Low-temperature soaping agent and preparation method thereof

A low-temperature soap and lotion technology, which is applied in the field of textile printing and dyeing, can solve the problems of difficult cleaning, the influence of shade on dyed fabrics, complex processes, etc., and achieve the effects of excellent hard water resistance, excellent anti-staining performance, and good chelating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

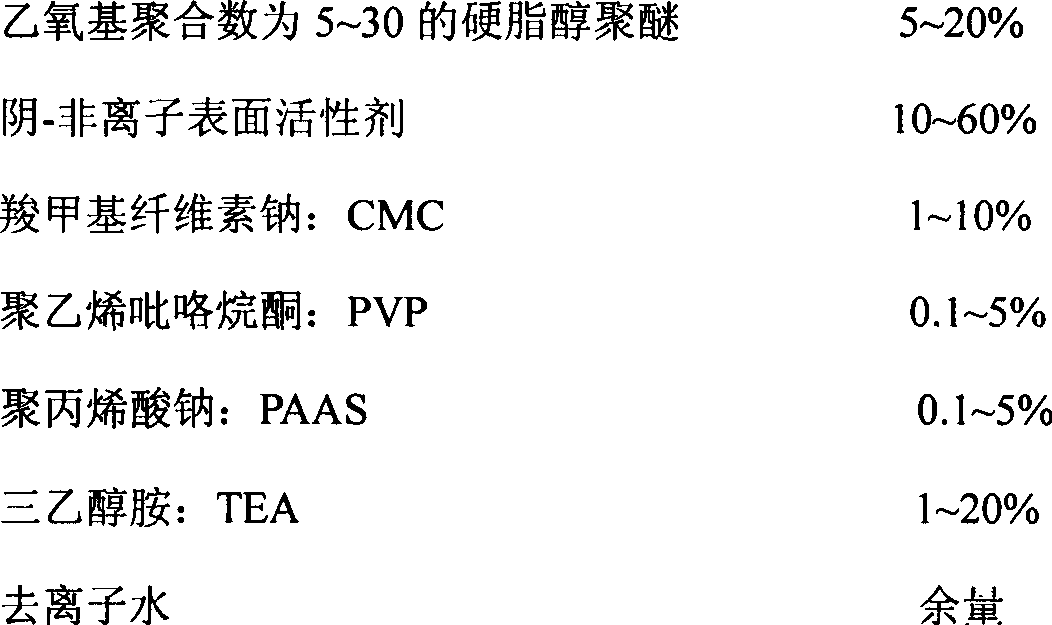

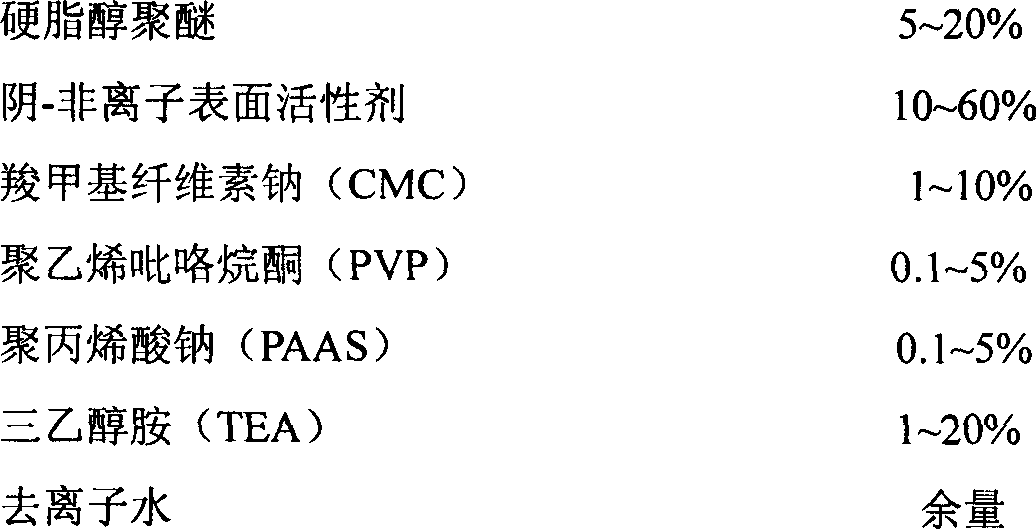

Method used

Image

Examples

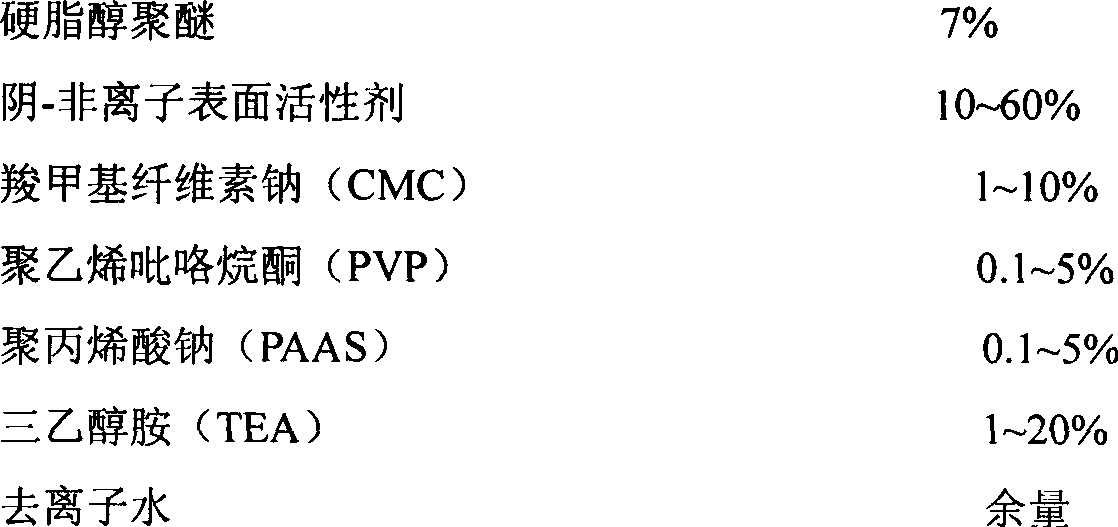

Embodiment 1

[0031] A kind of preparation method of low-temperature soaping agent, comprises the steps:

[0032] (1) Preparation of anionic-nonionic surfactant: Steareth and dicarboxylic acid (maleic anhydride) are added into the reactor at a molar ratio of 2:1.2, heated to 100°C, reacted for 0.5 hours, added Catalyst, be warming up to 200 ℃, react 5 hours, obtain intermediate stearyl maleic acid diester; Add 5wt% fumaric acid in intermediate steareth maleic acid diester, cool down to 100 ℃, add initiator 0.5wt%, heat preservation reaction for 8 hours, get anion-nonionic surfactant;

[0033] (2) Composite: add the anion-nonionic surfactant 40wt% that step (1) makes once in reactor, 5wt% steareth, 8wt% sodium carboxymethylcellulose (CMC), 1wt% polyvinylpyrrolidone PVP, 2wt% polyacrylic acid sodium (PAAS), 15wt% triethanolamine (TEA) and 30wt% deionized water, stirred evenly, and discharged to obtain a low-temperature soaping agent.

Embodiment 2

[0035] A kind of preparation method of low-temperature soaping agent, comprises the steps:

[0036] (1) Preparation of anionic-nonionic surfactant: Steareth and dibasic carboxylic acid (maleic anhydride) are added into the reactor at a molar ratio of 2:1, heated to 90°C, reacted for 1 hour, added Catalyst, be warming up to 220 ℃, react for 6 hours, get intermediate stearyl maleic acid diester; Add 8wt% fumaric acid in intermediate steareth maleic acid diester, cool down to 105 ℃, add initiator 2wt%, heat preservation reaction for 10 hours, get anion-nonionic surfactant;

[0037] (2) Composite: add the anion-nonionic surfactant 20wt% that step (1) makes once in reactor, 5wt% steareth, 5wt% sodium carboxymethylcellulose (CMC), 1% polyvinylpyrrolidone (PVP), 1wt% polyacrylic acid sodium (PAAS), 10wt% triethanolamine (TEA) and 58wt% deionized water, stirred evenly, and discharged to obtain a low-temperature soaping agent.

Embodiment 3

[0039] A kind of preparation method of low-temperature soaping agent, comprises the steps:

[0040] (1) Preparation of anionic-nonionic surfactant: Steareth and dibasic carboxylic acid (maleic anhydride) are added to the reactor at a molar ratio of 2:0.9, heated to 120°C, reacted for 0.5 hours, added Catalyst, be warming up to 190 ℃, react for 6 hours, get the intermediate steareth maleic acid diester; Add the fumaric acid of 10wt% in the intermediate steareth maleic acid diester, cool down to 95 ℃, add 0.5-5wt% initiator, and keep warm for 12 hours to obtain anion-nonionic surfactant;

[0041] (2) Composite: add the anion-nonionic surfactant 25wt% that step (1) makes once in reactor, 6wt% steareth, 4wt% sodium carboxymethylcellulose (CMC), 4wt% polyvinylpyrrolidone (PVP), 2wt% sodium polyacrylate (PAAS), 8wt% triethanolamine (TEA) and 51wt% deionized water, stirred evenly, and discharged to obtain a low-temperature soaping agent.

[0042] Take the soaping agent in Embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com