Jacquard acetate filament home textile fabric and production method thereof

A production method and the technology of the filament family, applied in the field of jacquard acetate filament home textile fabrics and its production, can solve the problems that the research work cannot be continued in depth, the output is less than 5,000 tons, etc., and achieve good hand feeling, economic and social benefits Visible, soft and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

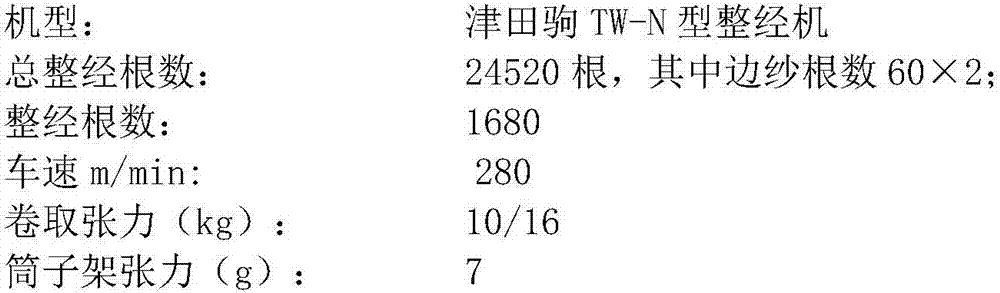

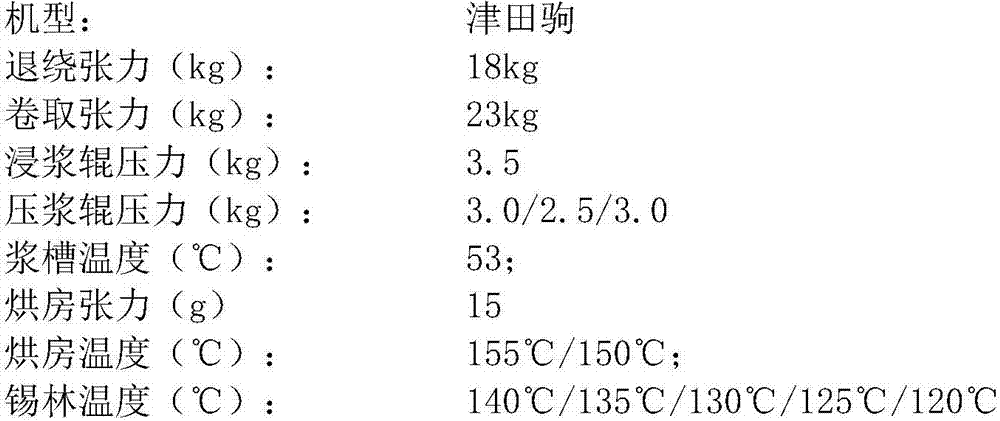

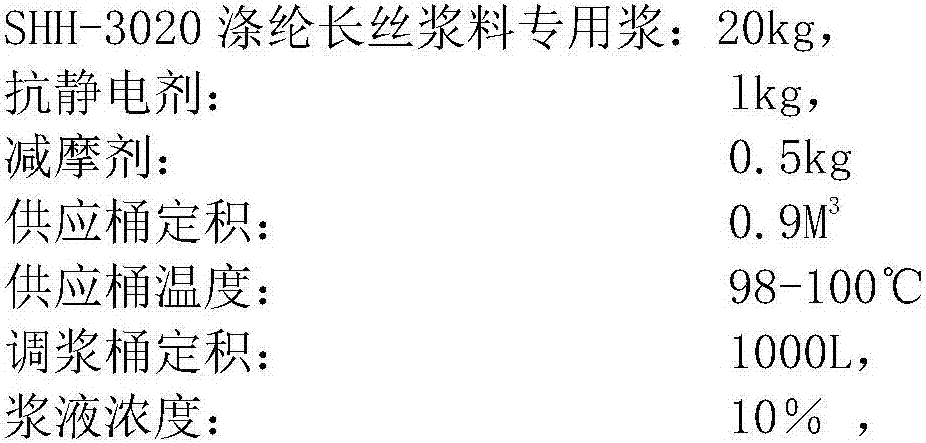

Method used

Image

Examples

Embodiment Construction

[0044] The water, electricity and steam energy consumption of acetate fiber is significantly lower than that of viscose fiber, and its environmental pollution is also less than that of viscose fiber. From this point of view, the development of acetic acid filament has a special practical significance for improving the competitiveness of my country's textile exports and facing the world's green trade barriers.

[0045] Acetate fiber is a natural substance extracted from wood pulp cellulose, which has the same chemical molecular composition as cotton fiber, and acetic anhydride as raw materials. It is made through a series of chemical processes and can be used for spinning and weaving. Acetate filament fiber, which uses cellulose as the basic skeleton, has the basic characteristics of cellulose fiber; but its performance is different from that of regenerated cellulose fiber, and has some characteristics of synthetic fiber.

[0046] Characteristics of acetate fiber:

[0047] 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com