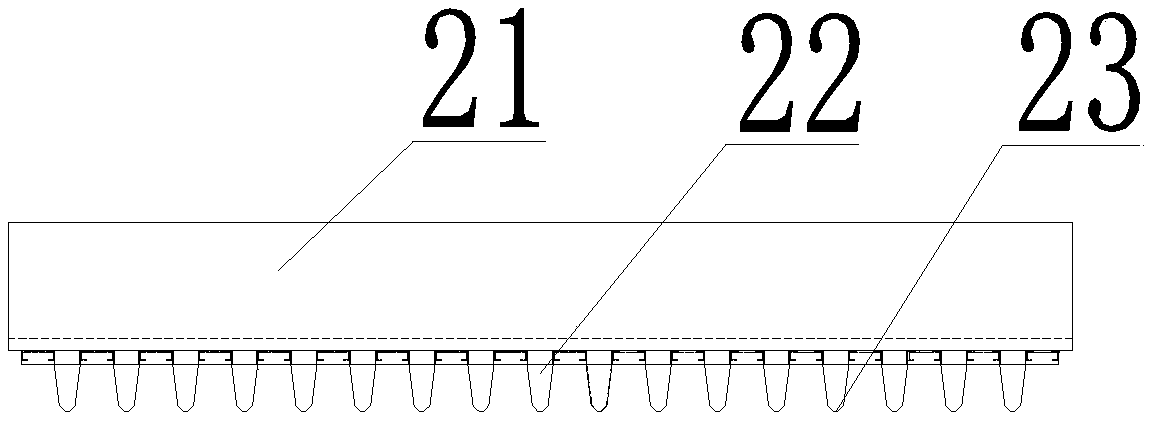

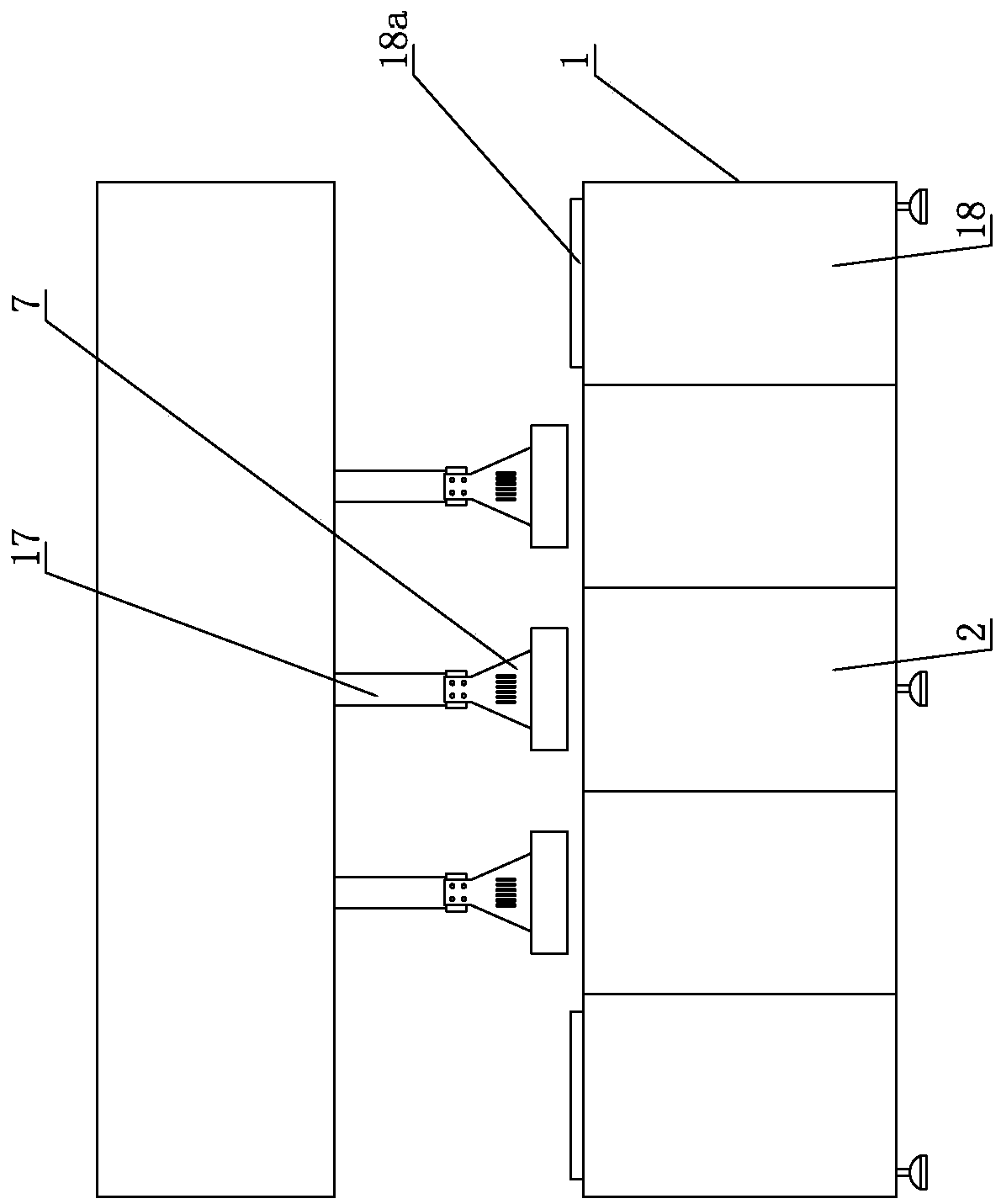

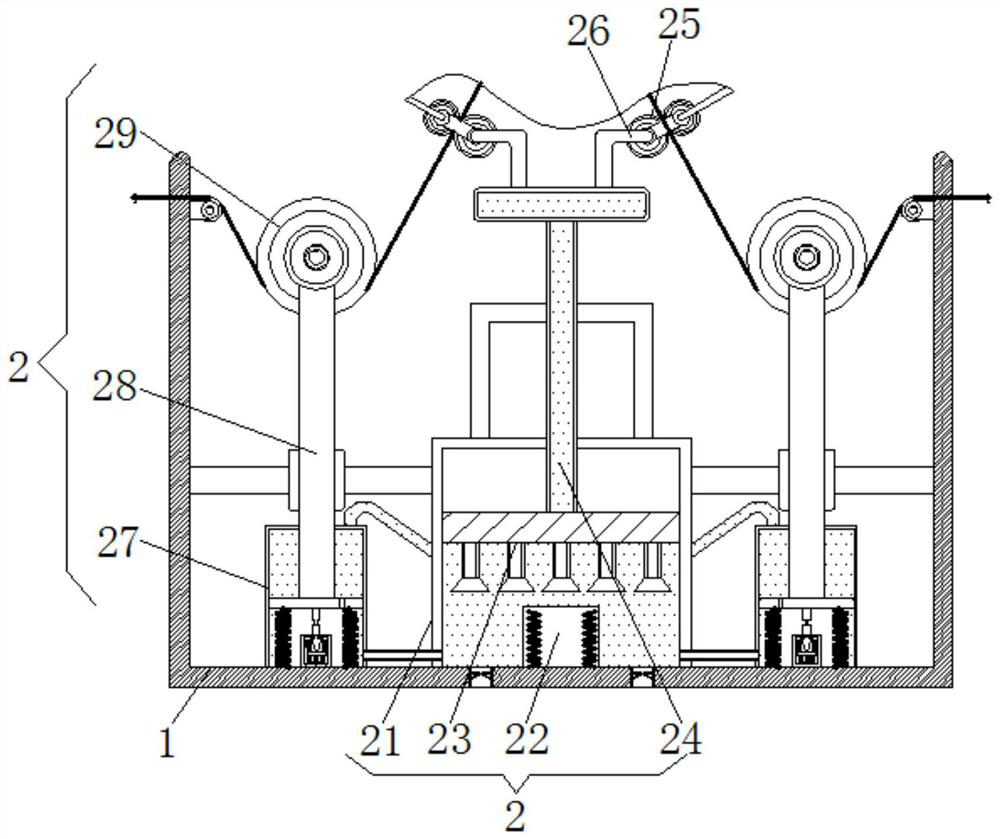

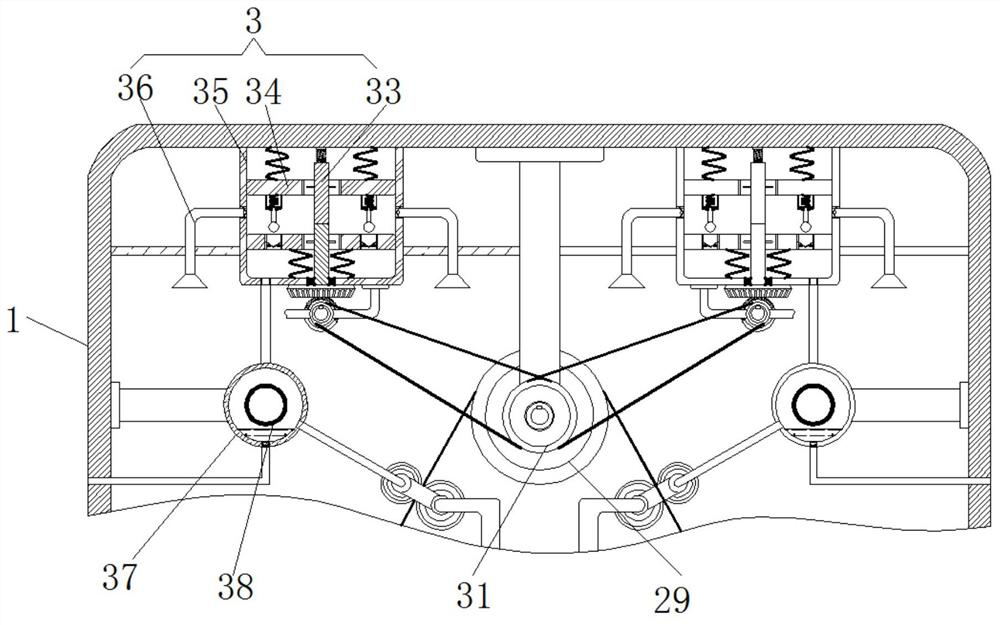

Device for drying gelatin foil

PendingCN108592592AReduce quality impactQuality improvementDrying gas arrangementsDrying machines with progressive movementsEngineeringMechanical engineering

The invention discloses a device for drying gelatin foil. The device comprises a control terminal, a draught fan, a rack and a drying box. The drying box is arranged on the rack, and the draught fan is connected with the drying box through an air flue. At least two conveying units and a plurality of air inlet boxes are arranged in the drying box. The air inlet boxes are arranged above the conveying units. The running directions of the two adjacent conveying units are opposite. The control terminal controls work of the draught fan and the conveying units. The gelatin foil drying work can be finished only through the two conveying units, time and labor are greatly saved, and the quality is well guaranteed.

Owner:常州腾拓机械设备有限公司

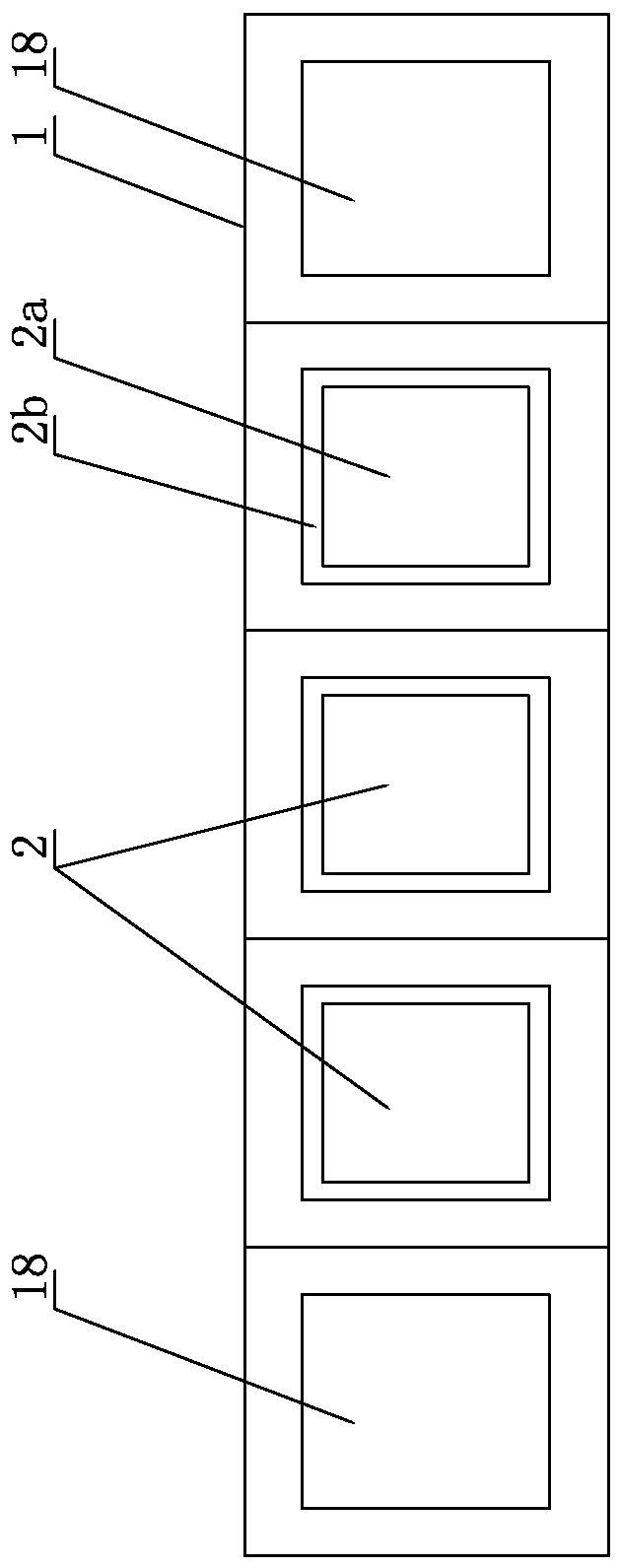

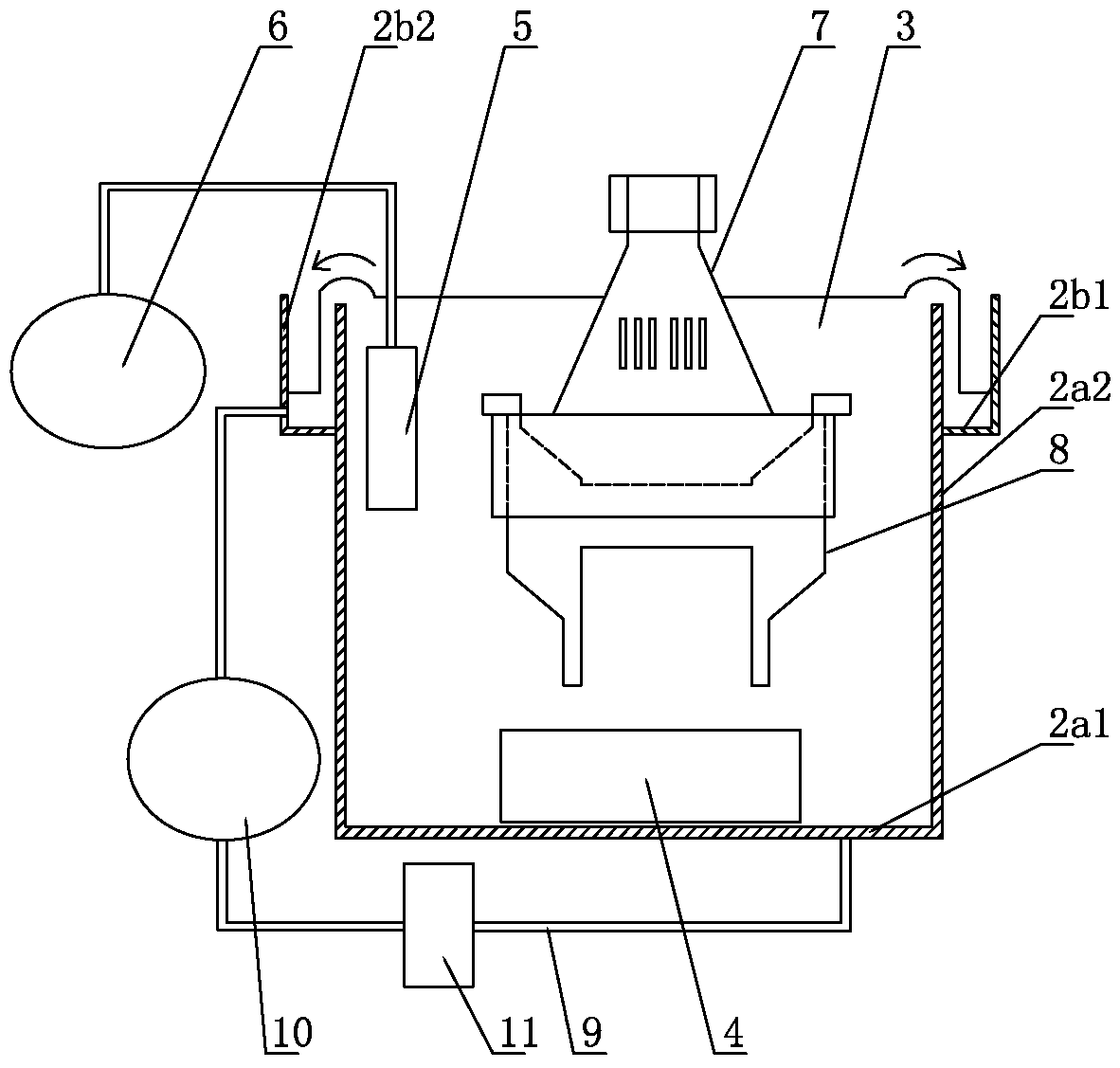

Integrated circuit chip photoresist removing device and process

PendingCN109946929APrevent sticking backImprove removal efficiencyPhotosensitive material processingEngineeringCirculating pump

The invention discloses an integrated circuit chip photoresist removing device and process in the field of a semiconductor integrated circuit. The device comprises a machine table. A plurality of photoresist removing groove bodies are arranged in order on the machine table, ultrasonic generators are arranged in inner groove bodies, heating devices are arranged in the inner groove bodies, wafer carriers capable of going up and down are placed in the inner groove bodies, wafer boats are placed on the wafer carriers, and the insides of outer groove bodies are connected to the bottoms of the innergroove bodies through external pipelines. The process includes a step of placing a wafer into each wafer groove of each wafer boat, a step of placing each wafer boat on a wafer carrier, a step of allowing a control rod to drive each wafer boat to go down to be submerged into a photoresist groove body, a step of allowing a circulation pump to work, at the same time, turning on the ultrasonic generators to work for N seconds, and then turning off the ultrasonic generators for N seconds, a step of repeating the above steps for M times, a step of put the wafer boats into a washing tank to wash off the photoresist on the wafers. According to the invention, the photoresist on the wafers can be removed, the photoresist is prevented from being stuck back to the wafers, and the photoresist removalefficiency is improved.

Owner:JIANGSU UNION SEMICON

Self-crosslinked polyacrylate latex and preparation method thereof, and water-based paper ink

InactiveCN102304262BPrevent sticking backFast dryingPaper coatingCoatingsHydrophilic monomerPolymer science

The invention discloses self-crosslinked polyacrylate latex and a preparation method thereof, and water-based paper ink. The preparation method for the self-crosslinked polyacrylate latex comprises the following steps of: mixing acrylate monomers, hydrophilic monomers and alcohol dehydrogenase (ADH) in a head tank A; mixing water, an emulsifier, acrylate monomers and diacetone acrylamide (DAAM) in a head tank B; adding water, an emulsifier and polymerization self-emulsification functional monomers into a normal-pressure reaction tank, stirring, heating to 75DEG C, dripping a mixture in the head tank A and an initiator, and preparing protective colloid; dripping a mixture in the head tank B and an initiator at 85DEG C; and reacting at constant temperature. The water-based paper ink is prepared by the following steps of: stirring and dissolving styrene-acrylate copolymer, a pH regulator and water at 60DEG C; adding pigments and necessary aids, and mixing to obtain color paste; and uniformly mixing the color paste, the self-crosslinked polyacrylate latex, a surface tension regulator and water. The water-based paper ink can be diluted by one of water and ethanol or a mixture of water and ethanol, and has high drying speed and good printing adaptability.

Owner:SUN YAT SEN UNIV +1

Self-crosslinking polyacrylate rubber latex, preparation method thereof and water-based paper printing ink

InactiveCN101870793BPrevent sticking backFast dryingPaper coatingCoatingsWater basedHydrophilic monomer

The invention discloses self-crosslinking polyacrylate rubber latex, a preparation method thereof and water-based paper printing ink. The self-crosslinking polyacrylate rubber latex is prepared by the following steps: mixing an acrylic ester monomer, a hydrophilic monomer and ADH in a head tank A; mixing water, an emulsifier, the acrylic ester monomer and DAAM in a head tank B; adding water, the emulsifier and polymerizable self-emulsifying functional monomer, stirring the mixture, heating the mixture to 75 DEG C, and dripping a mixture in the head tank A and an initiator to prepare a protective colloid first; dripping the mixture in the head tank B and the initiator at 85 DEG C; and performing a constant-temperature reaction. The water-based paper printing ink is prepared by the following steps: dissolving a phenylethylene-acrylic acid polymer and a pH value regulator in water at 60 DEG C with stirring; adding a pigment and necessary assistant and mixing the mixture to prepare color paste; and uniformly mixing the color paste with the self-crosslinking polyacrylate rubber latex, a surface tension regulator and water. The water-based paper printing ink can be diluted by one or a mixture of two of water and ethanol, can be dried quickly and has high printing adaptability.

Owner:SUN YAT SEN UNIV +1

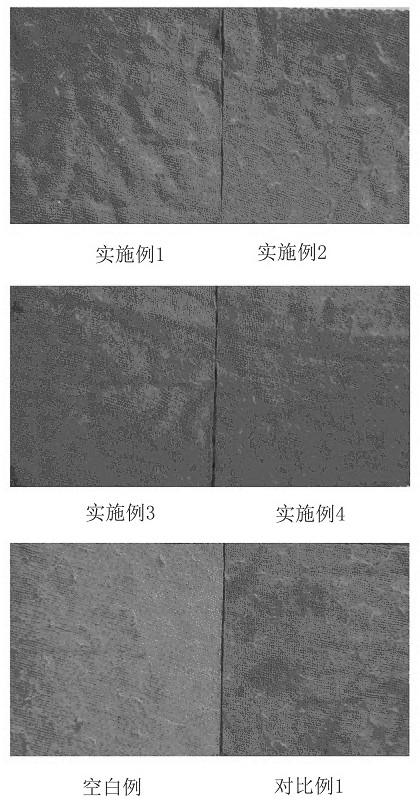

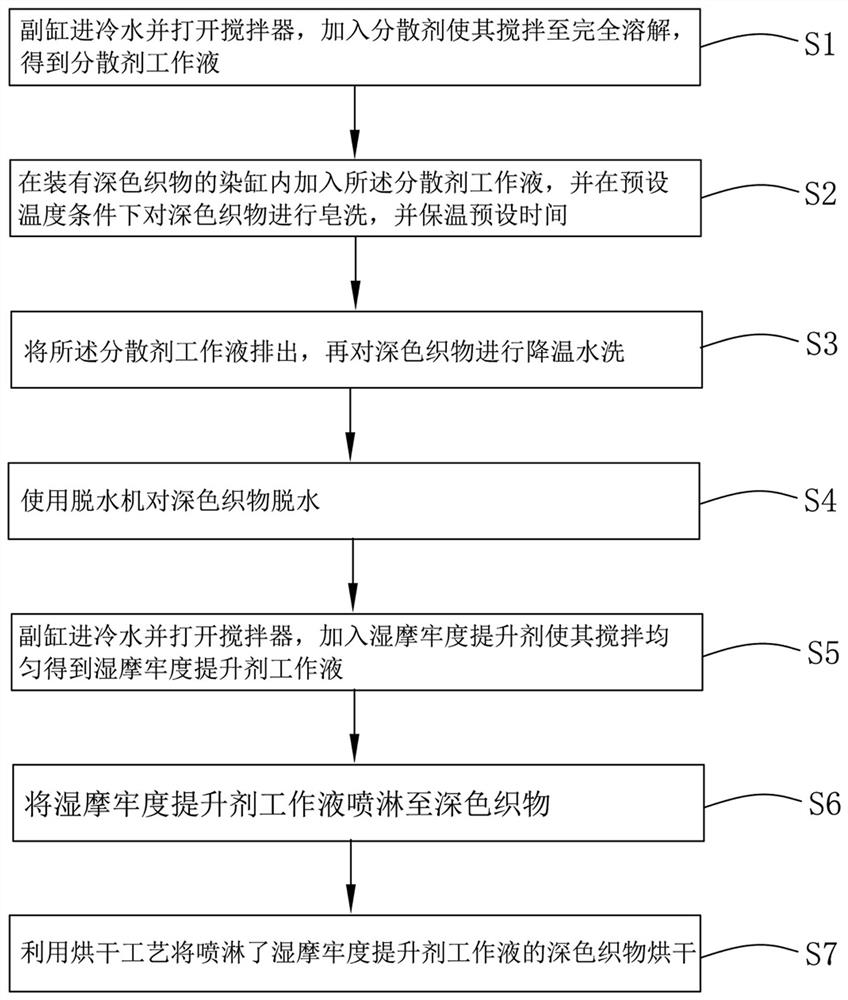

Post-treatment method for improving wet rubbing fastness of deep-color fabric

PendingCN113981722APrevent sticking backClose and strong tiesDyeing processTextile treatment by spraying/projectingProcess engineeringChemistry

The invention provides a post-treatment method for improving wet rubbing fastness of deep-color fabric, the method comprises the following steps: feeding cold water into an auxiliary cylinder, starting a stirrer, adding a dispersing agent, and stirring until the dispersing agent is completely dissolved to obtain a dispersing agent working solution; adding the dispersing agent working solution into a dye vat filled with the deep-color fabric, soaping the deep-color fabric under a preset temperature condition, and keeping the temperature for a preset time; discharging the dispersing agent working solution, and cooling and washing the deep-color fabric; dehydrating the deep-color fabric by using a dehydrator; feeding cold water into an auxiliary cylinder, starting a stirrer, adding a wet rubbing fastness improver, and uniformly stirring to obtain a wet rubbing fastness improver working solution; spraying the wet rubbing fastness improver working solution to the deep-color fabric; and drying the deep-color fabric sprayed with the wet rubbing fastness improver working solution by using a drying process. Compared with the prior art, the post-treatment method for improving the wet rubbing fastness of the deep-color fabric has the advantages that the wet rubbing fastness is effectively improved, the production cost is low, and the method is energy-saving and environment-friendly.

Owner:佛山市保力加科技有限公司

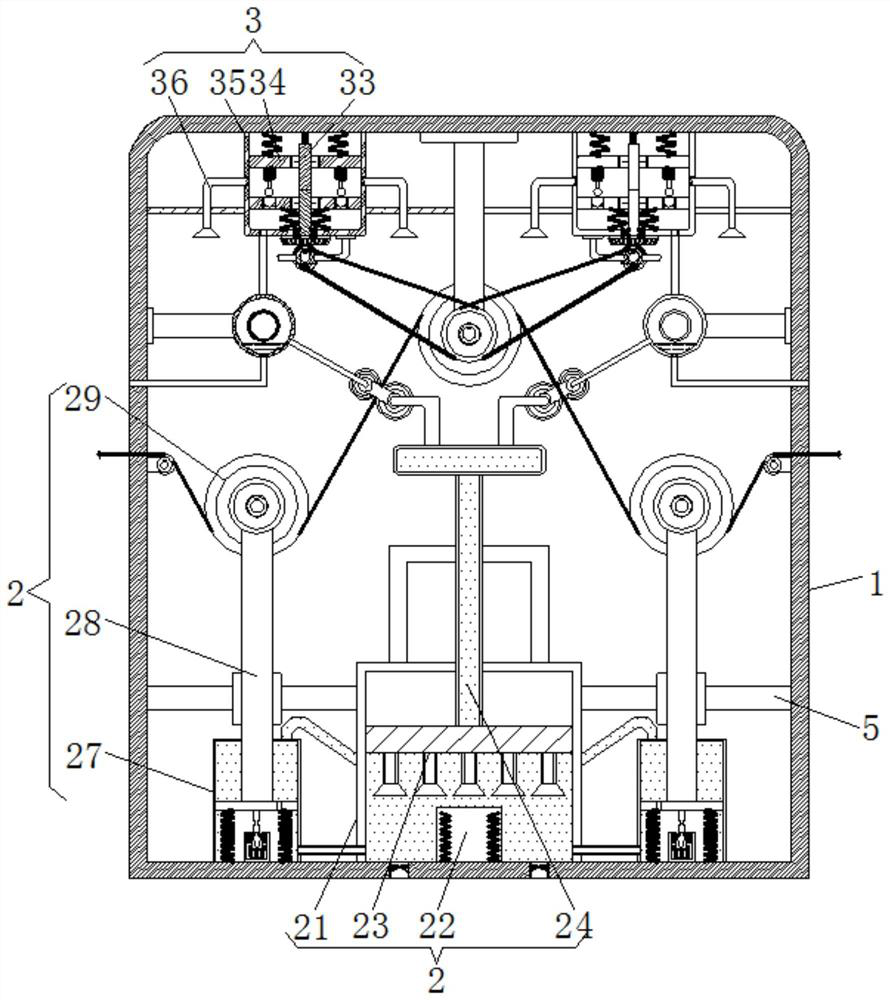

Fabric after-finishing softener with uniform adsorbability and processing equipment

PendingCN113215824AAvoid damagePrevent sticking backTextile treatment machine arrangementsGrip property fibresGlycosidePolymer science

The invention provides a fabric after-finishing softener with uniform adsorbability and processing equipment, and relates to the technical field of fabrics. A preparation method of the fabric after-finishing softener with uniform adsorbability comprises the following steps of S1, adding alkyl glycoside synthesized from glucose and fatty alcohol into a reactor, adding a KOH catalyst according to 0.5-2.0% of the total weight of the alkyl glycoside, heating the reactor to 90-110 DEG C, and performing vacuum dewatering for 0.5-2 hours to obtain a first mixed solution. According to the fabric after-finishing softener with uniform adsorbability and the processing equipment, a first connecting shaft is pushed by a first piston to move upwards, and certain kinetic energy can be generated only when the steam amount is relatively large, so that when the steam amount is relatively large, the longer the upward moving distance of a rotating part is, the smaller the stretching degree of a fabric is; when softening and shaping are carried out, the situation that the internal structure of the fabric is damaged due to the fact that the stretching degree of the fabric is higher due to the relatively large steam amount is avoided; and through hydroxybiphenyl, the softening effect is achieved, the strong infiltration effect is achieved, and the yellowing phenomenon is improved.

Owner:海宁市格林纺织助剂有限公司

Self-adhesive removal paste, preparation method and use method thereof

InactiveCN109112010AEasily peel offPrevent sticking backInorganic/elemental detergent compounding agentsDetergent mixture composition preparationSolventVolatile organic compound

The invention relates to a self-adhesive removal paste, a preparation method and a use method with the same. The raw material component of the self-adhesive removal paste comprises in parts by weight,40 to 50 parts of solvent oil, 20 to 30 parts of methanol, and 10 to 20 parts of dimethyl carbonate, 10 to 20 parts by weight of a surfactant and 0.5 to 1 part of silica; the preparation method comprises the following steps: the solvent oil, methanol, dimethyl carbonate, the surfactant and silicon oxide is weighed and then uniformly mixed to obtain the self-adhesive removal paste. The self-adhesive removal paste provided by the invention has the advantages of less dosage, quick removal, accurate coating, easy control of dosage, no drooping, safe construction in a confined space, and low consumption of volatile organic substances, which completely solves the problem that the self-adhesive is not easy to be removed.

Owner:范建民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com