Efficient anti-staining detergent for garment washing and preparation method of efficient anti-staining detergent

A cleaning agent and washing water technology, which is applied in the direction of detergent compounding agent, detergent composition, chemical equipment and methods, etc., can solve the problems of mutual staining and poor overall effect of garments, and achieve the goal of improving quality and value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

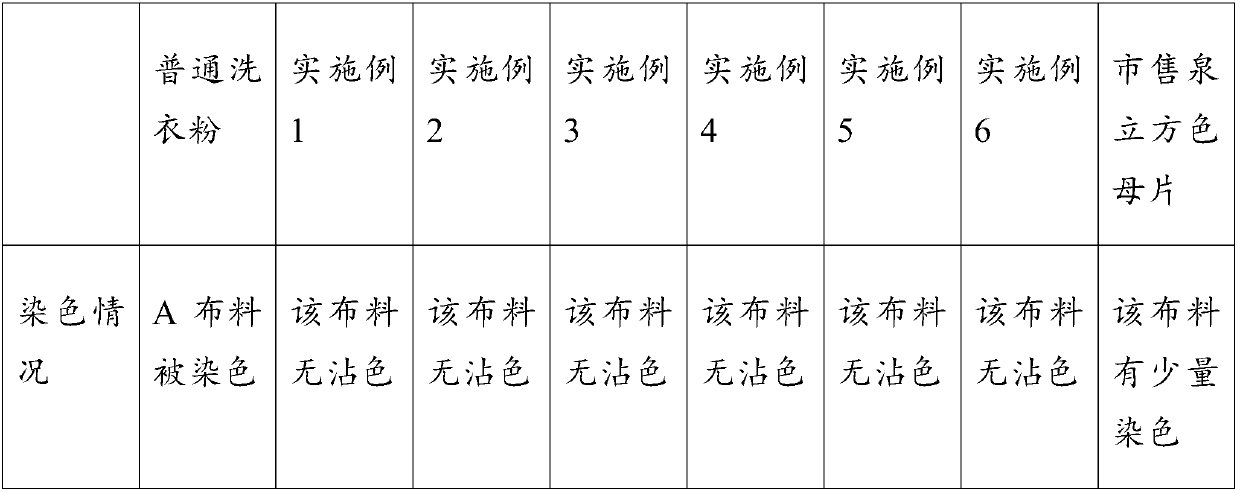

Examples

Embodiment 1

[0022] A high-efficiency anti-dyeing detergent for laundry washing water, which is composed of the following components by mass percentage: polyvinylpyrrolidone 5%, horse-propylene copolymer 40%, Pingpingjia O-25 10%, secondary alkylsulfonic acid Sodium 7%, C12 linear alkylbenzene sulfonic acid 8%, sodium benzoate 0.1%, deionized water 29.9%.

[0023] The preparation method of this high-efficiency anti-dyeing detergent, the specific preparation steps are:

[0024] Step 1: Calculate and weigh each component according to the above mass percentage;

[0025] Step 2: Mix the horse-propylene copolymer, sodium secondary alkylsulfonate, linear alkylbenzenesulfonic acid, and deionized water in the components, and stir for 20 minutes;

[0026] Step 3: Slowly add the polyvinylpyrrolidone in the components into the mixture of the above-mentioned step 2, add while stirring, and stir for 20 minutes after all the addition.

[0027] Step 4: Add the fatty alcohol polyoxyethylene ether in the...

Embodiment 2

[0031] A high-efficiency anti-dyeing detergent for laundry washing water, which is composed of the following components by mass percentage: polyvinylpyrrolidone K30 10%, horse-propylene copolymer 30%, Pingpingjia O-30 13%, secondary alkyl Sodium sulfonate 12%, C12 linear alkylbenzene sulfonic acid 8%, sodium benzoate 0.1%, deionized water 36.9%.

[0032] The preparation method of the high-efficiency anti-dyeing detergent for garment washing water, the specific preparation steps are:

[0033] Step 1: Calculate and weigh each component according to the above mass percentage;

[0034] Step 2: Mix the horse-propylene copolymer, sodium secondary alkylsulfonate, linear alkylbenzenesulfonic acid, and deionized water in the components, and stir for 20 minutes;

[0035] Step 3: Slowly add the polyvinylpyrrolidone in the components into the mixture of the above-mentioned step 2, add while stirring, and stir for 20 minutes after all the addition.

[0036] Step 4: Add the fatty alcohol ...

Embodiment 3

[0040] A high-efficiency anti-dyeing detergent for garment washing water, which consists of the following components by mass percentage: polyvinylpyrrolidone 8%, horse-propylene copolymer 20%, Pingpingjia O-25 12%, secondary alkylsulfonate Sodium NaCl 13%, C12 linear alkylbenzene sulfonic acid 5%, C12 alkyl dimethyl benzyl ammonium chloride 0.1%, deionized water 41.9%.

[0041] The preparation method of the high-efficiency anti-dyeing detergent for garment washing, the specific preparation steps are:

[0042] Step 1: Calculate and weigh each component according to the above mass percentage;

[0043] Step 2: Mix the horse-propylene copolymer, sodium secondary alkylsulfonate, linear alkylbenzenesulfonic acid, and deionized water in the components, and stir for 20 minutes;

[0044] Step 3: Slowly add the polyvinylpyrrolidone in the components into the mixture of the above-mentioned step 2, add while stirring, and stir for 20 minutes after all the addition.

[0045] Step 4: Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com