Patents

Literature

31results about How to "Good anti-staining effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid soaping agent

ActiveCN101781613AImprove washing fastnessGood anti-staining effectSurface-active detergent compositionsHydrophilic monomerMaleopimaric acid

The invention discloses an addition agent acid soaping agent for dyeing. Although the conventional soaping agent composite has good soaping function, but cannot neutralize the alkaline substances which are remained on the cloth, and the cloth is washed by water for multiple times until the pH value of the cloth is close to neutral, the cloth can be used, so a great amount of water resource is wasted. Fatty alcohol polyethenoxy ether is firstly reacted with acrylic acid or maleic acid to generate a polymerization monomer with surface activity, then under the existence of the evocating agent, the polymerization monomer is polymerized with hydrophilic monomer to generate a macromolecular polymer having dispersion chelation performance, and the macromolecular polymer is compounded with the surface active agent to obtain the acid soaping agent. The prepared acid soaping agent integrates the neutralization process and the soaping process after the dyeing of the active dye, so the process flow is greatly shortened, the water is saved, the energy is saved, the emulsion dispersion chelation performance is excellent, the loose color on the texture can be easy to wash, and the staining prevention performance is excellent.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

Low-temperature soaping agent and preparation method thereof

InactiveCN102994259AImprove performanceGood anti-staining effectOrganic detergent compounding agentsNon-ionic surface-active compoundsAlkylphenolSolvent

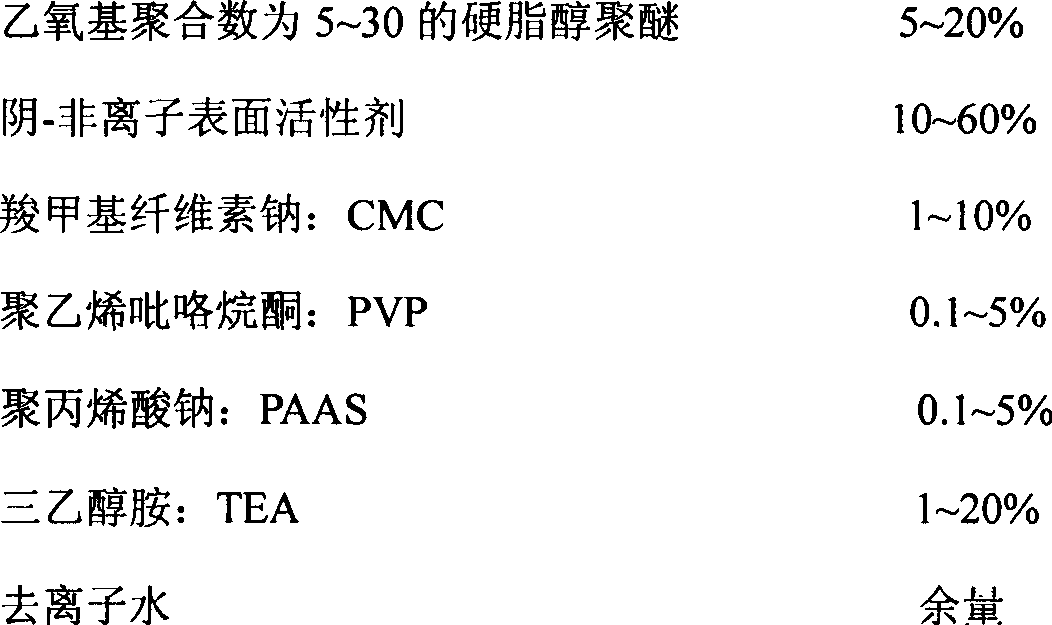

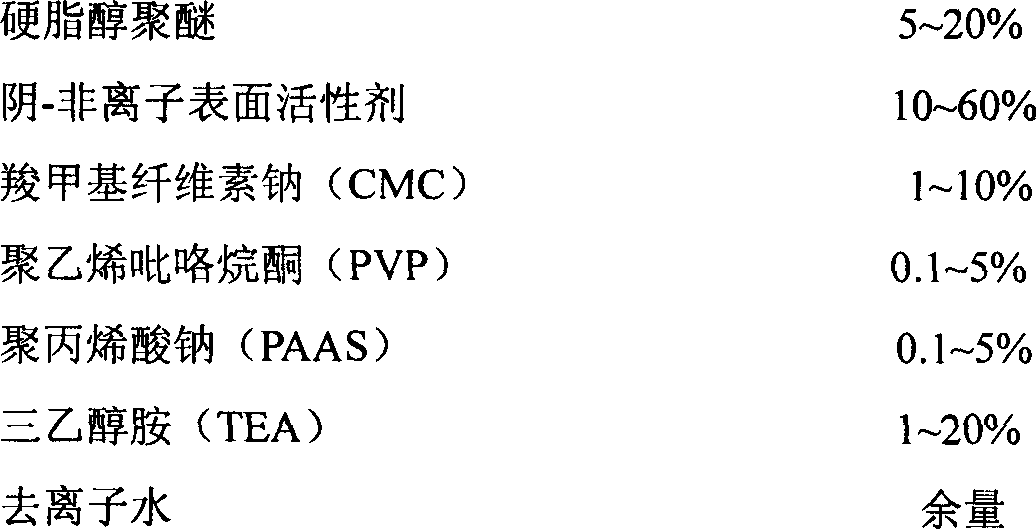

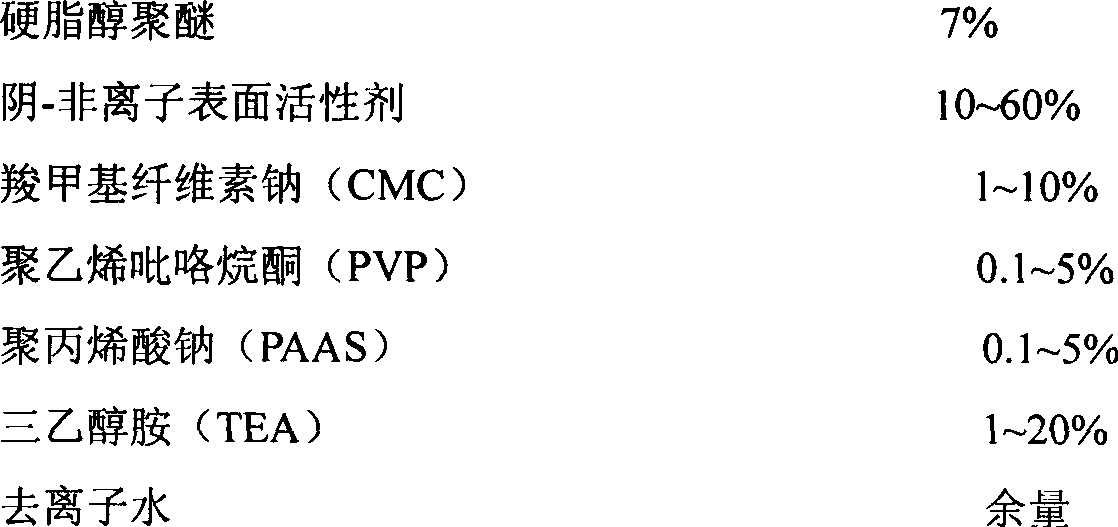

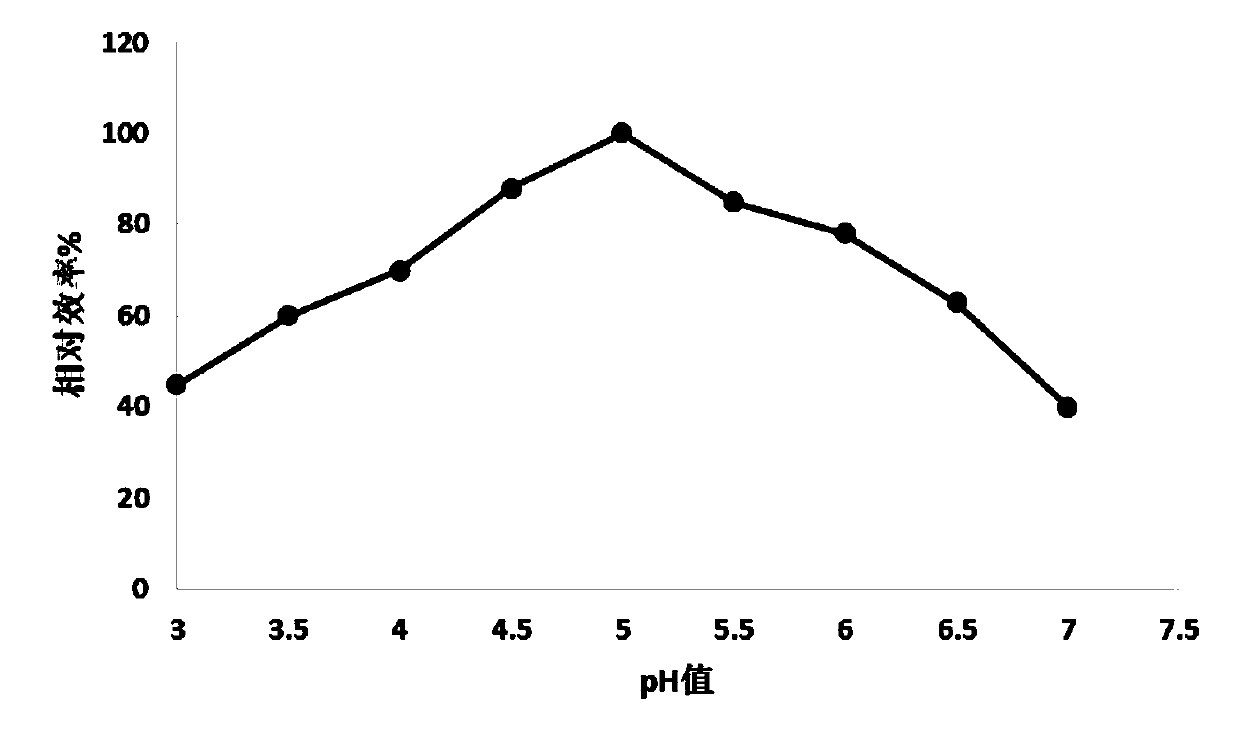

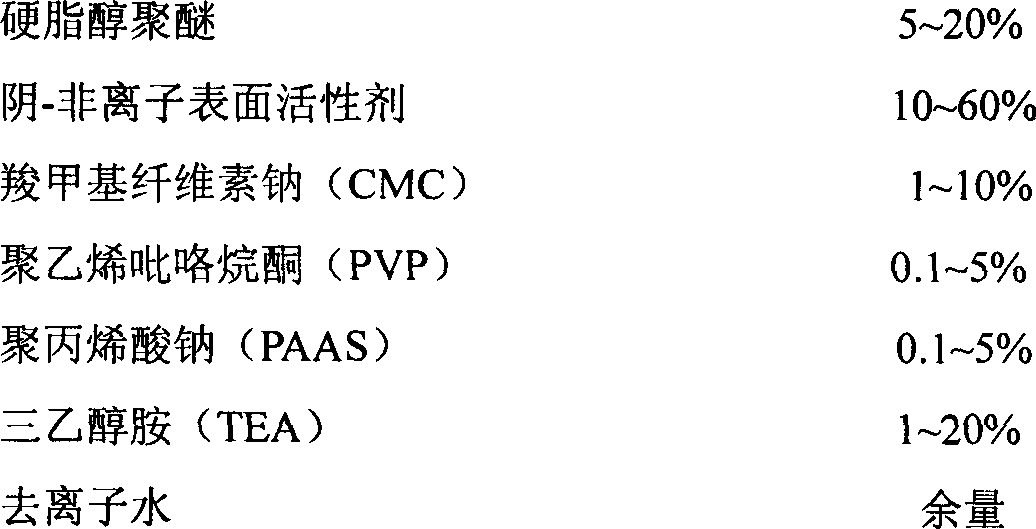

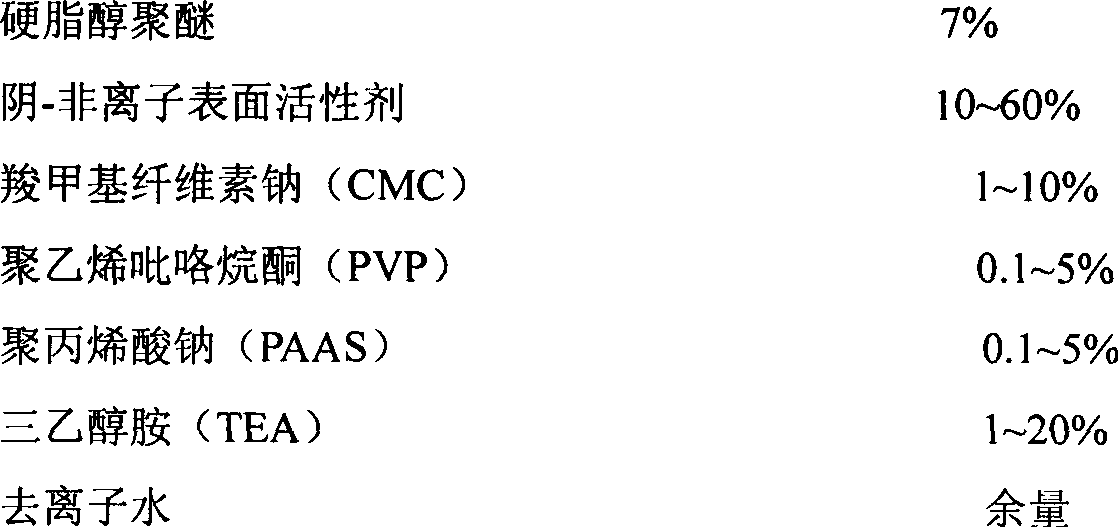

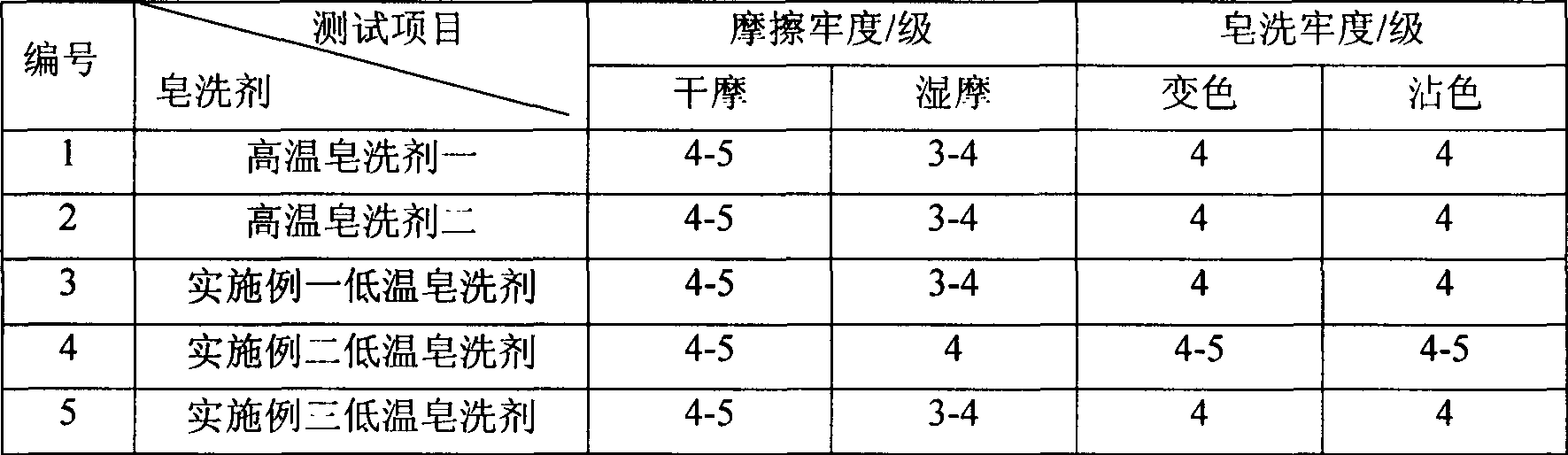

The invention discloses a low-temperature soaping agent for reactive dyes, belonging to the soaping process of the printing and dyeing industry. The low-temperature soaping agent is formed by compounding high-efficiency surfactant and auxiliaries, and comprises the following components in percentage by weight: 5-20wt% of stearyl alcohol polyether, 10-60wt% of anion- nonionic surfactant, 1-10wt% of sodium carboxymethyl cellulose (CMC), 0.1-5wt% of polyvinylpyrrolidone (PVP), 0.1-5wt% of sodium polyacrylate (PAAS), 1-20wt% of triethanolamine (TEA), and the balance being water. The soaping agent is free of phosphor, alkylphenol polyoxyethylene ether and harmful solvent, can be biodegradable, has low foaming performance and self-chelating performance, is used for soaping reactive dyes after dyeing, has a good soaping effect at a soaping temperature of 60 DEG C, and can save energy and reduce consumption.

Owner:JIANGNAN UNIV

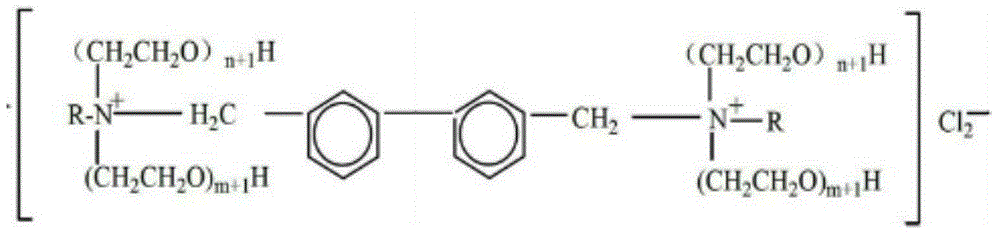

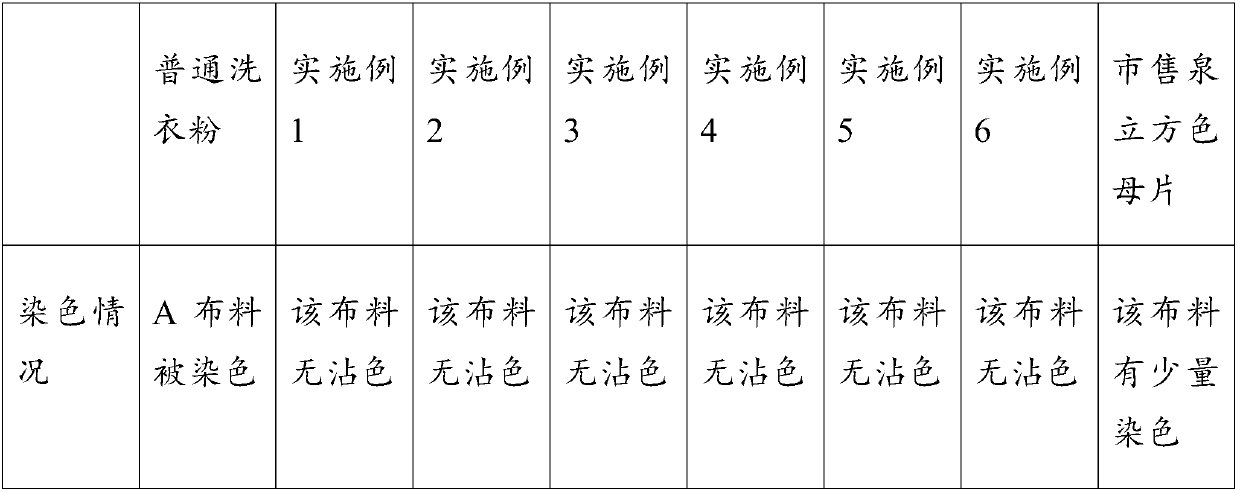

Novel acidic anti-staining soap lotion and preparation method thereof

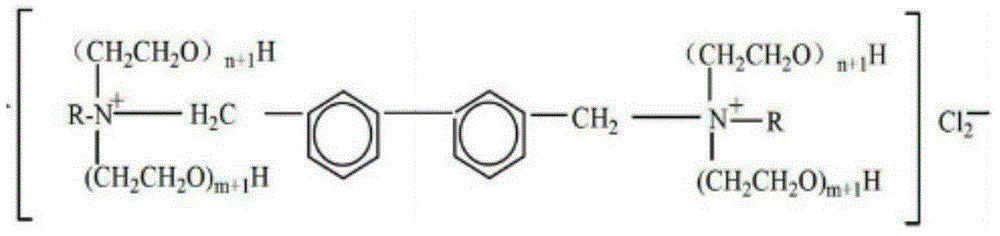

InactiveCN104087427AReduce dosageGood value for moneyCationic surface-active compoundsOrganic detergent compounding agentsFiberAliphatic amine

The invention discloses a novel acidic anti-staining soap lotion and a preparation method thereof. The novel acidic anti-staining soap lotion is prepared from aliphatic amine polyoxyethylene ether biquaternary ammonium salt, a maleic anhydride-acrylic acid-N-vinyl pyrrolidone terpolymer, a carboxyalkylthiosuccinic acid and water. The acidic anti-staining soap lotion has extremely strong dispersing and chelating abilities, and has the strong affinity to hydrolyzed reactive dyes and dissociative reactive dyes. When the acidic anti-staining soap lotion is applied to a soaping aftertreatment process of reactive dye dyeing cotton fabrics, the production procedures are reduced, the water consumption is lowered, the dyeing fastness of the fabrics is obviously improved and the good anti-staining effect is realized. Thus, under the same condition, the usage amount of the soap lotion is reduced, so that the damage to fibers is reduced. Therefore, the novel acidic anti-staining soap lotion has high performance-price ratio.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

Method for distressed rapid dyeing of wool sweater

The invention relates to a method for distressed rapid dyeing of a wool sweater. The method comprises the following steps: (1) wax-dipping: weighing liquid Evo wax with the amount of 1.05-1.15 times of the wool sweater fabric weight, at the room temperature, soaking the wool sweater in the wax liquid, and repeatedly kneading and pressing until being uniform; and carrying out low temperature drying or natural drying; (2) dyeing: putting the wool sweater fabric after wax-dipping pretreatment and drying into a prepared dyeing bath; heating up to 75-80 DEG C at a speed of 3 DEG C / min, and holding for 5-10 min to achieve dyeing; (3) carrying out color fixation: after dyeing, adding a cationic color-fixing agent for color fixation for 5 min, and then taking out the fabric; (4) cleaning: washing with a non-ionic surfactant for 15 min at the temperature of 70 DEG C; and (5) drying. After the wool sweater is dyed by the rapid dyeing process, a distressed effect of distinct depth levels and uniform overall appearance appears. In addition, compared with a conventional dyeing process, the dyeing time is shortened by 60%-70%, and the color fastness is at the level of 2.5 or above.

Owner:嘉兴俊雅服饰股份有限公司

An environmentally friendly soaping agent

InactiveCN104031776AReduce environmental pollutionExcellent performanceDetergent mixture composition preparationSurface-active non-soap compounds and soap mixture detergentsChemistryLacquer

An environmentally friendly soaping agent is disclosed. Preparation of the soaping agent includes: 1) preparing macroporous silicon dioxide, 2) preparing a chitosan solution, 3) immobilizing laccase and 4) preparing the soaping agent. The soaping agent is advantageous in that: (a) the soaping agent is free of acid washing, thus reducing environment pollution; (b) the soaping agent has excellent properties, namely, the soaping agent has good chelating, dispersing, suspending, and washing properties, and the soaping agent is capable of effectively removing flooding, protecting fabric from being contaminated by the flooding, guaranteeing the colour fastness, and making the color tune more bright and pure and the fabric surface cleaner; (c) the soaping agent can achieve low-temperature soaping, and is suitable for soaping at a temperature lower than 60 DEG C, excellent in anti-staining property and capable of reducing thermal loss; (d) foams are few; and (e) work hours are reduced and are only 30% of work hours of an original process, washing steps are largely reduced, the water using amount is only a quarter of an original water using amount, the process time is shortened, the cost and the treating load of waste water are reduced, and the pollution to the environment is reduced.

Owner:NINGBO JUYING CHEM

Anti-staining stabilizing additive composition, preparation method and applications thereof, and compounding cellulase and applications thereof

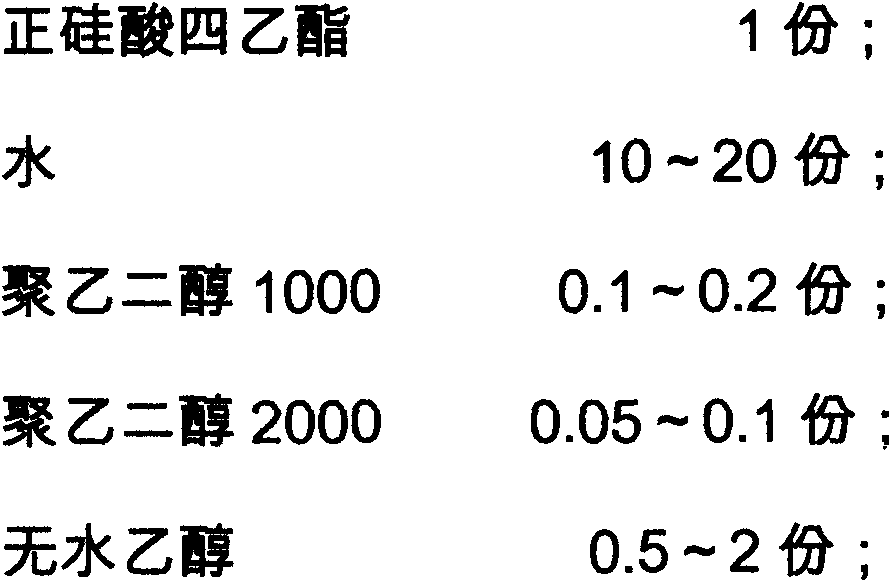

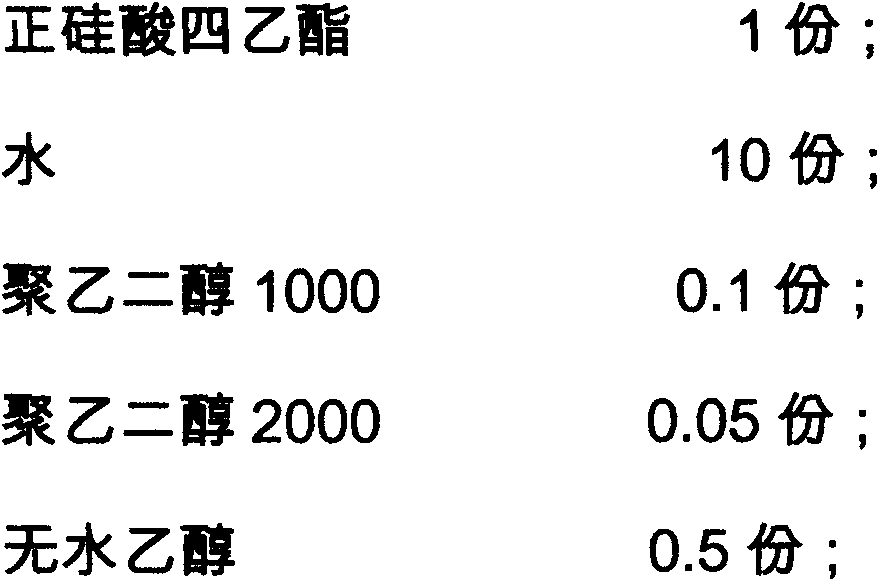

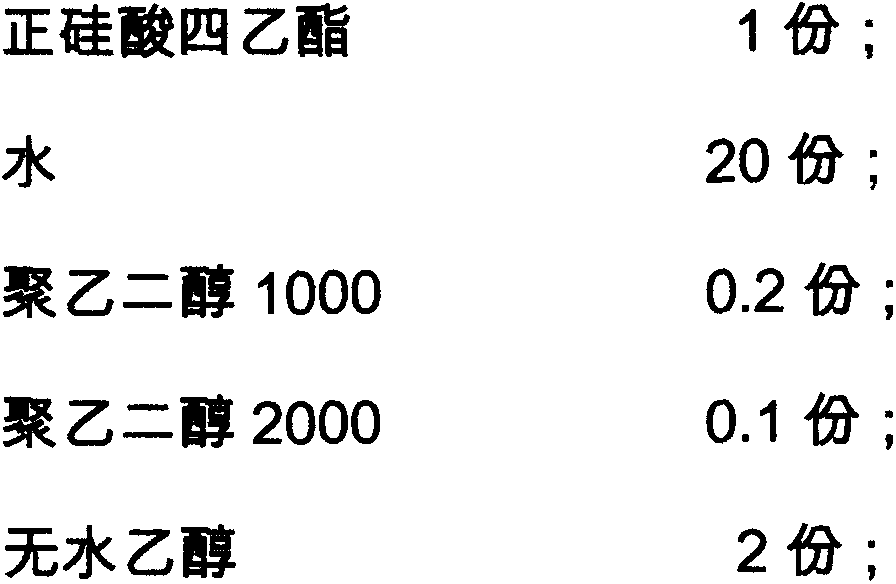

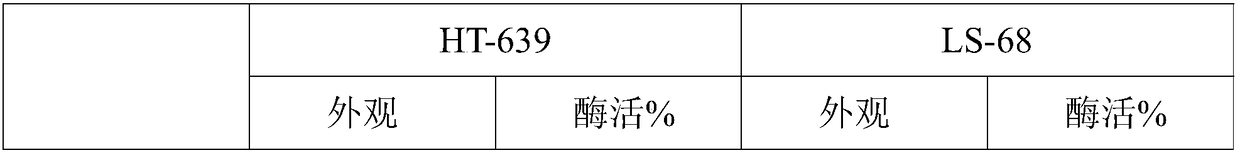

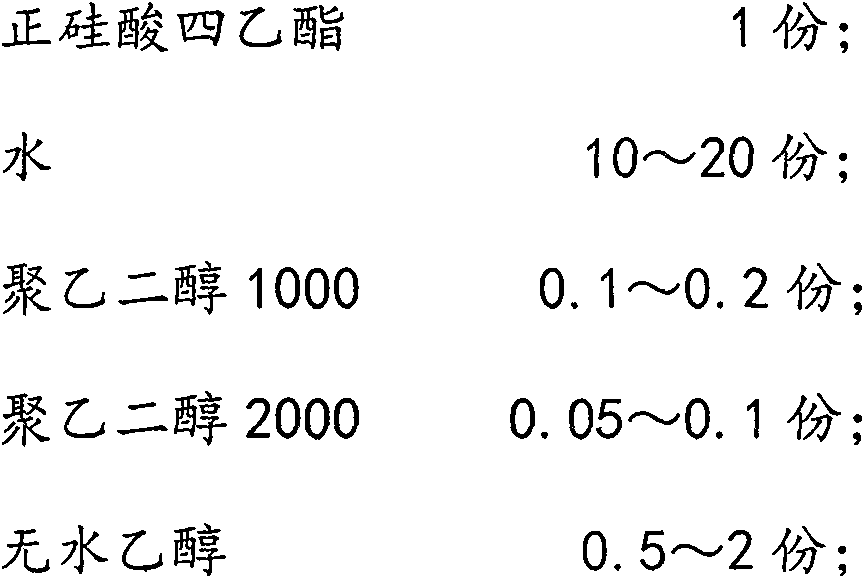

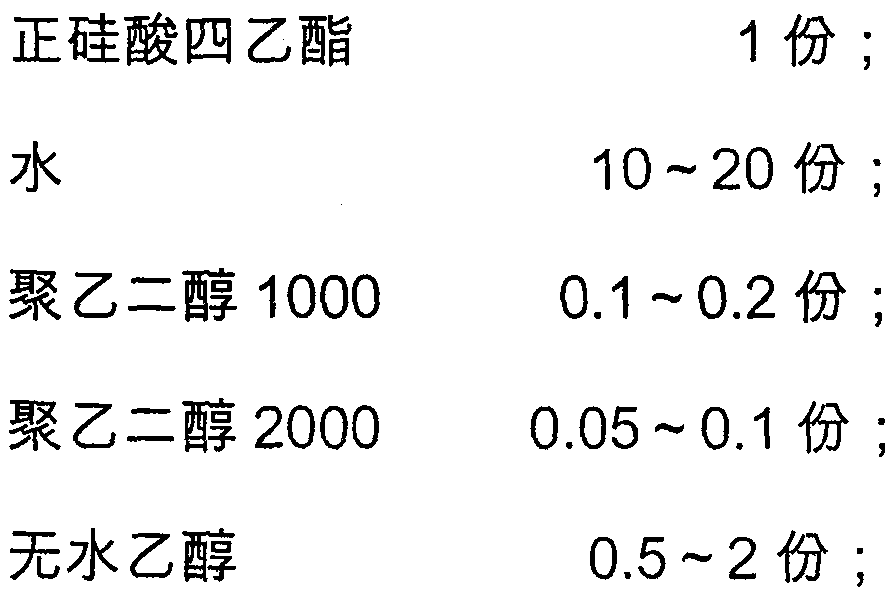

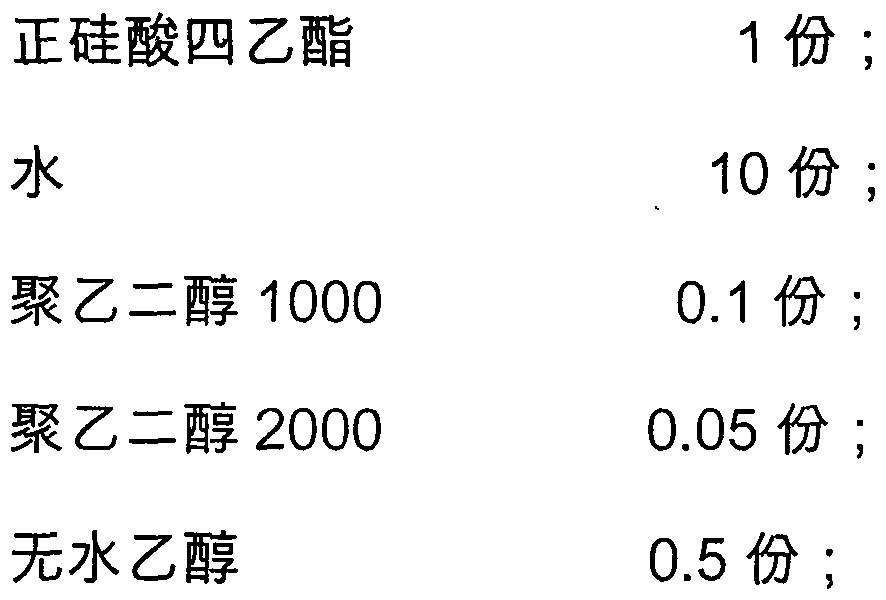

ActiveCN109267405AImprove stabilityPlay a synergistic roleEnzyme stabilisationDyeing processPolyesterPolyethylene glycol

The invention relates to the technical field of biological enzyme preparations and textile aids, and discloses an anti-staining stabilizing additive composition, a preparation method and applicationsthereof, and a compounding cellulase and applications thereof, wherein the anti-staining stabilizing additive composition contains 5-50 wt% of fatty alcohol polyoxyethylene ether, 1-20 wt% of polyethylene glycol, 1-30 wt% of an aqueous polyester, 2-20 wt% of sorbitol, 1-10 wt% of a saccharide substance, 0-10 wt% of polyvinylpyrrolidone, 0.05-2 wt% of a preservative, and the balance of deionized water. According to the present invention, the compounding cellulase contains the anti-staining stabilizing additive composition, has good stability, and can prevent Denim clothing from color staining to different degrees, color contamination and other phenomena during industrial water washing so as to improve the quality and the added value of Denim clothing.

Owner:广州大久生物科技有限公司

High-efficiency environment-friendly acidic soap washing agent, and preparation method thereof

ActiveCN110499218AGood anti-staining effectStrong dispersion abilityCationic surface-active compoundsOrganic detergent compounding agentsAcrylic acidSulfonic acid ester

The invention belongs to the field of fine chemistry, and more specifically relates to a high-efficiency environment-friendly acidic soap washing agent, and a preparation method thereof. The high-efficiency environment-friendly acidic soap washing agent comprises, by mass, 10 to 30 parts of carboxyalkylthiosuccinic acid, 30 to 50 parts of acrylic acid-2-acrylamido-2-methyl propyl sulfonic acid (AA / AMPS) copolymer 20 to 50 parts of sodium gluconate, 5 to 10 parts of hydrolytic polymaleic anhydride, 0.1 to 2 parts of a surfactant, 0.5 to 10 parts of a complexing agent, and 30 to 50 parts of water. When the high-efficiency environment-friendly acidic soap washing agent is used in cotton and cotton blended fabric reactive dye dying, surface dyeing removing effect is better, and fabric color fastness and brightness are ensured; the high-efficiency environment-friendly acidic soap washing agent contains no nitrogen and phosphorus, and is relatively high in acidity, so that the acid neutralizing process before common soaping can be avoided, waste discharge amount is reduced, human labor is saved, electricity cost is reduced, and better market advantages are achieved.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

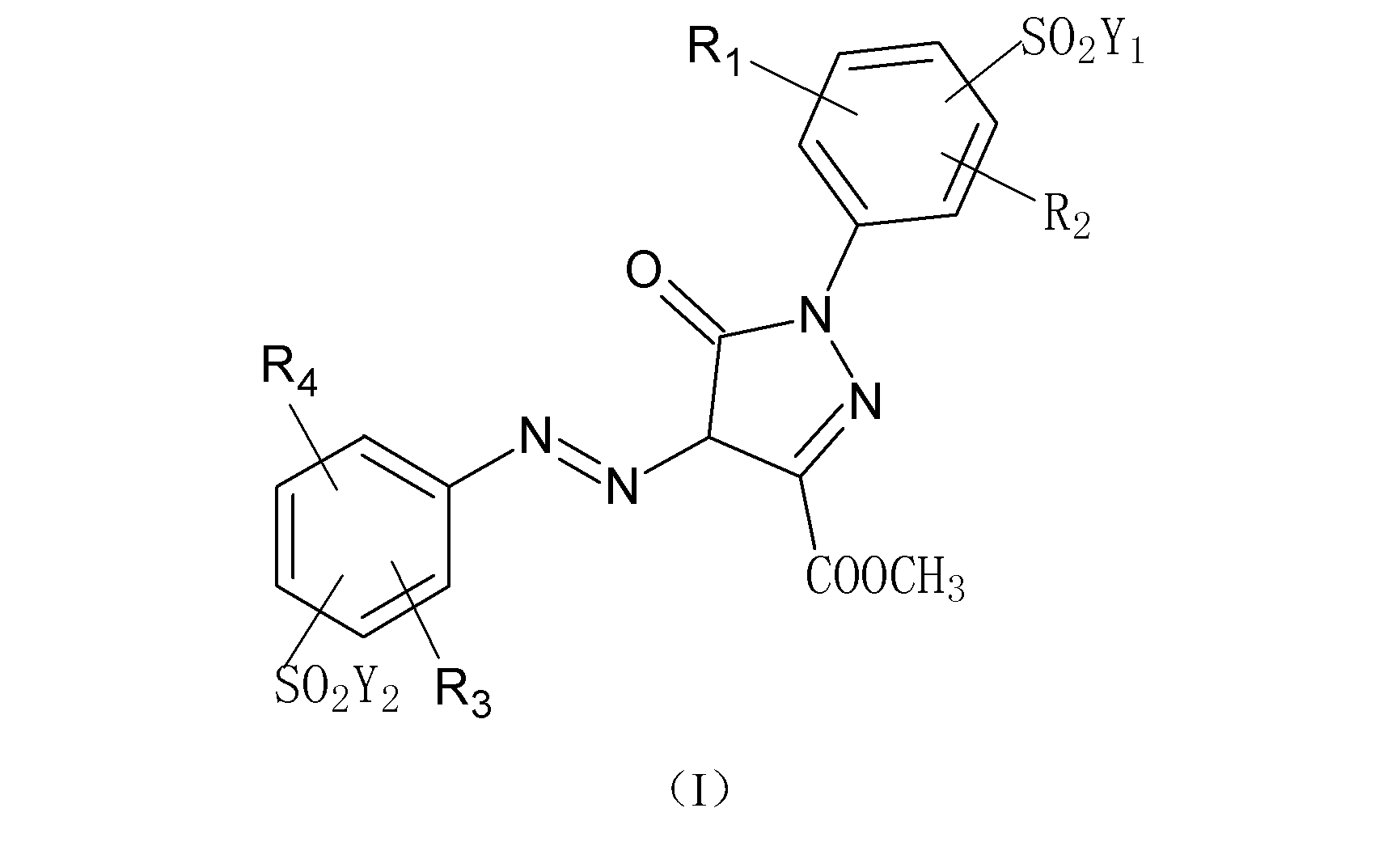

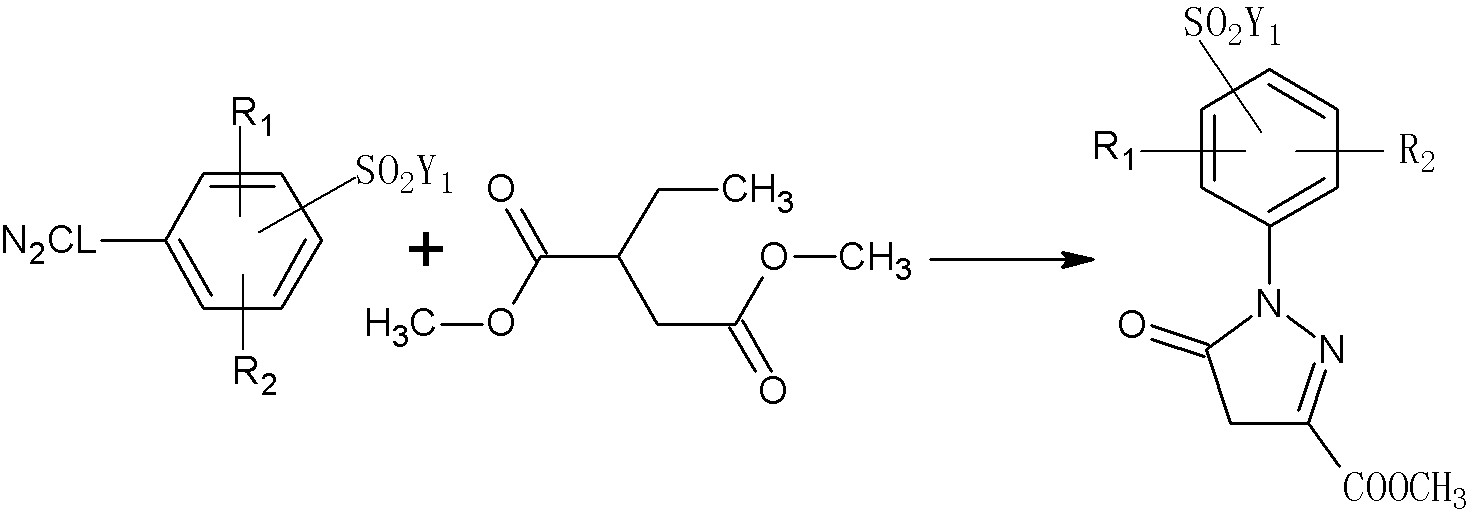

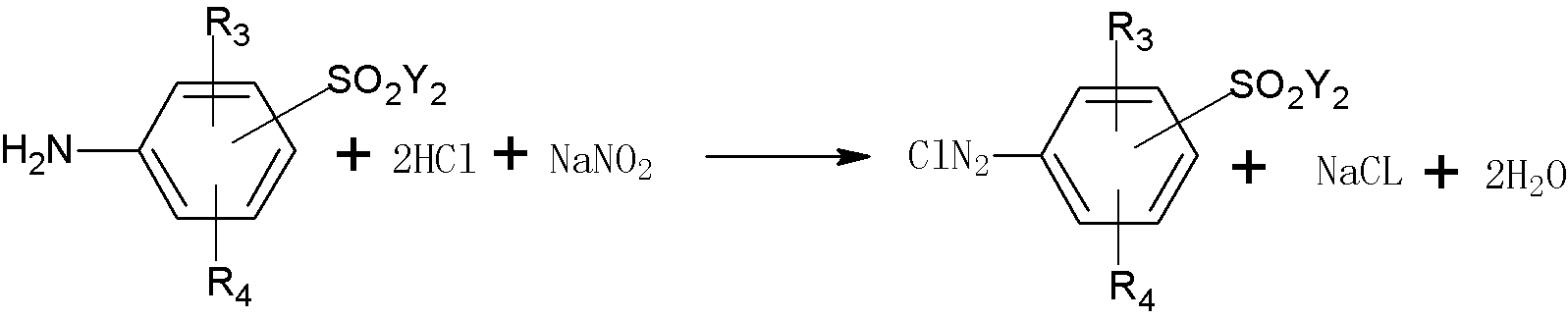

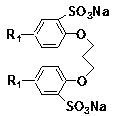

Yellow double-reactive-group dye compound, preparation method and composition thereof

InactiveCN103013168AMeet the requirements of energy saving and emission reductionGood light fastnessReactive dyesDyeing processFiberHydrogen

The invention discloses a yellow double-reactive-group dye compound, a preparation method and a composition thereof. Although the traditional yellow dye can present a fresh brilliant color, the dye not only causes old appearance of a textile, but also stains fibers in white or other colors and generates staining and overlapping due to sunshine and poor rubbing fastness. The general formula of the compound is as follows, wherein R1, R2, R3 and R4 are hydrogen, C1-C2 alkyl, halogen, -OCH3 or SO3M1; M1 is hydrogen or alkali metal, and Y1 andY2 are -CH=CH2 or -C2H4OSO3M2; and the definition of M2 is the same with that of M1. The dye has good light fastness and prominent wet fastness, the fixation rate is high, the lifting power is good, various fastnesses satisfy requirements, and particularly the light fastness is good.

Owner:ZHEJIANG YIDE CHEM +1

Denim garment desizing refining finishing agent and preparation process thereof

InactiveCN108166240AStrong damageImprove hydrophilicityDry-cleaning apparatus for textilesAlcoholEther

The present invention relates to a denim garment desizing refining finishing agent and a preparation process thereof. The finishing agent includes the following raw material ingredients by weight: 400-500 parts of a wide-temperature desizing enzyme, 50-100 parts of pectate lyase, 300-400 parts of alcohol ether, 0-3 parts of a defoamer and 50-250 parts of deionized water. Compared with the existingtechnology, the denim garment desizing refining finishing agent can still play high efficiency in the use of low temperature, and is more energy-saving and environmental-friendly, and the denim garment desizing refining finishing agent has a good impurity removal effect and better hand effect.

Owner:FIBER CHEM BIOLOGICAL CHEM

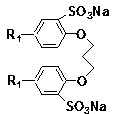

Low-temperature soaping agent for cellulose reactive dye

The invention relates to the technical field of textile printing and dyeing, and provides a low-temperature soaping agent for a cellulose reactive dye. The low-temperature soaping agent is prepared bycompounding a Gemini anionic sulfonate surfactant, polymer and other auxiliary agents, and comprises the following components in percentages by weight: 1-20% of sodium dialkyl diphenyl ether disulfonate, 5-15% of anionic surfactant AOT, 0.1-0.5% of a defoaming agent, 0.1-5% of beta-cyclodextrin, 0.2-2% of sodium polyacrylate, 1-10% of polyvinylpyrrolidone and the balance of deionized water. The soaping agent has the advantages of low foam, strong hard water resistance, remarkable color removal effect in low-temperature soaping at the temperature of 60 DEG C, energy conservation, emission reduction and production cost reduction, and has positive significance for improving the problem of high energy consumption in the printing and dyeing industry.

Owner:苏州新扬新材料科技有限公司

Acid cellulase preparation for low-temperature biological polishing and preparation method thereof

The invention relates to an acid cellulase preparation for low-temperature biological polishing and a preparation method thereof. The acid cellulase preparation for the low-temperature biological polishing is prepared from the following components in parts by weight: 500 to 650 parts of acid cellulase, 30 to 100 parts of pectinase, 50 to 150 parts of alcohol ether, 50 to 100 parts of sodium chloride, 0 to 50 parts of calcium chloride, 0 to 3 parts of kathon and 50 to 300 parts of deionized water. The preparation method comprises the following steps: (1) pouring the weighed deionized water, kathon, calcium chloride and sodium chloride into a stirring tank, stirring at normal temperature until the kathon, the calcium chloride and the sodium chloride are dissolved completely, wherein the rotating speed is 30 to 50 r / min; (2) pouring the weighed alcohol ether into the solution, regulating the rotating speed to be 10 to 20 r / min, and stirring at the normal temperature until the alcohol ether is mixed uniformly; (3) pouring the weighed pectinase and acid cellulase into the solution, regulating the rotating speed to be 10 to 20 r / min, and stirring at the normal temperature; (4) after allcomponents are thrown into the stirring tank, stirring for 10 minutes, discharging 10 to 20 parts of the mixture from the bottom of the stirring tank, and pouring the 10 to 20 parts of the mixture into the stirring tank from the top of the stirring tank; (6) after the mixture is stirred for 5 minutes, discharging and filling while stirring. Compared with the prior art, the acid cellulase preparation has the advantages that the acid cellulase preparation can have a high-efficiency polishing effect and the like at the low temperature of 20 to 40 DEG C.

Owner:FIBER CHEM BIOLOGICAL CHEM

Low-temperature soaping agent and preparation method thereof

InactiveCN102994259BImprove performanceGood anti-staining effectNon-ionic surface-active compoundsOrganic detergent compounding agentsAlkylphenolSolvent

Owner:JIANGNAN UNIV

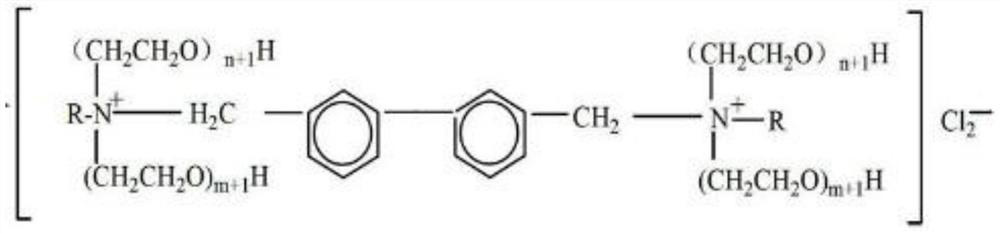

Efficient anti-staining detergent for garment washing and preparation method of efficient anti-staining detergent

InactiveCN107828534APrevent mutual stainingPrevent cross-color and other phenomenaNon-ionic surface-active compoundsOrganic detergent compounding agentsFiberBenzene

The invention discloses an efficient anti-staining detergent for garment washing and a preparation method of the efficient anti-staining detergent. The efficient anti-staining detergent is prepared from components in percentage by mass as follows: 5%-15% of polyvinylpyrrolidone, 10%-40% of a maleic acid-acrylic anhydride copolymer, 10%-20% of fatty alcohol polyoxyethylene ether, 5%-15% of secondary alkyl sodium sulfonate, 5%-8% of linear alkyl benzene sulfonic acid, 0.05%-0.1% of a preservative and 1.9%-64.95% of deionized water. Polyvinylpyrrolidone, the maleic acid-acrylic anhydride copolymer and fatty alcohol polyoxyethylene ether (peregal O) are taken as the raw materials, all the components play own role and have a synergistic effect, so that the detergent has a good anti-staining effect, phenomena such as mutual staining, color mixing and the like between different fiber materials and clothes in different colors are prevented in the garment washing process, and quality and valueof the product are improved; the raw materials are all environmentally friendly, non-toxic, harmless, non-irritant and pollution-free.

Owner:广州先盈生物科技有限公司

White-ground anti-staining soaping agent for nylon and preparation method of white-ground anti-staining soaping agent

PendingCN113529444AStrong dispersing and chelating abilityExcellent cleaning performanceDyeing processFunctional monomerVinyl acetate

The invention discloses a white-ground anti-staining soaping agent for nylon and a preparation method of the white-ground anti-staining soaping agent. The white-ground anti-staining soaping agent for nylon comprises the following raw materials of 40-60 parts of a mixed monomer, 1-5 parts of a film-forming colloid, 1-5 parts of an emulsifier, 0.2-0.5 part of an initiator, and 25-40 parts of deionized water. The white-ground anti-staining soaping agent is prepared from vinyl acetate, acrylate and functional monomers as main raw materials by adopting an emulsion polymerization method under the combined action of the film-forming colloid, the emulsifier and the initiator. The white-ground anti-staining soaping agent for nylon has the advantages that the storage stability is good, the stiffness is superior to that of polyvinyl acetate and vinyl acetate-acrylic copolymer, the stiffness effect of urea-formaldehyde resin is achieved, and the soaping agent does not contain formaldehyde; and through modified copolymerization of the functional monomers, the washing resistance of the polyvinyl acetate, the vinyl acetate-acrylic copolymer and other series of products is obviously improved, the technical defects of the series of products are better overcome, and the development trend of stiffening and finishing agents in the market is met.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

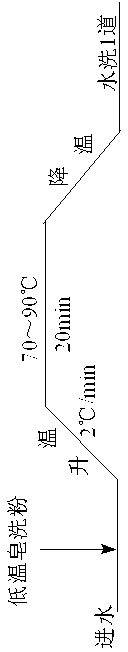

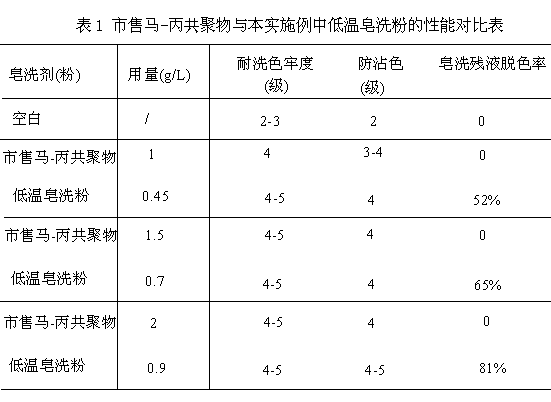

Low temperature soaping powder and preparation method thereof

ActiveCN102424771BFunction increaseGood anti-staining effectNon-surface-active detergent compositionsDetergent mixture composition preparationAqueous solutionVacuum drying

The invention relates to low temperature soaping powder and a preparation method thereof. So far, there has been no soaping powder which has excellent soaping performance at low temperature and decolouring performance to soaping residue. The low temperature soaping powder provided in the invention comprises, by weight, 25 to 65 parts of maleic anhydride-acrylic acid copolymer powder, 35 to 85 parts of sodium percarbonate and 35 to 85 parts of sodium perborate. The preparation method for the low temperature soaping powder comprises the following steps: with an aqueous solution of maleic anhydride-acrylic acid copolymer, sodium percarbonate and sodium perborate as raw materials, heating the aqueous solution of maleic anhydride-acrylic acid copolymer to a temperature of 70 to 90 DEG C under agitation, subjecting the aqueous solution of maleic anhydride-acrylic acid copolymer to vacuum distillation for 2 to 5 hours at a temperature of 70 to 90 DEG C and cooling the aqueous solution of maleic anhydride-acrylic acid copolymer to a temperature of 60 to 70 DEG C; subjecting the aqueous solution of maleic anhydride-acrylic acid copolymer to vacuum drying for 8 to 15 hours at a temperature of 100 to 150 DEG C, crushing dried maleic anhydride-acrylic acid copolymer and mixing crushed maleic anhydride-acrylic acid copolymer with sodium percarbonate and sodium perborate to prepare the soaping powder. The low temperature soaping powder provided in the invention has strong soaping performance, strong anti-staining performance, and decolouring performance to soaping residue.

Owner:JIANGSU NEW REBA TECH CO LTD

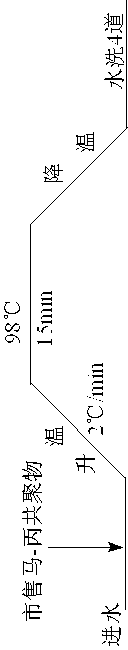

Dyeing process of anti-staining nylon color strip fabric cheese

InactiveCN111118926AStrong color fastnessAvoid prone to staining problemsDyeing processStaining techniqueColour fastness

The present invention discloses a dyeing process of an anti-staining nylon color strip fabric cheese, and relates to the technical field of textile dyeing. The dyeing process comprises the following steps of (1) preparing a dye liquor; (2) performing dyeing; (3) preparing a color fixation liquid; (4) performing color fixation; and (5) carrying out cleaning. Dyeing of the nylon cheese is completedby virtue of combination of dyeing of an active dye and two times of color fixation, the dye-uptake reaches almost 100%, the nylon cheese after being dyed is high in color fastness, an anti-staining effect is achieved during processing of the color strip fabric, and especially the problem of staining after water washing of the color strip fabric can be avoided effectively, thereby ensuring the appearance quality of the color strip fabric.

Owner:LANGXI YUANHUA TEXTILE

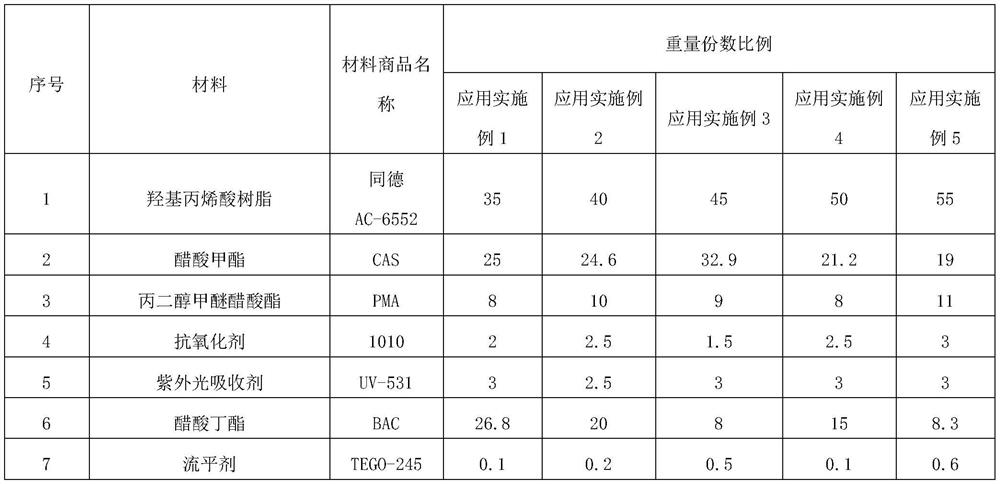

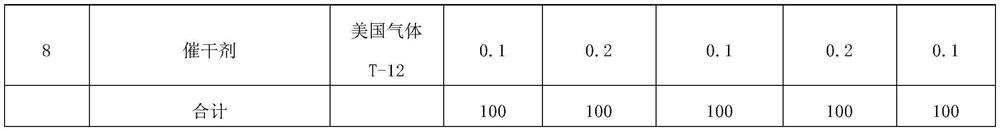

PU (polyurethane) golden oil capable of preventing dyeing and discoloration of veneers and preparation method of PU golden oil

InactiveCN114672231AFast drying and fast curingHigh hardnessPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

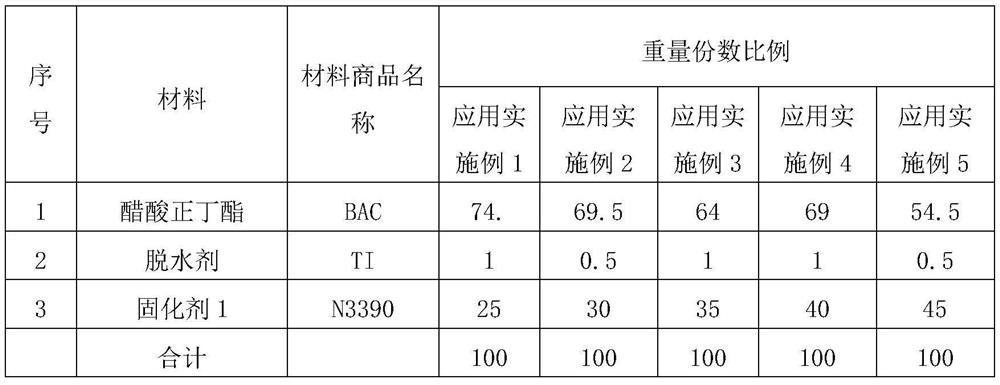

The invention discloses PU (polyurethane) gold oil for preventing dyeing and discoloration of veneers and a preparation method thereof. The PU gold oil comprises a component A and a component B in a mass ratio of 2: 1, the component A is prepared from the following components in parts by mass: 35 to 55 parts of hydroxy acrylic resin, 0.5 to 2 parts of antioxidant, 2 to 3 parts of ultraviolet absorbent, 5 to 10 parts of ether ester solvent, 20 to 40 parts of ester solvent, 0.1 to 0.5 part of defoaming agent, 0.05 to 0.1 part of flatting agent and 0.1 to 0.2 part of drier; and the component B comprises the following components in parts by mass: 55-75 parts of n-butyl acetate, 0.5-1 part of a dehydrating agent and 25-45 parts of an HDI curing agent. The dyeing-resistant veneer discoloration-resistant PU golden oil has the characteristics of good dyeing resistance, excellent yellowing resistance and excellent mechanical properties.

Owner:AODA KOALA PAINT HUIZHOU

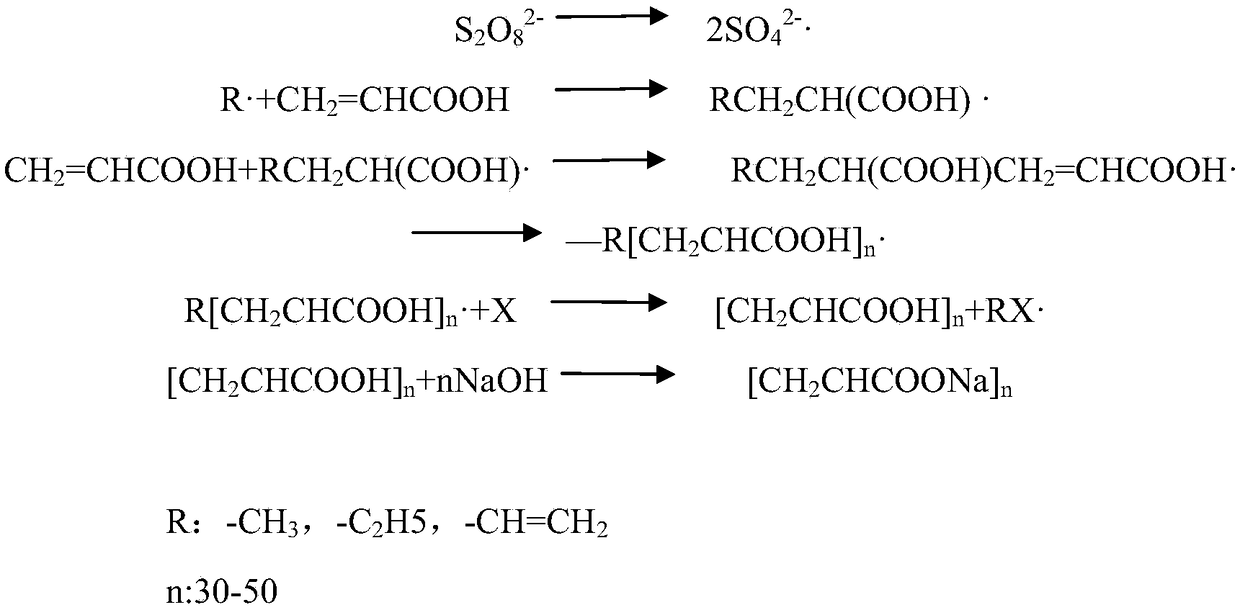

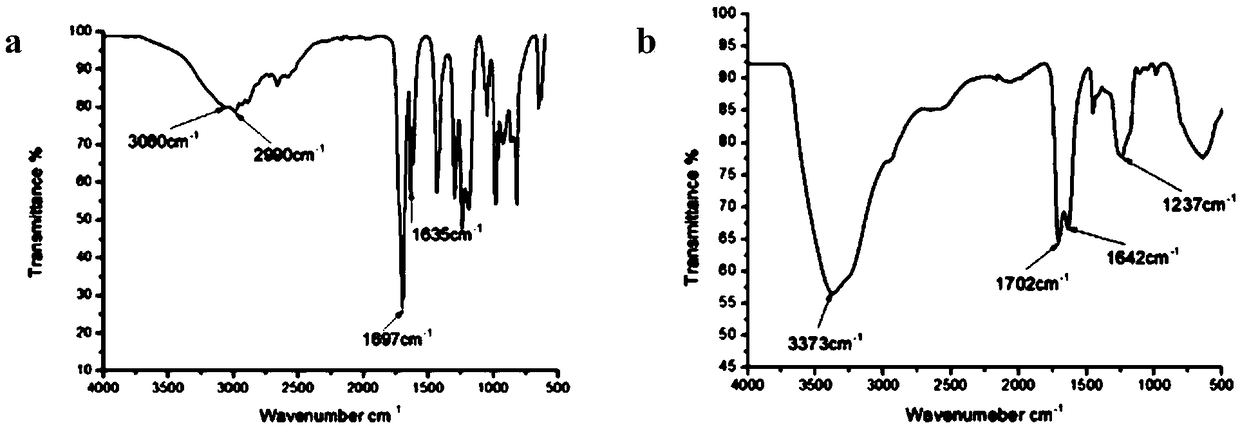

Method for treating acrylic-acid-containing waste water by microwave radiation technique

InactiveCN109455856ALow costReduce pollutionWater/sewage treatment by irradiationWater contaminantsRoom temperatureWastewater

The invention relates to a method for treating acrylic-acid-containing waste water by the microwave radiation technique, including the steps of pre-treating acrylic-acid-containing waste water, placing the pre-treated waste water in a four-neck flask, adding acrylic acid monomer and an initiator on the condition of microwave radiation, reacting for a certain time, cooling to the room temperature after the reaction is stopped, and regulating the pH through aqueous alkali; the product can be used as a reactive dye soaping agent. The method is simple in process, realizes recycling of waste waterand accords with the concept of ecological environmental protection; the soaping agent has excellent performance.

Owner:DONGHUA UNIV

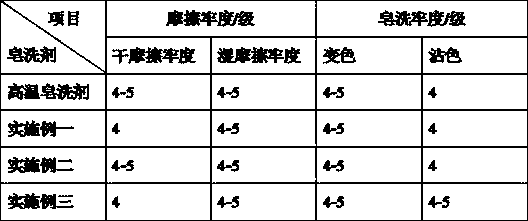

Soaping enzyme for denim fabric washing and preparation technology thereof

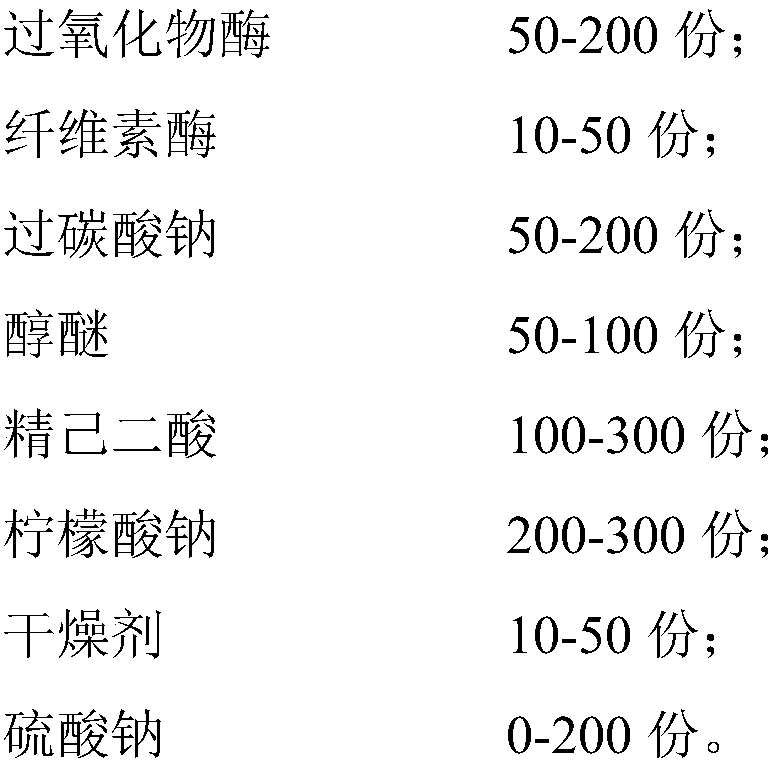

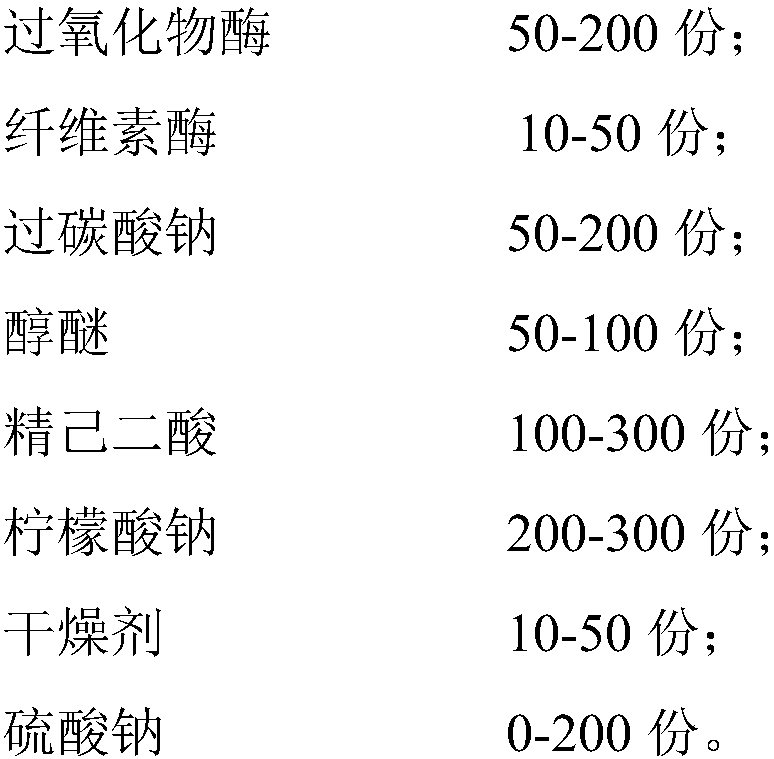

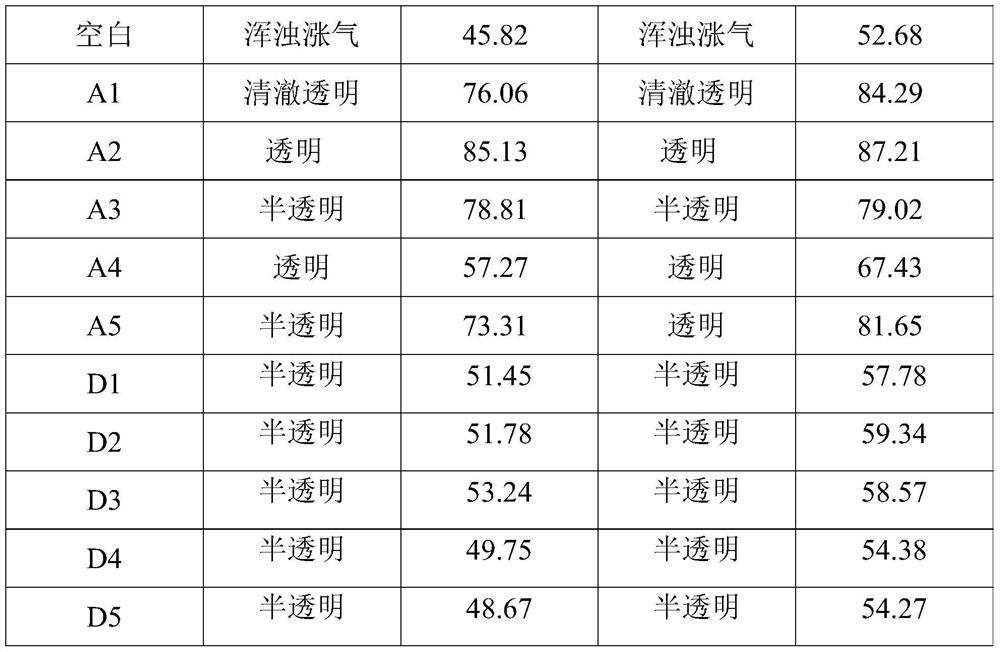

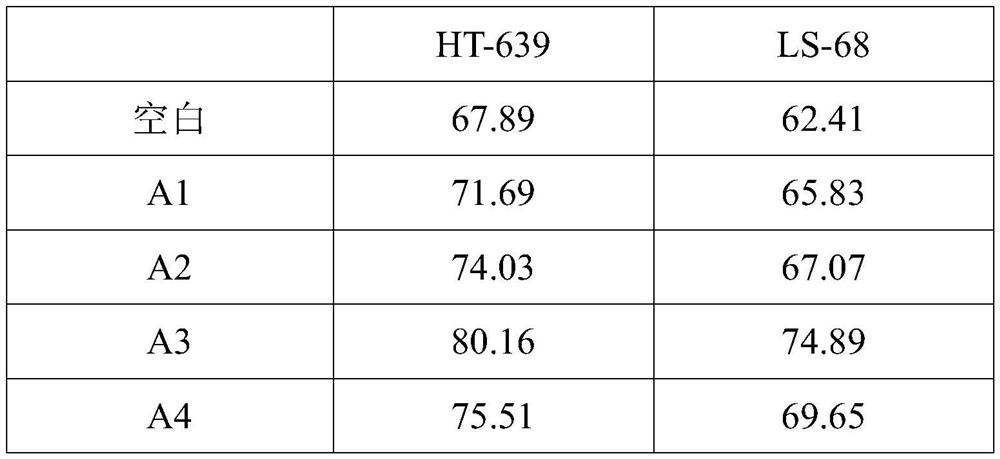

InactiveCN109629270AShort processing timeReduce processing timeDyeing processCitrate sodiumChemistry

The invention relates to a soaping enzyme used for denim fabric washing and a preparation technology thereof. The soaping enzyme is prepared by cross-feeding 50-200 parts of peroxidase, 10-50 parts ofcellulase, 50-200 parts of sodium percarbonate, 50-100 parts of alcohol ether, 100-300 parts of pure adipic acid, 200-300 parts of sodium citrate, 10-50 parts of a drying agent and 0-200 parts of sodium sulfate into a stainless steel double helix conical stirring tank for a reaction. Compared with the prior art, the soaping enzyme can be used at the low temperature ranging from 20 DEG C to 35 DEGC, the treatment time is short, and only 5-10 min is needed; by cooperating with a denim garment desizing and yeast grinding one-bath efficient integrated enzyme for use, the treatment time of the efficient integrated enzyme can be shortened, and the figure three-dimensional sense is higher compared with applying the efficient integrated enzyme separately. After spraying PP, the soap enzyme can replace traditional washing powder and detergent agent washing, washing powder is not used any more, and phosphorus emission is lowered; after the soaping enzyme treatment, the sand position definitionis higher, the cloth texture is clearer, and backstaining is lower.

Owner:FIBER CHEM BIOLOGICAL CHEM

Anti-staining and stabilizing additive composition and its preparation method and application, as well as compound cellulase and its application

ActiveCN109267405BImprove stabilityPlay a synergistic roleEnzyme stabilisationDyeing processPolyesterDenim

The invention relates to the technical field of biological enzyme preparations and textile aids, and discloses an anti-staining stabilizing additive composition, a preparation method and applicationsthereof, and a compounding cellulase and applications thereof, wherein the anti-staining stabilizing additive composition contains 5-50 wt% of fatty alcohol polyoxyethylene ether, 1-20 wt% of polyethylene glycol, 1-30 wt% of an aqueous polyester, 2-20 wt% of sorbitol, 1-10 wt% of a saccharide substance, 0-10 wt% of polyvinylpyrrolidone, 0.05-2 wt% of a preservative, and the balance of deionized water. According to the present invention, the compounding cellulase contains the anti-staining stabilizing additive composition, has good stability, and can prevent Denim clothing from color staining to different degrees, color contamination and other phenomena during industrial water washing so as to improve the quality and the added value of Denim clothing.

Owner:广州大久生物科技有限公司

Acid soaping agent

ActiveCN101781613BImprove washing fastnessGood anti-staining effectSurface-active detergent compositionsHydrophilic monomerPolymer science

The invention discloses an addition agent acid soaping agent for dyeing. Although the conventional soaping agent composite has good soaping function, but cannot neutralize the alkaline substances which are remained on the cloth, and the cloth is washed by water for multiple times until the pH value of the cloth is close to neutral, the cloth can be used, so a great amount of water resource is wasted. Fatty alcohol polyethenoxy ether is firstly reacted with acrylic acid or maleic acid to generate a polymerization monomer with surface activity, then under the existence of the evocating agent, the polymerization monomer is polymerized with hydrophilic monomer to generate a macromolecular polymer having dispersion chelation performance, and the macromolecular polymer is compounded with the surface active agent to obtain the acid soaping agent. The prepared acid soaping agent integrates the neutralization process and the soaping process after the dyeing of the active dye, so the process flow is greatly shortened, the water is saved, the energy is saved, the emulsion dispersion chelation performance is excellent, the loose color on the texture can be easy to wash, and the staining prevention performance is excellent.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

Anti-staining method for wool milling

ActiveCN105274831BTightly boundGood anti-staining effectAnimal fibresTextile parts treatmentStainingEngineering

Owner:ZHUHAI JIAN XUAN CLOTHING LTD

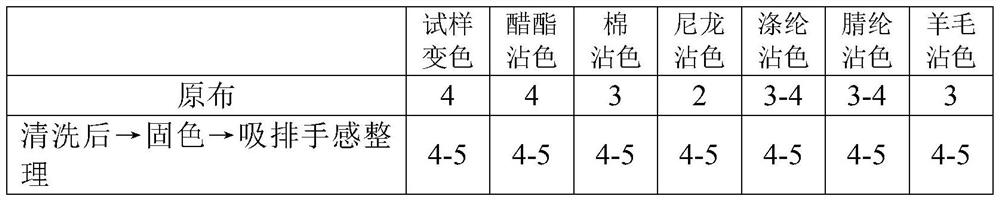

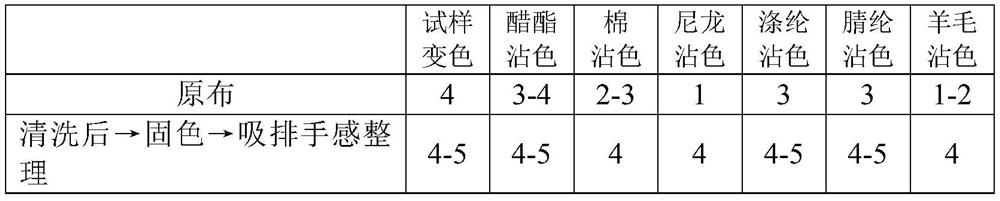

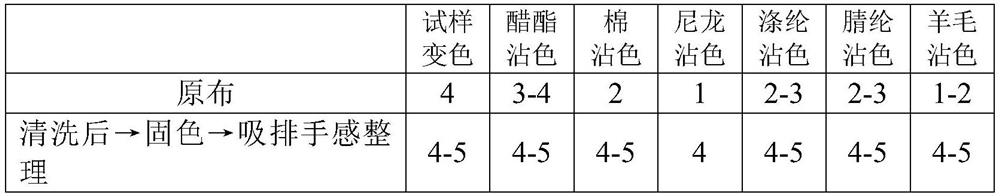

Method for improving wearability of nylon spandex printed fabric

ActiveCN112900099AEasy to use directlyMeet the environmental protection requirements of the orderStain/soil resistant fibresWrinkle resistant fibresTextile printerPolymer science

The invention relates to a method for improving wearability of a nylon spandex printed fabric. The method comprises the following steps of 1) providing a piece of aged and unwashed printed cloth; (2) continuously washing by using a 0.5-1.5 g / L cleaning and color fixation agent DM-2532N at the bath ratio of 1: (15-20), avoiding adjusting the pH value of a working solution, washing at room temperature for 2 minutes for the first time, washing at room temperature for 2 minutes for the second time, washing at 40-45 DEG C for 3 minutes for the third time, washing at 40-45 DEG C for 3 minutes for the fourth time, discharging liquid after each time of washing, washing with cold water, and dehydrating and drying for color fixation; 3) color fixation: adopting X% of the cleaning and color fixation agent DM-2532N, wherein the bath ratio is 1: (8-15), the pH of the working solution is not required to be adjusted, color fixation is carried out for 35-45 min at the temperature of 60-65 DEG C, and after washing with cold water, dewatering and drying are carried out for finishing; and 4) moisture absorption, quick drying and hand feeling finishing: adopting a multifunctional finishing agent DM-3545N with the concentration of 20-30 g / L and silicone oil T618 with the concentration of 30-40 g / L, dipping and rolling once, and drying at the temperature of 110-120 DEG C, wherein the liquid pretension rate is 70 + / - 5%. According to the method, the hydrophilicity of the nylon spandex woven fabric can be improved to be less than 5 seconds, the quick drying property is improved, the moisture evaporation rate of the fabric reaches 90% or above within 30 minutes, and the hand feeling is improved to be soft and smooth.

Owner:福建省晋江新德美化工有限公司

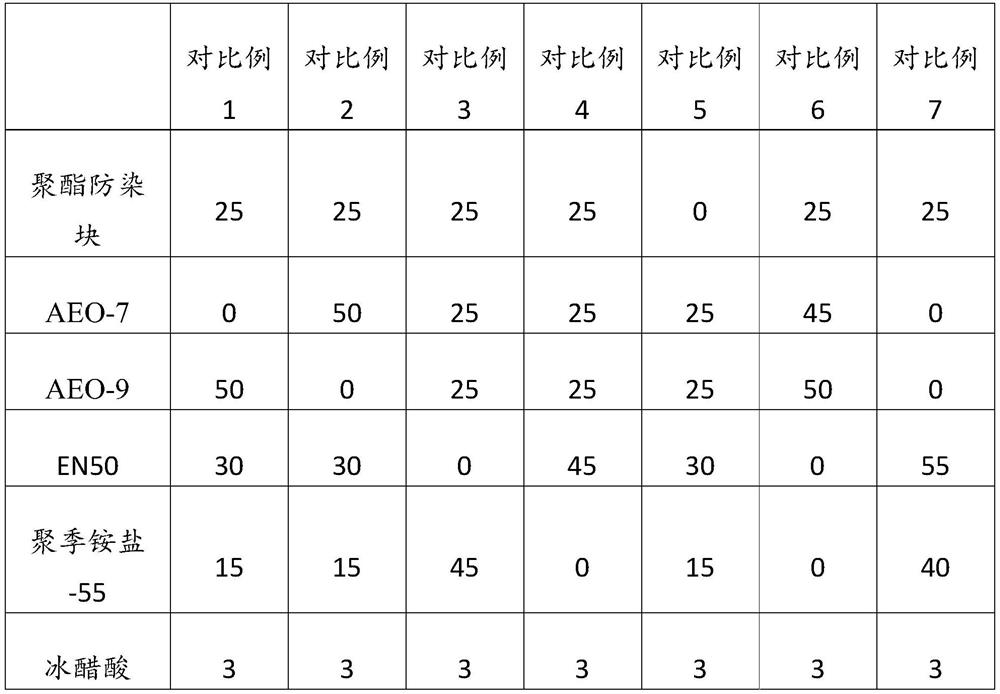

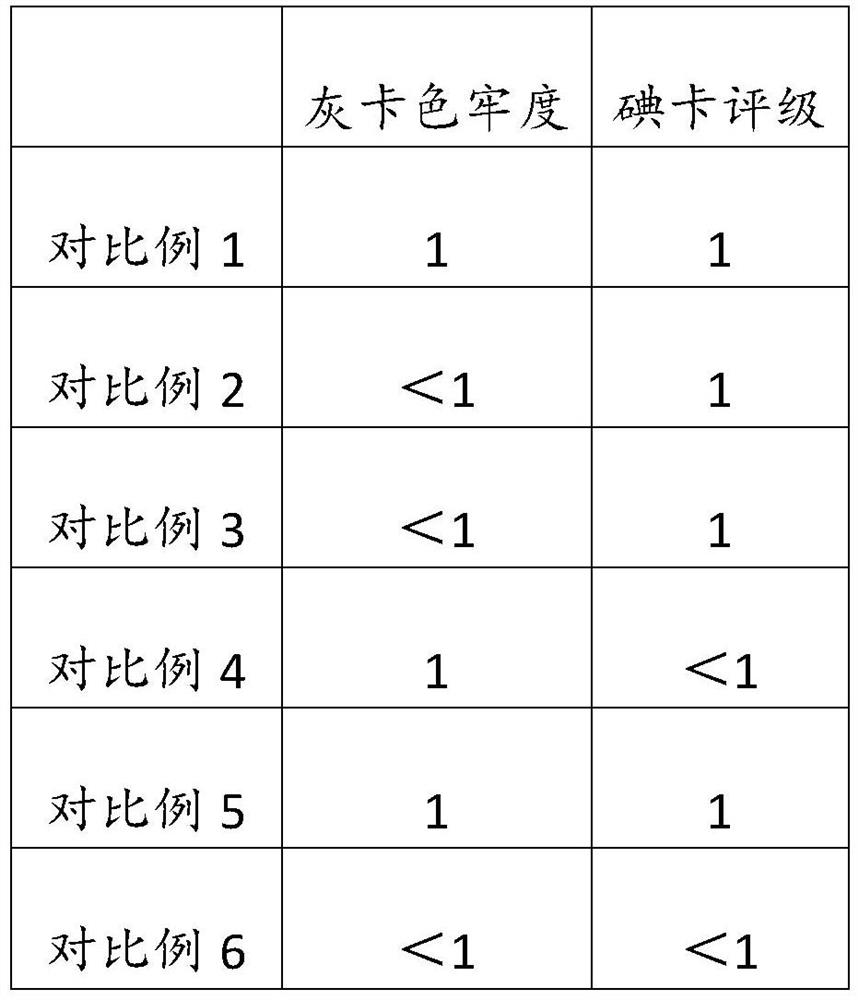

Desizing aid as well as preparation method and application thereof

InactiveCN112796091AThe dosage is easy to controlGood dosageDry-cleaning apparatus for textilesPolyesterActive agent

The invention discloses a desizing aid, and relates to the field of jean textile washing. The desizing aid comprises the following components in parts by weight of 20 to 30 parts of a polyester surfactant, 40 to 55 parts of a nonionic surfactant, 30 to 45 parts of a cationic surfactant and 2 to 4 parts of a pH regulator. The desizing aid provided by the invention can effectively desize and also has a good dye-resistant effect, and in the application process, dye-resistant products do not need to be additionally added, so that the use cost is saved for enterprises.

Owner:广州市德鹏新材料科技有限公司

Resist agent and preparation method thereof, and cloth dyeing method

The invention relates to the technical field of printing and dyeing, in particular to a resist agent and a preparation method thereof, and a cloth dyeing method. The resist agent provided by the invention is prepared from raw materials including soybean meal and clarified lime water, wherein the weight ratio of the soybean meal to the clarified lime water is 5: 8. The weight ratio of the soybean meal to the clarified lime water is limited, so that the soybean meal can be uniformly dispersed in the clarified lime water, and the viscosity is proper. The resist agent provided by the invention is good in adhesive force, fast to fall off in water, free of residual impurities on cloth, convenient for water washing treatment, and applicable to various kinds of fabric such as cotton, hemp, real silk, wool and the like; when the resist agent provided by the invention is used for dyeing cloth, a step of wetting an attached object with water and a traditional puttying step can be omitted, the resist agent can be directly cleaned with clear water, the problem that a plate is sealed by during slurry scraping when a traditional resist agent is used is solved, and the process is simplified; and the resist agent provided by the invention has high stability, is not limited by time, and can be operated in great heat days, great cold days or rainy season.

Owner:哀警卫 +4

A kind of acid cellulase preparation for low-temperature biopolishing and preparation method thereof

The invention relates to an acid cellulase preparation for low-temperature biopolishing and a preparation method thereof, comprising the following components by weight: acid cellulase: 500-650 parts; pectinase: 30-100 parts; alcohol ether: 50 parts ‑150 parts; Sodium chloride: 50‑100 parts; Calcium chloride: 0‑50 parts; Cathone: 0‑3 parts; Deionized water: 50‑300 parts. 1) Pour the weighed deionized water, Cathone, calcium chloride and sodium chloride into the mixing tank at a speed of 30-50r / min, and stir at room temperature until completely dissolved; 2) Pour the weighed alcohol ether 3) Pour the weighed pectinase and acid cellulase into the above solution, adjust the rotating speed 10-20r / min, and stir at room temperature ; 4) After all raw materials are put into the mixing tank, stir for 10 minutes, then release 10-20 parts from the bottom and put in from the top; 6) After stirring for 5 minutes, discharge and fill while stirring. Compared with the prior art, the present invention has the advantages of being able to have a high-efficiency polishing effect under the condition of low temperature (20-40° C.).

Owner:FIBER CHEM BIOLOGICAL CHEM

Acid soaping agent

PendingCN114164053AImprove bindingPrevent sticking backInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsMeth-Acyl group

The invention discloses an acid soaping agent. Comprising the following components in parts by weight: 13 to 18 parts of acrylic acid, 5 to 10 parts of hydrolytic polymaleic anhydride, 15 to 20 parts of pyrrolidone, 7 to 12 parts of lauryl sodium sulfate, 30 to 50 parts of an acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 200 to 300 parts of deionized water, 15 to 20 parts of N-cocoyl-L-glutamic acid, 7 to 12 parts of sodium lignin sulfonate and 10 to 30 parts of a microcapsule slow-release alkalescent aid, therefore, the anti-staining performance of the anti-staining agent can be greatly improved, so that the anti-staining agent has a better anti-staining effect, a better coordination effect, higher flooding absorption and removal capacity, higher biodegradability and higher acidity, the acid neutralization procedure before soaping can be reduced, the water consumption is reduced, and the cost is saved.

Owner:广东三兴高新材料科技有限公司

Chemical fiber auxiliary agent for improving chroma of chemical fibers

InactiveCN109505110AHigh chromaStrong alkali resistanceDry-cleaning apparatus for textilesFiberPolyester

The invention discloses a chemical fiber auxiliary agent for improving the chroma of chemical fibers. A non-foam detergent agent NP-2 is used so that a chemical fiber textile has good anti-staining performance and the problem that a chemical fiber product is easily stained by other colors in a polyester recycling technology is solved; the pure color of the chemical fiber product is ensured and thechroma of the chemical fiber product is improved; an efficient oil-removing agent is added, so that oil in polyester wastes can be effectively removed; tartaric acid is used as an anti-oxidization synergist, a set retarder, a tanning agent and a chelating agent to effectively ensure that the color on the surface of the chemical fiber product is pure and not lost; an oxygen bleaching stabilizer isa compound of organic carboxylic acid and a special auxiliary agent and has the advantages of high temperature resistance, strong alkali resistance, oxidization resistance and no toxicity; the stabilization effect of the oxygen bleaching stabilizer on hydrogen peroxide exceeds that of sodium silicate, and silicon scales which are difficult to remove are not generated; after the textile is subjected to oxygen bleaching, the whiteness is high and the hand feeling is soft; the chemical fiber auxiliary agent for improving the chroma of the chemical fibers has relatively strong alkali resistance,permeability and a certain emulsifying capability and is applicable to a pre-treatment technology of the polyester wastes and the high-quality chemical fiber products with high chroma are obtained.

Owner:马鞍山市永运家纺有限公司

A kind of high-efficiency environment-friendly acidic soaping agent and preparation method thereof

ActiveCN110499218BGood dispersionEvenly dispersedCationic surface-active compoundsOrganic detergent compounding agentsButanedioic acidMeth-

The invention belongs to the field of fine chemicals, and specifically relates to an environment-friendly acidic soaping agent and a preparation method thereof. The soaping agent comprises the following components in parts by mass: 10-30 parts of carboxyethylthiosuccinic acid, acrylic acid- 30-50 parts of 2‑acrylamide‑2 methylpropanesulfonic acid (AA / AMPS) copolymer, 20‑50 parts of sodium gluconate, 5‑10 parts of hydrolyzed polymaleic anhydride, 0.1‑2 parts of surfactant, Mixture 0.5-10 parts, water 30-50 parts. The invention acts on cotton and its blended fabrics after being dyed with reactive dyes to remove floating colors better, ensuring the color fastness and brightness of the fabrics; and the soaping agent component does not contain nitrogen and phosphorus, has strong acidity, and can It reduces the acid neutralization process before conventional soaping, reduces the pressure of wastewater discharge, saves manpower and electricity costs, and has a good market advantage.

Owner:山东京博众诚清洁能源有限公司

a soaping agent

InactiveCN104031776BReduce pollutionEfficient removalDetergent mixture composition preparationSurface-active non-soap compounds and soap mixture detergentsWater useAcid washing

An environmentally friendly soaping agent is disclosed. Preparation of the soaping agent includes: 1) preparing macroporous silicon dioxide, 2) preparing a chitosan solution, 3) immobilizing laccase and 4) preparing the soaping agent. The soaping agent is advantageous in that: (a) the soaping agent is free of acid washing, thus reducing environment pollution; (b) the soaping agent has excellent properties, namely, the soaping agent has good chelating, dispersing, suspending, and washing properties, and the soaping agent is capable of effectively removing flooding, protecting fabric from being contaminated by the flooding, guaranteeing the colour fastness, and making the color tune more bright and pure and the fabric surface cleaner; (c) the soaping agent can achieve low-temperature soaping, and is suitable for soaping at a temperature lower than 60 DEG C, excellent in anti-staining property and capable of reducing thermal loss; (d) foams are few; and (e) work hours are reduced and are only 30% of work hours of an original process, washing steps are largely reduced, the water using amount is only a quarter of an original water using amount, the process time is shortened, the cost and the treating load of waste water are reduced, and the pollution to the environment is reduced.

Owner:NINGBO JUYING CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com