Method for improving wearability of nylon spandex printed fabric

A nylon spandex, printing technology, applied in the direction of dyeing, textile and papermaking, improved hand fiber, etc., to achieve the effect of improving fast drying, low cost, excellent and easy decontamination function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

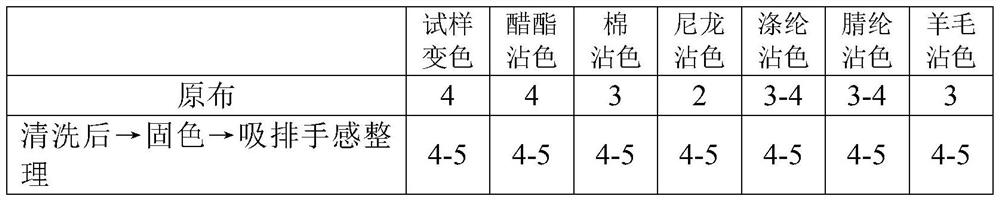

[0019] Example 1: Fujian Changle a print fabric red small fragile print cloth

[0020] 1.1 Continuous cleaning

[0021] 1.1.1 Cleaning prescription

[0022] Cleaning solid color DM-2532N 1.0G / L

[0023] 1.1.2 Cleaning Process

[0024] The bath ratio was 1:20, no working fluid pH, the first cylinder room temperature washed 2min, 2 min at the second cylinder, washed 3 minutes at 45 ° C, 45 ° C for 3 minutes, each cleaning, after cleaning After washing cold water, dry dry, to be solid.

[0025] 1.2 solid color

[0026] 1.2.1 formula

[0027] Cleaning solid color DM-2532N 6.0% (O.W.f)

[0028] 1.2.2 process

[0029] The bath ratio of 1: 10, DM-2532N does not adjust the working fluid pH, 65 ° C solid color 35min, cold water washed, dehydrated dry, to be sorted.

[0030] 1.3 Suction inspiration

[0031] 1.3.1 formula

[0032] Multi-function finishing agent DM-3545N 20g / L

[0033] Silicone oil T618 40G / L

[0034] 1.3.2 process

[0035] One immersed, 120 ° C × 2min bake, test quick ...

Embodiment 2

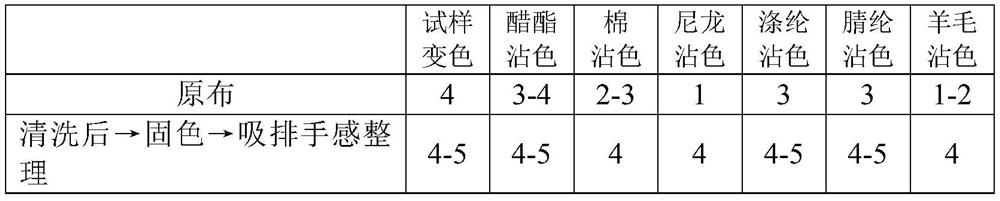

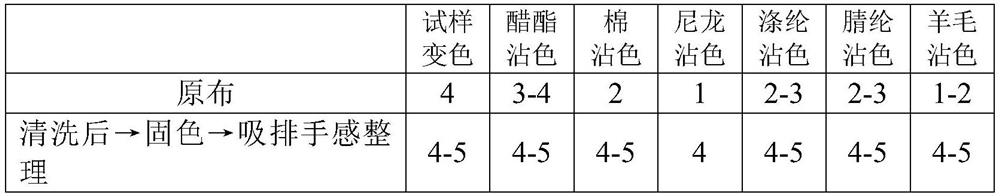

[0049] Example 2: Guangdong Foshan, a production of gancosid fabric factory, green / blue / brown, multi-spontaneous white land printing fabric

[0050] 1.1 Continuous cleaning

[0051] 1.1.1 Cleaning prescription

[0052] Cleaning solid color DM-2532N 1.2g / L

[0053] 1.1.2 Cleaning Process

[0054] The bath ratio was 1:15, the working fluid pH was not adjusted, and the first cylinder room was washed 2min, 2min, washed 2 min, and washed 3 minutes at 45 ° C, and washed 3 min in the fourth cylinder, and exhausted each time. After washing cold water, dry dry, to be solid.

[0055] 1.2 solid color

[0056] 1.2.1 formula

[0057] Cleaning solid color DM-2532N 7.0% (O.W.f)

[0058] 1.2.2 process

[0059] The bath ratio is 1: 8, DM-2532N does not adjust the working fluid pH, 65 ° C solid color 35min, cold water washed, dry dry, to be sorted.

[0060] 1.3 Suction inspiration

[0061] 1.3.1 formula

[0062] Multi-function finishing agent DM-3545N 25G / L

[0063] Silicone T618 30g / L

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com