Multifunctional degreasing agent for one-bath dyeing and preparation method thereof

A degreaser and multi-functional technology, which is applied in the dyeing and degreasing bath for chemical fiber blended fabrics, the multi-functional degreaser for dyeing in the same bath and its preparation field, can solve the problems of long process flow and large water consumption, and achieve economical improvement. Effective, easy to clean, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 2

[0049] A kind of multifunctional degreasing agent for dyeing and bathing, its mass parts are composed as follows:

[0050] Tridecyl alcohol polyoxyethylene ether (8EO): 15%

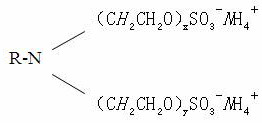

[0051] Sulfamic acid modified fatty amine polyoxyethylene ether: 10%

[0052] Glyceryl ether oleate: 1%

[0053] Fatty alcohol polyoxyethylene ether (80EO): 2%

[0054] Isomerized tridecyl alcohol polyoxyethylene ether (1340): 3%

[0055] Ammonium phenol ether sulfate: %

[0056] Polyether modified silicone ether ester: 1%

[0057] Ethylene glycol monobutyl ether: 9%

[0058] Water: balance.

[0059] The preparation method is the same as that of Example 1.

Embodiment example 3

[0061] A kind of multifunctional degreaser for dyeing with bath, its composition is as follows:

[0062] Tridecyl alcohol polyoxyethylene ether (10EO): 15%

[0063] Sulfamic acid modified fatty amine polyoxyethylene ether: 10%

[0064] Glyceryl ether oleate: 3%

[0065] Fatty alcohol polyoxyethylene ether (80EO): 2%

[0066] Isomerized tridecyl alcohol polyoxyethylene ether (1340): 1%

[0067] Phenol ether ammonium sulfate: 2%

[0068] Polyether modified silicone ether ester: 0.3%

[0069] Diethylene glycol monobutyl ether: 5%

[0070] Water: balance.

[0071] The preparation method is the same as that of Example 1.

Embodiment example 4

[0073] A kind of multifunctional degreasing agent for dyeing and bathing, according to mass percentage, its composition is as follows:

[0074] Tridecyl alcohol polyoxyethylene ether (8EO): 15%

[0075] Sulfamic acid modified fatty amine polyoxyethylene ether: 10%

[0076] Glyceryl ether oleate: 2%

[0077] Fatty alcohol polyoxyethylene ether (80EO): 2%

[0078] Isomerized tridecyl alcohol polyoxyethylene ether (1340): 2%

[0079] Phenol ether ammonium sulfate: 3%

[0080] Polyether modified silicone ether ester: 0.7%

[0081] Ethylene glycol monobutyl ether: 7%

[0082] Water: balance.

[0083] The preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com