Fabric after-finishing softener with uniform adsorbability and processing equipment

A kind of processing equipment and adsorption technology, which is applied in the direction of textile material equipment configuration, spray/jet textile material treatment, fiber treatment, etc., to achieve the effect of preventing back-sticking, improving yellowing phenomenon, and strong wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

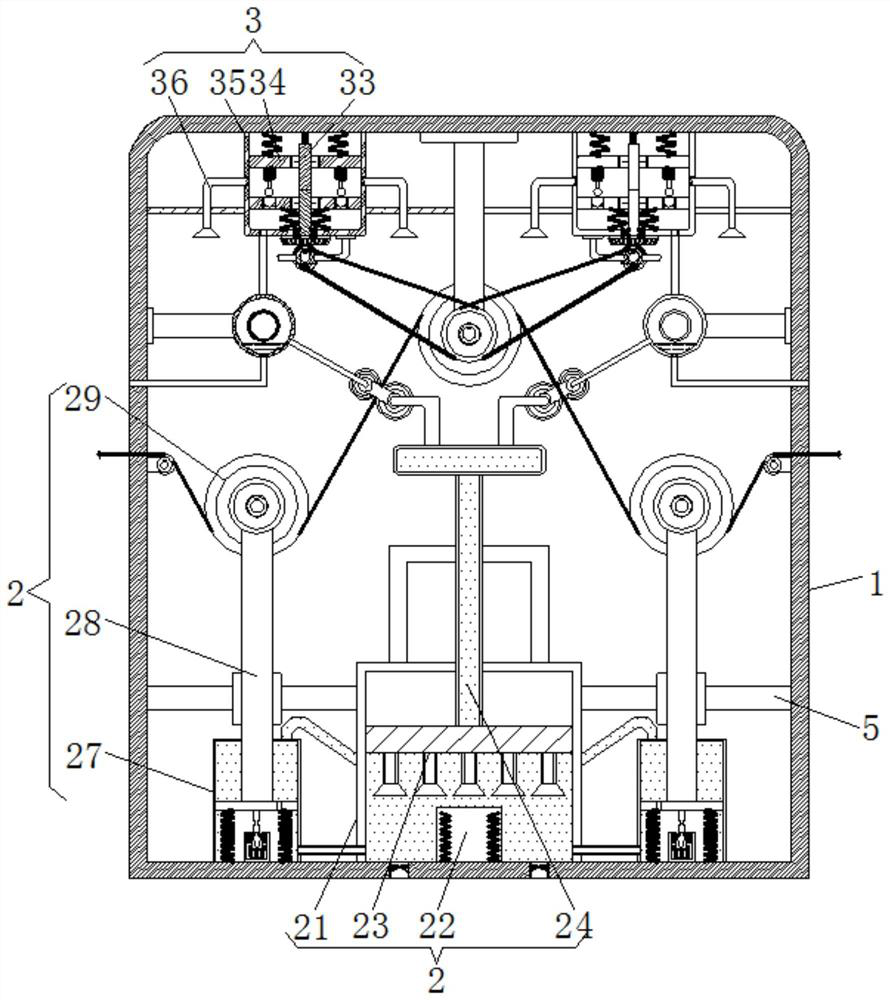

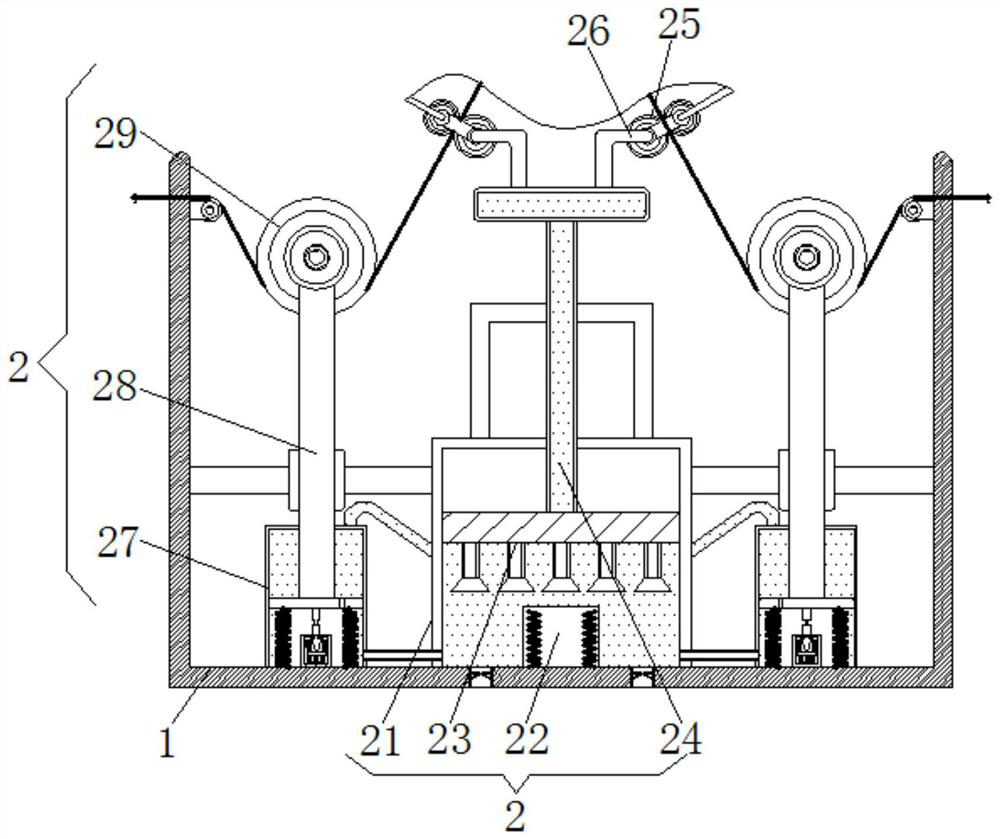

[0035] see Figure 1-4 , a fabric processing device with uniform adsorption, comprising a casing 1, a steam mechanism 2 is movable inside the casing 1, an adjustment mechanism 3 is movable inside the casing 1, a bracket 4 is fixedly connected to the inner wall of the bottom end of the casing 1, and the steam mechanism 2 includes a first housing 21, a heating device 22, a suction port 23, a first connecting pipe 24, a rotating nozzle 25, a second connecting pipe 26, a second housing 27, a first coupling shaft 28, a rotating member 29, and A heating device 22 is fixedly connected to the inside of a casing 21, a suction port 23 is fixedly connected to the inside of the first casing 21, and a first connecting pipe 24 is fixedly connected to the top of the suction port 23, and the top of the first connecting pipe 24 is rotatably connected to There is a rotating spout 25, the inside of the rotating spout 25 is movably connected with a second connecting pipe 26, the outside of the fi...

Embodiment 2

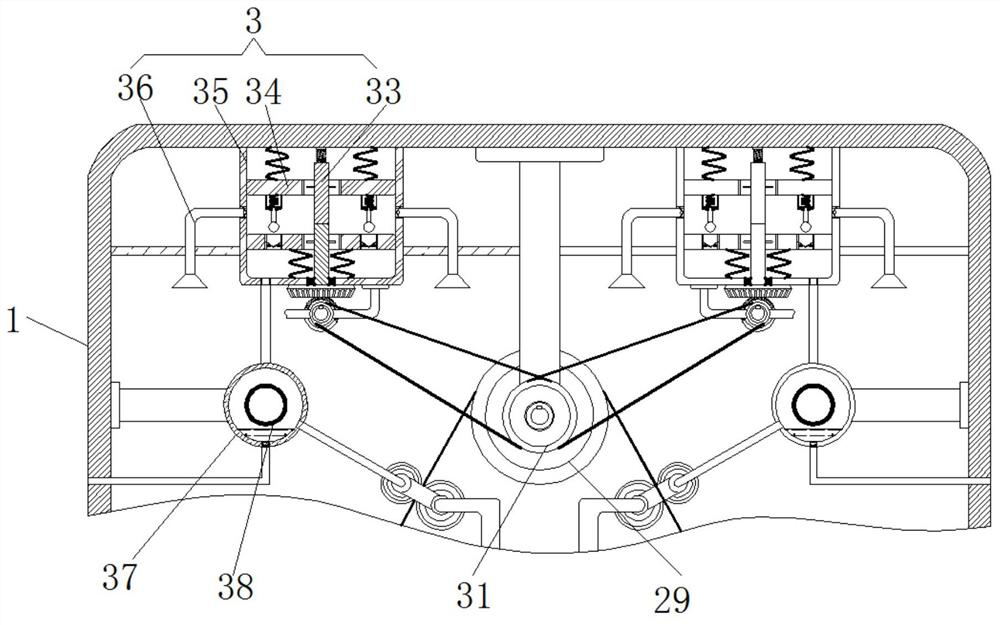

[0037] see Figure 1-4 , a kind of fabric processing equipment with uniform adsorption, comprising a casing 1, a steam mechanism 2 is installed movable inside the casing 1, an adjusting mechanism 3 is installed movable inside the casing 1, a bracket 4 is fixedly connected to the inner wall of the bottom end of the casing 1, and the adjusting mechanism 3 includes runner 31, runner 31, first gear 32, screw rod 33, second piston 34, third housing 35, third connecting pipe 36, fourth housing 37, heating resistance wire 38, runner 31 The outside of the first gear 32 is connected to the first gear 32, the inside of the first gear 32 is clamped with a screw 33, the outside of the screw 33 is threaded with a second piston 34, and the outside of the second piston 34 is slidably connected with a third housing 35. The middle part of the three casings 35 is fixedly connected with a third connecting pipe 36, the lower side of the third casing 35 is provided with a fourth casing 37, and the i...

Embodiment 3

[0039] A fabric after-finishing softener with uniform absorbency, comprising the following steps:

[0040] S1. Add the alkyl glucoside synthesized by glucose and fatty alcohol into the reactor, add KOH catalyst according to 0.5-2.0% of the total weight of the alkyl glycoside, heat the reaction vessel to 90-110° C., and dehydrate under vacuum for 0.5-2 hours. Obtain the first mixed solution;

[0041] S2. Cool the water to below 40°C, add 60-66 parts of cold water into the stirring container, then add 5-10 parts of guanidine compound to fully dissolve, stir while adding, add 11-45 parts of ethanol again, and stir evenly. Filtration, standing and purification to obtain the second mixed solution;

[0042] S3. Weigh 5-10 parts of 2-hydroxybiphenyl, 60-80 parts of amino silicone oil, 15-20 parts of hydroxyl-terminated polymethicone oil, and 40-50 parts of deionized water in the reactor;

[0043] S4. Add the first mixed solution to the reaction vessel in step S3, continue to heat u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com