Filter assembly for sampling

A filter and filter cartridge technology, applied in sampling, fixed filter element filter, filtration and separation, etc., can solve the problem of frequent renewal of filter media, achieve excellent cleaning performance, prevent filter residue deposition, reliable and continuous sample delivery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

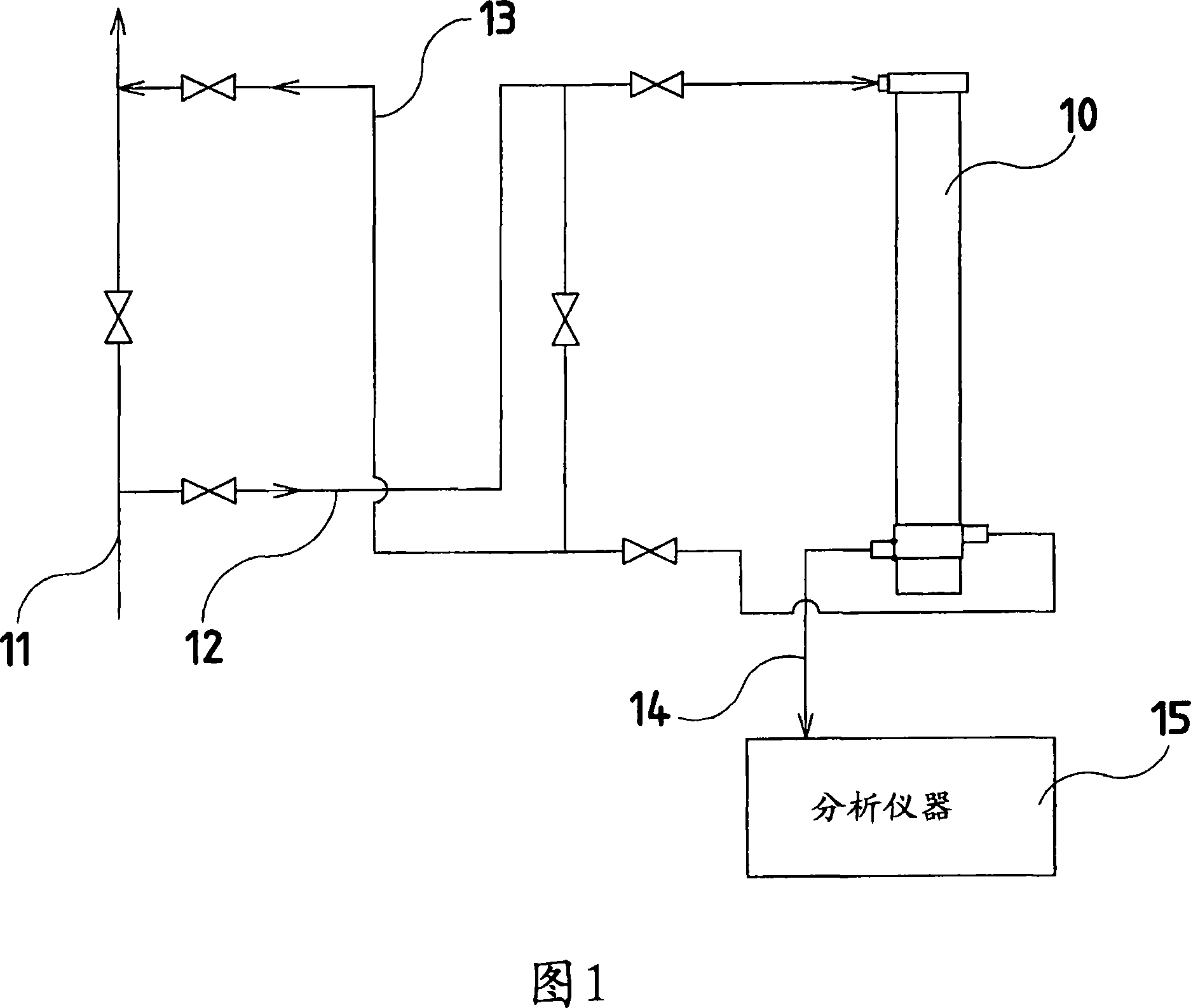

[0018] Figure 1 shows a simplified diagram of a possible connection of a filter assembly according to the invention between a process stream and an analytical instrument. The filter device 10 preferably works in a vertical position. A stream 12 is withdrawn from the main production stream 11 and directed to an inlet provided at the upper end of the filtering device 10 . The liquid stream 13 flowing through the spiral channel of the filter device 10 and out of the slurry outlet returns to the main production liquid stream 11 . Filtered sample stream 14 flows forward to analytical instrument 15 . Filter assemblies provide small amounts of filtered samples to analytical instruments and return large amounts of collected samples to production. The analytical instrument may include a pneumatic sample delivery station to deliver the filtered sample to the analytical chamber of the analytical instrument.

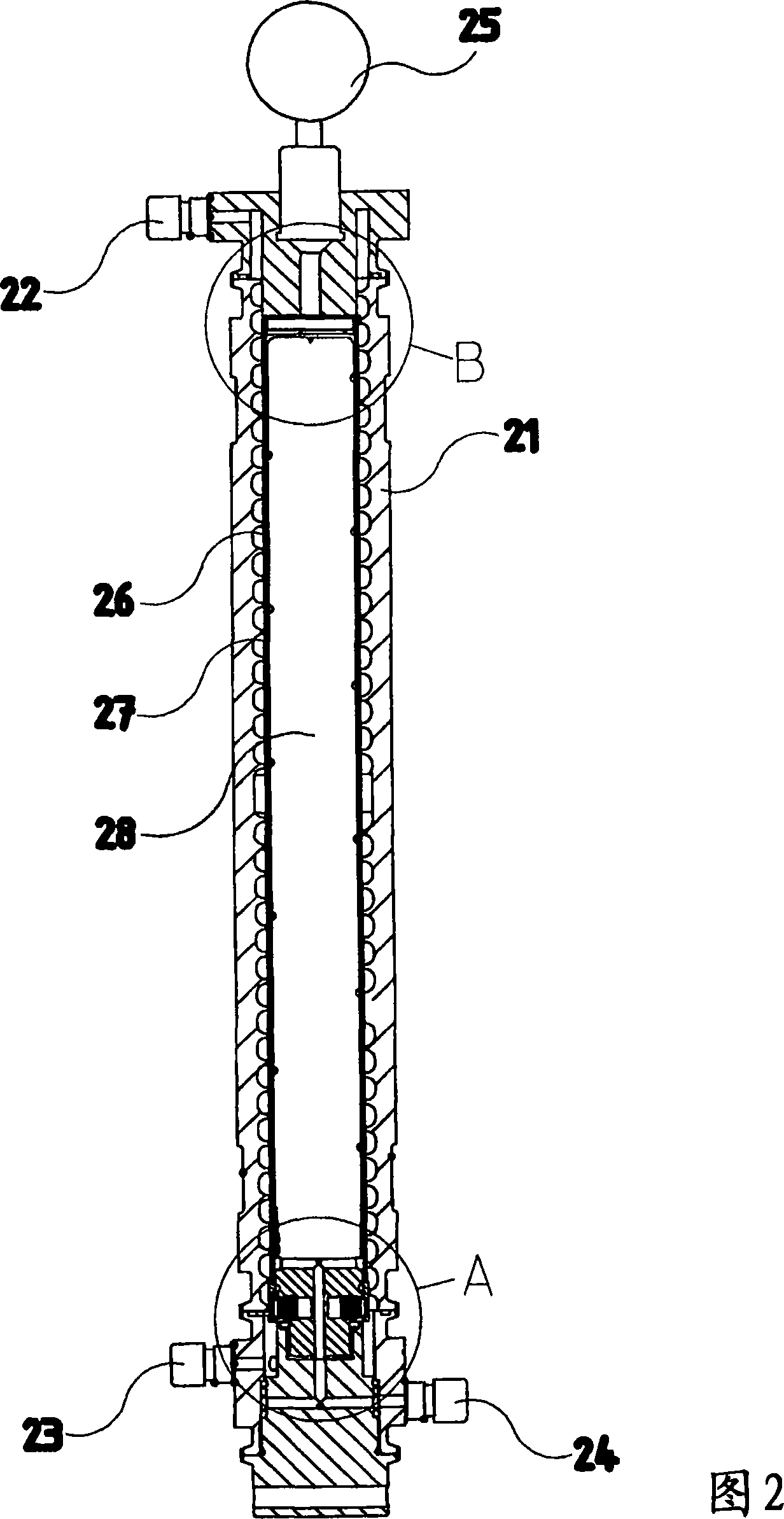

[0019] Fig. 2 is a cross-sectional view of an embodiment of a filtering devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com