White-ground anti-staining soaping agent for nylon and preparation method of white-ground anti-staining soaping agent

An anti-staining soaping agent, white background technology, applied in the field of textile printing and dyeing, can solve the problems of insufficient cleaning power, unclean floating color removal, high price, etc., and achieves strong dispersing and chelating ability, excellent anti-staining effect. , the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

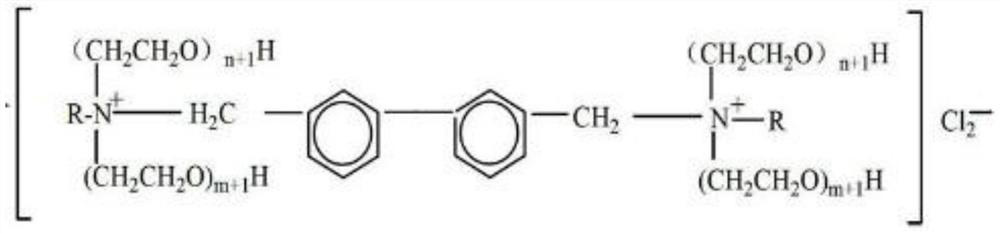

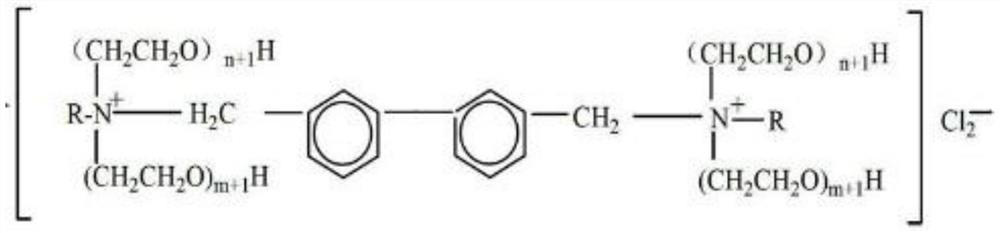

[0024] Preparation of fatty amine polyoxyethylene ether diquaternary ammonium salt:

[0025] Add 15.6g of aliphatic amine polyoxyethylene ether AC-1815715 and 37.5g of biphenyl benzyl dichloride into a four-necked flask, raise the temperature to 100°C-150°C, react for 4 hours, cool down to 50°C, add 85.3g of deionized water, and keep the temperature for reaction 10h, a brown viscous liquid was obtained.

[0026] Preparation of maleic anhydride-acrylic acid-N-vinylpyrrolidone terpolymer:

[0027] In a four-neck flask equipped with a reflux condenser and a dropping funnel, add 50.0 g of maleic anhydride and 55.0 g of water, heat to 60°C-70°C and stir to make it completely dissolved and transparent; add NaOH aqueous solution to adjust the pH to neutral, Continue to raise the temperature. When the temperature rises to 80°C-90°C, add 150.0g of acrylic acid, 12.5g of N-vinylpyrrolidone and 5.0g of ammonium persulfate solution dropwise at the same time. React at a constant temperat...

Embodiment 2

[0031] Preparation of fatty amine polyoxyethylene ether diquaternary ammonium salt:

[0032] Add 27.8g of aliphatic amine polyoxyethylene ether AC-18303 and 42.5g of biphenyl benzyl dichloride into a four-necked flask, raise the temperature to 100°C-150°C, react for 10h, cool down to 50°C, add 75.0g of deionized water, and keep the temperature for reaction 6h, a brown viscous liquid was obtained.

[0033] Preparation of maleic anhydride-acrylic acid-N-vinylpyrrolidone terpolymer:

[0034] In a four-necked flask equipped with a reflux condenser and a dropping funnel, add 45.0 g of maleic anhydride and 55.0 g of water, heat to 70°C-80°C and stir to make it completely dissolved and transparent; add NaOH aqueous solution to adjust the pH to neutral, Continue to raise the temperature. When the temperature rises to 80°C-90°C, add 135.0g of acrylic acid, 20.2g of N-vinylpyrrolidone and 8.0g of sodium persulfate solution dropwise at the same time. React at a constant temperature of ...

Embodiment 3

[0038] Preparation of fatty amine polyoxyethylene ether diquaternary ammonium salt:

[0039] Add aliphatic amine polyoxyethylene ether AC-1860287.0g and biphenyl benzyl dichloride 37.5g into a four-neck flask, raise the temperature to 100°C-150°C, react for 10h, cool down to 50°C, add 97.4g of deionized water, and keep the temperature for reaction 6h, a brown viscous liquid was obtained.

[0040]Preparation of maleic anhydride-acrylic acid-N-vinylpyrrolidone terpolymer:

[0041] In a four-necked flask equipped with a reflux condenser and a dropping funnel, add 45.0 g of maleic anhydride and 55.0 g of water, heat to 70°C-80°C and stir to make it completely dissolved and transparent; add NaOH aqueous solution to adjust the pH to neutral, Continue to raise the temperature. When the temperature rises to 80°C-90°C, add 135.0g of acrylic acid, 15.7g of N-vinylpyrrolidone and 8.0g of sodium persulfate solution dropwise at the same time. React at a constant temperature of 90°C for 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com