A kind of acid cellulase preparation for low-temperature biopolishing and preparation method thereof

A technology of acid cellulase and bio-polishing, applied in the fields of biochemical fiber treatment, fiber treatment, textiles and papermaking, etc., can solve the problems of air pollution, etc., achieve the effects of reducing usage, good anti-staining effect, and lowering the use temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

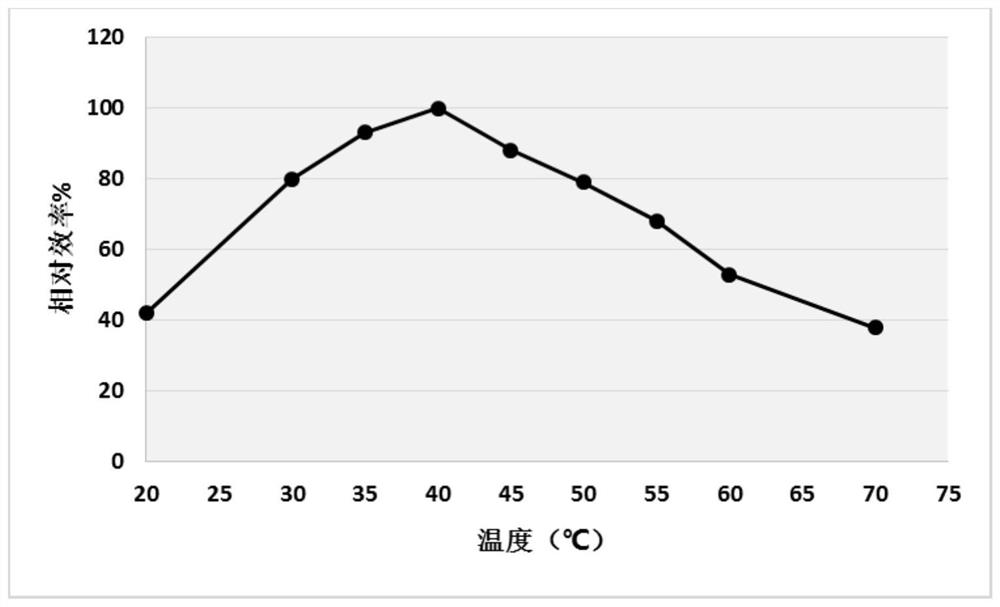

[0034] 1. Determination of enzyme activity

[0035] 1.1 Enzyme activity determination method: under the conditions of 50°C and pH=4.8, the amount of enzyme required to degrade and release 1 μmol of reducing sugar per minute from a carboxymethyl cellulose solution with a concentration of 10 mg / ml is an activity unit (IU) , calculated as IU / ml.

[0036] Add 0.5ml of CMC substrate to each of the five test tubes, preheat together with the enzyme solution to be tested in a water bath at 50°C for 5 minutes; add 0.5ml of the enzyme solution to be tested to each of the first, second, third and fourth test tubes, and time, ℃ water bath for 15 minutes; after the reaction is completed, add 1.5ml of DNS reagent to each of the five test tubes, and add 0.5ml of the enzyme solution to be tested to the fifth test tube; React in the bath for 5 minutes; quickly cool to room temperature, and dilute to 5ml with water. Measure the absorbance of the test solutions in the first, second, third and ...

Embodiment 2

[0064] Embodiment 2: the acid cellulase of low temperature biological polishing in the biological ferment washing of denim washing

[0065] Fabric: 12 pieces of 40s / 1 pure indigo knitted jeans, 12 pieces of 10*10 woven blue and black jeans, weighing about 10kg;

[0066] Washing equipment: industrial washing machine

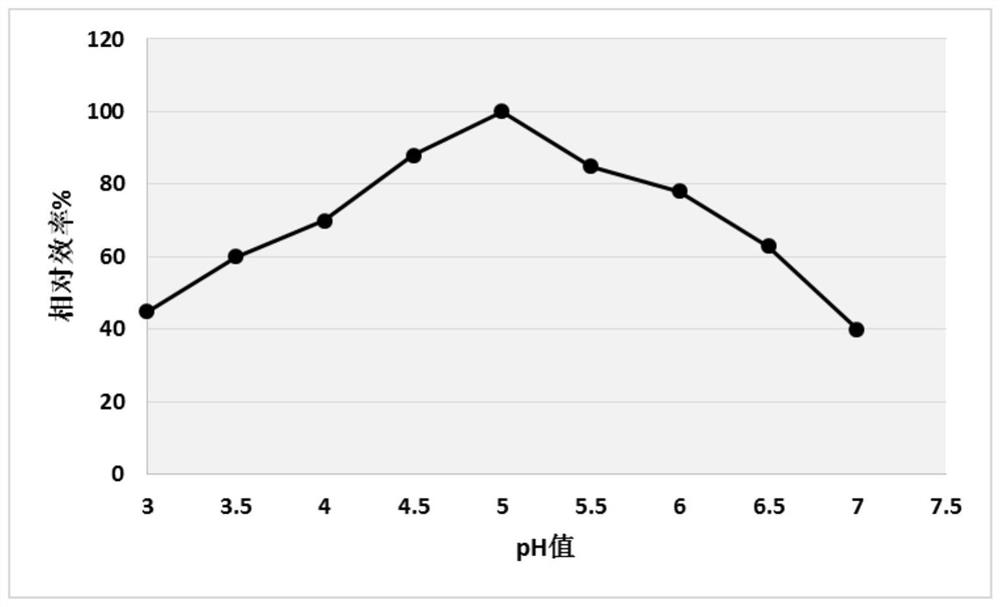

[0067] Process: Put the above 24 pairs of jeans into the industrial washing machine, add water to 100L, the total hardness of the water is 100-200ppm, heat the water to 35°C by steam heating, adjust the pH value of the solution to about 5.0, and the rotation speed is 35 rpm , Turn on and turn the industrial washing machine, add low-temperature desizing enzyme, low-temperature acid cellulose enzyme solution and anti-staining powder while turning, keep warm and turn for 40 minutes, drain the solution, and wash with water twice.

[0068] The ratio of this low-temperature acid cellulase solution is: acid cellulase: 550 parts; pectinase: 80 parts; alcohol ether: 150 p...

Embodiment 3

[0071] A low-temperature biopolishing acid cellulase preparation, comprising the following components by weight:

[0072] Enzyme activity is 10000IU / ml acid cellulase: 500 parts;

[0073] Enzyme activity is 5000IU / ml pectinase: 100 parts;

[0074] Alcohol ether: 50 parts;

[0075] Sodium chloride: 50 parts;

[0076] Calcium chloride: 50 parts;

[0077] Casson: 3 parts;

[0078] Deionized water: 300 parts.

[0079] The structure of the alcohol ether is: EO-PO-EO, wherein EO is ethylene oxide, PO is propylene oxide, the number of EO is 3-15, and the number of carbon chains is C 12 -C 18 .

[0080] The acid cellulase preparation of above-mentioned low-temperature biological polishing is prepared by the following method:

[0081] 1) Pour the weighed deionized water, Cathone, calcium chloride and sodium chloride into the mixing tank at a speed of 30r / min, and stir at room temperature until completely dissolved;

[0082] 2) Pour the weighed alcohol ether into the above solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com