Post-treatment method for improving wet rubbing fastness of deep-color fabric

A wet rubbing fastness and fabric technology, applied in the field of textile printing and dyeing, can solve the problems of increased production costs, increased water consumption, high energy consumption, etc., to achieve the goal of strengthening the combination, improving wet rubbing fastness, and avoiding the decline of dyeing fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

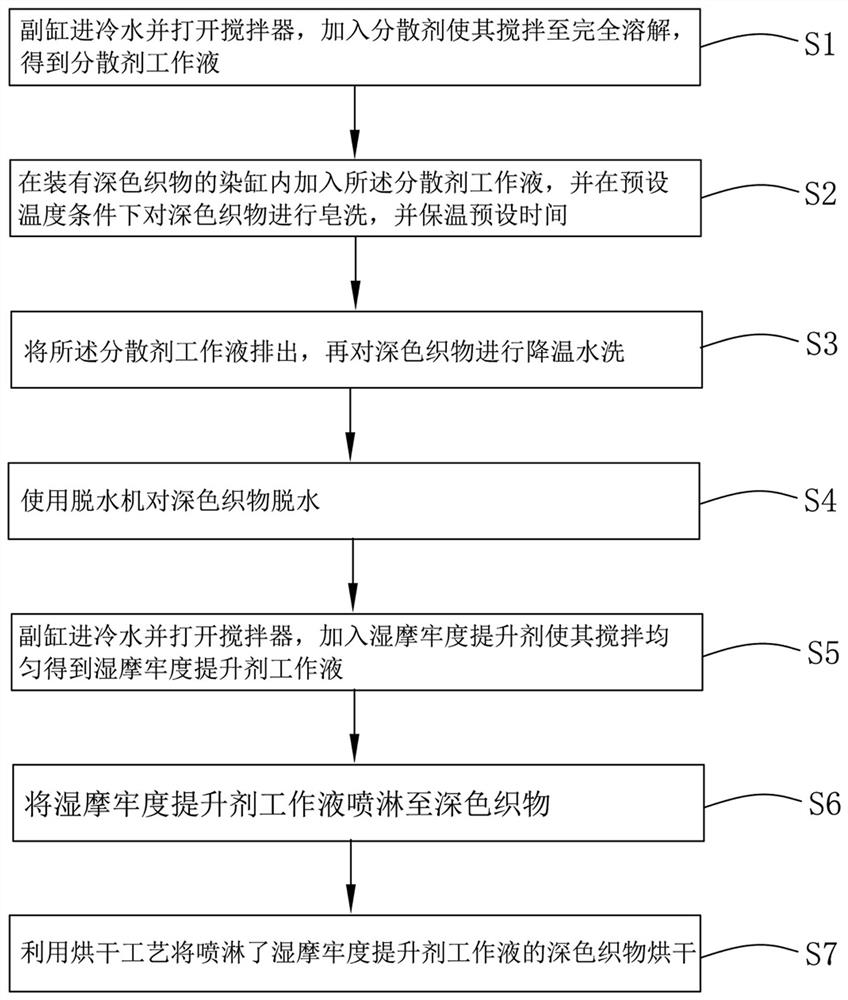

Method used

Image

Examples

Embodiment 1

[0048] 32S black cotton plain weave is selected as the fabric for mass production for dark fabrics.

[0049] Soaping: In this step, the dispersant standard is 0.5% (owf), and the dark fabric is soaped at 80°C and kept warm for 20 minutes.

[0050] Water washing: In this step, cool down to drain the dispersant working solution, and wash twice with water (two tanks).

[0051] Dehydration: dehydration machine dehydration.

[0052] Spraying: Spray the working solution of wet rub fastness improver with a concentration of 70g / L onto the dark fabric.

[0053] Drying: The drying temperature is 100°C.

[0054] Result evaluation: the wet rubbing fastness before treatment is grade 2, and the wet rubbing fastness after treatment reaches grade 3.

Embodiment 2

[0056] For the dark fabric, 21S black cotton 2×2 sweater fabric is used for mass production.

[0057] Soaping: In this step, the dispersant standard is 1.0% (owf), and the dark fabric is soaped at 80°C and kept warm for 20 minutes.

[0058] Water washing: In this step, cool down to drain the dispersant working solution, and wash twice with water (two tanks).

[0059] Dehydration: dehydration machine dehydration.

[0060] Spraying: Spray the working solution of wet rub fastness improver with a concentration of 70g / L onto the dark fabric.

[0061] Drying: The drying temperature is 100°C.

[0062] Result evaluation: the wet rubbing fastness before treatment is grade 1-2, and the wet rubbing fastness after treatment reaches grade 3.

Embodiment 3

[0064] 21S bright red cotton 2×2 rib fabric is selected as the fabric for mass production for the dark fabric.

[0065] Soaping: In this step, the dispersant standard is 0.8% (owf), and the dark fabric is soaped at 80°C and kept warm for 20 minutes.

[0066] Water washing: In this step, cool down to drain the dispersant working solution, and wash twice with water (two tanks).

[0067] Dehydration: dehydration machine dehydration.

[0068] Spray: Spray the working solution of wet rub fastness improver with a concentration of 90g / L onto the dark fabric.

[0069] Drying: The drying temperature is 100°C.

[0070] Result evaluation: the wet rubbing fastness before treatment is grade 2, and the wet rubbing fastness after treatment reaches grade 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com